Is my engine damaged?

#27

there's no mystery here. you don't have enough fuel for the turbo.

your situation is an example of:

fuel rule number one:

always size your fuel for max air output from your turbo at 10.0 to 1

if you don't, a stuck wastegate spells doom. do not assume you can always control your turbo output.

note max output of the GTX35 at one pressure ratio (which is the "2" on the Y axis) is 67.

67 pounds of air at 14.7 psi

requires 6.7 pounds of fuel or 1.055 gallons per minute which is 3993 CC per minute net of lag and duty cycle into the motor.

you have 5440 nominal but you have to remove lag and an 85% max duty cycle.

5440 X .74 = 4025 cc

you have 4025 and you need 3993 to max out your turbo at 14.7 psi boost.

at 15 PSI and 43.5 static fuel pressure your fuel pump must produce 245 liters per hour.

at 13.5 volts your fuel pump will do 250 liters per hour before removing flow loss due to line and filter restriction.

The 250 at 58.5 psi is also at 13.5 volts. is your fuel pump hardwired into your car? if not, it is probably seeing just less than 12 V.

flow rises and falls w the square of the voltage...

for instance, if you were running at 13.5 V to the pump flow would be 250 L/H.

if the same pump was seeing 12.5 V flow would be 214 L/H or 3566 CC/Min

what is your V at the pump?

finally, your turbo can make 77 pounds of air... you need to resize your fuel system to work w that output even though you may not ever run at that level.

you need 4588 net CC/minute or 6200CC/min of nominal injector capacity.

max air on your turbo is at 2.85 pressure ratios or 27 psi.

your fuel pump must deliver 275 liters per hour at 27 psi. hard wire your pump and I suggest you use a Kenne Bell Boost A Pump (20 amp 13.5 base V) at plus 20% V gain.

my guess is a chipped apex seal, flattened corner seal springs and a cracked corner seal or two.

rotor housings may or may not be usable. If you had Goopy apex seals, it is unlikely they would be broken. i also believe that Atkins solid corner seals would increase your chances of being O K w re to CS.

most of your motor should be fine.

you can run another set of secondary injectors w a Ground Zero manifold and a separate driver module from AEM to remove the strain on the PFC injector drivers.

howard

your situation is an example of:

fuel rule number one:

always size your fuel for max air output from your turbo at 10.0 to 1

if you don't, a stuck wastegate spells doom. do not assume you can always control your turbo output.

note max output of the GTX35 at one pressure ratio (which is the "2" on the Y axis) is 67.

67 pounds of air at 14.7 psi

requires 6.7 pounds of fuel or 1.055 gallons per minute which is 3993 CC per minute net of lag and duty cycle into the motor.

you have 5440 nominal but you have to remove lag and an 85% max duty cycle.

5440 X .74 = 4025 cc

you have 4025 and you need 3993 to max out your turbo at 14.7 psi boost.

at 15 PSI and 43.5 static fuel pressure your fuel pump must produce 245 liters per hour.

at 13.5 volts your fuel pump will do 250 liters per hour before removing flow loss due to line and filter restriction.

The 250 at 58.5 psi is also at 13.5 volts. is your fuel pump hardwired into your car? if not, it is probably seeing just less than 12 V.

flow rises and falls w the square of the voltage...

for instance, if you were running at 13.5 V to the pump flow would be 250 L/H.

if the same pump was seeing 12.5 V flow would be 214 L/H or 3566 CC/Min

what is your V at the pump?

finally, your turbo can make 77 pounds of air... you need to resize your fuel system to work w that output even though you may not ever run at that level.

you need 4588 net CC/minute or 6200CC/min of nominal injector capacity.

max air on your turbo is at 2.85 pressure ratios or 27 psi.

your fuel pump must deliver 275 liters per hour at 27 psi. hard wire your pump and I suggest you use a Kenne Bell Boost A Pump (20 amp 13.5 base V) at plus 20% V gain.

my guess is a chipped apex seal, flattened corner seal springs and a cracked corner seal or two.

rotor housings may or may not be usable. If you had Goopy apex seals, it is unlikely they would be broken. i also believe that Atkins solid corner seals would increase your chances of being O K w re to CS.

most of your motor should be fine.

you can run another set of secondary injectors w a Ground Zero manifold and a separate driver module from AEM to remove the strain on the PFC injector drivers.

howard

One little correction, FIC injectors are called 720 and 2000 but in reality they flow 750 and 2200 @43.5psi so they are 5900cc nominal.

I had my NipponDenso Supra pump hard wired. I have seen similar fuel setups for GT35R and since wasn't going to push my GTX35R to full potential I thought it would be enough.

I will have to get back to you about the V on the pump.

I am doing preliminary research at this stage and ALSrotary site is down. Where can I get ALS seals? Even though my engine was almost brand new JDM version, I still need the Atkins or another master rebuild kit with all the seals, o-rings and gaskets right?

If I am to rebuild my engine or buy a rebuild one from a vendor it has to be streetported. In which case I will need a template but judge ito ones are discontinued afaik.

I am also considering replacing my ECU with a more advanced ECU, tuners around here are not familiar with PFC (even though it's very simple). In this case I guess I can control the extra injectors.

Looks like it will be an expensive rebuild with the new LIM and all that. Totally ruined my plans

#28

Alpsta,

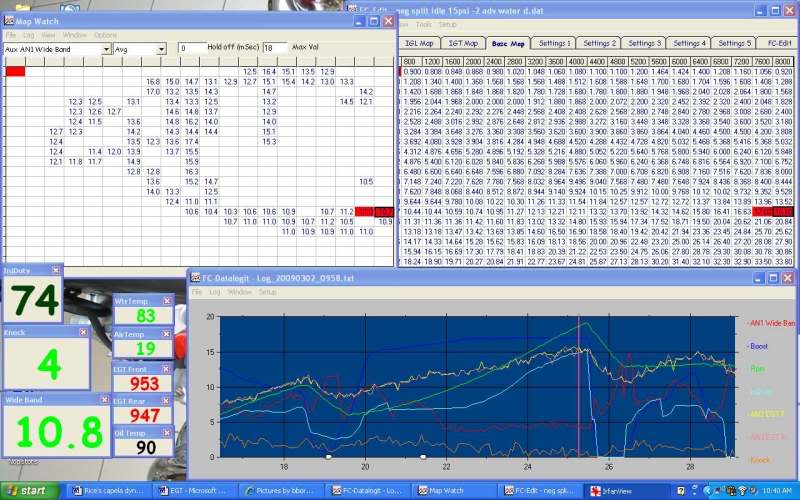

Check your last logs.....

What were the AFRs around 8000 rpm?

What was the injector duty at 8000 rpm?

What was the highest knock value on the map?

Then disassemble the engine and check for damage....

Are any of the Apex seals chipped?

Are the apex seal faces flat when facing each other?

Do the housings have carbon spots on both sides of the plug holes?

Post pictures.

Barry

Check your last logs.....

What were the AFRs around 8000 rpm?

What was the injector duty at 8000 rpm?

What was the highest knock value on the map?

Then disassemble the engine and check for damage....

Are any of the Apex seals chipped?

Are the apex seal faces flat when facing each other?

Do the housings have carbon spots on both sides of the plug holes?

Post pictures.

Barry

Will try but I don't think the tuner will provide that now, it will be quite obvious why I am asking for it. Having said that, I connect my own laptop and get a copy of the last map.

#29

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

Thank you for all this info Howard, I will take these into account for my new engine.

One little correction, FIC injectors are called 720 and 2000 but in reality they flow 750 and 2200 @43.5psi so they are 5900cc nominal.

I had my NipponDenso Supra pump hard wired. I have seen similar fuel setups for GT35R and since wasn't going to push my GTX35R to full potential I thought it would be enough.

I will have to get back to you about the V on the pump.

I am doing preliminary research at this stage and ALSrotary site is down. Where can I get ALS seals? Even though my engine was almost brand new JDM version, I still need the Atkins or another master rebuild kit with all the seals, o-rings and gaskets right?

If I am to rebuild my engine or buy a rebuild one from a vendor it has to be streetported. In which case I will need a template but judge ito ones are discontinued afaik.

I am also considering replacing my ECU with a more advanced ECU, tuners around here are not familiar with PFC (even though it's very simple). In this case I guess I can control the extra injectors.

Looks like it will be an expensive rebuild with the new LIM and all that. Totally ruined my plans

One little correction, FIC injectors are called 720 and 2000 but in reality they flow 750 and 2200 @43.5psi so they are 5900cc nominal.

I had my NipponDenso Supra pump hard wired. I have seen similar fuel setups for GT35R and since wasn't going to push my GTX35R to full potential I thought it would be enough.

I will have to get back to you about the V on the pump.

I am doing preliminary research at this stage and ALSrotary site is down. Where can I get ALS seals? Even though my engine was almost brand new JDM version, I still need the Atkins or another master rebuild kit with all the seals, o-rings and gaskets right?

If I am to rebuild my engine or buy a rebuild one from a vendor it has to be streetported. In which case I will need a template but judge ito ones are discontinued afaik.

I am also considering replacing my ECU with a more advanced ECU, tuners around here are not familiar with PFC (even though it's very simple). In this case I guess I can control the extra injectors.

Looks like it will be an expensive rebuild with the new LIM and all that. Totally ruined my plans

you don't need a streetport. the denso supra pump is good to low to mid 400WHP. your turbo is a monster in terms of output, and if you were up at the top of its rpm and boosting 15PSI....might have run lean.

Just wondering, did you slowly go row by row up? did you start at like 8PSI wastegate or something low and slowly bring the car higher and higher doing runs?

I am so careful with peoples cars (and mine) I literally just slowly walk the car higher with the boost. I have the driver part throttle it most of the time to ensure wastegate opens (you slowly creep up on the wastegate and ensure everything is connected correctly) and you also can see how much fuel is being used/injector duty cycle, knock, etc. I also tell the owner of the car who is driving it that you need to slowly bring the car up into these ranges, if you see X,Y,Z you lift the throttle.

I tuned a stock twin turbo all the way to 99% injector duty cycle and said, you need to back this down to 85% max. did so with the boost controller and I told him to rail it in 2nd gear. We still overboosted a little and got into the 90's%.

Be careful and walk slowly when tuning. I know how expensive things can get. I would upgrade the fuel pump or get more voltage to it, and slowly tune this beast you have.

Good luck, and I do like your set up! I run a GT3574R.

#32

you don't need a streetport. the denso supra pump is good to low to mid 400WHP. your turbo is a monster in terms of output, and if you were up at the top of its rpm and boosting 15PSI....might have run lean.

Just wondering, did you slowly go row by row up? did you start at like 8PSI wastegate or something low and slowly bring the car higher and higher doing runs?

I am so careful with peoples cars (and mine) I literally just slowly walk the car higher with the boost. I have the driver part throttle it most of the time to ensure wastegate opens (you slowly creep up on the wastegate and ensure everything is connected correctly) and you also can see how much fuel is being used/injector duty cycle, knock, etc. I also tell the owner of the car who is driving it that you need to slowly bring the car up into these ranges, if you see X,Y,Z you lift the throttle.

I tuned a stock twin turbo all the way to 99% injector duty cycle and said, you need to back this down to 85% max. did so with the boost controller and I told him to rail it in 2nd gear. We still overboosted a little and got into the 90's%.

Be careful and walk slowly when tuning. I know how expensive things can get. I would upgrade the fuel pump or get more voltage to it, and slowly tune this beast you have.

Good luck, and I do like your set up! I run a GT3574R.

Just wondering, did you slowly go row by row up? did you start at like 8PSI wastegate or something low and slowly bring the car higher and higher doing runs?

I am so careful with peoples cars (and mine) I literally just slowly walk the car higher with the boost. I have the driver part throttle it most of the time to ensure wastegate opens (you slowly creep up on the wastegate and ensure everything is connected correctly) and you also can see how much fuel is being used/injector duty cycle, knock, etc. I also tell the owner of the car who is driving it that you need to slowly bring the car up into these ranges, if you see X,Y,Z you lift the throttle.

I tuned a stock twin turbo all the way to 99% injector duty cycle and said, you need to back this down to 85% max. did so with the boost controller and I told him to rail it in 2nd gear. We still overboosted a little and got into the 90's%.

Be careful and walk slowly when tuning. I know how expensive things can get. I would upgrade the fuel pump or get more voltage to it, and slowly tune this beast you have.

Good luck, and I do like your set up! I run a GT3574R.

I am not denying the possibility of a tuner error but we can only come to a conclusion once I download the latest map and I open up the engine and inspect the parts.

As to why I wasn't running lower boost, I had 12psi wg springs because from what I know, the less difference in boost you want to run and wg springs the better. My plan was to run 2 or 3 different boost pressures between 12 - 20psi.

Possible future streetport is for my ear pleasure and for better whp not because I think it's compulsory.

l00katme I'm sure are very careful with the cars you tune, I wish there were tuners like you around. I have tried everything from long distance tuning by experts (via teamviewer) to downloading other maps before giving up and going with the local tuners.

I will look into the fuel system and overkill it if I have to. Maybe 2 extra 2200cc injectors in an excessive manifold and an extra fuel pump will fix it. The reason I didn't go with dual pump setup is when one pump goes bad there is a bigger risk of blowing up your engine, compared to single pump.

In summary this thread has been a very interesting one for me. I've done plenty of research before my build and didn't skip on parts. Followed plenty of GT35R threads, spoke to few rotary gurus, I didn't get any negative comments or advices for my port, fuel system, and other parts. Now it feels the opposite. But I'm finding all these comments constructive and very helpful so again thank you all.

#33

Thank you for all this info Howard, I will take these into account for my new engine.

One little correction, FIC injectors are called 720 and 2000 but in reality they flow 750 and 2200 @43.5psi so they are 5900cc nominal.

I had my NipponDenso Supra pump hard wired. I have seen similar fuel setups for GT35R and since wasn't going to push my GTX35R to full potential I thought it would be enough.

I will have to get back to you about the V on the pump.

I am doing preliminary research at this stage and ALSrotary site is down. Where can I get ALS seals? Even though my engine was almost brand new JDM version, I still need the Atkins or another master rebuild kit with all the seals, o-rings and gaskets right?

If I am to rebuild my engine or buy a rebuild one from a vendor it has to be streetported. In which case I will need a template but judge ito ones are discontinued afaik.

I am also considering replacing my ECU with a more advanced ECU, tuners around here are not familiar with PFC (even though it's very simple). In this case I guess I can control the extra injectors.

Looks like it will be an expensive rebuild with the new LIM and all that. Totally ruined my plans

One little correction, FIC injectors are called 720 and 2000 but in reality they flow 750 and 2200 @43.5psi so they are 5900cc nominal.

I had my NipponDenso Supra pump hard wired. I have seen similar fuel setups for GT35R and since wasn't going to push my GTX35R to full potential I thought it would be enough.

I will have to get back to you about the V on the pump.

I am doing preliminary research at this stage and ALSrotary site is down. Where can I get ALS seals? Even though my engine was almost brand new JDM version, I still need the Atkins or another master rebuild kit with all the seals, o-rings and gaskets right?

If I am to rebuild my engine or buy a rebuild one from a vendor it has to be streetported. In which case I will need a template but judge ito ones are discontinued afaik.

I am also considering replacing my ECU with a more advanced ECU, tuners around here are not familiar with PFC (even though it's very simple). In this case I guess I can control the extra injectors.

Looks like it will be an expensive rebuild with the new LIM and all that. Totally ruined my plans

Look for E&J seals , that is the original ALS a few vendors here on the site .

#35

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

The car was tuned before it wasn't perfect but it drove ok. It wasn't a power tune. After I had concerns about my ignition system I decided to replace the HKS Twin Power and oem coils with AEM Smart Coils. In the process I also changed the TPS and ISC. After all this idle wasn't great but above 2k rpm the car drove ok. I am not an expert like some of you guys in here but from what I could see in data display, AFR, EGT and all other values seemed perfectly normal, no red flags. So when we went to tune the car we first took care of the rough idle and once the idle was smooth again we took care of other parts of the map. So we didn't WOT straight away with no tune.

I am not denying the possibility of a tuner error but we can only come to a conclusion once I download the latest map and I open up the engine and inspect the parts.

As to why I wasn't running lower boost, I had 12psi wg springs because from what I know, the less difference in boost you want to run and wg springs the better. My plan was to run 2 or 3 different boost pressures between 12 - 20psi.

Possible future streetport is for my ear pleasure and for better whp not because I think it's compulsory.

l00katme I'm sure are very careful with the cars you tune, I wish there were tuners like you around. I have tried everything from long distance tuning by experts (via teamviewer) to downloading other maps before giving up and going with the local tuners.

I will look into the fuel system and overkill it if I have to. Maybe 2 extra 2200cc injectors in an excessive manifold and an extra fuel pump will fix it. The reason I didn't go with dual pump setup is when one pump goes bad there is a bigger risk of blowing up your engine, compared to single pump.

In summary this thread has been a very interesting one for me. I've done plenty of research before my build and didn't skip on parts. Followed plenty of GT35R threads, spoke to few rotary gurus, I didn't get any negative comments or advices for my port, fuel system, and other parts. Now it feels the opposite. But I'm finding all these comments constructive and very helpful so again thank you all.

I am not denying the possibility of a tuner error but we can only come to a conclusion once I download the latest map and I open up the engine and inspect the parts.

As to why I wasn't running lower boost, I had 12psi wg springs because from what I know, the less difference in boost you want to run and wg springs the better. My plan was to run 2 or 3 different boost pressures between 12 - 20psi.

Possible future streetport is for my ear pleasure and for better whp not because I think it's compulsory.

l00katme I'm sure are very careful with the cars you tune, I wish there were tuners like you around. I have tried everything from long distance tuning by experts (via teamviewer) to downloading other maps before giving up and going with the local tuners.

I will look into the fuel system and overkill it if I have to. Maybe 2 extra 2200cc injectors in an excessive manifold and an extra fuel pump will fix it. The reason I didn't go with dual pump setup is when one pump goes bad there is a bigger risk of blowing up your engine, compared to single pump.

In summary this thread has been a very interesting one for me. I've done plenty of research before my build and didn't skip on parts. Followed plenty of GT35R threads, spoke to few rotary gurus, I didn't get any negative comments or advices for my port, fuel system, and other parts. Now it feels the opposite. But I'm finding all these comments constructive and very helpful so again thank you all.

There are different philosophies on how to get things done. Some are right, others make more sense.

I do like Howards approach with spec'ing a fuel system that can provide more fuel than your turbo can air, always having enough to run the system rich.

perhaps your tuner isn't at fault, I have no idea what happened, perhaps the fuel couldn't take it, I don't know.

When I tune the guys cars here, (I am self taught and don't consider myself a pro by any means), I just take things slow and would go about it the way I would tune my own car. I typically am not time constrained like some pro tuners are and go slow. I look for out of the ordinary things and am conservative.

My philosophy is this. You tune the car the way it is driven on the street (street tune the car). Try and create the base map in the same conditions the car is driven in (same water temp, air temp, etc). Watch for knock spikes (some cars are noisy and have a lot of knock above certain rpms). Then when you tune the base map at that same water temp/air temp/ etc......I let the owner/friend know how I tuned the car and that this is where you want to keep the temps are if possible. If the car starts running hot all the time or its going all over the place (hot and cold) that is when things can go wrong. I do put safety factors in the tuning (retard timing, more fuel, etc based off extremes) but the driver should know what the extremes are and back off when those extremes happen.

I know you are considering other seals than OEM, my question is why? Why do a streetport when you don't have to. Perhaps I am a little old school in my thinking, but I like the OEM seals, I like the stock ports as you get better spool and it focuses the WHP/torque for a street car where I perfer it to be. It also reduces the chance of something failing to a bad streetport job, or poorly engineered seals. Speedjunkies seals went out on his car and his housings looked pretty bad (chattering marks, etc) from ALS (E&J) seals. Most of the housings look great with the OEM seals. I would run OEM. I would run stock ports.

I would tune the car up to 13-14PSI (peak) without any injection on 91-93 octane fuel with a rich 11.0 AFR or so and a conservative timing map. I would add 100% water injection above that and tune it the rest of the way to where you want it. I would then do water/meth and lean out the mixture a little to where the car runs great, but not soo aggressive that if the water/meth failed I would run super lean without it. I would ensure to take things slow when tuning and continue to test and monitor things during the tuning process. This might catch some problems with the car mechanically so nothing bad happens. Then when everything looks sound, slowly tune higher and higher PSI.

Perhaps I am watching/reading the wrong build threads, but I have read some threads where a car is basically fabricated with a ton of different parts by hand, thrown together, some small look overs done over the work, and I am seeing a tuner doing a 15PSI pass on a dyno the next day. That just seems so risky. Makes me cringe.

I tuned 15U's car on here with stock twins. We took the car to 16PSI on those twins and on the stock fuel system (he wanted to push it). We went to 100% duty cycle. We backed it off and he runs at a max of 85% duty cycle. He did a shake down of the car in 100 degree heat on the track pushing the water temps and air temps (up to 80C) even against my suggestion of 60C or less and you back off. I had all the safety factors engaged when he was at the track (retarded timing, more fuel, etc). I also pulled some timing from peak torque in the upper load cells. His car ran great I guess, but I personally wouldn't have pushed the car that hard in those conditions. Upgrade the intercooler to bring down those high air temps.

Be smart and observant, have patience when tuning and take it slow. Also, when you hit higher loads (boost), go row by row and then map it directly after. If you are seeing a jump in Ms on-time out of no where, it is signaling a problem with fuel delivery. These are the small clues that you might need to queue in on.

#36

He has enough fuel injector. Pump is the weakspot. At 13 to 15psi the pump wouldn't have fallen on its face, but MAYBE slightly trailed off and could have been somewhat compensated for by opening the injectors logger. Even though that compressor flows that much air, the turbine wheel cannot keep up. Fuel flow follows the torque curve. That is a midrange turbo, not a high RPM turbo. Stock or small porting is the way to go with that turbo.

The car was probably tuned to the end of 4th gear as this gives a lot more information as the RPMS are buzzing by as fast. Sounds like it was probably just run too lean. Its easy to max pump gas out if you aren't running rich...

You should have had the water injection ON from the get go. Not sure why anyone would recommend otherwise. I assume you don't have access to a dyno with load control? Logging is pretty critical for street tuning, you should have TONs of logs...

The car was probably tuned to the end of 4th gear as this gives a lot more information as the RPMS are buzzing by as fast. Sounds like it was probably just run too lean. Its easy to max pump gas out if you aren't running rich...

You should have had the water injection ON from the get go. Not sure why anyone would recommend otherwise. I assume you don't have access to a dyno with load control? Logging is pretty critical for street tuning, you should have TONs of logs...

#37

I know you are considering other seals than OEM, my question is why? Why do a streetport when you don't have to. Perhaps I am a little old school in my thinking, but I like the OEM seals, I like the stock ports as you get better spool and it focuses the WHP/torque for a street car where I perfer it to be. It also reduces the chance of something failing to a bad streetport job, or poorly engineered seals. Speedjunkies seals went out on his car and his housings looked pretty bad (chattering marks, etc) from ALS (E&J) seals. Most of the housings look great with the OEM seals. I would run OEM. I would run stock ports.

I would tune the car up to 13-14PSI (peak) without any injection on 91-93 octane fuel with a rich 11.0 AFR or so and a conservative timing map. I would add 100% water injection above that and tune it the rest of the way to where you want it. I would then do water/meth and lean out the mixture a little to where the car runs great, but not soo aggressive that if the water/meth failed I would run super lean without it. I would ensure to take things slow when tuning and continue to test and monitor things during the tuning process. This might catch some problems with the car mechanically so nothing bad happens. Then when everything looks sound, slowly tune higher and higher PSI.

The reason for considering other seals is simply because oem ones failed in such a short time. Maybe my fault maybe not I don't know but I may try something else. Like I have mentioned in this thread before, OEM seals made sense as they are softer and made for longevity and factory warranty and if the tuning is right then there shouldn't be too much stress on the seals. But I guess that is in a perfect world. Yeah I've read stories about harder seals raping the housings etc. Nothing is decided yet, I am trying to more careful this time.

I also don't see anything wrong with a mild streetport. It enhances the rotary sound and character imo. It gives a bit more power and the little loss of low end is not a big deal with a turbo like GTX35R.

Before talking tuning, I may look into another ecu which is more suitable for tuners around here. Perhaps a Haltech P2000, Elite or an Autronic will do a better job in saving my next engine against driver and tuner errors. I know with some ecus you dial in target values and it keeps/adjusts the tune within/according to those parameters.

So much research to do

#38

He has enough fuel injector. Pump is the weakspot. At 13 to 15psi the pump wouldn't have fallen on its face, but MAYBE slightly trailed off and could have been somewhat compensated for by opening the injectors logger. Even though that compressor flows that much air, the turbine wheel cannot keep up. Fuel flow follows the torque curve. That is a midrange turbo, not a high RPM turbo. Stock or small porting is the way to go with that turbo.

The car was probably tuned to the end of 4th gear as this gives a lot more information as the RPMS are buzzing by as fast. Sounds like it was probably just run too lean. Its easy to max pump gas out if you aren't running rich...

You should have had the water injection ON from the get go. Not sure why anyone would recommend otherwise. I assume you don't have access to a dyno with load control? Logging is pretty critical for street tuning, you should have TONs of logs...

The car was probably tuned to the end of 4th gear as this gives a lot more information as the RPMS are buzzing by as fast. Sounds like it was probably just run too lean. Its easy to max pump gas out if you aren't running rich...

You should have had the water injection ON from the get go. Not sure why anyone would recommend otherwise. I assume you don't have access to a dyno with load control? Logging is pretty critical for street tuning, you should have TONs of logs...

#39

He has enough fuel injector. Pump is the weakspot. At 13 to 15psi the pump wouldn't have fallen on its face, but MAYBE slightly trailed off and could have been somewhat compensated for by opening the injectors logger. Even though that compressor flows that much air, the turbine wheel cannot keep up. Fuel flow follows the torque curve. That is a midrange turbo, not a high RPM turbo. Stock or small porting is the way to go with that turbo.

The car was probably tuned to the end of 4th gear as this gives a lot more information as the RPMS are buzzing by as fast. Sounds like it was probably just run too lean. Its easy to max pump gas out if you aren't running rich...

You should have had the water injection ON from the get go. Not sure why anyone would recommend otherwise. I assume you don't have access to a dyno with load control? Logging is pretty critical for street tuning, you should have TONs of logs...

The car was probably tuned to the end of 4th gear as this gives a lot more information as the RPMS are buzzing by as fast. Sounds like it was probably just run too lean. Its easy to max pump gas out if you aren't running rich...

You should have had the water injection ON from the get go. Not sure why anyone would recommend otherwise. I assume you don't have access to a dyno with load control? Logging is pretty critical for street tuning, you should have TONs of logs...

#41

The only thing wrong with Mazda 2mm apex seals are tuners! That being said, everyone will recommend what has worked for them. There are a lot of good aftermarket seals out there but all they do is compensate for a bad tuner. You are getting a lot of good information here so use it. The overall set up of the car makes a huge difference. Take your time and good luck.

#42

Not yet, I am waiting for the workshop to become available so we start taking things apart and once we do I will update this thread. Looks like it'll be a week or two though. Will post pics also to find out the cause of the failure.

This thread proved once again there are too many conflicting theories/experiences within our small community. I've been quite active in the forum and I have a build thread as well. During my build and parts purchase I've talked with many gurus/builders/mechanics/vendors/knowledgeable members etc. No one raised these issues (fuel system, water injection, seals etc.) at the time. I am not trying to defend my build project but "sufficient" is the word I'd use for even the worst part I used on my car. Of course when such disasters happen first things that come to mind are extra safety measures for next time. Too many decisions to be made

The only thing wrong with Mazda 2mm apex seals are tuners! That being said, everyone will recommend what has worked for them. There are a lot of good aftermarket seals out there but all they do is compensate for a bad tuner. You are getting a lot of good information here so use it. The overall set up of the car makes a huge difference. Take your time and good luck.

#43

Parts/mods list:

Brand new JDM engine (from Ray @ Malloy Mazda)

A-Spec GTX35R kit

Dual Tial MVR 44mm wastegates

Custom V-mount intercooler

Koyo Radiator

Custom AST

Apexi Power FC

GM 3bar map sensor

Apexi AVC-R

AEM Smart Coils

AEM Water/Meth injection kit

CJ-Motorsports primary rail

CJ-Motorsports secondary rail

FIC720 (Bosch EV-14) primary injectors

FIC2000 (Bosch EV-14) secondary injectors

NipponDenso Supra fuel pump

FC Thermoswitch

Pettit Starter Booster

Touge Pulley kit

Banzai Racing oil pan brace

Banzai Racing block-off kit

Dimple Magnetic Oil drain plug

Exedy Hyper Twin Plate clutch

Odyssey PC925 Battery

Below is a pic of the engine bay before the AEM Smart Coils. It's not the best but everything was put together well and was in working order. My next project was to move the intercooler to the side and build a custom air intake.

Although I don't know the cause of the engine failure, for my next build I'm focusing on a new ecu, gauges and sensor placement before looking into seals and fuel system because I am still suspecting the tune or gauges displaying wrong figures which lead us to believe everything was in order. Like I said it is not the best setup but should also not fail at 12psi wg spring boost (15psi peak) regardless of the seals or water injection. People thrash worse 13b setups and the engines survive. I don't know if a rotary engine is this fragile, unless the tune was way off.

Brand new JDM engine (from Ray @ Malloy Mazda)

A-Spec GTX35R kit

Dual Tial MVR 44mm wastegates

Custom V-mount intercooler

Koyo Radiator

Custom AST

Apexi Power FC

GM 3bar map sensor

Apexi AVC-R

AEM Smart Coils

AEM Water/Meth injection kit

CJ-Motorsports primary rail

CJ-Motorsports secondary rail

FIC720 (Bosch EV-14) primary injectors

FIC2000 (Bosch EV-14) secondary injectors

NipponDenso Supra fuel pump

FC Thermoswitch

Pettit Starter Booster

Touge Pulley kit

Banzai Racing oil pan brace

Banzai Racing block-off kit

Dimple Magnetic Oil drain plug

Exedy Hyper Twin Plate clutch

Odyssey PC925 Battery

Below is a pic of the engine bay before the AEM Smart Coils. It's not the best but everything was put together well and was in working order. My next project was to move the intercooler to the side and build a custom air intake.

Although I don't know the cause of the engine failure, for my next build I'm focusing on a new ecu, gauges and sensor placement before looking into seals and fuel system because I am still suspecting the tune or gauges displaying wrong figures which lead us to believe everything was in order. Like I said it is not the best setup but should also not fail at 12psi wg spring boost (15psi peak) regardless of the seals or water injection. People thrash worse 13b setups and the engines survive. I don't know if a rotary engine is this fragile, unless the tune was way off.

#44

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

I agree, it shouldn't have blown. I run basically the same set up as you, my motor was rebuilt with super seals, I didn't rebuild my engine, the guy who owned it before me did. I run 650/2000 ev14 injector with a denso supra pump and a GT3574R tubro. I have run my car up to 17PSI at 6300 above sea level. My MAP sensor was reading under 15PSI still on my tuning logs. so I was around 14PSI sea level. I ran the car a lot at about 1 bar boost or 11.5 PSI sea level. no problems on 91 octane fuel.

Re Amemiya runs stock seals, barry bordes above in this thread runs stock seals, and they have pushed these engines pretty hard. Barry runs H2o injection. I am running water injection as well, but used to not run it. any access to the logs you have? if not maybe just peak at the map? I don't think you apexi power fc is the problem either.....I run it on mine.

Re Amemiya runs stock seals, barry bordes above in this thread runs stock seals, and they have pushed these engines pretty hard. Barry runs H2o injection. I am running water injection as well, but used to not run it. any access to the logs you have? if not maybe just peak at the map? I don't think you apexi power fc is the problem either.....I run it on mine.

#46

Thanks l00katme, like you said you setup is similar to mine and there are plenty others in the forum driving around similar setup with no problems.

Apexi Power FC is not the problem but I may invest in a more advanced ecu for added functions and tunability.

I am trying to get in touch with the tuner, I will try to see if he kept the logs, and I will also try to connect to datalogit myself and see what I can dig up. Worst case scenario current map will be in the ecu.

Apexi Power FC is not the problem but I may invest in a more advanced ecu for added functions and tunability.

I am trying to get in touch with the tuner, I will try to see if he kept the logs, and I will also try to connect to datalogit myself and see what I can dig up. Worst case scenario current map will be in the ecu.

#47

"Elusive, not deceptive!”

Mine runs down the passenger side of the radiator with a separate scoop in the grill.

I am able to maintain about 6*C of ambient temperature.

View from the grill

View from the bottom

And if you are using 50/50 water meth the inlet air temps should not rise on a pull.

#48

^^ looks good Barry. My setup is v-mount so air has no where to escape anyway. I don't think I need to position the pickup point (entry) so low, as long as I move the intercooler to the side i can fabricate an air intake starting from the side of the intercooler or my other option is to extend the air filter to the side of the intercooler.

#49

After a long break from the RX7 due to the workloads of both myself and my mechanic we finally made some time today and took the engine out so the adventure began. We don't have a rotary compression tester but as you know from the beginning of the thread the symptoms are pointing to engine damage. When we listened to the engine there were definitely metallic sounds coming from the engine.

I would like to emphasise that this is both my and my mechanics first rotary rebuild. We will probably need some tips and help along the way.

As you can see in the pics below we tried to look inside the engine with a monitoring device but had no luck. We've seen a number 4 mark though, maybe the engine is trying to ask me for a 4 rotor conversion We tried looking through the spark plug holes and through the exhaust ports. When we look through the exhaust ports, although not clear it looks like both the front and rear housings are scratched (brownish marks), however all the apex seals seem to be in place. Maybe one of them chipped on the edge I don't know but hearing the metallic sounds from the engine I thought I shattered one into pieces.

We tried looking through the spark plug holes and through the exhaust ports. When we look through the exhaust ports, although not clear it looks like both the front and rear housings are scratched (brownish marks), however all the apex seals seem to be in place. Maybe one of them chipped on the edge I don't know but hearing the metallic sounds from the engine I thought I shattered one into pieces.

On Monday we are planning to open the engine. Any suggestions or comments about things to do or watch out for are welcome.

I would like to emphasise that this is both my and my mechanics first rotary rebuild. We will probably need some tips and help along the way.

As you can see in the pics below we tried to look inside the engine with a monitoring device but had no luck. We've seen a number 4 mark though, maybe the engine is trying to ask me for a 4 rotor conversion

We tried looking through the spark plug holes and through the exhaust ports. When we look through the exhaust ports, although not clear it looks like both the front and rear housings are scratched (brownish marks), however all the apex seals seem to be in place. Maybe one of them chipped on the edge I don't know but hearing the metallic sounds from the engine I thought I shattered one into pieces.

We tried looking through the spark plug holes and through the exhaust ports. When we look through the exhaust ports, although not clear it looks like both the front and rear housings are scratched (brownish marks), however all the apex seals seem to be in place. Maybe one of them chipped on the edge I don't know but hearing the metallic sounds from the engine I thought I shattered one into pieces.On Monday we are planning to open the engine. Any suggestions or comments about things to do or watch out for are welcome.

#50

"Elusive, not deceptive!”

Use the loosening sequence in the manual for the through bolts.

Take pictures as you remove each plate.

Observe clearances of side seal to corner seals and which oil scrapers are loose.

Take pictures of the spark plug area.

Can't wait to see the results,

Barry

Take pictures as you remove each plate.

Observe clearances of side seal to corner seals and which oil scrapers are loose.

Take pictures of the spark plug area.

Can't wait to see the results,

Barry