13B-RE Rebuild - Technical Opinions needed!

#1

Back Story

I purchased my car back in 2005 with a JDM 13B-RE. I got it running to discover the that twin turbo oil seals were bad. I put a second set of twins on which also had a problem with the oil seals. It was winter time by then, so I decided to rebuild the engine due to the time it could have been setting around. All of the housing and rotors spec'ed out. I purchased and installed a master rebuild kit from Rotary Aviation (before they had super seals and classic seals). I got it running in the following spring. I built a WBO2 wideband unit and installed one EGT per rotor to help tune it. I found a map that was similar, so I started with that. I only ever adjusted the fuel maps as I wasn't experienced.

I decided to go back to school, so I didn't do much with the car until the last couple of years. The tune remain untouched until my car had all the necessary components for high HP. This summer, I noticed that my front rotor was running about 40 degrees F cooler than my back rotor. I decided to check compression. My front rotor was ~90 psi and the rear was 106psi. My rear rotor had three pulses of 85 psi. My front rotor had two lower pulses of 75psi and one pulse of 85psi. Unfortunately I never documented my compression after the rebuild, but I believe both rotors were around 110psi. I decided to tear the engine apart since it wasn't hard.

Issues

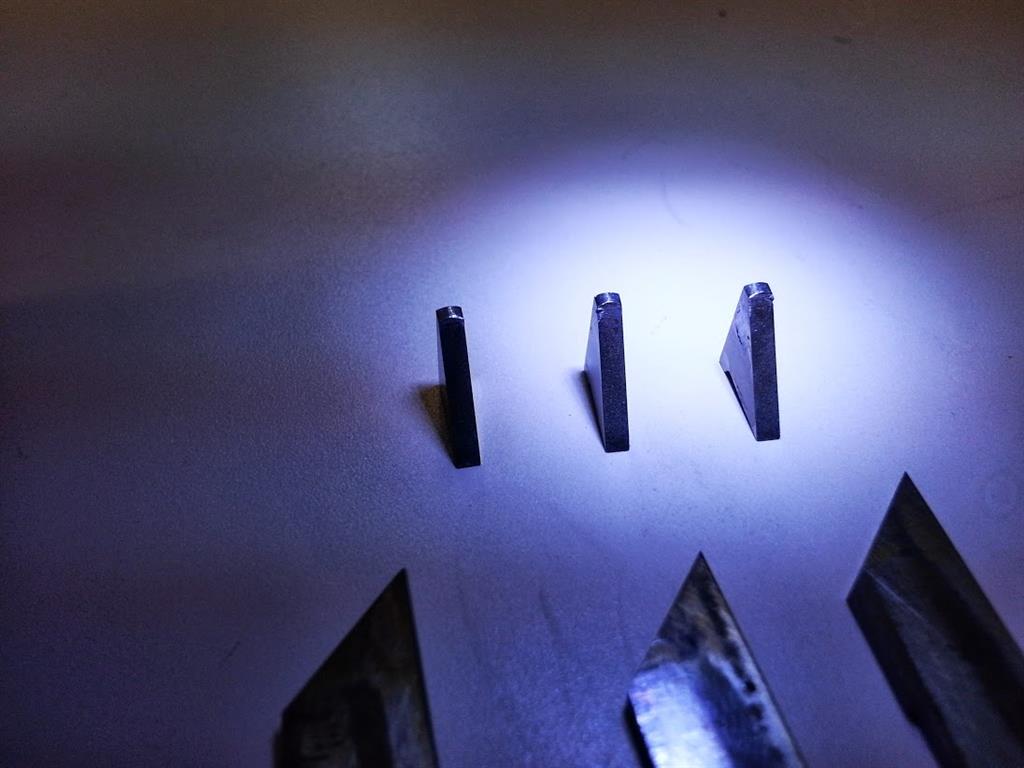

Upon tear down, I discovered a few interesting things. I believe the two lower compression pulses were due to two cracked corner seals. Note that all side seals were clearanced between 0.005" to 0.007" which was verified during my inspection yesterday. I'm guessing that I may have had some detonation due to my waste gate not opening twice (saw 23psi +). I never heard or felt anything. The first time it happened was due to the vacuum line falling off. The second time occurred when I replaced my side feed injectors with top feed injectors. One large vacuum line is routed by the injector nozzles, and that was the line I was using...... I could always have my colleague analyze why the part failed. It almost looks like it cracked from the inside out.

Those two corner seals were the only major issue I found. Everything else was within the Mazda FSM spec. I scanned my measurements and placed them in the Google Doc link below if anyone cares to see them.

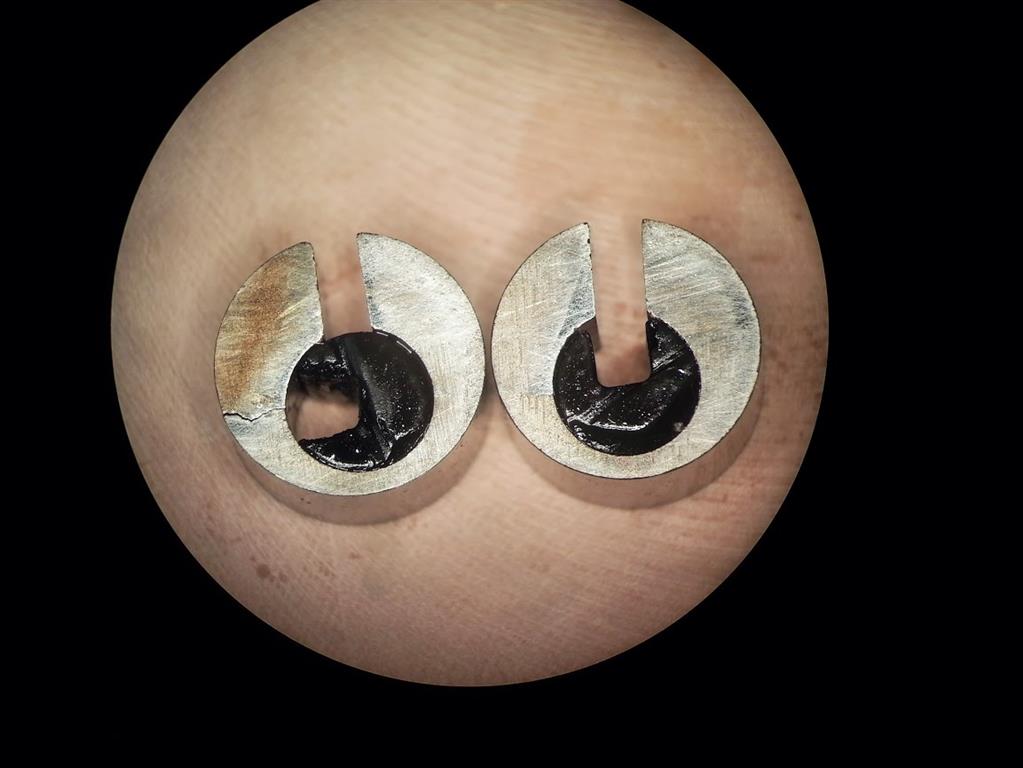

I did notice something strange with my apex seals (small piece) which is shown in the two picture below.

I'm having trouble explaining that wear as it is on the edge as apposed to the center. There is no wear on the larger apex seals in that area. My only thought could be that that edge was nicked during assembly. It does line up pretty well with the rotor housing when the seal isn't seated to the larger apex seal. I never glued them on install. I was able to use petroleum jelly to hold them in place. Anyone have any thoughts on this?

I did discover one thing I never did during my first rebuild. I never clearanced the apex seals with respect to the rotor grove. They are less than 0.001" but they still move freely. I noticed that the clearance gets looser by the corner seals. I found the gap to get as loose as 0.0025". I noticed that Howard Coleman asked what issue this would cause, but he was referred to another section on these forums. Does anyone know what kinds of issues this would cause? I can see them not moving as freely under certain loads. See the bottom of this post for a link to rebuild pictures which show the wear on the apex seals.

My apex seals, which are Rotary Aviation (pre super seals / classic seals), are well within the FSM spec. However, I question the nicks that have occurred. I can sand them down, or get a new set of seals. I don't even mind getting the Mazda OEM ones. I would just be worried about detonation. I want to learn how to tune my car well. I have a knock meter, but I have to create a little knock so I can set the gain properly. What would you guys recommend? My springs are the Mazda OEM ones and are well within the specs.

The rotor housings do have some nicks, but they are within 2mm of the edge. One is near 2mm.

Goals

I would like to get my compression between 110 to 120 psi. My goals on pump gas at 15psi is 450 HP. I will eventually install a water / meth system and would like to hit 500 - 550 HP on pump gas.

Action Plan

1. Replace all corner seals and springs with OEM

2. Sand apex seals & clearance them, or replace with ?

3. Replace side seals and clearance tips towards 0.002" ?

4. Anything else ?

Notes

1. The car had approximately 3000 miles since the first rebuild.

2. The engine is premixed with 1oz to 1 Gallon

3. Not engine parts were cleaned yet. Everything was at least clean enough for accurate inspection measurements.

4. Larger pictures of the above can be found in the Rebuild Pictures link below.

Links

Rebuild Pictures with comments

Inspection Measurements

I have some pictures from my first rebuild in my sig.

I purchased my car back in 2005 with a JDM 13B-RE. I got it running to discover the that twin turbo oil seals were bad. I put a second set of twins on which also had a problem with the oil seals. It was winter time by then, so I decided to rebuild the engine due to the time it could have been setting around. All of the housing and rotors spec'ed out. I purchased and installed a master rebuild kit from Rotary Aviation (before they had super seals and classic seals). I got it running in the following spring. I built a WBO2 wideband unit and installed one EGT per rotor to help tune it. I found a map that was similar, so I started with that. I only ever adjusted the fuel maps as I wasn't experienced.

I decided to go back to school, so I didn't do much with the car until the last couple of years. The tune remain untouched until my car had all the necessary components for high HP. This summer, I noticed that my front rotor was running about 40 degrees F cooler than my back rotor. I decided to check compression. My front rotor was ~90 psi and the rear was 106psi. My rear rotor had three pulses of 85 psi. My front rotor had two lower pulses of 75psi and one pulse of 85psi. Unfortunately I never documented my compression after the rebuild, but I believe both rotors were around 110psi. I decided to tear the engine apart since it wasn't hard.

Issues

Upon tear down, I discovered a few interesting things. I believe the two lower compression pulses were due to two cracked corner seals. Note that all side seals were clearanced between 0.005" to 0.007" which was verified during my inspection yesterday. I'm guessing that I may have had some detonation due to my waste gate not opening twice (saw 23psi +). I never heard or felt anything. The first time it happened was due to the vacuum line falling off. The second time occurred when I replaced my side feed injectors with top feed injectors. One large vacuum line is routed by the injector nozzles, and that was the line I was using...... I could always have my colleague analyze why the part failed. It almost looks like it cracked from the inside out.

Those two corner seals were the only major issue I found. Everything else was within the Mazda FSM spec. I scanned my measurements and placed them in the Google Doc link below if anyone cares to see them.

I did notice something strange with my apex seals (small piece) which is shown in the two picture below.

I'm having trouble explaining that wear as it is on the edge as apposed to the center. There is no wear on the larger apex seals in that area. My only thought could be that that edge was nicked during assembly. It does line up pretty well with the rotor housing when the seal isn't seated to the larger apex seal. I never glued them on install. I was able to use petroleum jelly to hold them in place. Anyone have any thoughts on this?

I did discover one thing I never did during my first rebuild. I never clearanced the apex seals with respect to the rotor grove. They are less than 0.001" but they still move freely. I noticed that the clearance gets looser by the corner seals. I found the gap to get as loose as 0.0025". I noticed that Howard Coleman asked what issue this would cause, but he was referred to another section on these forums. Does anyone know what kinds of issues this would cause? I can see them not moving as freely under certain loads. See the bottom of this post for a link to rebuild pictures which show the wear on the apex seals.

My apex seals, which are Rotary Aviation (pre super seals / classic seals), are well within the FSM spec. However, I question the nicks that have occurred. I can sand them down, or get a new set of seals. I don't even mind getting the Mazda OEM ones. I would just be worried about detonation. I want to learn how to tune my car well. I have a knock meter, but I have to create a little knock so I can set the gain properly. What would you guys recommend? My springs are the Mazda OEM ones and are well within the specs.

The rotor housings do have some nicks, but they are within 2mm of the edge. One is near 2mm.

Goals

I would like to get my compression between 110 to 120 psi. My goals on pump gas at 15psi is 450 HP. I will eventually install a water / meth system and would like to hit 500 - 550 HP on pump gas.

Action Plan

1. Replace all corner seals and springs with OEM

2. Sand apex seals & clearance them, or replace with ?

3. Replace side seals and clearance tips towards 0.002" ?

4. Anything else ?

Notes

1. The car had approximately 3000 miles since the first rebuild.

2. The engine is premixed with 1oz to 1 Gallon

3. Not engine parts were cleaned yet. Everything was at least clean enough for accurate inspection measurements.

4. Larger pictures of the above can be found in the Rebuild Pictures link below.

Links

Rebuild Pictures with comments

Inspection Measurements

I have some pictures from my first rebuild in my sig.

Last edited by ggoldfingerd; 07-30-13 at 07:55 PM. Reason: Grammer

Thread

Thread Starter

Forum

Replies

Last Post

Frisky Arab

2nd Generation Specific (1986-1992)

13

08-18-15 05:30 PM

rx8volks

Canadian Forum

0

08-13-15 04:55 AM