Engine failure Diagnosis. Strange Tip Breakage (photos)

#1

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Engine failure Diagnosis. Strange Tip Breakage (photos)

I have just posted this in the non technical 2nd gen section by mistake (sorry)

I have a kit car with a turbo II engine in it, i first ran the car with the stock turbo and it went really well, its mildly street ported Series 5 engine running on a microtec ecu. I then changed the turbo to a TO4 E and since then its blown twice.

Has anyone seen a tip break like this before. The engine died on the dyno rollers at 10psi with everything seemingly ok (AF's inj duty, temps etc). It had been worked harder at higher boost while drifting with no problems on the same set up only weeks before. I went back to the rollers to map up to 1 bar but never got that far. It seems a strange way for it to break. There is no housing damage at all (bonus i spose)

The tip was still in situe when i stripped the engine and there is no damage to the rotor.

This is the second time the engine has died since fitting the turbo and manifold, before the turbo change it was driven in anger on track many times without missing a beat. Its only ever running quite low boost. The fuel pump and filter were changed after it went last time and the injectors were flow checked, I also run premix. The tip breakage is very similar to the last time.

Any ideas.?? I have many years experience with rotaries and build my own engines and have never had problems like this before, i also use the same rotary specialist to map on the dyno and they have no idea. The car has all the required supporting mods, runs on colder plugs and 99 ron fuel.

One thought, I have a divided TO4 turbo and my manifold is divided all the way to the turbo so effectively, one port feeds one side of the turbo and the other port feeds the other side of the turbo and they will never meet to balance out. is this a problem? (Its a home made manifold).

I have a kit car with a turbo II engine in it, i first ran the car with the stock turbo and it went really well, its mildly street ported Series 5 engine running on a microtec ecu. I then changed the turbo to a TO4 E and since then its blown twice.

Has anyone seen a tip break like this before. The engine died on the dyno rollers at 10psi with everything seemingly ok (AF's inj duty, temps etc). It had been worked harder at higher boost while drifting with no problems on the same set up only weeks before. I went back to the rollers to map up to 1 bar but never got that far. It seems a strange way for it to break. There is no housing damage at all (bonus i spose)

The tip was still in situe when i stripped the engine and there is no damage to the rotor.

This is the second time the engine has died since fitting the turbo and manifold, before the turbo change it was driven in anger on track many times without missing a beat. Its only ever running quite low boost. The fuel pump and filter were changed after it went last time and the injectors were flow checked, I also run premix. The tip breakage is very similar to the last time.

Any ideas.?? I have many years experience with rotaries and build my own engines and have never had problems like this before, i also use the same rotary specialist to map on the dyno and they have no idea. The car has all the required supporting mods, runs on colder plugs and 99 ron fuel.

One thought, I have a divided TO4 turbo and my manifold is divided all the way to the turbo so effectively, one port feeds one side of the turbo and the other port feeds the other side of the turbo and they will never meet to balance out. is this a problem? (Its a home made manifold).

#3

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Hi

The Turbo is a TO4E with a 1.0 hot side. The injectors are stock 550 prims, and 1000cc secondaries. All were cleaned and flow checked before the last rebuild along with a new pump and fuel filter.

The Turbo is a TO4E with a 1.0 hot side. The injectors are stock 550 prims, and 1000cc secondaries. All were cleaned and flow checked before the last rebuild along with a new pump and fuel filter.

#5

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

well thats a strange one, when i first fitted the turbo the dyno boost reading showed boost dropping off but on the road the boost would creep up. The turbo had an internal wastegate and even by wiring it open the boost didnt reduce so i fitted a 60mm external wastegate and welded the internal one shut. I then had stable boost control and could hold it as low as 6 psi. I could then increase it using the electronic boost controller which all worked well, hence i went back to the dyno for some more mapping for the newly found low boost and to go upto about 1 bar.

The reason i needed less boost was the fact that the car only weighs 650 kg and with nearly 400 bhp it was undriveable on track so i wanted to be able to run less power..... unusual i know.!

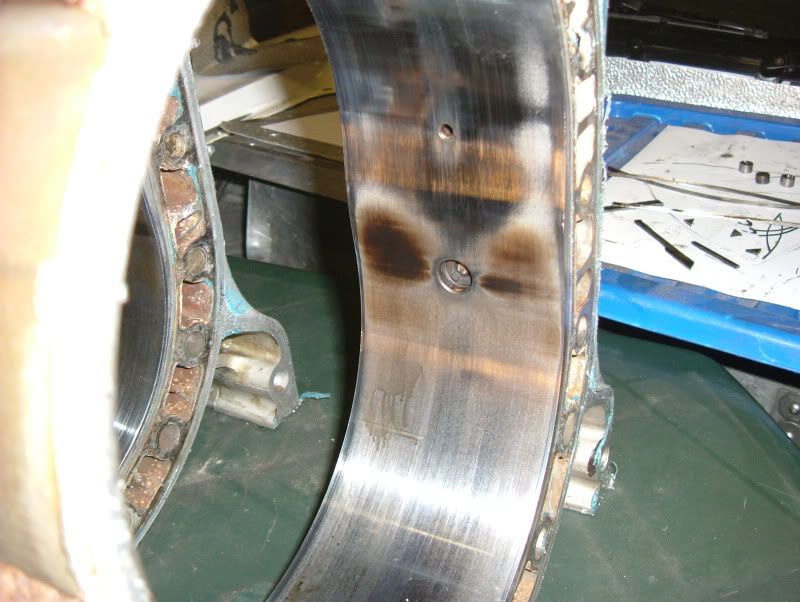

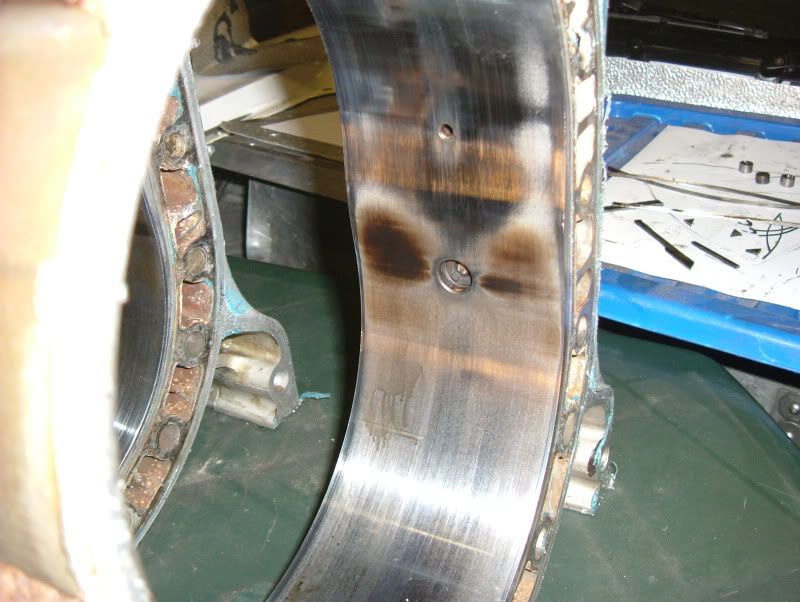

Pic of the the rotor housings and the apex seal grove in question

The reason i needed less boost was the fact that the car only weighs 650 kg and with nearly 400 bhp it was undriveable on track so i wanted to be able to run less power..... unusual i know.!

Pic of the the rotor housings and the apex seal grove in question

#7

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

when you say 1k bottom and 12 top, what do you mean?

nothing has shown signs of running lean. All the af's were good and all the exhaust components look the right colour.

nothing has shown signs of running lean. All the af's were good and all the exhaust components look the right colour.

Trending Topics

#9

good AFRs with no boost creep. well, the only thing i can come up with next would be ignition. what are you running (coils, ignitors, etc.)? do you have logs of your timing? have you checked for any signs of crossfiring?

what about cooling? how are your oil and water temperatures?

what about cooling? how are your oil and water temperatures?

#10

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

oil never goes over 90degrees C and water never over 86. The ignition is stock series 5 coils and ignitors run from the microtech. There was no sign of ignition break up on the map which i have seen before on other cars but of course that doesnt mean that it just didnt fail. The tuners will have logs, i have spoken to them and they will double check the timing while the car is running on the rollers next time as i have heard stories of timing doing strange things when on the rollers. After the first time it died i changed the Leading coil.

Anyone know what options i have for better coild on the LTX10.?

One other thing of note is that it completed the power run and it was only at the very end of the run or on overun that it died. It made good power all the way up the revs.

Anyone know what options i have for better coild on the LTX10.?

One other thing of note is that it completed the power run and it was only at the very end of the run or on overun that it died. It made good power all the way up the revs.

#11

well this is quite the intriguing query, isn't it?

up fornt, i admit my experiences are not extensive when it comes to turbocharged tuning and applications, but with that said, i've always been a great believer in the Gen II ignition system - even over the Gen III and Rx-8. the only components that have piqued my interest were the coils from www.bmepfuelandtuning.com, but they seem to be going through a bit of trouble business-wise. i know some people in the Rx-8 community use GM coils (LS2, i think) and have had success lighting off turbocharged applications there.

anyway, for me and my humble assessment, it is clear heat is an issue with your new setup, but you just have to figure out the source. i've thought about lean mixes, backpressure and ignition issues and so far, you've checked out good with all. hopefully smarter heads will chime in soon.

in the meantime, i'll keep thinking about it simply because i like the challenge.

up fornt, i admit my experiences are not extensive when it comes to turbocharged tuning and applications, but with that said, i've always been a great believer in the Gen II ignition system - even over the Gen III and Rx-8. the only components that have piqued my interest were the coils from www.bmepfuelandtuning.com, but they seem to be going through a bit of trouble business-wise. i know some people in the Rx-8 community use GM coils (LS2, i think) and have had success lighting off turbocharged applications there.

anyway, for me and my humble assessment, it is clear heat is an issue with your new setup, but you just have to figure out the source. i've thought about lean mixes, backpressure and ignition issues and so far, you've checked out good with all. hopefully smarter heads will chime in soon.

in the meantime, i'll keep thinking about it simply because i like the challenge.

#13

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

its a new walbro pump and fuel filter, the injectors were flow checked and cleaned at rebuild and the plugs are 10's and 11's.

As i mentioned above the car had been driven very much in anger drifting it at much higher temps and boost only weeks before

As i mentioned above the car had been driven very much in anger drifting it at much higher temps and boost only weeks before

#14

Original Gangster/Rotary!

iTrader: (213)

How much premix are you running? I'd verify the OMP is working correctly, the break appears to happen right in the center, which I have never seen. Detonation tends to break the edge of the tip on the 2 piece side.

Also, there are excessive burn marks on the rotor housing by the leading plug hole. What kind of mileage is on those rotor housings?

Those appear to be b10egv's or the like, that dont screw all the way into the rotor housing. I've heard anecdotally of reports of detonation caused by carbon build up in the exposed threads of the inner spark plug boss. I run the NGK rotary-specific race plugs (6725s or the iridium 7420s) which bottom out as they should.

Just food for thought

Also, there are excessive burn marks on the rotor housing by the leading plug hole. What kind of mileage is on those rotor housings?

Those appear to be b10egv's or the like, that dont screw all the way into the rotor housing. I've heard anecdotally of reports of detonation caused by carbon build up in the exposed threads of the inner spark plug boss. I run the NGK rotary-specific race plugs (6725s or the iridium 7420s) which bottom out as they should.

Just food for thought

Last edited by GoodfellaFD3S; 10-30-09 at 04:28 PM.

#15

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Hi

I dont use the OMP, i run 10 -1 premix in the tank, i have always done this. I have also used these plugs before but i am concerned at the amount of black marking by the lug hole as the engine had only done a few hundred miles since rebuild and they were clean (not new) when i rebuilt it.

The engine was running rich for while which i dont suposed helped but i was running water injection when it was on the dyno (100%water) which should help keep it clean.

Any idea why the housings would blacken so quickly?

I dont use the OMP, i run 10 -1 premix in the tank, i have always done this. I have also used these plugs before but i am concerned at the amount of black marking by the lug hole as the engine had only done a few hundred miles since rebuild and they were clean (not new) when i rebuilt it.

The engine was running rich for while which i dont suposed helped but i was running water injection when it was on the dyno (100%water) which should help keep it clean.

Any idea why the housings would blacken so quickly?

#17

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

i have a fully baffled and foam filled tank that i made for the car with a built in swirl pot in the tank, it was also filled to the brim with fuel before the dyno session. I can thrash it round a track with less than 1/4 of a tank of fuel with no fuel starvation problems.

I have had all types of rx7 for the last 15 years and everyone i have modified and built and never had any unexplained problems like this. my Last turbo II was used for 2 years for Nurburgring trips, drifting, drag racing and track days and the engine didnt miss a beat at 380 rwhp runing a gt35/40, i took it out after 2 years and sold it as a running engine as i had my new one ready and waiting to go in.

the carousel at the nurburgring

I have had all types of rx7 for the last 15 years and everyone i have modified and built and never had any unexplained problems like this. my Last turbo II was used for 2 years for Nurburgring trips, drifting, drag racing and track days and the engine didnt miss a beat at 380 rwhp runing a gt35/40, i took it out after 2 years and sold it as a running engine as i had my new one ready and waiting to go in.

the carousel at the nurburgring

#19

Full Member

Thread Starter

Join Date: Oct 2005

Location: England

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

the only things that changed when i changed the turbo were the manifold and dowwnpipe which went from 2.5 inch on the stock turbo to 3 inch on the new one.

When it blew the first time which was the first time on track after the dyno session it blew the first time i went flat out in fourth gear. There were a couple of things i could have put it down to which is why i have changed the pump, filter, leading coil and plugs

I can never go flat out in 4th gear on the road as it has 3.09 final drive diff with a stock Tii gearbox so its geared 235 mph at 7k rpm in 5th it does 80 mph in second!

it does 80 mph in second!

The water temps only ever go to 86 according to the microtech controller on road or track, it goes higher when i'm drifting and in traffic but the fans bring it down easily. On the dyno it stayed at 86 as it does on track.

I have cleaned the engine parts today and noticed that around the leading plug hole on the rotor housings the metal is shiny but to each side of it is carboned up as per the picture which indicated that there is a high spot on the rotor housing. This is more evident now i have cleaned it and put a straight edge on it.

What would cause the bulge?

When it blew the first time which was the first time on track after the dyno session it blew the first time i went flat out in fourth gear. There were a couple of things i could have put it down to which is why i have changed the pump, filter, leading coil and plugs

I can never go flat out in 4th gear on the road as it has 3.09 final drive diff with a stock Tii gearbox so its geared 235 mph at 7k rpm in 5th

it does 80 mph in second!

it does 80 mph in second!The water temps only ever go to 86 according to the microtech controller on road or track, it goes higher when i'm drifting and in traffic but the fans bring it down easily. On the dyno it stayed at 86 as it does on track.

I have cleaned the engine parts today and noticed that around the leading plug hole on the rotor housings the metal is shiny but to each side of it is carboned up as per the picture which indicated that there is a high spot on the rotor housing. This is more evident now i have cleaned it and put a straight edge on it.

What would cause the bulge?

#21

Building my car...

iTrader: (1)

Join Date: Apr 2004

Location: Arizona

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

I am not saying this is the issue , i have not seen the internals . I have seen apex seals go like this a couple of times one set went because of the wrong plugs the center electrode came out and bam. This does not apear to be the issue, the second was two parts one , the exhaust port was to sharp at the top of the exhaust port window, this cought the apex seal after some heat soke on the track and broke the seal almost identically . Sorry for the terrible spelling its late.....

Are you running a ported exhaust if so show some pictures.

Hope this helps

Are you running a ported exhaust if so show some pictures.

Hope this helps

#23

Building my car...

iTrader: (1)

Join Date: Apr 2004

Location: Arizona

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

Its hard to tell in your picture if the upper part of the window is the issue fom your pictures. The one that has not been re touched I circled what I was seening. Basically I cant tell you this is the issue however I would go quite a bit more raduis on that top edge to be safe. Remeber the apex seal wants to push into the exhuast port as it passes by. I also put a picture of one of the ports I have done disregard the profile yours is fine, I would suggest having a radius like mine at the top of the exhuast window.

Hope this helps

Hope this helps

#24

"Elusive, not deceptive!”

The reason for the carbon marks on both sides of the spark plugs is the same problem that we are addressing by running cold plugs.

The surface becomes a hill in that area. The topography of which resembles this surface heat map from Mazda.

See “Why Apex Seals Fail”

https://www.rx7club.com/showthread.p...errerid=101407

Barry

The surface becomes a hill in that area. The topography of which resembles this surface heat map from Mazda.

See “Why Apex Seals Fail”

https://www.rx7club.com/showthread.p...errerid=101407

Barry