I blow apex seals way too easy

#1

I blow apex seals way too easy

Well guys seems i have some kind of problem on my hand. My engine likes to blow apex seals. First time was right after i rebuilt it, i was doing a little bit of med throttle accel (35-40%) tps car was decently tuned afr wise by then. let out of the gas and it died, got it to barely run and limped it home. did a compression test, rear rotor lost 1 apex barely.

Result of teardown:

anywho, replace that seal and got a new oring kit. assembled the engine and broke it in. (had >1000 when it blew up this time) had the tune working very well, was doing mid range boosting, afrs dipping into the tens as it passed 5psi (safe afr while learning to tune) well i decided to do a full throttle pull to 6500 in third gear. afr's were good and stayed stable at 10.5, my boost was only 7-8psi on a stock s5 turbo. let off the gas and its dies, this time wont start while cranking. I haven't torn into it yet but i sounded like maybe 2 apex seals went in the rear this time.

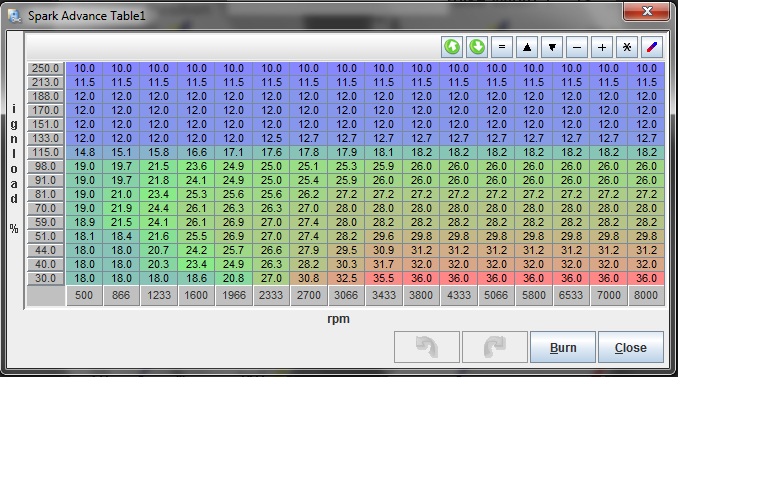

Im going to rebuild this motor, i want to know what i can do different to prevent this from happening. im going to try to get my timing map up for people to see.

Specs:

s5 13b turbo shortblock stock ports

full atkins rebuild kit with atkins cyro apex seals

fd stat gears

stock s5 turbo

stock 550's

Megasquirt 3 with ms3x full sequential inj

fd uim with throttle body

fd flywheel

Result of teardown:

anywho, replace that seal and got a new oring kit. assembled the engine and broke it in. (had >1000 when it blew up this time) had the tune working very well, was doing mid range boosting, afrs dipping into the tens as it passed 5psi (safe afr while learning to tune) well i decided to do a full throttle pull to 6500 in third gear. afr's were good and stayed stable at 10.5, my boost was only 7-8psi on a stock s5 turbo. let off the gas and its dies, this time wont start while cranking. I haven't torn into it yet but i sounded like maybe 2 apex seals went in the rear this time.

Im going to rebuild this motor, i want to know what i can do different to prevent this from happening. im going to try to get my timing map up for people to see.

Specs:

s5 13b turbo shortblock stock ports

full atkins rebuild kit with atkins cyro apex seals

fd stat gears

stock s5 turbo

stock 550's

Megasquirt 3 with ms3x full sequential inj

fd uim with throttle body

fd flywheel

#6

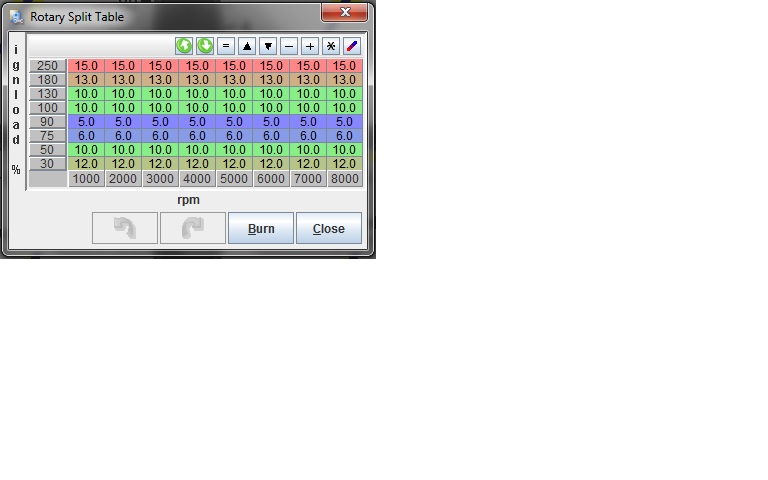

AFRs aren't the only thing that blow engines. what are your timing splits from leading to trailing?

not familiar with megasquirt but your timing is too drastic during transitions and that can also be problematic.

and stop using the Atkins cryo seals, they're too brittle for boosted engines.

not familiar with megasquirt but your timing is too drastic during transitions and that can also be problematic.

and stop using the Atkins cryo seals, they're too brittle for boosted engines.

#7

AFRs aren't the only thing that blow engines. what are your timing splits from leading to trailing?

not familiar with megasquirt but your timing is too drastic during transitions and that can also be problematic.

and stop using the Atkins cryo seals, they're too brittle for boosted engines.

not familiar with megasquirt but your timing is too drastic during transitions and that can also be problematic.

and stop using the Atkins cryo seals, they're too brittle for boosted engines.

next time i will try to smooth out the timing transistion going into boost.

I will not use atkins cryo again, my current plan is to talk to you about having my rotors milled to 3mm and purchasing some goopy 3mm seals.

Trending Topics

#8

AFRs aren't the only thing that blow engines. what are your timing splits from leading to trailing?

not familiar with megasquirt but your timing is too drastic during transitions and that can also be problematic.

and stop using the Atkins cryo seals, they're too brittle for boosted engines.

not familiar with megasquirt but your timing is too drastic during transitions and that can also be problematic.

and stop using the Atkins cryo seals, they're too brittle for boosted engines.

Just Because it's cyro it must be better right? NOT.

Mazda heat treated their apex too, but ONLY at the edge. and there is a reason for it.

I rather use Stock OEM than ANYTHING from Atkins. actually yeah, stock is better than ANYTHING from Atkins, that's just me

#9

dyno queen potentials

Join Date: Oct 2007

Location: ga

Posts: 445

Likes: 0

Received 0 Likes

on

0 Posts

^+1, also check your timing on the pulley and make sure it's the same on your laptop. cheap set of apex seals you can start out with is rotary aviation, since you're in to r&d

#10

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,770

Received 2,562 Likes

on

1,822 Posts

good suggestions.

i would run stock apex seals, although there are choices...

second i would pull a couple degrees of timing off the 98 row, like Karack says, make it a smoother transition. i might also make everything over the boost it wants to run (6-7psi?) something safe, like 10BTDC.

thirdly, i would make the split in boost 15 degrees all the time. it should also be 15 degrees at idle, and stock is only running near zero in part throttle cruise. later once its tuned a little better, then you can experiment, but everything Mazda has made with more than 160hp runs a 15 degree split under load.

fourth, make sure the timing is zeroed correctly, IE the timing on the ecu agrees with the timing on your engine.

i would run stock apex seals, although there are choices...

second i would pull a couple degrees of timing off the 98 row, like Karack says, make it a smoother transition. i might also make everything over the boost it wants to run (6-7psi?) something safe, like 10BTDC.

thirdly, i would make the split in boost 15 degrees all the time. it should also be 15 degrees at idle, and stock is only running near zero in part throttle cruise. later once its tuned a little better, then you can experiment, but everything Mazda has made with more than 160hp runs a 15 degree split under load.

fourth, make sure the timing is zeroed correctly, IE the timing on the ecu agrees with the timing on your engine.

#11

another issue i find is mixed up pulleys, the FC pulleys can be swapped around and the hub may not match your pulley. timing can be up to 30 degrees off in either direction! as time goes on and engine parts get mixed and matched this becomes more of an issue that people don't even realize.

if you do go with Goopy seals i would stick with the 2mm, they are still damn durable even with the smaller seal. only reason to move up in size is if the rotor slot is damaged.

if you do go with Goopy seals i would stick with the 2mm, they are still damn durable even with the smaller seal. only reason to move up in size is if the rotor slot is damaged.

#12

Also might want to check your wiring harness. How new (or old) is it? Take some time to perform a continuity check. How old is your fuel pump? Do you have it wired directly to your battery? How about the fuel filter? Has it been changed lately?

Just some thoughts.

Just some thoughts.

#13

another issue i find is mixed up pulleys, the FC pulleys can be swapped around and the hub may not match your pulley. timing can be up to 30 degrees off in either direction! as time goes on and engine parts get mixed and matched this becomes more of an issue that people don't even realize.

if you do go with Goopy seals i would stick with the 2mm, they are still damn durable even with the smaller seal. only reason to move up in size is if the rotor slot is damaged.

if you do go with Goopy seals i would stick with the 2mm, they are still damn durable even with the smaller seal. only reason to move up in size is if the rotor slot is damaged.

i will run the 2mm then if my slots are good.

Thanks for the responses guys, im going to try to pull the engine this weekend and find out why it blew, or at least how bad.

#14

good suggestions.

i would run stock apex seals, although there are choices...

second i would pull a couple degrees of timing off the 98 row, like Karack says, make it a smoother transition. i might also make everything over the boost it wants to run (6-7psi?) something safe, like 10BTDC.

thirdly, i would make the split in boost 15 degrees all the time. it should also be 15 degrees at idle, and stock is only running near zero in part throttle cruise. later once its tuned a little better, then you can experiment, but everything Mazda has made with more than 160hp runs a 15 degree split under load.

fourth, make sure the timing is zeroed correctly, IE the timing on the ecu agrees with the timing on your engine.

i would run stock apex seals, although there are choices...

second i would pull a couple degrees of timing off the 98 row, like Karack says, make it a smoother transition. i might also make everything over the boost it wants to run (6-7psi?) something safe, like 10BTDC.

thirdly, i would make the split in boost 15 degrees all the time. it should also be 15 degrees at idle, and stock is only running near zero in part throttle cruise. later once its tuned a little better, then you can experiment, but everything Mazda has made with more than 160hp runs a 15 degree split under load.

fourth, make sure the timing is zeroed correctly, IE the timing on the ecu agrees with the timing on your engine.

#15

you mean 9 o'clock i assume.

it will get you close but still won't verify if the timing is close enough to not cause an issue. the keyway is a very rough method and assumes the pulley is close enough to be good. if the engine was original and all parts reused then it shouldn't be a problem. it is more a problem from builders who throw parts together from a misc. box.

it will get you close but still won't verify if the timing is close enough to not cause an issue. the keyway is a very rough method and assumes the pulley is close enough to be good. if the engine was original and all parts reused then it shouldn't be a problem. it is more a problem from builders who throw parts together from a misc. box.

#16

I thought the keyway was accurate enough to place the engine timing? At least for you to verify the timing marks on the pully are at the right spot?

I bought an under drive pully from mazdatrix or racing beat not sure which so I assume there is not mixing or matching issue there. How can the stock pulleys be different. They should be the same? iF not as most people now mix and match parts how can you tell your timing is at the right spot? WTF is with rotaries anyway. LOL

My friend blew up multiple engines. Tuner couldn’t figure it out. I was sitting in his car monitoring datalogs and noticed that the car would go full advanced out of the blue. Needless to say the first time he got on it and that happened boom. I think it ended up being an ECU issue because with a new ECU no more blown engines. Could have been a wiring issue. No idea.

Either way datalog your timing.

Note: I also thought it was keyway at 3oclock = TDC

I bought an under drive pully from mazdatrix or racing beat not sure which so I assume there is not mixing or matching issue there. How can the stock pulleys be different. They should be the same? iF not as most people now mix and match parts how can you tell your timing is at the right spot? WTF is with rotaries anyway. LOL

My friend blew up multiple engines. Tuner couldn’t figure it out. I was sitting in his car monitoring datalogs and noticed that the car would go full advanced out of the blue. Needless to say the first time he got on it and that happened boom. I think it ended up being an ECU issue because with a new ECU no more blown engines. Could have been a wiring issue. No idea.

Either way datalog your timing.

Note: I also thought it was keyway at 3oclock = TDC

#17

you mean 9 o'clock i assume.

it will get you close but still won't verify if the timing is close enough to not cause an issue. the keyway is a very rough method and assumes the pulley is close enough to be good. if the engine was original and all parts reused then it shouldn't be a problem. it is more a problem from builders who throw parts together from a misc. box.

it will get you close but still won't verify if the timing is close enough to not cause an issue. the keyway is a very rough method and assumes the pulley is close enough to be good. if the engine was original and all parts reused then it shouldn't be a problem. it is more a problem from builders who throw parts together from a misc. box.

#18

it requires you to remove the main hub and use one that is a prestamped unit. either buying one from mazda as a complete unit(both pieces matched) or buy a racing beat unit which isn't marked for the FC 5/20ATDC but it does have a 0TDC mark and 10ATDC mark, so if you are setting it up and tuning it based off the 5/20 marks for pre-established timing maps then you set it up between the first and second marks which will put the engine at 5* ATDC, which is the right/leading timing mark on stock hubs.

the keyway is at a perfect 9 oclock position at TDC, problem is there is no way to know if it is exactly at 9 o'clock by eye.

i spent a whole day a while back deciphering the FC pulleys and had many many variations and no discerning way to establish TDC without a preset hub to put onto the engines, which i now have to verify the hubs coming in on engines are correct.

the rotor tip to rotor tip method some people mentioned does not work either, it actually isn't even close. for the series 4 it was 30 degrees out and series 5 was even further off... i did this on a disassembled engine with the rotor set exactly to TDC in the housing so there was no question about pulleys.

sometimes it's worth spending the $100 or so to be sure your timing is accurate. you can also do this while you have your engine apart by placing the front half of the engine together, place the front rotor at TDC against the spark plugs and check your pulley, you may be surprised how far off your pulley may be, you may have gotten lucky also and it was not the problem.

the keyway is at a perfect 9 oclock position at TDC, problem is there is no way to know if it is exactly at 9 o'clock by eye.

i spent a whole day a while back deciphering the FC pulleys and had many many variations and no discerning way to establish TDC without a preset hub to put onto the engines, which i now have to verify the hubs coming in on engines are correct.

the rotor tip to rotor tip method some people mentioned does not work either, it actually isn't even close. for the series 4 it was 30 degrees out and series 5 was even further off... i did this on a disassembled engine with the rotor set exactly to TDC in the housing so there was no question about pulleys.

sometimes it's worth spending the $100 or so to be sure your timing is accurate. you can also do this while you have your engine apart by placing the front half of the engine together, place the front rotor at TDC against the spark plugs and check your pulley, you may be surprised how far off your pulley may be, you may have gotten lucky also and it was not the problem.

Last edited by RotaryEvolution; 11-13-12 at 02:34 PM.

#19

it requires you to remove the main hub and use one that is a prestamped unit. either buying one from mazda as a complete unit(both pieces matched) or buy a racing beat unit which isn't marked for the FC 5/20ATDC but it does have a 0TDC mark and 10ATDC mark, so if you are setting it up and tuning it based off the 5/20 marks for pre-established timing maps then you set it up between the first and second marks which will put the engine at 5* ATDC, which is the right/leading timing mark on stock hubs.

the keyway is at a perfect 9 oclock position at TDC, problem is there is no way to know if it is exactly at 9 o'clock by eye.

i spent a whole day a while back deciphering the FC pulleys and had many many variations and no discerning way to establish TDC without a preset hub to put onto the engines, which i now have to verify the hubs coming in on engines are correct.

the rotor tip to rotor tip method some people mentioned does not work either, it actually isn't even close. for the series 4 it was 30 degrees out and series 5 was even further off... i did this on a disassembled engine with the rotor set exactly to TDC in the housing so there was no question about pulleys.

sometimes it's worth spending the $100 or so to be sure your timing is accurate. you can also do this while you have your engine apart by placing the front half of the engine together, place the front rotor at TDC against the spark plugs and check your pulley, you may be surprised how far off your pulley may be, you may have gotten lucky also and it was not the problem.

the keyway is at a perfect 9 oclock position at TDC, problem is there is no way to know if it is exactly at 9 o'clock by eye.

i spent a whole day a while back deciphering the FC pulleys and had many many variations and no discerning way to establish TDC without a preset hub to put onto the engines, which i now have to verify the hubs coming in on engines are correct.

the rotor tip to rotor tip method some people mentioned does not work either, it actually isn't even close. for the series 4 it was 30 degrees out and series 5 was even further off... i did this on a disassembled engine with the rotor set exactly to TDC in the housing so there was no question about pulleys.

sometimes it's worth spending the $100 or so to be sure your timing is accurate. you can also do this while you have your engine apart by placing the front half of the engine together, place the front rotor at TDC against the spark plugs and check your pulley, you may be surprised how far off your pulley may be, you may have gotten lucky also and it was not the problem.

when i disassemble the engine i will set the number 1 to tdc and check my pulley. it would make sense if this was my problem because setting my cps was never an easy task because when id line the notches on the cps it would still be off from the 5 degree mark.

#21

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,770

Received 2,562 Likes

on

1,822 Posts

it requires you to remove the main hub and use one that is a prestamped unit. either buying one from mazda as a complete unit(both pieces matched) or buy a racing beat unit which isn't marked for the FC 5/20ATDC but it does have a 0TDC mark and 10ATDC mark, so if you are setting it up and tuning it based off the 5/20 marks for pre-established timing maps then you set it up between the first and second marks which will put the engine at 5* ATDC, which is the right/leading timing mark on stock hubs.

the keyway is at a perfect 9 oclock position at TDC, problem is there is no way to know if it is exactly at 9 o'clock by eye.

i spent a whole day a while back deciphering the FC pulleys and had many many variations and no discerning way to establish TDC without a preset hub to put onto the engines, which i now have to verify the hubs coming in on engines are correct.

the rotor tip to rotor tip method some people mentioned does not work either, it actually isn't even close. for the series 4 it was 30 degrees out and series 5 was even further off... i did this on a disassembled engine with the rotor set exactly to TDC in the housing so there was no question about pulleys.

sometimes it's worth spending the $100 or so to be sure your timing is accurate. you can also do this while you have your engine apart by placing the front half of the engine together, place the front rotor at TDC against the spark plugs and check your pulley, you may be surprised how far off your pulley may be, you may have gotten lucky also and it was not the problem.

the keyway is at a perfect 9 oclock position at TDC, problem is there is no way to know if it is exactly at 9 o'clock by eye.

i spent a whole day a while back deciphering the FC pulleys and had many many variations and no discerning way to establish TDC without a preset hub to put onto the engines, which i now have to verify the hubs coming in on engines are correct.

the rotor tip to rotor tip method some people mentioned does not work either, it actually isn't even close. for the series 4 it was 30 degrees out and series 5 was even further off... i did this on a disassembled engine with the rotor set exactly to TDC in the housing so there was no question about pulleys.

sometimes it's worth spending the $100 or so to be sure your timing is accurate. you can also do this while you have your engine apart by placing the front half of the engine together, place the front rotor at TDC against the spark plugs and check your pulley, you may be surprised how far off your pulley may be, you may have gotten lucky also and it was not the problem.

i do like to put the rotor on TDC, and put the front cover and pulley on and check it.

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM