Rotarded MG project.

#51

Reread this thread from page one. It shows everything I've mentioned from the reverse runner intake manifold, to the R5 oil pan, the superlight steel 8 pound GReddy flywheel that I decided not to use and the cutout in the frame rail the PO added for his RX-3 12A pan which I was able to use with my R5 13B pan.

#52

Oh, I didn't mean breaking diffs or anything like that, I meant breaking loose the tires as in tendency to do burn outs from a standing start. I was wondering if a lighter flywheel would help keep the tires from leaving rubber behind from every standing start. But I think you answered that question pretty good. More the more isn't necessarily more better (pardon the poor grammar). And I didn't take the counter weights into consideration.

Moving the oil drain plug and sealing off the oil level sensor hole were the first things I ever welded. 11-12 yrs ago I took the oil pan to a welder and he wanted $75 hr for his trouble. I don't blame him for the rate, but at that price I decided to buy a Lincoln MIG and learn how to use it. I still have that baby MIG, and I've welded way more things than I can remember. A work trailer that I made and use everyday has about 80K miles on it, and not a single cracked weld.

The bottom of my oil pan is fairly flush with the bottom of the frame rails. I'm glad that it's not hanging down below since having the oil pan destroyed by road debris would be a bad thing. Although it's common, I'm not comfortable with making 'reliefs' in the bottom frame rails. Once the engine bay is sorted out, I'm going to add a bunch of removable supports for the front. I took out the trans tunnel cross member, but I'm going to weld a new one in it's place.

I might redo everything I've done with the trans tunnel through the center of the car to the footwells. Maybe a backbone frame that bolts-in, covered in aluminum sheet. It would integrate into the rear suspension and the roll cage. Sounds heavy though.

I'm definitely going to fab up a torque brace to control the engine twist. There should be enough clearance for the starter so it won't make metal to metal contract. But there is no way I would be able to pull it out of the bell housing.

IF I ever get that far, I would cut a whole in the hood, and remove the passenger's legs to give the Camden a home. I have a suspicion that my feelings regarding more power is going to change once experiencing this setup. Didn't you say "pucker factor"?

I have a suspicion that my feelings regarding more power is going to change once experiencing this setup. Didn't you say "pucker factor"?

Moving the oil drain plug and sealing off the oil level sensor hole were the first things I ever welded. 11-12 yrs ago I took the oil pan to a welder and he wanted $75 hr for his trouble. I don't blame him for the rate, but at that price I decided to buy a Lincoln MIG and learn how to use it. I still have that baby MIG, and I've welded way more things than I can remember. A work trailer that I made and use everyday has about 80K miles on it, and not a single cracked weld.

The bottom of my oil pan is fairly flush with the bottom of the frame rails. I'm glad that it's not hanging down below since having the oil pan destroyed by road debris would be a bad thing. Although it's common, I'm not comfortable with making 'reliefs' in the bottom frame rails. Once the engine bay is sorted out, I'm going to add a bunch of removable supports for the front. I took out the trans tunnel cross member, but I'm going to weld a new one in it's place.

I might redo everything I've done with the trans tunnel through the center of the car to the footwells. Maybe a backbone frame that bolts-in, covered in aluminum sheet. It would integrate into the rear suspension and the roll cage. Sounds heavy though.

I'm definitely going to fab up a torque brace to control the engine twist. There should be enough clearance for the starter so it won't make metal to metal contract. But there is no way I would be able to pull it out of the bell housing.

IF I ever get that far, I would cut a whole in the hood, and remove the passenger's legs to give the Camden a home.

I have a suspicion that my feelings regarding more power is going to change once experiencing this setup. Didn't you say "pucker factor"?

I have a suspicion that my feelings regarding more power is going to change once experiencing this setup. Didn't you say "pucker factor"?

#53

Well for some reason the light steel provides a confidence that the aluminum just does not. I can't explain it. The lighter S4 rotors I decided to use this time, maybe? For whatever reason, it motivated me to pull the engine to change just the flywheel. Then once it was out, it seemed logical to throw it in the REPU for test running purposes. Not like I can run it in the MG. And it's a nice way to come full circle. And I get to test the 24 pound S4 NA flywheel and a long primary exhaust with the same carb I tested in the MG before (74 Hitachi and reverse runner manifold). If this setup hauls in the truck, I'll have a pucker factor the likes of which a proctologist has never seen.

You see before, the old REPU engine was so gutless, being my first rotary engine and all and having major problems that at the time I didn't understand, it barely could get out of its own way. And the fact the rear diff is geared tall like a '77 at 3.90 or something was just adding insult to injury. No wonder I looked into ways to make more power like long primary exhausts, direct fire ignition, superchargers etc (and soon turbos if necessary).

Anyway when that engine that was frankly an embarrasment to the bold "ROTARY POWER" decals emblazoned across the tailgate went into the also poorly set up at the time MG, it came to life in a big way. It also ran better too. Heck I could reach in, crank the key for a second and it would idle perfectly on a warm engine. It never did that in the truck. Of course the truck has an 11 foot long aluminum battery cable and older starter vs the one or two foot cables in the MG and an FC reman starter, which probably cranks faster. So I swapped in an FC starter in the truck and will eventually switch to copper a bit later.

Sorry I'm kind of taking so long to answer your questions. It's nice to write about this subject knowing that I think I'm finally figuring things out. It was my first rotary car, the MG, and it's been my greatest education. Now I think I've gotten the very best parts together to make the best engine combo possible with the knowledge I have, and so something like a light steel flywheel vs aluminum suddenly becomes a super important subject and if necessary requires a day or two of work to remedy, which I gladly find time for. I mean heck I chose a year specific 1981 rear Y plate because it was the last year to use a threaded heater core fitting so I could install a block off bolt from RB, and it is the only Y with that feature. No more short piece of hose with something inside to block it for me! The 1980 plate was a heavy R5 and could have been used, but the 81 Y is lighter, and the 1982 had a pressed in fitting making it no good. Things like that kept me up at night. If I have to have an OCD, I'm glad it's about this.

As for going long primary in the MG, I'm going to cut up a nearly new RB center section so the presilencers can come out. I've struggled with this idea for a while and keep coming to the same conclusion. These are the modern light weight and somewhat shorter presilencers that are weld-in only that RB sells in their center sections to save weight. They use similar materials to the RB universal 2.5 and 3" mufflers. They are shorter than the old style which had heavy 3/8" end caps designed for flanges and gaskets with studs and 14 gauge mild steel shells. I have a set of these but just couldn't bring myself to use them in the MG. Glad I didn't as my REPU needs a long primary exhaust too. I'd much rather throw these heavy units in the truck and keep the lighter shorter ones for the MG.

The rest of the exhaust will use a set of Magnapacks with a 4" diameter shell. 14" length and a 2" core. Then the pipes will 90 degree across the bottom of the car then straighten again. This is where they will collect to 2.5" to go up over the rearend in the stock location under the driver's side. Then it will 90 degree to the passenger side and have one more long Magnapack as the final muffler under the bumper. This should be quiet enough for the street. This exhaust is a 100% improvement over the old tiny 1 3/4" to 1 7/8" POS the PO welded back in '89 or whenever. If the old exhaust provided pucker factor with the old crappy REPU engine, I'll need Dr. Buttmonger stat when the new engine and exhaust go in.

You see before, the old REPU engine was so gutless, being my first rotary engine and all and having major problems that at the time I didn't understand, it barely could get out of its own way. And the fact the rear diff is geared tall like a '77 at 3.90 or something was just adding insult to injury. No wonder I looked into ways to make more power like long primary exhausts, direct fire ignition, superchargers etc (and soon turbos if necessary).

Anyway when that engine that was frankly an embarrasment to the bold "ROTARY POWER" decals emblazoned across the tailgate went into the also poorly set up at the time MG, it came to life in a big way. It also ran better too. Heck I could reach in, crank the key for a second and it would idle perfectly on a warm engine. It never did that in the truck. Of course the truck has an 11 foot long aluminum battery cable and older starter vs the one or two foot cables in the MG and an FC reman starter, which probably cranks faster. So I swapped in an FC starter in the truck and will eventually switch to copper a bit later.

Sorry I'm kind of taking so long to answer your questions. It's nice to write about this subject knowing that I think I'm finally figuring things out. It was my first rotary car, the MG, and it's been my greatest education. Now I think I've gotten the very best parts together to make the best engine combo possible with the knowledge I have, and so something like a light steel flywheel vs aluminum suddenly becomes a super important subject and if necessary requires a day or two of work to remedy, which I gladly find time for. I mean heck I chose a year specific 1981 rear Y plate because it was the last year to use a threaded heater core fitting so I could install a block off bolt from RB, and it is the only Y with that feature. No more short piece of hose with something inside to block it for me! The 1980 plate was a heavy R5 and could have been used, but the 81 Y is lighter, and the 1982 had a pressed in fitting making it no good. Things like that kept me up at night. If I have to have an OCD, I'm glad it's about this.

As for going long primary in the MG, I'm going to cut up a nearly new RB center section so the presilencers can come out. I've struggled with this idea for a while and keep coming to the same conclusion. These are the modern light weight and somewhat shorter presilencers that are weld-in only that RB sells in their center sections to save weight. They use similar materials to the RB universal 2.5 and 3" mufflers. They are shorter than the old style which had heavy 3/8" end caps designed for flanges and gaskets with studs and 14 gauge mild steel shells. I have a set of these but just couldn't bring myself to use them in the MG. Glad I didn't as my REPU needs a long primary exhaust too. I'd much rather throw these heavy units in the truck and keep the lighter shorter ones for the MG.

The rest of the exhaust will use a set of Magnapacks with a 4" diameter shell. 14" length and a 2" core. Then the pipes will 90 degree across the bottom of the car then straighten again. This is where they will collect to 2.5" to go up over the rearend in the stock location under the driver's side. Then it will 90 degree to the passenger side and have one more long Magnapack as the final muffler under the bumper. This should be quiet enough for the street. This exhaust is a 100% improvement over the old tiny 1 3/4" to 1 7/8" POS the PO welded back in '89 or whenever. If the old exhaust provided pucker factor with the old crappy REPU engine, I'll need Dr. Buttmonger stat when the new engine and exhaust go in.

#54

To answer your specific questions, as for tires, as long as you have good tires, you'll be fine. The GLC has old hard tires and when it had the Camden in it before, it would burn out at every stop sign. It has the Camden in it again, but will be getting new tires when I start driving it. It has a GReddy 8 pound steel flywheel but I don't think that is a factor. The peanut shaped rotors in the SC also add rotating mass that transitions from parasitic to power-adding depending on RPM and load (in boost or not). Hope that's clear as a bell.

I think you meant "if some is good, more is better" right? Like a big carb?

Oh ok so your pan is already modified. You should make a new thread and post pics and info so I can see what your pan looks like.

My MG has already been driven with the relief in the frame, so they did a good enough job.

My trans tunnel crossmember was partially chopped out and they added a plate to make it compatible with a stock tranny mount. This is good because I was able to throw in a competition one from RB. Now the parts aren't hitting metal to metal anymore back there. But it raised the tranny up some so I gotta redo the trans tunnel that had to be partially removed to fit the shifter position. I'll also redo the shifter because it acts like a short throw shifter, being originally the long type from an RX-2 but was separated at the rubber joint and shortened the same length as an FB. Its throws are super short. It also has a gross Hurst T handle that the PO added. I'll throw on a stock FB **** and extend the length by like 1 inch or something. It is just too notchy right now.

I don't need a torque brace anymore now that it's got competition motor mounts. Seriously. They are good enough you don't need a torque brace! Just ask any FB owner who has them. Heck my REPU has them. They're awesome! I noticed in RX-Midget's pics he had to add a torque brace. lol Add one if you need to, but I'm telling you if you've got stock FB mounts in there now, do yourself a favor and get the competitions first.

Note for this specific project I do not recommend hockey pucks. They can work well in REPUs and FBs but the MGs do not provide access to the top and bottom at the same time for a through-bolt. Only a stock style motor mount can work well here with two opposite facing studs.

Whatever you do with your trans tunnel, don't make it take forever. I feel kinda bad when I think of all the driving I've missed out with mine taking as long as it has.

Maybe the '65 has a narrower frame. No wait you can still fit the oil pan between them; the sump part right? Not the lip with the bolts? Mine is like that. The starter should squeeze out between the tranny and the frame rail. Especially a smooth case tranny like yours. Do you have an FC starter? If not, GET ONE! It will fit. The body is narrow and light compared with 85 and older. They also crank faster thanks to a slightly bigger gear with more teeth.

Don't bother with a Camden in an MG. Sounds kinda dumb honestly. You were kidding, right? I'd rather go turbo since there might be room down there for one. But obviously a long primary NA setup is the best. Easy, simple, reliable which the old MG engines were not. So just pick a carb that will work with the engine you've got (DCOE), and remember to unclench between shifts.

I think you meant "if some is good, more is better" right? Like a big carb?

Oh ok so your pan is already modified. You should make a new thread and post pics and info so I can see what your pan looks like.

My MG has already been driven with the relief in the frame, so they did a good enough job.

My trans tunnel crossmember was partially chopped out and they added a plate to make it compatible with a stock tranny mount. This is good because I was able to throw in a competition one from RB. Now the parts aren't hitting metal to metal anymore back there. But it raised the tranny up some so I gotta redo the trans tunnel that had to be partially removed to fit the shifter position. I'll also redo the shifter because it acts like a short throw shifter, being originally the long type from an RX-2 but was separated at the rubber joint and shortened the same length as an FB. Its throws are super short. It also has a gross Hurst T handle that the PO added. I'll throw on a stock FB **** and extend the length by like 1 inch or something. It is just too notchy right now.

I don't need a torque brace anymore now that it's got competition motor mounts. Seriously. They are good enough you don't need a torque brace! Just ask any FB owner who has them. Heck my REPU has them. They're awesome! I noticed in RX-Midget's pics he had to add a torque brace. lol Add one if you need to, but I'm telling you if you've got stock FB mounts in there now, do yourself a favor and get the competitions first.

Note for this specific project I do not recommend hockey pucks. They can work well in REPUs and FBs but the MGs do not provide access to the top and bottom at the same time for a through-bolt. Only a stock style motor mount can work well here with two opposite facing studs.

Whatever you do with your trans tunnel, don't make it take forever. I feel kinda bad when I think of all the driving I've missed out with mine taking as long as it has.

Maybe the '65 has a narrower frame. No wait you can still fit the oil pan between them; the sump part right? Not the lip with the bolts? Mine is like that. The starter should squeeze out between the tranny and the frame rail. Especially a smooth case tranny like yours. Do you have an FC starter? If not, GET ONE! It will fit. The body is narrow and light compared with 85 and older. They also crank faster thanks to a slightly bigger gear with more teeth.

Don't bother with a Camden in an MG. Sounds kinda dumb honestly. You were kidding, right? I'd rather go turbo since there might be room down there for one. But obviously a long primary NA setup is the best. Easy, simple, reliable which the old MG engines were not. So just pick a carb that will work with the engine you've got (DCOE), and remember to unclench between shifts.

#55

I know what you mean about the importance of a threaded heater core fitting. I remember being pretty pissed that I couldnít remove the pressed in fitting that had corroded to a point that all I could do to block it off was crimp it and weld it shut. Someday Iíll worry about what to do about a heater, but Iíll deal with that issue when I get to that point.

Do we even have enough room for a long primary system? Page 16 of the RacingBeat catalog defines long-primary as 120-125 inches for non-bridge/non-peripheral port. I just went out to measure my system, and I had to put my collector at 46 inches, so Iím at neither short or long primary. Short is between 22-25 inches. I canít get into the science of exhaust systems. Far smarter people than I have failed to explain that topic well. So my exhaust pulses are likely optimized at some useless point on the rpm range.

I may have made a mistake putting the hi-flow cat on, but itís there now, and Iím not going to take it off unless it catches fire or ends up blowing out my tailpipe. Since I was planning on doing injection, I still have the O2 sensor installed, so an air/fuel gauge is a no brainer choice. My muffler is a Spintech for an RV. No packing materials, just baffles to swirl the exhaust around. I donít know if it will work, or if it is just a load of bull, but well shall see. My 8 gal aluminum fuel cell is up in the trunk. From the headers back, there are no bends. All RB sourced heavy gauge 2Ē tubes with header wrap to the cat.

Thatís good advice on using the competition motor mounts. I have the stock rubber mounts on now and they are too soft. I can rock the motor. My mounting point is a piece I welded in between the frame rails, so the mounts aren't spaced apart very far. Narrow footprint. I think Iím going to need the torque brace. I could probably use hockey pucks, but I'm not a hockey fan.

My engine sits a few inches behind the front axles. So I guess this would be defined as mid-engine, or FMR (Front Mid-engine/Rear-wheel drive). My guess is that the rotary being partially aluminum is lighter than the stock A-serries cast iron block that came with the Midget. But my planned rear end conversion and larger wheels/tires will be heavier than the stock unit I have now. I also adjusted the driver position as far back as possible. I hope my weight distribution isnít too far back. I weighed the full unmodified -SE rear-end with disks and calipers attached and it came out to 150 lbs.

Iíll share some more images (and start a new thread) after I paint the engine compartment gray, like an electrical box. Iím very disappointed at the black. It makes seeing things and taking pictures difficult. That black paint went back to my teens when I worked on 60ís Fords.

Do we even have enough room for a long primary system? Page 16 of the RacingBeat catalog defines long-primary as 120-125 inches for non-bridge/non-peripheral port. I just went out to measure my system, and I had to put my collector at 46 inches, so Iím at neither short or long primary. Short is between 22-25 inches. I canít get into the science of exhaust systems. Far smarter people than I have failed to explain that topic well. So my exhaust pulses are likely optimized at some useless point on the rpm range.

I may have made a mistake putting the hi-flow cat on, but itís there now, and Iím not going to take it off unless it catches fire or ends up blowing out my tailpipe. Since I was planning on doing injection, I still have the O2 sensor installed, so an air/fuel gauge is a no brainer choice. My muffler is a Spintech for an RV. No packing materials, just baffles to swirl the exhaust around. I donít know if it will work, or if it is just a load of bull, but well shall see. My 8 gal aluminum fuel cell is up in the trunk. From the headers back, there are no bends. All RB sourced heavy gauge 2Ē tubes with header wrap to the cat.

Thatís good advice on using the competition motor mounts. I have the stock rubber mounts on now and they are too soft. I can rock the motor. My mounting point is a piece I welded in between the frame rails, so the mounts aren't spaced apart very far. Narrow footprint. I think Iím going to need the torque brace. I could probably use hockey pucks, but I'm not a hockey fan.

My engine sits a few inches behind the front axles. So I guess this would be defined as mid-engine, or FMR (Front Mid-engine/Rear-wheel drive). My guess is that the rotary being partially aluminum is lighter than the stock A-serries cast iron block that came with the Midget. But my planned rear end conversion and larger wheels/tires will be heavier than the stock unit I have now. I also adjusted the driver position as far back as possible. I hope my weight distribution isnít too far back. I weighed the full unmodified -SE rear-end with disks and calipers attached and it came out to 150 lbs.

Iíll share some more images (and start a new thread) after I paint the engine compartment gray, like an electrical box. Iím very disappointed at the black. It makes seeing things and taking pictures difficult. That black paint went back to my teens when I worked on 60ís Fords.

#56

My car won't have a heater. The PO saad just the two little open vents was all it needed. I did order a new defroster hose from victoria british though. I have yet to drive it with it.

The way I understand it, a long primary can be around 80 to 90 inches and still work well. The one in my REPU is like 68 inches I think. It works exceptionally well with the too tall diff gears. As for yours at like 46 inches, that would be more like a medium primary. Yeah, not sure where it'll peak, probably at 12 grand or something. However there will be a harmonic within the rev range that can be utilized. Think of it like a 5/8 wave or 1/2 wave CB antenna.

To answer your question, I believe I have enough room for a long primary if I do it right. I've had the idea rattling around since the success of the truck's system. But there were some unique challenges to overcome.

Don't beat yourself up over the old exhaust you did. Let it bother you until it builds up and you have to rip it out of there.

If I remember right, you had a webpage with pictures and text describing why you wanted to use a cat and why you ran the pipes above the floor. I disagreed with your motives (environmentalism?) but respected your conviction, so I never brought it up until now since you are questioning it yourself.

And yes it's good to have an O2 bung. I'll add one to mine on one of the primaries. Might as well while I'm in there, you know? Probably won't need it since the Hitachi and Holley are already tuned... presumeably. If I was doing a wideband, I'd add it in the crotch of the collector because it has its own heater.

Your RV muffler with baffles is a no-no on a rotary. They want straight through. Something about the reversion wave that bounces from the tailpipe back up to the exhaust port is not in favor of baffles. It was rotarygod or Paul Yaw who talked about that theory stuff. I don't fully understand it, but I know straight through works so it's what I use and have been happy with it.

If you can take some constructive critisism, ditch your current exhaust and redo it to a proper long primary. Run it under the car if you can. In the mean time read up on it as much as you can, then make a decision when you're better informed. Heck I've made and scrapped plans for my MG's exhaust a dozen times. Infact I was all set and a plan finalized this time last year, but it stalled out. Low and behold a set of old school (heavy) presilencers dropped in my lap a couple months later so I revamped to go long primary, then it petered out again when I got busy building an exhaust for the brown car. Glad it did because now I have a set of pristine lightweight modern slightly shorter presilencers that will work about 100 times better here and I think my discussing the plan to use them is proof that this plan is correct and won't peter out. But the proof is in the pudding, right? Yep, this year the new exhaust is gonna happen. All I need now are some 2.5" u-bends and a set of flanges which I can order from Mazdatrix next time I need to do an order. Should be soon!

Yeah I remember the pictures of your motor mounts right next to each other. Yeesh! Now I can't take credit for mine since the PO did all that, but he did space them well apart on the area where it angles up 45 degrees near the weird lever shocks. He used one existing hole on each side to poke the stud through. Must have been where the stock piston motor mounts were.

He had to cut off the outer shell of the motor mount and ditch the little cup on the bottom. Problem is he used a cutting torch which cooked the rubber and made it partially separate from the steel. My engine was disturbingly sloppy and needed a torque brace until I discovered his error. I then cut off the shells of two competition motor mounts with a cutting disc slowly to keep heat down and viola! Now my engine is as stiff as a board. You grab the alternator and it shakes the whole car! Even up on jack stands! The engine stays put.

Oh I'm not a hocky fan either, but you can still buy them at Big 5 Sporting Goods or wherever. They don't discriminate. Infact if you're sticking to your narrow mounts, hockey pucks and a torque brace will be necessary. But please consider redoing your mounts. The wider placement provides superior leverage to keep the engine in its place and you already have a set of holes available.

Actually the A series is a light motor. From what I was reading, the rotary doesn't decrease the weight of the car. Of course I read it over a decade ago. Do we know how much the A series actually weighs?

MGs are back heavy, by the way.

Yeah I think the gray will look great! Mine is blue.

The way I understand it, a long primary can be around 80 to 90 inches and still work well. The one in my REPU is like 68 inches I think. It works exceptionally well with the too tall diff gears. As for yours at like 46 inches, that would be more like a medium primary. Yeah, not sure where it'll peak, probably at 12 grand or something. However there will be a harmonic within the rev range that can be utilized. Think of it like a 5/8 wave or 1/2 wave CB antenna.

To answer your question, I believe I have enough room for a long primary if I do it right. I've had the idea rattling around since the success of the truck's system. But there were some unique challenges to overcome.

Don't beat yourself up over the old exhaust you did. Let it bother you until it builds up and you have to rip it out of there.

If I remember right, you had a webpage with pictures and text describing why you wanted to use a cat and why you ran the pipes above the floor. I disagreed with your motives (environmentalism?) but respected your conviction, so I never brought it up until now since you are questioning it yourself.

And yes it's good to have an O2 bung. I'll add one to mine on one of the primaries. Might as well while I'm in there, you know? Probably won't need it since the Hitachi and Holley are already tuned... presumeably. If I was doing a wideband, I'd add it in the crotch of the collector because it has its own heater.

Your RV muffler with baffles is a no-no on a rotary. They want straight through. Something about the reversion wave that bounces from the tailpipe back up to the exhaust port is not in favor of baffles. It was rotarygod or Paul Yaw who talked about that theory stuff. I don't fully understand it, but I know straight through works so it's what I use and have been happy with it.

If you can take some constructive critisism, ditch your current exhaust and redo it to a proper long primary. Run it under the car if you can. In the mean time read up on it as much as you can, then make a decision when you're better informed. Heck I've made and scrapped plans for my MG's exhaust a dozen times. Infact I was all set and a plan finalized this time last year, but it stalled out. Low and behold a set of old school (heavy) presilencers dropped in my lap a couple months later so I revamped to go long primary, then it petered out again when I got busy building an exhaust for the brown car. Glad it did because now I have a set of pristine lightweight modern slightly shorter presilencers that will work about 100 times better here and I think my discussing the plan to use them is proof that this plan is correct and won't peter out. But the proof is in the pudding, right? Yep, this year the new exhaust is gonna happen. All I need now are some 2.5" u-bends and a set of flanges which I can order from Mazdatrix next time I need to do an order. Should be soon!

Yeah I remember the pictures of your motor mounts right next to each other. Yeesh! Now I can't take credit for mine since the PO did all that, but he did space them well apart on the area where it angles up 45 degrees near the weird lever shocks. He used one existing hole on each side to poke the stud through. Must have been where the stock piston motor mounts were.

He had to cut off the outer shell of the motor mount and ditch the little cup on the bottom. Problem is he used a cutting torch which cooked the rubber and made it partially separate from the steel. My engine was disturbingly sloppy and needed a torque brace until I discovered his error. I then cut off the shells of two competition motor mounts with a cutting disc slowly to keep heat down and viola! Now my engine is as stiff as a board. You grab the alternator and it shakes the whole car! Even up on jack stands! The engine stays put.

Oh I'm not a hocky fan either, but you can still buy them at Big 5 Sporting Goods or wherever. They don't discriminate. Infact if you're sticking to your narrow mounts, hockey pucks and a torque brace will be necessary. But please consider redoing your mounts. The wider placement provides superior leverage to keep the engine in its place and you already have a set of holes available.

Actually the A series is a light motor. From what I was reading, the rotary doesn't decrease the weight of the car. Of course I read it over a decade ago. Do we know how much the A series actually weighs?

MGs are back heavy, by the way.

Yeah I think the gray will look great! Mine is blue.

#57

I let the website languish after it was buried deep in my business's url. For a few years it was at the very top of the Google search with anything related to rotary engine conversions into MGs. I won't revive it until real progress has been made. Even if it's full of obvious mistakes, I hope that something helpful within it helped others along.

When I made the exhaust I built into it the ability to quickly remove the collector and cat. My dual header pipes are pretty long and they end at a dual flange, then comes the collector after the flange. So a redo won't mean starting from scratch. As insane as it looks, I really like keeping the exhaust up in between the frame rails and not hanging down below. I know I keep saying "track-track-track" a lot but 98% of the time will be spent on the street. It's my play car, not a commuter, so I'm taking a few liberties. So rather than being on the floor, I'm going to raise the passenger floor over the exhaust. Even with the 2" lower springs from the Winner's Circle, my ground clearance is decent. I didn't want my exhaust to be within 3" of the ground. For now I'm going to go with the exhaust as-is to see what kind of mistakes I may have made. I don't need to be at 100% efficiency at the start.

My current goal is to get the car to move under it's own power, then sort out what needs to be sorted. Even the rear end is a project that could be years away from realization. So I don't mind if I'm driving a while with primer and missing internal sheet metal. Once it's on the road I'm sure that I'll have to revise many things as I discover them.

The addition of a cat is more for an attempt to reduce the smell coming out the back of the car. My RX7 has a full on RB short primary system, and when go to pickup one of my daughters from school I can't help to be self-conscious of the noxious smell of the exhaust while in line with all the moms in their mini vans. Kids these days aren't used to getting their minerals from the air they breath. Even I don't miss the 80's with smog alerts. I live in a fairly dense suburbia, and I can spend just as much time waiting at signal lights as I do actually moving. The cat is more out of courtesy if anything. Like deodorant. But without an air-pump and proper air/fuel management, it probably won't last long.

But without an air-pump and proper air/fuel management, it probably won't last long.

As for the environment, I believe that all new production cars, work vehicles, and any mode of mass commuter transportation should be pollution controlled. Any old car is better off being kept running on the road even if it's a chimney because it is much more environmentally damaging to scrap it and build a replacement. That's what these idiots in their Prius's don't understand. Heck, one trip one a jet plane makes more pollution than I'll ever make in my unplugged rotary.

I found an interesting engine weight chart while googling:

http://fixrambler.com/engineweightchart.txt

260-300 lbs - 13B

253 lbs - A-series

460-500 lbs Ford 289/302 (LOL, just had to look.)

The paper lists it's sources, but the engine dress (ancillaries) may be different so comparisons are difficult.

Some transmission weights are also listed.

My bathroom scale is good to 320 lbs and I recently bought a postal scale, so I'll try to remember to weight things as I put them back into the car.

Somewhere I saw a blue-print of a 59? Sprite spec'd at 1200 lbs. So I set a goal to reduce the weight of the Midget to 1100 lbs for track days. Even with the windshield removed and fiberglass deck lids, I'm think goal my may be too optimistic. Midgets are mid 1500 lbs stock. I won't have an interior and gutted the door glass/parts. There is a shop nearby that still makes fiberglass panels, or carbon-fiber if I win the lottery. I tend to aim high at the start of a project, but I don't mind settling once reality kicks in.

When I made the exhaust I built into it the ability to quickly remove the collector and cat. My dual header pipes are pretty long and they end at a dual flange, then comes the collector after the flange. So a redo won't mean starting from scratch. As insane as it looks, I really like keeping the exhaust up in between the frame rails and not hanging down below. I know I keep saying "track-track-track" a lot but 98% of the time will be spent on the street. It's my play car, not a commuter, so I'm taking a few liberties. So rather than being on the floor, I'm going to raise the passenger floor over the exhaust. Even with the 2" lower springs from the Winner's Circle, my ground clearance is decent. I didn't want my exhaust to be within 3" of the ground. For now I'm going to go with the exhaust as-is to see what kind of mistakes I may have made. I don't need to be at 100% efficiency at the start.

My current goal is to get the car to move under it's own power, then sort out what needs to be sorted. Even the rear end is a project that could be years away from realization. So I don't mind if I'm driving a while with primer and missing internal sheet metal. Once it's on the road I'm sure that I'll have to revise many things as I discover them.

The addition of a cat is more for an attempt to reduce the smell coming out the back of the car. My RX7 has a full on RB short primary system, and when go to pickup one of my daughters from school I can't help to be self-conscious of the noxious smell of the exhaust while in line with all the moms in their mini vans. Kids these days aren't used to getting their minerals from the air they breath. Even I don't miss the 80's with smog alerts. I live in a fairly dense suburbia, and I can spend just as much time waiting at signal lights as I do actually moving. The cat is more out of courtesy if anything. Like deodorant.

But without an air-pump and proper air/fuel management, it probably won't last long.

But without an air-pump and proper air/fuel management, it probably won't last long.As for the environment, I believe that all new production cars, work vehicles, and any mode of mass commuter transportation should be pollution controlled. Any old car is better off being kept running on the road even if it's a chimney because it is much more environmentally damaging to scrap it and build a replacement. That's what these idiots in their Prius's don't understand. Heck, one trip one a jet plane makes more pollution than I'll ever make in my unplugged rotary.

I found an interesting engine weight chart while googling:

http://fixrambler.com/engineweightchart.txt

260-300 lbs - 13B

253 lbs - A-series

460-500 lbs Ford 289/302 (LOL, just had to look.)

The paper lists it's sources, but the engine dress (ancillaries) may be different so comparisons are difficult.

Some transmission weights are also listed.

My bathroom scale is good to 320 lbs and I recently bought a postal scale, so I'll try to remember to weight things as I put them back into the car.

Somewhere I saw a blue-print of a 59? Sprite spec'd at 1200 lbs. So I set a goal to reduce the weight of the Midget to 1100 lbs for track days. Even with the windshield removed and fiberglass deck lids, I'm think goal my may be too optimistic. Midgets are mid 1500 lbs stock. I won't have an interior and gutted the door glass/parts. There is a shop nearby that still makes fiberglass panels, or carbon-fiber if I win the lottery. I tend to aim high at the start of a project, but I don't mind settling once reality kicks in.

#58

Your website was influencial and memorable. The evidence for that is I can still remember it.

I didn't know you had 2" lower springs. Keeping your exhaust up was a good idea.

As for your cat, sounds like a good idea in theory, but it's gonna die.

I also don't worry about the opinions of SUV drivers since I think they're all a bit deranged anyway. If you take an SUV off-roading, you void the warranty. I was shocked when I heard that. So then what was the point of getting one in the first place? Ignorance? Stupidity? Conveniece? Utility? Either get a truck or a van or a 4x4 or a baja so they can be used for their intended purpose, not some joke of a crossover that can't do either one very well. They're less safe and get in far more roll-over accidents than cars.

Sorry if my ignorance is showing, but I never understood the point of an SUV ever since the late 90s when they became unavoidable on the roads. Not to mention the dangerousness when a soccer mom drives one.

Small, light and nimble is what I like. But if you've seen the obesity in this country lately, I guess bigger bodies require bigger vehicles, huh? They are what sells, or were before 2008. I haven't kept up on the latest car trends but I think all new cars are ugly anyway so I just avoid the whole thing.

As for having emission control devices on all newer vehicles, yeah I'm for that too. The masses run around on auto pilot all the time anyway. Might as well make it worth somebody's while. That's a lot of platinum out there.

But I hadn't thought about what you said about scrapping an old car and building a new one makes way more pollution than just leaving the old one on the road. I felt that way but never articulated it like that before. And it makes perfect sense. Thanks!

The A series really is lighter. But you can lighten a 13B with lighter parts (ancillaries) like aluminum on aluminum waterpumps (GMB on an FC housing), light carb like a DCOE, aluminum flywheel etc.

Sounds like your car is bare bones. Good luck with it!

I didn't know you had 2" lower springs. Keeping your exhaust up was a good idea.

As for your cat, sounds like a good idea in theory, but it's gonna die.

I also don't worry about the opinions of SUV drivers since I think they're all a bit deranged anyway. If you take an SUV off-roading, you void the warranty. I was shocked when I heard that. So then what was the point of getting one in the first place? Ignorance? Stupidity? Conveniece? Utility? Either get a truck or a van or a 4x4 or a baja so they can be used for their intended purpose, not some joke of a crossover that can't do either one very well. They're less safe and get in far more roll-over accidents than cars.

Sorry if my ignorance is showing, but I never understood the point of an SUV ever since the late 90s when they became unavoidable on the roads. Not to mention the dangerousness when a soccer mom drives one.

Small, light and nimble is what I like. But if you've seen the obesity in this country lately, I guess bigger bodies require bigger vehicles, huh? They are what sells, or were before 2008. I haven't kept up on the latest car trends but I think all new cars are ugly anyway so I just avoid the whole thing.

As for having emission control devices on all newer vehicles, yeah I'm for that too. The masses run around on auto pilot all the time anyway. Might as well make it worth somebody's while. That's a lot of platinum out there.

But I hadn't thought about what you said about scrapping an old car and building a new one makes way more pollution than just leaving the old one on the road. I felt that way but never articulated it like that before. And it makes perfect sense. Thanks!

The A series really is lighter. But you can lighten a 13B with lighter parts (ancillaries) like aluminum on aluminum waterpumps (GMB on an FC housing), light carb like a DCOE, aluminum flywheel etc.

Sounds like your car is bare bones. Good luck with it!

#59

Enough of that unpleantness. Now on to something fun!

The 74 carb pictured earlier in this thread turns out to have had a couple clogged inlet screens above the needle and seats. That would explain the lean spike this carb has had on primaries and the pathetic secondaries that had like no power.

I decided to leave them out and rely on a regular fuel filter like all other carbs.

See, I know these 74 carbs have power. It's just that this one never had any power on the secondaries. The first car I ever tested it in was the MG and it had great insane power on primaries but when I mashed the pedal the open the secondaries, it had nothing. I always blamed the tiny exhaust until I tested this carb in the blue car last year. That was the ulitmate 74 spec setup with a full RB long primary exhaust. This carb had the same lack of secondary power so I knew something was up. Turns out my suspicion about the inlet screens was true. Yay!

So it's kinda neat that I'll get to use this carb here in the MG again. I'm very excited! I'll test run it in the REPU and if it starts up easily and doesn't feel like it needs a lengthy break in, I'm free to yank it to go back in the MG! Then another engine can go in for test running. Hmm, 6 port 12A or 6 port 13B? Sorry, that's a discussion for another thread.

The 74 carb pictured earlier in this thread turns out to have had a couple clogged inlet screens above the needle and seats. That would explain the lean spike this carb has had on primaries and the pathetic secondaries that had like no power.

I decided to leave them out and rely on a regular fuel filter like all other carbs.

See, I know these 74 carbs have power. It's just that this one never had any power on the secondaries. The first car I ever tested it in was the MG and it had great insane power on primaries but when I mashed the pedal the open the secondaries, it had nothing. I always blamed the tiny exhaust until I tested this carb in the blue car last year. That was the ulitmate 74 spec setup with a full RB long primary exhaust. This carb had the same lack of secondary power so I knew something was up. Turns out my suspicion about the inlet screens was true. Yay!

So it's kinda neat that I'll get to use this carb here in the MG again. I'm very excited! I'll test run it in the REPU and if it starts up easily and doesn't feel like it needs a lengthy break in, I'm free to yank it to go back in the MG! Then another engine can go in for test running. Hmm, 6 port 12A or 6 port 13B? Sorry, that's a discussion for another thread.

#60

Turns out it wasn't the flywheel at all. It was the disc! The old one was 7.4ish while the nearly new one is over 9mm thick! Uncompressed. Tried it with the light steel and the pedal was vastly improved. Then I wanted the light steel for the GSL-SE so I did a quickie swap the other day. It was never about the flywheel.

So now the aluminum one is back in the MG. This realigns with my original vision of the lightest rotating assembly easily obtainable for someone like me who has a spare set of S4 NA rotors and an aluminum flywheel for this really light car. It makes a 31.5 pound assembly.

If it winds up too light, I'll look at getting a light steel for it, but until then, I'll try this aluminum flywheel.

So now the aluminum one is back in the MG. This realigns with my original vision of the lightest rotating assembly easily obtainable for someone like me who has a spare set of S4 NA rotors and an aluminum flywheel for this really light car. It makes a 31.5 pound assembly.

If it winds up too light, I'll look at getting a light steel for it, but until then, I'll try this aluminum flywheel.

#61

I swapped back to the light steel. Reason why is I just tested the RB Holley 600 I intend to use in the MG, in the brown car and it seems the light steel is the better choice as the carb is rather cold blooded and kinda glitchy even when warm. The brown car's current engine has a similar S4 NA rotating assembly and a long primary to what the MG has. The light steel felt perfect to drive in this situation. So, I swapped it back in the MG. Finally some real world testing to give the answers. That's all I needed.

Carb is on the adapter on the reverse runner manifold; all bolted in. Header is done. Center section is getting there. Dizzy and cap are in. Waterpump and radiator went in today. Had to come back out to reverse fan blade direction to a pusher. Still have fan wiring and a brake job to do, plus lots of other stuff... I'll be able to test fire it in a week or two (depending on exhaust completion) and then save up for the brake job.

Carb is on the adapter on the reverse runner manifold; all bolted in. Header is done. Center section is getting there. Dizzy and cap are in. Waterpump and radiator went in today. Had to come back out to reverse fan blade direction to a pusher. Still have fan wiring and a brake job to do, plus lots of other stuff... I'll be able to test fire it in a week or two (depending on exhaust completion) and then save up for the brake job.

#62

I got some pics of the new long primary exhaust during the build.

Center section had to be built first. Two RB presilencers welded to two Magnapacks. You could yell through one of these and hardly hear it at the other end. Should be good enough.

The long primary header. It looks a lot like the one RX-Midget built. Great minds?

That's a snug nad!

Making progress.

Ok I brought up the gamma correction so you can see the details. The front pipe hugs the frame rail to give not only enough room for the other pipe, but you need clearance for the exhaust studs sticking out of the rotor housings. Nothing like forcing something big in a small opening. Now I'm starting to sound like Aaron Cake.

Center section had to be built first. Two RB presilencers welded to two Magnapacks. You could yell through one of these and hardly hear it at the other end. Should be good enough.

The long primary header. It looks a lot like the one RX-Midget built. Great minds?

That's a snug nad!

Making progress.

Ok I brought up the gamma correction so you can see the details. The front pipe hugs the frame rail to give not only enough room for the other pipe, but you need clearance for the exhaust studs sticking out of the rotor housings. Nothing like forcing something big in a small opening. Now I'm starting to sound like Aaron Cake.

#63

I went with 800x600 to see more details. Had the break out the big halogen light. Compare this under-car pic with the other one from earlier in this thread showing the old exhaust built be the previous owner back in 1988 or something. Glad it's got a long primary now. Can you spot the O2 bung I just added yesterday?

Now for some clearance shots. I used a competition tranny mount installed backwards because they used a stock tranny mount installed backwards. That's how they did it back then for some reason. Presumably for clearance reasons. It was old, sagging cracked etc so I got a new competition mount from Racing Beat and had to be creative to get it in there. It raised the bolts up above where they had been rubbing metal on metal and making a horrible noise. I'm serious when I say there are only a few mm here and there to work with.

That's not an optical illusion. The starter really is about 5mm from the frame rail. To prevent it from making contact in reverse gear, I went with competition motor mounts too.

They helped on the other side as well because the previous owner's oil pan was always hitting the frame and it caused an oil leak during acceleration when the engine twists this way. I ground down the lip on my pan just at the rear corners to hopefully prevent this too.

This shot shows the FC clutch slave I installed.

Now for some clearance shots. I used a competition tranny mount installed backwards because they used a stock tranny mount installed backwards. That's how they did it back then for some reason. Presumably for clearance reasons. It was old, sagging cracked etc so I got a new competition mount from Racing Beat and had to be creative to get it in there. It raised the bolts up above where they had been rubbing metal on metal and making a horrible noise. I'm serious when I say there are only a few mm here and there to work with.

That's not an optical illusion. The starter really is about 5mm from the frame rail. To prevent it from making contact in reverse gear, I went with competition motor mounts too.

They helped on the other side as well because the previous owner's oil pan was always hitting the frame and it caused an oil leak during acceleration when the engine twists this way. I ground down the lip on my pan just at the rear corners to hopefully prevent this too.

This shot shows the FC clutch slave I installed.

#64

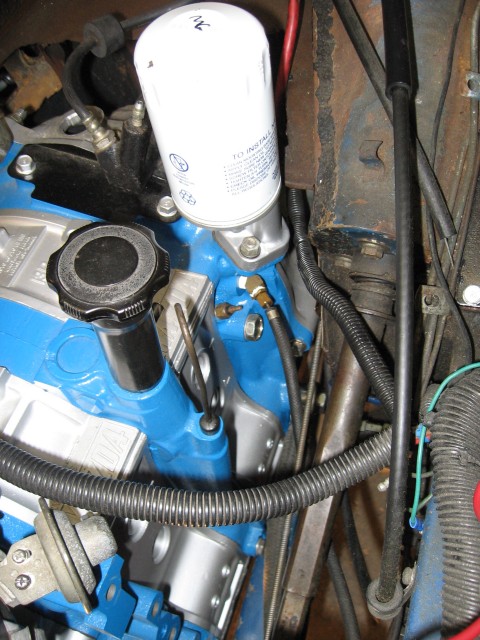

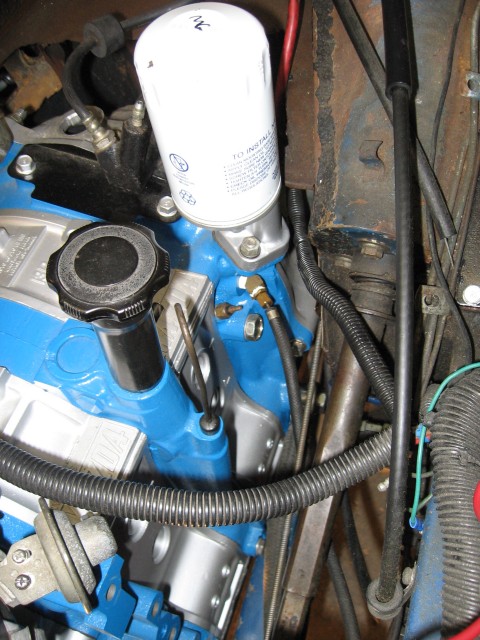

And here is the FC clutch master. A brake master is coming soon.

I went with an old school tall style oil filter pedestal, and I think you can see why.

This radiator fits under the hood. The car's stock rad support brackets needed clearancing. None of it was done by me so I can't say how to do it. Hopefully you can get some ideas from this pic. The lower radiator hose attatches under the rack and pinion tube. Can you see the nipple down there?

I went with an old school tall style oil filter pedestal, and I think you can see why.

This radiator fits under the hood. The car's stock rad support brackets needed clearancing. None of it was done by me so I can't say how to do it. Hopefully you can get some ideas from this pic. The lower radiator hose attatches under the rack and pinion tube. Can you see the nipple down there?

#65

These are old school 13B oil pans. A pan like one of these went on the engine. I don't see any other type of pan fitting. Plus you kinda need to use a 1st gen or old school front cover for the motor mount bar anyway, with which these pans are compatible. You also need an old school pickup tube that has a sort of S pipe and a big strainer (not pictured).

This shows off where/how everything fits under and over the frame rail, and where they bent the pinchweld down for oil pan clearance.

The notch in the frame rail for the oil pan drain bolt. Looks like they used a piece of ERW exhaust pipe or something. Others don't usually go this far on their conversions. They instead do a custom oil pan. Well, that really limits you in my opinion. I'm glad the most I needed to do was maybe grind down the rear corner lip of the pan, but having installed competition motor and trans mounts, maybe even that step was not necessary. The engine is freaking solid in there. No way I can rock it enough to cause anything to make contact; the whole car shakes instead.

And lastly the notch from another perspective. I've got plenty of room for a 19mm or 3/4" wrench.

This shows off where/how everything fits under and over the frame rail, and where they bent the pinchweld down for oil pan clearance.

The notch in the frame rail for the oil pan drain bolt. Looks like they used a piece of ERW exhaust pipe or something. Others don't usually go this far on their conversions. They instead do a custom oil pan. Well, that really limits you in my opinion. I'm glad the most I needed to do was maybe grind down the rear corner lip of the pan, but having installed competition motor and trans mounts, maybe even that step was not necessary. The engine is freaking solid in there. No way I can rock it enough to cause anything to make contact; the whole car shakes instead.

And lastly the notch from another perspective. I've got plenty of room for a 19mm or 3/4" wrench.

#67

Now that the exhaust is done, getting back to the intake, if you refer to post #61 https://www.rx7club.com/old-school-o.../#post11576159 where I said I was needing to use a light steel flywheel due to the glitchy holley, I've changed my mind about that. I've gotten pretty good at Nikkis lately and have recently modded one to be perfect for the MG. It wasn't really intended for this but it turns out that the carb exhibits the correct behaviors for a setup like this. It has the biggest primary venturis I've ever done while still driving pretty well when I test ran it in the brown car with the wideband. The result was just a tad lean at 13.3 at about 50 degrees F. So I lightly kissed the inside of the jets with a slightly bigger drill bit and reduced the primary short slow air bleeds from 118 down to the smallest I do in cases like this: 105. This reduction in unwanted air and the slight increase in primary jets should bring me closer to the ideal 13.0. But only test driving it on its intended engine will let us know for sure. Plus the MG doesn't have a leaky brake booster like the brown car, so that's a plus for unwanted air reduction.

This Nikki has some great tip-in and should allow an aluminum flywheel to work fine and not feel too light. If you refer to post #60 https://www.rx7club.com/old-school-o.../#post11442436 you'll see the reasons for wanting to use it. And if it is too light, a light steel could be swapped in at a later time. It's just not seeming like such a necessity anymore.

I'm so glad to be swapping to a Nikki. I can get out from under the ball and chain, or I mean the Holley. It means I won't have to install a Carter fuel pump. I can replace the little Facet fuel pump with a newer modern one and won't need to drill into the car. The old mounting holes should work.

I can get out from under the ball and chain, or I mean the Holley. It means I won't have to install a Carter fuel pump. I can replace the little Facet fuel pump with a newer modern one and won't need to drill into the car. The old mounting holes should work.

This Nikki has some great tip-in and should allow an aluminum flywheel to work fine and not feel too light. If you refer to post #60 https://www.rx7club.com/old-school-o.../#post11442436 you'll see the reasons for wanting to use it. And if it is too light, a light steel could be swapped in at a later time. It's just not seeming like such a necessity anymore.

I'm so glad to be swapping to a Nikki.

I can get out from under the ball and chain, or I mean the Holley. It means I won't have to install a Carter fuel pump. I can replace the little Facet fuel pump with a newer modern one and won't need to drill into the car. The old mounting holes should work.

I can get out from under the ball and chain, or I mean the Holley. It means I won't have to install a Carter fuel pump. I can replace the little Facet fuel pump with a newer modern one and won't need to drill into the car. The old mounting holes should work.

Thread

Thread Starter

Forum

Replies

Last Post