diesel rotary for senior project

#1

Full Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: wilmington nc

Posts: 160

Likes: 0

Received 0 Likes

on

0 Posts

diesel rotary for senior project

it could rev to 15000rpm

im going for 250ccm 2rotor engine and yes i plan to make it.

what are your thoughts on it?

to me it sounds perfect because bio diesel and regular diesel for that matter is a lubricant.

thanx for all your opinions.

im going for 250ccm 2rotor engine and yes i plan to make it.

what are your thoughts on it?

to me it sounds perfect because bio diesel and regular diesel for that matter is a lubricant.

thanx for all your opinions.

#4

Senior Member

Join Date: Apr 2001

Location: Charlotte, NC

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

By no means am I any sort of expert but isn't detonation what you try to avoid in a rotary. That is what cracks and blows seals. This is why desiel engines knock so much and why if you look at the block of a desiel engine they are so stout. I know I have gone through 4 engines and 3 of them were due to excesive heat in the engine. This will also be a problem with a desiel because it burns at a much hotter temperature and therefore will need a lot better cooling.

This should not slow you down however as these are just obstacles to overcome. All great designs have had hurdles to jump and just maybe you can find a way around them.

Good Luck!

This should not slow you down however as these are just obstacles to overcome. All great designs have had hurdles to jump and just maybe you can find a way around them.

Good Luck!

#5

There are multiple legit engineering papers written about spark ignited diesel and multi-fuel capable wankel rotary engines. PM me about them. You need to read through all of them and see what has already been done. Oh, and forget about 15,000 rpm. That's pointless and stupid. Mazda's own race engines never revved that high.

#7

Moller industries, a company that produces another version of the rotary engine hasn't even finished development on the diesel powered rotary but from my understanding is they use a 80% diesel/20% water blended fuel to reduce the chance to detonate. this supposably would allow the fuel to be spark ignited versus run on detonation cycles which most all current diesels run based off of. diesels can run on less compression, which alternates the engines away from detonation firing versus ignition firing, so then the position at which the fuel is ignited can be controlled, leading to a smooth combustion versus violent in current diesels.

i really don't foresee spark ignited diesels making much power for any real applications though, even from moller they only plan on making the engine for generator purposes which generally do not need alot of torque or horsepower.

http://www.freedom-motors.com/index....Itemid=96#1.36

i really don't foresee spark ignited diesels making much power for any real applications though, even from moller they only plan on making the engine for generator purposes which generally do not need alot of torque or horsepower.

http://www.freedom-motors.com/index....Itemid=96#1.36

Last edited by RotaryEvolution; 05-19-11 at 10:57 AM.

Trending Topics

#9

Full Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: wilmington nc

Posts: 160

Likes: 0

Received 0 Likes

on

0 Posts

well for 15000rpm its gonna be small only .25l twin rotor and i plan to make it beefy. the e-shaft im making is out of titanium. i also found a way to get the compresion up in the e-shaft. kinda like a sroker.and then add a small twin screw supercharger im making for it.

i have read most the stuff iv found, but they all have the same problem like the rolls roys one(it cant seal or have compresion). i got the cooling system drawn out and all the numbers about it. i also have some rough blueprints that im refining.

And jdrift i will.

i have read most the stuff iv found, but they all have the same problem like the rolls roys one(it cant seal or have compresion). i got the cooling system drawn out and all the numbers about it. i also have some rough blueprints that im refining.

And jdrift i will.

#12

Been here since dirt...

Join Date: Jan 2009

Location: AZ

Posts: 327

Likes: 0

Received 0 Likes

on

0 Posts

Wow. Some really old/bad info on diesels here.

Let's clear up some things first. First, most curent diesels are at about 16.5:1 to cut down NOx, which is made with compression and heat. And turboed because they usually don't have the porting and engine speed to be N/A. I worked on some Italian diesels that ran at 3.2 bar.

Second, Most, if not all current diesels have two or more injection phases. Pilot , and main . Pilot loads the piston, so it cuts down on the detonation, main is the power. This is how the TDI can operate cleanly and with little to no noise over a standard gasoline engine.

Diesels tolerate detonation. They don't thrive on it or use it to ignite fuel.

I believe that the torque a diesel makes is a product of stoke and bore, so the rotary won't magically produce tons of torque just because it uses a different fuel. Most diesels have longer stroke than bore, and a rotary is drastically the other way.

GD

Let's clear up some things first. First, most curent diesels are at about 16.5:1 to cut down NOx, which is made with compression and heat. And turboed because they usually don't have the porting and engine speed to be N/A. I worked on some Italian diesels that ran at 3.2 bar.

Second, Most, if not all current diesels have two or more injection phases. Pilot , and main . Pilot loads the piston, so it cuts down on the detonation, main is the power. This is how the TDI can operate cleanly and with little to no noise over a standard gasoline engine.

Diesels tolerate detonation. They don't thrive on it or use it to ignite fuel.

I believe that the torque a diesel makes is a product of stoke and bore, so the rotary won't magically produce tons of torque just because it uses a different fuel. Most diesels have longer stroke than bore, and a rotary is drastically the other way.

GD

Last edited by gawdodirt; 07-18-11 at 05:03 PM.

#13

Been here since dirt...

Join Date: Jan 2009

Location: AZ

Posts: 327

Likes: 0

Received 0 Likes

on

0 Posts

In addition to my earlier comments. Fuel burn rate is key as diesel burns slower than gas due to it's lower volatility. So 15,000 is a goal , but not a reality at this time. Figure out a way to capture a longer combustion power cycle with a rotary and you'll have a jewel. John Deere has a license for Wankel with alternative fuels and would be a great resource.

GD

GD

#15

Full Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: wilmington nc

Posts: 160

Likes: 0

Received 0 Likes

on

0 Posts

In addition to my earlier comments. Fuel burn rate is key as diesel burns slower than gas due to it's lower volatility. So 15,000 is a goal , but not a reality at this time. Figure out a way to capture a longer combustion power cycle with a rotary and you'll have a jewel. John Deere has a license for Wankel with alternative fuels and would be a great resource.

GD

GD

thanks for the imput though.

#17

compression ignition

Join Date: Feb 2007

Location: Cincinnati Ohio

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

thats the key to it reving that high though. the rotor moves 1/3 the speed of the e shaft so 15000rpm means the rotor is moving at 5000rpm not to hard to do with diesel. and for the more tq it has more btus and in its case gas expansion, wich means more preasure at lower amounts of air and fuel.

thanks for the imput though.

thanks for the imput though.

#18

Did the OP ever do the work of reading about the diesel prototypes that have already been made? You can't engineer something new without understanding what's already been done. The Wright Brothers didn't really just invent powered flight in their garage by tinkering around. They looked at all the other failed flying machines, identified the specific issues and failure points, and then addressed them in order to have a successful flight. The same thing happened when Edison invented the light bulb. He had a library and a whole staff of guys who just read patents and books about inventions that had already been made.

#19

Full Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: wilmington nc

Posts: 160

Likes: 0

Received 0 Likes

on

0 Posts

im working on it and i think that if u make it so it mimics a longer stroke and a better position of the combustion chamber, and moving injectors down on the housing like a s4 vs s5 houdings. the way i look at it if this fails il still have a really high compression and DPI wich would take out that nasty det. prone zone between 1500 and 4000rpm. and i really think rotaries would benifit from DPI. gas or not

#22

******

iTrader: (7)

Join Date: May 2009

Location: miami

Posts: 901

Likes: 0

Received 0 Likes

on

0 Posts

well for 15000rpm its gonna be small only .25l twin rotor and i plan to make it beefy. the e-shaft im making is out of titanium. i also found a way to get the compresion up in the e-shaft. kinda like a sroker.and then add a small twin screw supercharger im making for it.

i have read most the stuff iv found, but they all have the same problem like the rolls roys one(it cant seal or have compresion). i got the cooling system drawn out and all the numbers about it. i also have some rough blueprints that im refining.

And jdrift i will.

i have read most the stuff iv found, but they all have the same problem like the rolls roys one(it cant seal or have compresion). i got the cooling system drawn out and all the numbers about it. i also have some rough blueprints that im refining.

And jdrift i will.

good luck

#23

Senior Member

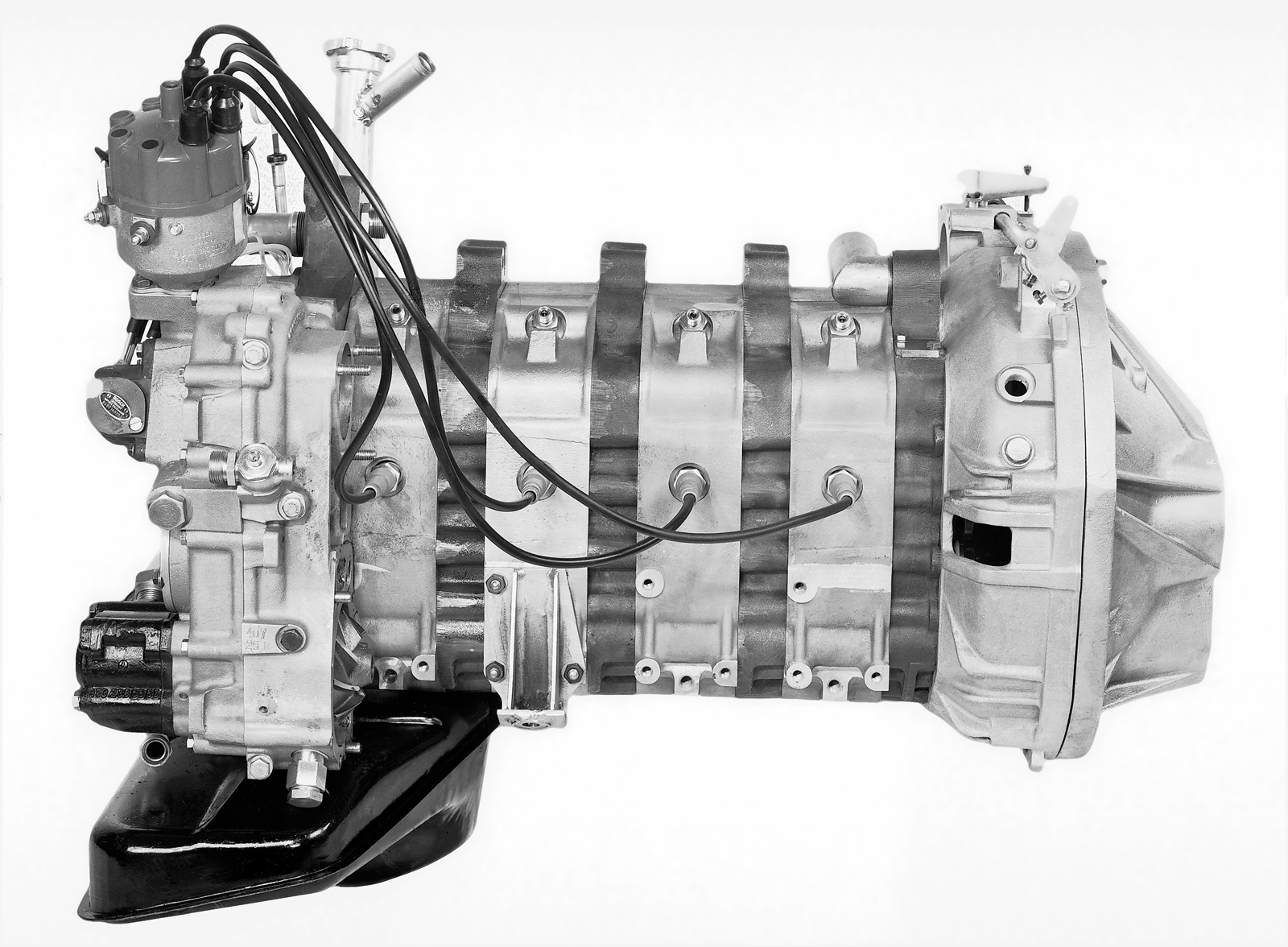

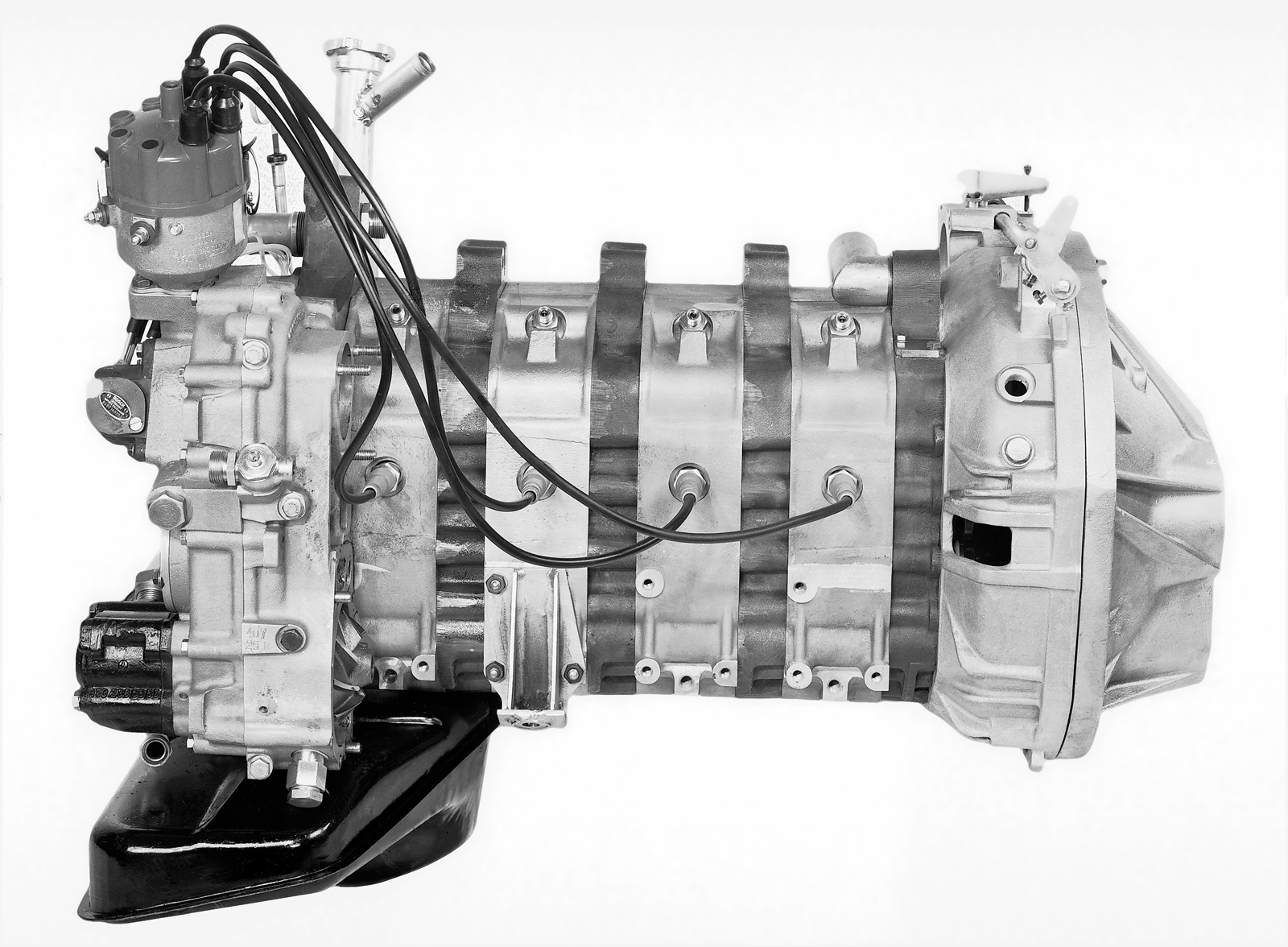

Mercedes Benz had a 3 and quad rotor diesel, so they know to what is possible.

http://www.youtube.com/watch?v=t3jIIS3FFAQ

Picture of the engine 400HP of a diesel.

http://www.der-wankelmotor.de/Fahrze.../mercedes.html

Even Roys-Rolls know it

http://en.wikipedia.org/wiki/Wankel_...#Disadvantages

A full article.

http://retro-motoring.blogspot.com/2...1_archive.html

http://www.youtube.com/watch?v=t3jIIS3FFAQ

Picture of the engine 400HP of a diesel.

http://www.der-wankelmotor.de/Fahrze.../mercedes.html

Even Roys-Rolls know it

http://en.wikipedia.org/wiki/Wankel_...#Disadvantages

A full article.

http://retro-motoring.blogspot.com/2...1_archive.html

#24

Junior Member

Join Date: Nov 2011

Location: Fingerlakes Regoin NY

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

I could see a diesel injection rotary working just fine. You could run an injection pump cam off the eccentric shaft that would drive the fuel to the delivery valves and time the injection. A dual pop injector would help with ignition timing. Crafty thought if ever.