FD Brake Ducting and Ti Backing Plates questions

#1

Rotary Poseur

Thread Starter

Join Date: Feb 2001

Location: Richmond, BC, Canada

Posts: 718

Likes: 0

Received 0 Likes

on

0 Posts

FD Brake Ducting and Ti Backing Plates questions

Hi all,

Where does one get ducting for directing air to the front brake rotors on an FD? I finally experienced overheating on my AP Racing CP5200 (man, was that ever scary).

On a similar note, I thought I saw a thread somewhere discussing either the merit of or a group purchase of titanium backing plates to reduce heat transfer. Did it get purged in the forum cleanup? Anyone recall who makes them?

Thx.

Where does one get ducting for directing air to the front brake rotors on an FD? I finally experienced overheating on my AP Racing CP5200 (man, was that ever scary).

On a similar note, I thought I saw a thread somewhere discussing either the merit of or a group purchase of titanium backing plates to reduce heat transfer. Did it get purged in the forum cleanup? Anyone recall who makes them?

Thx.

#4

HedgeHog,

What I whipped together:

http://www.negative-camber.org/crisp...tedducting.htm

The duct openings in the lip are small and the NTech backing plates are satisfactory and could be much improved but overall IMO a step in the right direction for brake cooling for a street/track car.

HTH,

Crispy

What I whipped together:

http://www.negative-camber.org/crisp...tedducting.htm

The duct openings in the lip are small and the NTech backing plates are satisfactory and could be much improved but overall IMO a step in the right direction for brake cooling for a street/track car.

HTH,

Crispy

#7

Originally Posted by KaiFD3S

here is a link to a sample pic of the brake ducting

http://www.zeckhausen.com/Mazda/RX-7...stallation.htm

http://www.zeckhausen.com/Mazda/RX-7...stallation.htm

Trending Topics

#9

Rotary Poseur

Thread Starter

Join Date: Feb 2001

Location: Richmond, BC, Canada

Posts: 718

Likes: 0

Received 0 Likes

on

0 Posts

KaiFD3S: Thx for the Zeckhausen link. Basically what I need but the site mentions custom ducts...but from whom?

Crispy: Same thing...thx. I should have ordered the ducts from Duane when I got the IC. But then again, I recall Wael not liking them too much. On your site, where did you source the non-CWR ducts? Those would work. But my problem will be where to duct the air from. My bumper openings are all taken by the VMIC and the twin oil coolers. Mebbe a NACA duct on my undertray...

Rynberg: I've got low end stuff for now...HPS w/ Motul 5.1. Was thinking of getting Ferodo DS2500 for autox/lapping and maybe an extra set of DS3000 for brake killer tracks. Also, planning on flushing system using ATE Super Blue (so I can tell when it's all out). Not ready to spend on Castrol SRF yet (yikes). Any other recommendation?

Here are my symptoms: After 6-8 really aggressive laps, the brakes would just bottom...like all fluid leaked out. Pumping the pedal makes no difference. And it comes on abruptly; that is, it's not like a gradual fade a few corners before hand...it's rock solid then suddenly nothing. I limp back to the pits and check...level still @ Max in reservoir. No drips. Discs aren't blue. BTW, i had to use the e-brake to come to a stop in the pits. Leave car for the rest of the session and by the time my next session arrives, it's all good again. Then it repeats....5-8 hard laps and blam...nothing. So I end up braking lighter but earlier for the last 2 sessions...it still goes soft at about the same lap count. At the end of the day I drive home and it's fine.

Anyone tried the new Hawk DTC stuff? HT-10? I heard blues are scary since they have a narrow operating temp range.

Thx again.

Crispy: Same thing...thx. I should have ordered the ducts from Duane when I got the IC. But then again, I recall Wael not liking them too much. On your site, where did you source the non-CWR ducts? Those would work. But my problem will be where to duct the air from. My bumper openings are all taken by the VMIC and the twin oil coolers. Mebbe a NACA duct on my undertray...

Rynberg: I've got low end stuff for now...HPS w/ Motul 5.1. Was thinking of getting Ferodo DS2500 for autox/lapping and maybe an extra set of DS3000 for brake killer tracks. Also, planning on flushing system using ATE Super Blue (so I can tell when it's all out). Not ready to spend on Castrol SRF yet (yikes). Any other recommendation?

Here are my symptoms: After 6-8 really aggressive laps, the brakes would just bottom...like all fluid leaked out. Pumping the pedal makes no difference. And it comes on abruptly; that is, it's not like a gradual fade a few corners before hand...it's rock solid then suddenly nothing. I limp back to the pits and check...level still @ Max in reservoir. No drips. Discs aren't blue. BTW, i had to use the e-brake to come to a stop in the pits. Leave car for the rest of the session and by the time my next session arrives, it's all good again. Then it repeats....5-8 hard laps and blam...nothing. So I end up braking lighter but earlier for the last 2 sessions...it still goes soft at about the same lap count. At the end of the day I drive home and it's fine.

Anyone tried the new Hawk DTC stuff? HT-10? I heard blues are scary since they have a narrow operating temp range.

Thx again.

#10

Hedge,

The backing plates for the rotor are N-Tech... the CWR's didn't use dedicated hose. As far as the inlets at the bumper, Crispy's are one-offs. Others (inlcuding the car pictured) use generics as available from BakerPrecision.com or Pegasus, or other race supply places.

I'm doing mine right now, and as Crispy noted, the pic headache is the house routing. I'll post pics when I'm done.

EDIT:

YIKES.. I just read your description of the problem.... sounds like something else is wrong.

The backing plates for the rotor are N-Tech... the CWR's didn't use dedicated hose. As far as the inlets at the bumper, Crispy's are one-offs. Others (inlcuding the car pictured) use generics as available from BakerPrecision.com or Pegasus, or other race supply places.

I'm doing mine right now, and as Crispy noted, the pic headache is the house routing. I'll post pics when I'm done.

EDIT:

YIKES.. I just read your description of the problem.... sounds like something else is wrong.

#12

I see braking issues as of three kinds. HARD pedal, SOFT pedal, and NO pedal (pedal goes - clunk - to the floor)

A hard pedal is usually pad related - overheating the pad or cooking the rotor which is overheating the pad. What kind of pads are you using? I could also potentailly be a piston getting hung up in the caliper but this is unlikely to occur in all EIGHT bores giving you NO brakes at all.

A soft pedal is almost always fluid related. Boiling fluid pust gas in the line making for a spongy pedal and reduced braking. Boiling fluid comes from heat transmission fromt he pad to the piston through the postion and into the fluid.

Aluminum pistons are excellent conductors of heat therefore pad for brakes - SS is better, titanium is the best. I have SS in mine calipers. Use backing plates - those SS shims. They add a minute air layer between pad and piston which insulates the piston. And of course use good NEW fluid that has been properly bled.

NO pedal is anyones guess. A leak somewhere, a problem with the MC, a problem with the pedal linkages.

FWIW and apologies if this is preaching to the choir.

Crispy

PS good ducting is going to help no matter what

#13

Rotary Poseur

Thread Starter

Join Date: Feb 2001

Location: Richmond, BC, Canada

Posts: 718

Likes: 0

Received 0 Likes

on

0 Posts

Thx guys...

As posted previous, my pads are Hawk HPS and fluid is Motul 5.1. Brakes are the AP Racing CP5200 13" fronts and stock rears.

So where do I get titanium plates? As I recalled there was a potential group buy but that thread seems to have vanished. Does this alter the pad thickness requirement? Eg. a new set of Hawks for the front calls for .654" so when you add the Ti plates to them, does the pads need to be thinner or does one need to mill it down or does it not matter.

Does this alter the pad thickness requirement? Eg. a new set of Hawks for the front calls for .654" so when you add the Ti plates to them, does the pads need to be thinner or does one need to mill it down or does it not matter.

The braking problem is a weird one. I just ran a day of autox and it was fine...drove there: fine....ran the event: rock solid....drove home: fine. Checked, no leaks on the group (at home, at the grid spot @ autox, nor at the grid spot @ lapping). Fluid level at MC is at the Max level still...fluid is clean. AARRRRGGHGHHGHG!!!!

Welp, I'm going to swap to newer/better pads and do a full system flush (incl. clutch slave cylinder). Change to Super Blue also....fingers are crossed.

Oh, ducting is always a concern for me....for lapping definitely but for cone chasing: hmmmmm....

Thx again ppl!

As posted previous, my pads are Hawk HPS and fluid is Motul 5.1. Brakes are the AP Racing CP5200 13" fronts and stock rears.

So where do I get titanium plates? As I recalled there was a potential group buy but that thread seems to have vanished.

Does this alter the pad thickness requirement? Eg. a new set of Hawks for the front calls for .654" so when you add the Ti plates to them, does the pads need to be thinner or does one need to mill it down or does it not matter.

Does this alter the pad thickness requirement? Eg. a new set of Hawks for the front calls for .654" so when you add the Ti plates to them, does the pads need to be thinner or does one need to mill it down or does it not matter.The braking problem is a weird one. I just ran a day of autox and it was fine...drove there: fine....ran the event: rock solid....drove home: fine. Checked, no leaks on the group (at home, at the grid spot @ autox, nor at the grid spot @ lapping). Fluid level at MC is at the Max level still...fluid is clean. AARRRRGGHGHHGHG!!!!

Welp, I'm going to swap to newer/better pads and do a full system flush (incl. clutch slave cylinder). Change to Super Blue also....fingers are crossed.

Oh, ducting is always a concern for me....for lapping definitely but for cone chasing: hmmmmm....

Thx again ppl!

#14

Junior Member

Join Date: May 2002

Location: Flower Mound, TX

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

Hi Hedgehog,

One thing you should double check is the orientation/direction of your brake rotors. If I am not mistaked your rotors use curved vanes and are therefore directional. Using them backwards can actually be detrimental to the performance and might even lead to an increase in rotor temp which could lead to the fluid fade you are experiencing.

Per Brembo: "A curved vane disc must be installed with the vanes running back from the inside to outside diameters in the direction of rotation."

If you have slotted rotors the slots are usually machined in the opposite direction of the vanes.

BR,

Dennis

One thing you should double check is the orientation/direction of your brake rotors. If I am not mistaked your rotors use curved vanes and are therefore directional. Using them backwards can actually be detrimental to the performance and might even lead to an increase in rotor temp which could lead to the fluid fade you are experiencing.

Per Brembo: "A curved vane disc must be installed with the vanes running back from the inside to outside diameters in the direction of rotation."

If you have slotted rotors the slots are usually machined in the opposite direction of the vanes.

BR,

Dennis

#15

Lives on the Forum

Join Date: Dec 2001

Location: San Lorenzo, California

Posts: 14,716

Likes: 0

Received 8 Likes

on

8 Posts

I'm just going to be really blunt and state that those pads should NEVER be used on the track, at any skill level. They are completely inadequate for any form of tracking the car and you should swap them out immediately.

I would do this before doing anything else. I'm not sure why you are looking at expensive backing plates when you are still running street pads. I would strongly advise switching from Hawk pads period. I melted a set of HP+ in three sessions.

I would do this before doing anything else. I'm not sure why you are looking at expensive backing plates when you are still running street pads. I would strongly advise switching from Hawk pads period. I melted a set of HP+ in three sessions.

#16

Rotary Poseur

Thread Starter

Join Date: Feb 2001

Location: Richmond, BC, Canada

Posts: 718

Likes: 0

Received 0 Likes

on

0 Posts

Yup...will be swapping them out for Ferodo DS2500 (and maybe a spare set of DS3000 for lapping only). I realized the HPS are not good track pads but the symptoms don't make any sense.

Anyhoo, ducting is not expensive when compared with price of race pads for AP calipers.

Anyhoo, ducting is not expensive when compared with price of race pads for AP calipers.

I'm just going to be really blunt and state that those pads should NEVER be used on the track, at any skill level. They are completely inadequate for any form of tracking the car and you should swap them out immediately.

I would do this before doing anything else. I'm not sure why you are looking at expensive backing plates when you are still running street pads. I would strongly advise switching from Hawk pads period. I melted a set of HP+ in three sessions.

I would do this before doing anything else. I'm not sure why you are looking at expensive backing plates when you are still running street pads. I would strongly advise switching from Hawk pads period. I melted a set of HP+ in three sessions.

#17

Rotary Poseur

Thread Starter

Join Date: Feb 2001

Location: Richmond, BC, Canada

Posts: 718

Likes: 0

Received 0 Likes

on

0 Posts

Thx Dennis,

The rotors are spinning in the right direction. The orientation of the vanes are "flinging" air instead of "scooping" so air is drawn from center out.

The rotors are spinning in the right direction. The orientation of the vanes are "flinging" air instead of "scooping" so air is drawn from center out.

Hi Hedgehog,

One thing you should double check is the orientation/direction of your brake rotors. If I am not mistaked your rotors use curved vanes and are therefore directional. Using them backwards can actually be detrimental to the performance and might even lead to an increase in rotor temp which could lead to the fluid fade you are experiencing.

Per Brembo: "A curved vane disc must be installed with the vanes running back from the inside to outside diameters in the direction of rotation."

If you have slotted rotors the slots are usually machined in the opposite direction of the vanes.

BR,

Dennis

One thing you should double check is the orientation/direction of your brake rotors. If I am not mistaked your rotors use curved vanes and are therefore directional. Using them backwards can actually be detrimental to the performance and might even lead to an increase in rotor temp which could lead to the fluid fade you are experiencing.

Per Brembo: "A curved vane disc must be installed with the vanes running back from the inside to outside diameters in the direction of rotation."

If you have slotted rotors the slots are usually machined in the opposite direction of the vanes.

BR,

Dennis

#18

HedgeHog,

Rynberg hit the nail on the head. Pads. Those pads are street pads. You MUST use a track pad on the track. The Ferodos 2500's will fail also - they came with my calipers. I got fade after a single lap using the 2500's when i was too lazy to swap pads for only a few laps - big mistake. Pedal went rock hard and the car wouldn't slow down. The 2500s are a street pad also. Stick with a tried and true track pad like a Hawk Blue or a Performance Friction 01 compound.

As for the backing plates - titanium is the best but SS will suffice just fine.

First things first though - get track pads.

HTH,

Crispy

Rynberg hit the nail on the head. Pads. Those pads are street pads. You MUST use a track pad on the track. The Ferodos 2500's will fail also - they came with my calipers. I got fade after a single lap using the 2500's when i was too lazy to swap pads for only a few laps - big mistake. Pedal went rock hard and the car wouldn't slow down. The 2500s are a street pad also. Stick with a tried and true track pad like a Hawk Blue or a Performance Friction 01 compound.

As for the backing plates - titanium is the best but SS will suffice just fine.

First things first though - get track pads.

HTH,

Crispy

#19

Hedge, NO AMOUNT of ducting, backing plates, big rotors, etc, etc., will allow you to run a street brake pad for track activity. You'd be 100% better off with track pads on stock brakes, unducted, unbacked, than you would be with the full-blown race brake set-up and street pads.

You've got to bite the bullet my friend, or just stick with autocrossing.

You've got to bite the bullet my friend, or just stick with autocrossing.

Yup...will be swapping them out for Ferodo DS2500 (and maybe a spare set of DS3000 for lapping only). I realized the HPS are not good track pads but the symptoms don't make any sense.

Anyhoo, ducting is not expensive when compared with price of race pads for AP calipers.

Anyhoo, ducting is not expensive when compared with price of race pads for AP calipers.

#20

Ok, to add to what everyone else has said, with a modified car and good tires those pads are not going to be sufficient. As an example, I started last year with stock brakes and about 300rwhp, and using R-comps I was cooking HT-10 front pads and front rotors every 1.5 hours of track time. Rears were lasting about 6-8 hours of track time. This is with 20-25 minute sessions, and I did have some ducting dumping air off the nose into the rotors. The fluid would be cooked after 5-6 laps in each session (depending on the track - more or less) and the pedal would be very squishy by the end of a weekend. When I wasn't attuned to it, it seemed very sudden. One corner, brakes are fine, next corner, no brakes. As I became more used to it I was able to better predict when it was going to happen, and creep up to the edge. Anyway, it was borderline no longer safe, and I'd have to slow down quite a bit to be careful.

Midway through the year I added in some titanium backing plates, and I no longer boiled the fluid anymore, but a couple additional laps and the pedal would get very hard, without slowing the car! Textbook pad fade from overheating. Definite improvement but I obviously still needed more heat capacity in the front brakes.

Fast-forward to this year and I upgraded to Damian's old 993TT calipers and custom rotors in the front. I had purchased a set of N-Tech aluminum plates, but couldn't use them because they didn't fit the rotors. If you want a set of the N-Tech plates for 13" rotors, I have that set for sale - new and unused. Here's the link: https://www.rx7club.com/showthread.php?t=634299

It took alot of work, and more $$$ and time than I wanted, but I'm very happy with the result of the project: (as always, click pics for the full size images)

Here's where the air enters the ducting, just below the oil coolers. This is a 7x3" duct that I got from RacerPartsWholesale with #6 stainless mesh over the top to prevent stuff from getting in. It's bolted to the nose and held tight to the oil lines with zip ties.

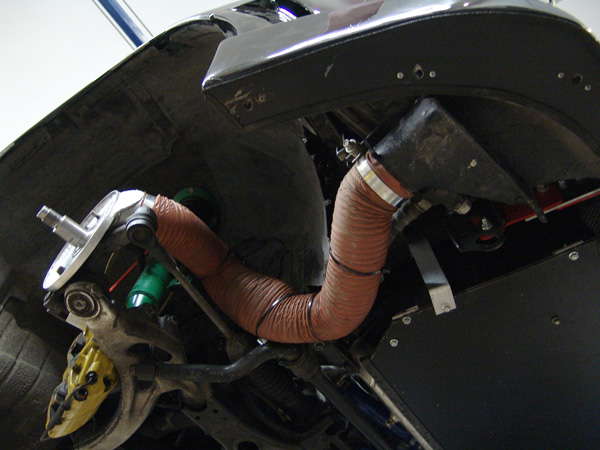

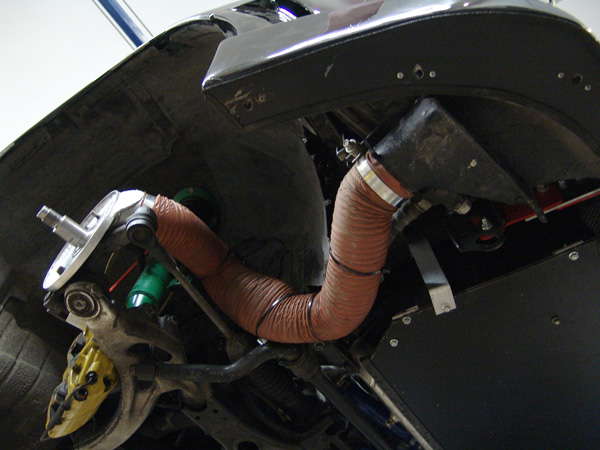

Here's the routing of the brake duct hose. This is the same 3" silicone hose that Crispy uses I think, again from RacerPartsWholesale. You have to be circuitious here to avoid hitting it when you turn the wheels full lock. I was able to smash the hose into an oval and keep it tight to the wall with zip ties. Also the top part is tied to the a-arm with ties as well. It is fastened on each end with a 3" Breeze stainless constant torque hose clamp.

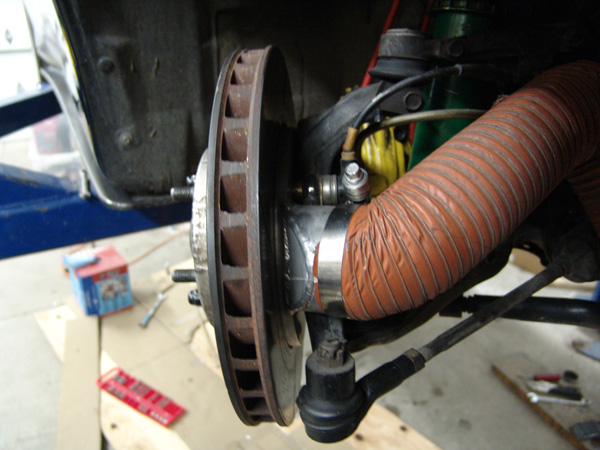

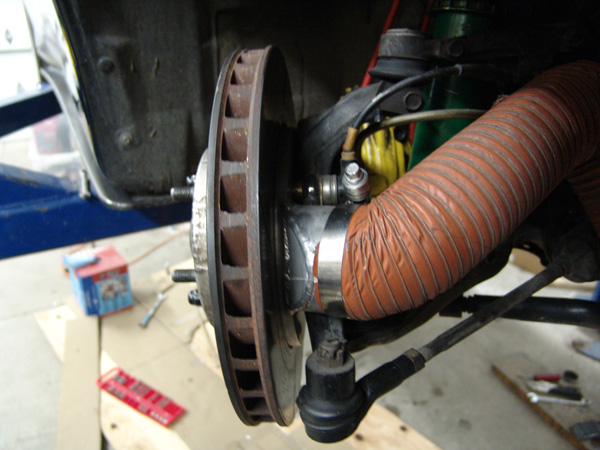

Here's the backside where the hose is clamped to the duct. I did roll a bead on the piping so it won't disconnect itself. You can also see that the edge of the duct actually goes inside the lip of the rotor, in this case about 3-4mm. It is flush with the position of the original stock plate so there is a 10mm lip around the edge of the main plate to make this happen.

Here's the duct opening. I'm really proud of this part, it took a while to make and is practically art. about 75-80% of the hose area is able to get inside of the 12.67" (322mm) rotors I'm using. You can also see there's a bolt missing here that would normally hold the stock plate on. I modified the spindle and cut the part that normally holds the threads for that bolt to get more room for my opening. This is the main way I was able to make the hose input area so big. I did this because Damian did the same thing for his ducts.

about 75-80% of the hose area is able to get inside of the 12.67" (322mm) rotors I'm using. You can also see there's a bolt missing here that would normally hold the stock plate on. I modified the spindle and cut the part that normally holds the threads for that bolt to get more room for my opening. This is the main way I was able to make the hose input area so big. I did this because Damian did the same thing for his ducts.

Here's the plates from the back, you can see how closely they fit inside the rotors, I would say not more than 1mm gap at any point around the rotor. You could ask how I was that precise, and I'd have to say that I spent alot of time fitting, sanding, and refitting in the end I let the rotor itself do the final 'clearancing' hahaha. The entire brake duct is sealed except for that small gap, so ALL air is coming from the nose of the car.

Sorry about the quality on this one, but here's one last pic so you can see the welding work to seal the inside of the duct and the overall shape. The material is 6061-T6 Aluminum in 1/8" thickness. Thickness was chosen because of the removal of the one bolt. With the lip around the edge and the welding this thing is SOLID, and I would say it weighs something like 1-1.5 lbs. Sure would have been nice to go carbon fiber, but cost was prohibitive.

So, results? This setup now with Hawk Blue pads all the way around is capable of braking for 20-30 minute sessions even though I upped the power 10-15% with the pads getting better and better as they warm up. Not once have I had any sort of fade even over 4 days on the track. I also have used less than 1/2 one set of pads. Depending on the outside temp I actually tape off part of the ducts to get the rotors/pads up to operating temp! I'm going to switch pads simply because I don't like the corrosive dust, but that's more of a cosmetic deal.

To answer your original question, I think the thread you are talking about was the one I started last year...

https://www.rx7club.com/group-buy-center-69/titanium-backing-plates-stock-fd-calipers-564700/

However I think you should get proper ducting from the front of the car IN ADDITION to better race pads and titanium shims and you will be good to go. I spent probably twice as much last year on pads and rotors last year because I didn't get the proper setup in the first place, and the brakes were always questionable.

Midway through the year I added in some titanium backing plates, and I no longer boiled the fluid anymore, but a couple additional laps and the pedal would get very hard, without slowing the car! Textbook pad fade from overheating. Definite improvement but I obviously still needed more heat capacity in the front brakes.

Fast-forward to this year and I upgraded to Damian's old 993TT calipers and custom rotors in the front. I had purchased a set of N-Tech aluminum plates, but couldn't use them because they didn't fit the rotors. If you want a set of the N-Tech plates for 13" rotors, I have that set for sale - new and unused. Here's the link: https://www.rx7club.com/showthread.php?t=634299

It took alot of work, and more $$$ and time than I wanted, but I'm very happy with the result of the project: (as always, click pics for the full size images)

Here's where the air enters the ducting, just below the oil coolers. This is a 7x3" duct that I got from RacerPartsWholesale with #6 stainless mesh over the top to prevent stuff from getting in. It's bolted to the nose and held tight to the oil lines with zip ties.

Here's the routing of the brake duct hose. This is the same 3" silicone hose that Crispy uses I think, again from RacerPartsWholesale. You have to be circuitious here to avoid hitting it when you turn the wheels full lock. I was able to smash the hose into an oval and keep it tight to the wall with zip ties. Also the top part is tied to the a-arm with ties as well. It is fastened on each end with a 3" Breeze stainless constant torque hose clamp.

Here's the backside where the hose is clamped to the duct. I did roll a bead on the piping so it won't disconnect itself. You can also see that the edge of the duct actually goes inside the lip of the rotor, in this case about 3-4mm. It is flush with the position of the original stock plate so there is a 10mm lip around the edge of the main plate to make this happen.

Here's the duct opening. I'm really proud of this part, it took a while to make and is practically art.

about 75-80% of the hose area is able to get inside of the 12.67" (322mm) rotors I'm using. You can also see there's a bolt missing here that would normally hold the stock plate on. I modified the spindle and cut the part that normally holds the threads for that bolt to get more room for my opening. This is the main way I was able to make the hose input area so big. I did this because Damian did the same thing for his ducts.

about 75-80% of the hose area is able to get inside of the 12.67" (322mm) rotors I'm using. You can also see there's a bolt missing here that would normally hold the stock plate on. I modified the spindle and cut the part that normally holds the threads for that bolt to get more room for my opening. This is the main way I was able to make the hose input area so big. I did this because Damian did the same thing for his ducts.

Here's the plates from the back, you can see how closely they fit inside the rotors, I would say not more than 1mm gap at any point around the rotor. You could ask how I was that precise, and I'd have to say that I spent alot of time fitting, sanding, and refitting in the end I let the rotor itself do the final 'clearancing' hahaha. The entire brake duct is sealed except for that small gap, so ALL air is coming from the nose of the car.

Sorry about the quality on this one, but here's one last pic so you can see the welding work to seal the inside of the duct and the overall shape. The material is 6061-T6 Aluminum in 1/8" thickness. Thickness was chosen because of the removal of the one bolt. With the lip around the edge and the welding this thing is SOLID, and I would say it weighs something like 1-1.5 lbs. Sure would have been nice to go carbon fiber, but cost was prohibitive.

So, results? This setup now with Hawk Blue pads all the way around is capable of braking for 20-30 minute sessions even though I upped the power 10-15% with the pads getting better and better as they warm up. Not once have I had any sort of fade even over 4 days on the track. I also have used less than 1/2 one set of pads. Depending on the outside temp I actually tape off part of the ducts to get the rotors/pads up to operating temp! I'm going to switch pads simply because I don't like the corrosive dust, but that's more of a cosmetic deal.

To answer your original question, I think the thread you are talking about was the one I started last year...

https://www.rx7club.com/group-buy-center-69/titanium-backing-plates-stock-fd-calipers-564700/

However I think you should get proper ducting from the front of the car IN ADDITION to better race pads and titanium shims and you will be good to go. I spent probably twice as much last year on pads and rotors last year because I didn't get the proper setup in the first place, and the brakes were always questionable.

Last edited by GooRoo; 05-08-07 at 01:24 PM. Reason: Small Change

#22

I am happy with the result, even though it wasn't easy to get there.

I am happy with the result, even though it wasn't easy to get there.For people that are less inclined to spend 3 days making these you could do nearly the same things I did without starting from scratch by getting with the N-tech plates. Just get a 5-10mm strip of aluminum and have it welded around the edge (being careful to make sure it fits INSIDE the rotor) and get the input air tube welded 360 degrees. The only fabrication would be to play with a grinding bit on the lip of the opening to smooth it out. I believe Nick can make plates for the stock rotors too.

That way there would be no modification of the spindles and alot less time into making it all fit. The opening wouldn't be quite as large, but it would probably be 80% as effective at 20% of the cost once you consider your time.

Also, I can't take 100% credit for these. This is the culmination of looking at many other people's brake setups, competition setups from the ALMS cars, SpeedGT cars etc etc etc. I had significant help from Damian as well. Thanks to all.

I will let you know if I decide to sell them... but they're really only useful for the custom 322mm rotors, aren't yours a different size? I have to warn you, based on the time I have into them they might as well be made of gold.

Besides, if you like mine, wait until you see the brake thread damian says he's going to post...

Besides, if you like mine, wait until you see the brake thread damian says he's going to post...

#23

Rotary Poseur

Thread Starter

Join Date: Feb 2001

Location: Richmond, BC, Canada

Posts: 718

Likes: 0

Received 0 Likes

on

0 Posts

That's a great piece of work, GooRoo! Thx for sharing the pix and info. As recommended by all, I am getting better pads. Given what I participate in, I think 2 sets (at least a different front set) of pads is going to be defacto. I don't get enough heat autoxing so street pads will suffice. And a good set of track pads for lapping with.

I may get your N-Tech ducts and work with them. My concern is the hose clearnance that you've shown (I also run external reservoirs on my dampers so there'll be hoses everywhere) and also where to duct the air from. My GTC bumper openings are all "consumed" by oil coolers and VMIC.

One thing though....without the oem brake dust shield, are you worried about the heat off the rotors damaging the steering tie-rod knuckle? The rubber boot is mightly close.

I may get your N-Tech ducts and work with them. My concern is the hose clearnance that you've shown (I also run external reservoirs on my dampers so there'll be hoses everywhere) and also where to duct the air from. My GTC bumper openings are all "consumed" by oil coolers and VMIC.

One thing though....without the oem brake dust shield, are you worried about the heat off the rotors damaging the steering tie-rod knuckle? The rubber boot is mightly close.

#24

That's a great piece of work, GooRoo! Thx for sharing the pix and info. As recommended by all, I am getting better pads. Given what I participate in, I think 2 sets (at least a different front set) of pads is going to be defacto. I don't get enough heat autoxing so street pads will suffice. And a good set of track pads for lapping with.

I may get your N-Tech ducts and work with them. My concern is the hose clearnance that you've shown (I also run external reservoirs on my dampers so there'll be hoses everywhere) and also where to duct the air from. My GTC bumper openings are all "consumed" by oil coolers and VMIC.

One thing though....without the oem brake dust shield, are you worried about the heat off the rotors damaging the steering tie-rod knuckle? The rubber boot is mightly close.

I may get your N-Tech ducts and work with them. My concern is the hose clearnance that you've shown (I also run external reservoirs on my dampers so there'll be hoses everywhere) and also where to duct the air from. My GTC bumper openings are all "consumed" by oil coolers and VMIC.

One thing though....without the oem brake dust shield, are you worried about the heat off the rotors damaging the steering tie-rod knuckle? The rubber boot is mightly close.

The hose clearance is tight regardless, sounds like yours might be real tight. You just have to make it work. I replace the duct hose every year because it rubs through on something or other. The gain is worth the effort though.

Not sure where else you can draw air from... NACA ducts underneath drawing air up may work, not sure there. For sure anything will be an improvement, whether it's enough or not you won't know til you're on track. Even if you made something that was like 1" x 8" and then put that right by the wheel under the car that will pickup alot of air. One thing that I emphasize is that the good rotors (Not straight vane ones like stock) are actually air pumps... So even with just a fresh air *source* they will pump that air through and cool themselves. Of course if you can ram air into the pump that makes the flow even higher, but sounds like you might not have a good place for a ram style duct.

The steering tie-rod knuckle boot was already toasted on mine from my stock rotors overheating. Funny thing is even though it's closer there's actually less heat radiating now than before. I do plan on making a small aluminum shield that covers it up when I get a chance and can replace the boot.

#25

Senior Member

Join Date: Mar 2003

Location: London, UK

Posts: 390

Likes: 0

Received 0 Likes

on

0 Posts

I sent N-Tech an email about the plates the other day and still not had a reply.

Wonder if they think because I am in the UK, they might not want to deal with me.

Fish

Wonder if they think because I am in the UK, they might not want to deal with me.

Fish