Motor issue... Stuck Corner Seal?

#1

Motor issue... Stuck Corner Seal?

Got a few questions for the experienced people on the board, but first a little background.

Car has been running well since I installed the new motor last summer. I have run probably 10-12 event days at the track, and maybe another 5000 miles on the street, so 8000 total. I ran the wastegate spring (~9psi - On the dyno dynamics dyno, about 300 rwhp) for a long time, and I only started upping the boost slightly a month or so ago. (10.5 psi)

I ran two events in June, car ran good. I ran an event near the end of July, car ran great. Idle hasn't been working that well since about mid-june, but I don't drive it on the street much so I didn't care.

Took it out this past week to drive to MRR after it sat for about 3-4 weeks while I worked on the brakes etc. Ran fine on the way to work. Then on the way down to Road America Damian and I did a couple boost runs. The car felt like it had a miss at medium-high RPM under boost. I did 2 pulls then stopped because of the miss. AFR was the same as always, around 10.5-11. Otherwise car ran just like always, and I got almost 20 mpg. For the next 2 days, almost every time I started the car, it acted a little bit poorer. Eventually it started to feel like the miss was also affecting the car under high vac/rpm. The idle got lumpier and lumpier. I did try to go WOT 2-3 times. Once it felt the same as before, just a slight (inconsistent) missing.

On the way back from MRR the car would switch between two modes, one where it felt like it was running fine, and one where it felt like it was running on one rotor. When the car felt like it was on one rotor, I wasn't able to build boost at 3000 rpm anymore because the missing was very prominent.

By the time we got back, it feels like the motor runs on one rotor all the time, and the vac is now low, about 10" at 800rpm, maybe 15" top at 1200 rpm. Normally - and idling well - I was at 16" at 950rpm.

I pulled the plugs and checked them out. The rear rotor the leading plug was black and wet, and had carbon built up on it probablly 1/16". The trailing plug was black, but no raised carbon build-up. The front rotor the leading looked pretty good, mostly brown and dry, a little black near 1/4. The trailing looked a bit whiter, but still a small amount of black.

At this point we did a quick comp test with a modified piston tester just to see if I still had compression. The numbers were about 95/95/95 across the front rotor, and 95/25/25 on the rear rotor. The absolute number is probably not very accurate given the way we tested, I was just looking for even numbers, and they are definitely not at all on the rear rotor.

I pulled the turbo/manifold and Damian looked into the rear rotor. All apex seals are in there and moving within their grooves. There's no abnormal scoring on the housing or irons. Actually it all looks pretty good, however there is a lot of carbon on the rotor. Compared to the front rotor, there's probably 2-3 times as much.

Here's my list of questions:

1)It would seem that I have a stuck corner seal since I have low compression on 2 sides, but seals that are all intact and moving?

1b) If so, is there anything I should try to get it unstuck without pulling the motor? (ATF/acetone/something else) I am trying to make an event this weekend.

1c) If the rear rotor was getting too much fuel, would that cause all the carbon, and therefore stick the seal? So I should check all the injectors to make sure they're working ok?

1d) If the rear rotor wasn't getting proper spark, would that cause all the carbon, and therefore stick the seal?

So I should check the coils/wires to make sure they're working ok?

1e) Is it possible that I just left the plugs in too long, and combined with the long time imbetween driving the car, the carbon gummed up the side seal? I haven't checked them in a while, but last time I did they looked fine. I cleaned them a bit and put them back in.

2) Is there anything else I'm missing, or that I should be checking?

3) Would it be wiser for me to just pull the motor and pull the back iron off? That would essentially mean I miss this weekend's event. However, if there's a chance I mess the motor up further by trying something I'm willing to do it. If there's no/very little chance of further damage then I'd like to at least try something while it's still in the car.

4) Any other comments?

Car has been running well since I installed the new motor last summer. I have run probably 10-12 event days at the track, and maybe another 5000 miles on the street, so 8000 total. I ran the wastegate spring (~9psi - On the dyno dynamics dyno, about 300 rwhp) for a long time, and I only started upping the boost slightly a month or so ago. (10.5 psi)

I ran two events in June, car ran good. I ran an event near the end of July, car ran great. Idle hasn't been working that well since about mid-june, but I don't drive it on the street much so I didn't care.

Took it out this past week to drive to MRR after it sat for about 3-4 weeks while I worked on the brakes etc. Ran fine on the way to work. Then on the way down to Road America Damian and I did a couple boost runs. The car felt like it had a miss at medium-high RPM under boost. I did 2 pulls then stopped because of the miss. AFR was the same as always, around 10.5-11. Otherwise car ran just like always, and I got almost 20 mpg. For the next 2 days, almost every time I started the car, it acted a little bit poorer. Eventually it started to feel like the miss was also affecting the car under high vac/rpm. The idle got lumpier and lumpier. I did try to go WOT 2-3 times. Once it felt the same as before, just a slight (inconsistent) missing.

On the way back from MRR the car would switch between two modes, one where it felt like it was running fine, and one where it felt like it was running on one rotor. When the car felt like it was on one rotor, I wasn't able to build boost at 3000 rpm anymore because the missing was very prominent.

By the time we got back, it feels like the motor runs on one rotor all the time, and the vac is now low, about 10" at 800rpm, maybe 15" top at 1200 rpm. Normally - and idling well - I was at 16" at 950rpm.

I pulled the plugs and checked them out. The rear rotor the leading plug was black and wet, and had carbon built up on it probablly 1/16". The trailing plug was black, but no raised carbon build-up. The front rotor the leading looked pretty good, mostly brown and dry, a little black near 1/4. The trailing looked a bit whiter, but still a small amount of black.

At this point we did a quick comp test with a modified piston tester just to see if I still had compression. The numbers were about 95/95/95 across the front rotor, and 95/25/25 on the rear rotor. The absolute number is probably not very accurate given the way we tested, I was just looking for even numbers, and they are definitely not at all on the rear rotor.

I pulled the turbo/manifold and Damian looked into the rear rotor. All apex seals are in there and moving within their grooves. There's no abnormal scoring on the housing or irons. Actually it all looks pretty good, however there is a lot of carbon on the rotor. Compared to the front rotor, there's probably 2-3 times as much.

Here's my list of questions:

1)It would seem that I have a stuck corner seal since I have low compression on 2 sides, but seals that are all intact and moving?

1b) If so, is there anything I should try to get it unstuck without pulling the motor? (ATF/acetone/something else) I am trying to make an event this weekend.

1c) If the rear rotor was getting too much fuel, would that cause all the carbon, and therefore stick the seal? So I should check all the injectors to make sure they're working ok?

1d) If the rear rotor wasn't getting proper spark, would that cause all the carbon, and therefore stick the seal?

So I should check the coils/wires to make sure they're working ok?

1e) Is it possible that I just left the plugs in too long, and combined with the long time imbetween driving the car, the carbon gummed up the side seal? I haven't checked them in a while, but last time I did they looked fine. I cleaned them a bit and put them back in.

2) Is there anything else I'm missing, or that I should be checking?

3) Would it be wiser for me to just pull the motor and pull the back iron off? That would essentially mean I miss this weekend's event. However, if there's a chance I mess the motor up further by trying something I'm willing to do it. If there's no/very little chance of further damage then I'd like to at least try something while it's still in the car.

4) Any other comments?

#2

I blew my motor and it the apx seal just split for the last 1/2 inch or so. Looking through the exhaust ports I couldnt tell anything was wrong. Hopefully that isnt your case, but just be careful until you are 100% certain that isnt the problem.

If you really think it could be a stuck seal a bit of marvel mystery oil through the spark plug holes may help. Crank it over a few times by hand and let it sit a few hours or over night. ATF might be hard on rubber seals so I would play it safe and not try that.

If you really think it could be a stuck seal a bit of marvel mystery oil through the spark plug holes may help. Crank it over a few times by hand and let it sit a few hours or over night. ATF might be hard on rubber seals so I would play it safe and not try that.

#3

Try spraying some Marvel's Mystery Oil into the rear chamber through the spark plug hole, cycle the engine to distribute the oil, let it sit over night and then start it the next day. You will smoke heavily for several minutes while the oil is burned out, but it will breakdown the carbon build-up in the rotor seals. This is what I have been told second hand by a rotary mechanic as a solution to a problem like yours, so I do not have any direct experience. I would then check the compression numbers the next day.

#4

Originally Posted by Tom93R1

I blew my motor and it the apx seal just split for the last 1/2 inch or so. Looking through the exhaust ports I couldnt tell anything was wrong. Hopefully that isnt your case, but just be careful until you are 100% certain that isnt the problem.

If you really think it could be a stuck seal a bit of marvel mystery oil through the spark plug holes may help. Crank it over a few times by hand and let it sit a few hours or over night. ATF might be hard on rubber seals so I would play it safe and not try that.

If you really think it could be a stuck seal a bit of marvel mystery oil through the spark plug holes may help. Crank it over a few times by hand and let it sit a few hours or over night. ATF might be hard on rubber seals so I would play it safe and not try that.

When your apex seal split, was there any scoring on the housing at all?

I'm probably going to try something with regard to unsticking the seal, either MMO or ATF. I have some people telling me one and some the other. I'm not sure what I'll try yet. I might also try MMO first and if that doesn't work try ATF.

#5

development

I agree with tom...a chipped or cracked apex seal wouldn't be visible thru the ports and probably wouldn't yield a 0psi reading, but a low one for two faces.

good luck...(BTW a stuck side seal, would only effect 1 face)

good luck...(BTW a stuck side seal, would only effect 1 face)

#6

Originally Posted by dubulup

I agree with tom...a chipped or cracked apex seal wouldn't be visible thru the ports and probably wouldn't yield a 0psi reading, but a low one for two faces.

good luck...(BTW a stuck side seal, would only effect 1 face)

good luck...(BTW a stuck side seal, would only effect 1 face)

Ah crap, I screwed up the name on the topic. I meant stuck corner seal. That's what I wrote in the dissertation up above.

You're right of course, side seal = one face. I had one of those hosed up before.

Of course it's too late to edit the topic now... DOH!

#7

Rotary Enthusiast

I had almost the same symptoms as you and it was bad corner seal.

Who rebuilt your motor and what supplier did they use for the seals?

A bunch of engines, including mine, that were rebuilt last spring suffered from stuck corner seals. Apparently the corner seal manufacturer made changes without letting anyone know and the new design is defective resulting is stuck seals after 500-3000 miles.

My engine builder had all three engines he used these seals in fail (although mine was the first to go and is now almost done with the first of three warranty rebuilds he has to do... poor guy)

My builder says many other builders had the same problem he did.

Apparently the old design of the seals was stronger than stock and good for a engine used on the track but the new design is defective.

Everyone is now just rebuilding with stock corner seals.

Talk to your engine builder. Maybe he'll be as nice as mine was and rebuild you for free.

Who rebuilt your motor and what supplier did they use for the seals?

A bunch of engines, including mine, that were rebuilt last spring suffered from stuck corner seals. Apparently the corner seal manufacturer made changes without letting anyone know and the new design is defective resulting is stuck seals after 500-3000 miles.

My engine builder had all three engines he used these seals in fail (although mine was the first to go and is now almost done with the first of three warranty rebuilds he has to do... poor guy)

My builder says many other builders had the same problem he did.

Apparently the old design of the seals was stronger than stock and good for a engine used on the track but the new design is defective.

Everyone is now just rebuilding with stock corner seals.

Talk to your engine builder. Maybe he'll be as nice as mine was and rebuild you for free.

Last edited by John Magnuson; 08-22-06 at 06:50 PM.

Trending Topics

#10

Very interesting. My motor was built in March of 2005... Is that about when you are talking about?

He used the stock mazda 3mm corner seals as far as I know. I will ask to make sure though.

I'm having a hard time figuring out what you mean by this.... Do you mean the new design was better or worse?

Thanks for the info.

He used the stock mazda 3mm corner seals as far as I know. I will ask to make sure though.

Apparently the old design of the seals was stronger than stock and good for a engine used on the track but the new design is defective.

Thanks for the info.

Originally Posted by John Magnuson

I had almost the same symptoms as you and it was bad corner seal.

Who rebuilt your motor and what supplier did they use for the seals?

A bunch of engines, including mine, that were rebuilt last spring suffered from stuck corner seals. Apparently the corner seal manufacturer made changes without letting anyone know and the new design is defective resulting is stuck seals after 500-3000 miles.

My engine builder had all three engines he used these seals in fail (although mine was the first to go and is now almost done with the first of three warranty rebuilds he has to do... poor guy)

My builder says many other builders had the same problem he did.

Apparently the old design of the seals was stronger than stock and good for a engine used on the track but the new design is defective.

Everyone is now just rebuilding with stock corner seals.

Talk to your engine builder. Maybe he'll be as nice as mine was and rebuild you for free.

Who rebuilt your motor and what supplier did they use for the seals?

A bunch of engines, including mine, that were rebuilt last spring suffered from stuck corner seals. Apparently the corner seal manufacturer made changes without letting anyone know and the new design is defective resulting is stuck seals after 500-3000 miles.

My engine builder had all three engines he used these seals in fail (although mine was the first to go and is now almost done with the first of three warranty rebuilds he has to do... poor guy)

My builder says many other builders had the same problem he did.

Apparently the old design of the seals was stronger than stock and good for a engine used on the track but the new design is defective.

Everyone is now just rebuilding with stock corner seals.

Talk to your engine builder. Maybe he'll be as nice as mine was and rebuild you for free.

#11

Rotary Enthusiast

Originally Posted by GooRoo

Very interesting. My motor was built in March of 2005... Is that about when you are talking about?

The defective corner seals were an aftermarket product that many engine builders were using for years with good results before the manufacturer changed them.

#12

Ah ok. I'm pretty sure I had stock Mazda ones. Thanks for the info though. Maybe it will help someone else who reads the thread.

Originally Posted by John Magnuson

No, the defective seals were in winter and spring of 2006. So the defective seal problem is probably not it.

The defective corner seals were an aftermarket product that many engine builders were using for years with good results before the manufacturer changed them.

The defective corner seals were an aftermarket product that many engine builders were using for years with good results before the manufacturer changed them.

#13

Originally Posted by GooRoo

I agree with your analysis, but wouldn't that be inconsistent with the behavior that I experienced? By that I mean that there was no specific event where the motor operation changed, it was a slow decline, with intermittent reversions to mostly nominal.

When your apex seal split, was there any scoring on the housing at all?

When your apex seal split, was there any scoring on the housing at all?

I did end up with a big score in the housing and a worn spot in the side housing. I actually lost a small chunk off the end of one seal that snagged another seal which split. No damage was apparent looking through the exhaust ports and a compression test showed something like 90-40-40 if I remember right. The split seal still sealed ok.

Hopefully it turns out to just be a corner seal, but 25 seems pretty low pressure to be that small of a compression leak. If it were me I would probably just play it safe and pull the motor.

#14

My 50 cents on this is that if a seal broke as happened with Tommy (Tom93R1), it is already likely that you have scored the rotor housing. However, if it is just a stuck seal and it can be freed with MMO, what have you lost. On the other hand, maybe you're one of the lucky ones not to have sustained damage yet to the housing and cracking the motor now will save a housing. By the way, Tommy's motor broke after a very recent rebuild, so it is entirely possible that that is what happened with yours. I was there when he broke down the motor and there was nothing evident from the exhaust port of the problem.

#15

Yeah, 25 is really low. I was using a 'rigged' piston tester, but I know I had 110-115 in the front rotor not that long ago (2500 miles) and this test is showing 95ish, so if you scale that up the 25 would be closer to 40ish. Really, I wasn't paying much attention to the absolute numbers, all I wanted to see was how even they were, and how they compared between rotors.

I will say this, we looked in the exhaust port closely again last night and there was nothing at all on any part of the rotor, housing or iron that we could see.

I went with seafoam, and if that doesn't work I'll try MMO. If it doesn't work tonight, I'm probably going to give up and pull the motor regardless. I have a bunch of other things I'd like to change anyway. I have another event the week of the 15th (NASA Nationals) that I would try to have everything working by.

I will say this, we looked in the exhaust port closely again last night and there was nothing at all on any part of the rotor, housing or iron that we could see.

I went with seafoam, and if that doesn't work I'll try MMO. If it doesn't work tonight, I'm probably going to give up and pull the motor regardless. I have a bunch of other things I'd like to change anyway. I have another event the week of the 15th (NASA Nationals) that I would try to have everything working by.

Originally Posted by Tom93R1

I did end up with a big score in the housing and a worn spot in the side housing. I actually lost a small chunk off the end of one seal that snagged another seal which split. No damage was apparent looking through the exhaust ports and a compression test showed something like 90-40-40 if I remember right. The split seal still sealed ok.

Hopefully it turns out to just be a corner seal, but 25 seems pretty low pressure to be that small of a compression leak. If it were me I would probably just play it safe and pull the motor.

Hopefully it turns out to just be a corner seal, but 25 seems pretty low pressure to be that small of a compression leak. If it were me I would probably just play it safe and pull the motor.

#16

Yep, that's pretty much it. I filled it up last night and rotated it every 30 minutes for 2 hours last night, and then left it with the bad apex in the soup. I'll try firing it up tonight and see what happens.

Mine isn't a super recent rebuild, I've had it running about 14 months. I did have a bad side seal right away though, so the motor has been opened once already.

Mine isn't a super recent rebuild, I've had it running about 14 months. I did have a bad side seal right away though, so the motor has been opened once already.

Originally Posted by jd to rescue

My 50 cents on this is that if a seal broke as happened with Tommy (Tom93R1), it is already likely that you have scored the rotor housing. However, if it is just a stuck seal and it can be freed with MMO, what have you lost. On the other hand, maybe you're one of the lucky ones not to have sustained damage yet to the housing and cracking the motor now will save a housing. By the way, Tommy's motor broke after a very recent rebuild, so it is entirely possible that that is what happened with yours. I was there when he broke down the motor and there was nothing evident from the exhaust port of the problem.

#17

Just an update, I ran the car a bit, same issue, even after soaking. Also the oil catch can filled up really quickly when I went under boost, so it might be a side seal(s) issue.

Will continue to update the thread with pics etc when I pull the motor. I have another event in 2.5 weeks, so I'm going to try to finish it up by then.

Will continue to update the thread with pics etc when I pull the motor. I have another event in 2.5 weeks, so I'm going to try to finish it up by then.

#18

Yeah, let us know. I am in the midst of rebuilding an S4 motor to put in a project car I hope to take club racing eventually. I am trying to learn as much as possible about what is and is not adviseable in making power for the track. So I'll be interested in what you find.

2.5 weeks to do a rebuild!! Let's hope you don't need a rotor housing.

2.5 weeks to do a rebuild!! Let's hope you don't need a rotor housing.

#19

Original Gangster/Rotary!

iTrader: (213)

With the help of my friend Ihor (rotary experiment seven), I rebuilt my engine in less than 36 hours in a garage with no lift back in 2002, right before my deployment. It is possible to do it one weekend

#20

Well, I have more info to report, we pulled the motor and last night Damian cracked it for me.

Looked good until we picked up the rear rotor. There was 5 issues. One, a corner seal was stuck. Two, the side seal adjacent to it was stuck and broken. Three, the side seal adjacent to that was also stuck and broken. Four, the inner O-ring was mashed. Five, there's two issues with the port on the center housing, one is that it looks like the seals hit the port trailing edge and beat it up a little bit, and the other is that it almost looks like the port is cracked through on the runner.

The rotor housing looks fine, and the rear iron is also fine.

That brings up all sorts of scenarios that could have been the cause. I'm basically just going to check every part (coils/injectors/etc etc to make sure they are fine, but I need to get the parts ASAP if I still want to make the event in 2 weeks.

If I expect to make NASA nationals, I need to get the replacement parts tomorrow or Saturday. The sideseals/springs are stock, so those are no big deal, but if anybody knows the Mazdacomp part numbers for the 3mm solid corner seals and springs, please PM/email me. I ordered what I think is the correct part from Mazdacomp, I looked on this page on Mazdatrix but all I see is the part number for 'All Early (OEM pre-'76) (for 3mm apex seals)' which may be correct, but I'm not sure. I contacted my engine builder separately, but he's busy, and I don't have time to wait. So if anybody knows that these are the ones, again PM/post here please.

Ok, so, for the o-ring issue, there is a scratch, about 1cm in length, and .1-.2mm deep directly in line with the o-ring. I'm assuming I can just polish/sand that one out and put a new o-ring and it will be fine?

Two is the rotor slots for the side seals are a little dinged up in a couple spots. I'm assuming I can just open those back up a little so that the seal can go in and out of the groove without binding? Is there anything else to worry about there?

Third the corner that had the stuck seal is a little dinged up, mainly from the side seal impacting the corner seal. I would think that I can just polish that out as well and make sure that the seal moves freely in the hole?

Finally the two port issues, it looks like there's a hit on the trailing edge of the port, presumably from the side seal's broken edge. I'm thinking I can just polish that out so there's nothing for the side seal to catch as it sweeps by? The second issue with the crack I'm unsure about. Should it be really smooth in there, or might there be something to worry about if there's a black line in the port area? I can feel there's a depression in the casting, but I'm not sure if that is normal or not?

I can get pics of all these issues when I have a minute to take/post them.

Thanks for the help/advice.

Looked good until we picked up the rear rotor. There was 5 issues. One, a corner seal was stuck. Two, the side seal adjacent to it was stuck and broken. Three, the side seal adjacent to that was also stuck and broken. Four, the inner O-ring was mashed. Five, there's two issues with the port on the center housing, one is that it looks like the seals hit the port trailing edge and beat it up a little bit, and the other is that it almost looks like the port is cracked through on the runner.

The rotor housing looks fine, and the rear iron is also fine.

That brings up all sorts of scenarios that could have been the cause. I'm basically just going to check every part (coils/injectors/etc etc to make sure they are fine, but I need to get the parts ASAP if I still want to make the event in 2 weeks.

If I expect to make NASA nationals, I need to get the replacement parts tomorrow or Saturday. The sideseals/springs are stock, so those are no big deal, but if anybody knows the Mazdacomp part numbers for the 3mm solid corner seals and springs, please PM/email me. I ordered what I think is the correct part from Mazdacomp, I looked on this page on Mazdatrix but all I see is the part number for 'All Early (OEM pre-'76) (for 3mm apex seals)' which may be correct, but I'm not sure. I contacted my engine builder separately, but he's busy, and I don't have time to wait. So if anybody knows that these are the ones, again PM/post here please.

Ok, so, for the o-ring issue, there is a scratch, about 1cm in length, and .1-.2mm deep directly in line with the o-ring. I'm assuming I can just polish/sand that one out and put a new o-ring and it will be fine?

Two is the rotor slots for the side seals are a little dinged up in a couple spots. I'm assuming I can just open those back up a little so that the seal can go in and out of the groove without binding? Is there anything else to worry about there?

Third the corner that had the stuck seal is a little dinged up, mainly from the side seal impacting the corner seal. I would think that I can just polish that out as well and make sure that the seal moves freely in the hole?

Finally the two port issues, it looks like there's a hit on the trailing edge of the port, presumably from the side seal's broken edge. I'm thinking I can just polish that out so there's nothing for the side seal to catch as it sweeps by? The second issue with the crack I'm unsure about. Should it be really smooth in there, or might there be something to worry about if there's a black line in the port area? I can feel there's a depression in the casting, but I'm not sure if that is normal or not?

I can get pics of all these issues when I have a minute to take/post them.

Thanks for the help/advice.

#21

Got some pics of the damage...

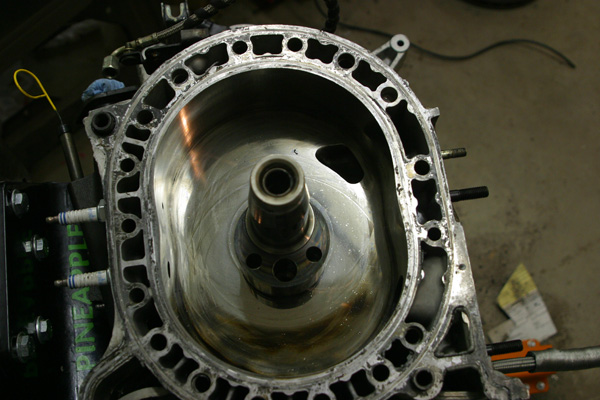

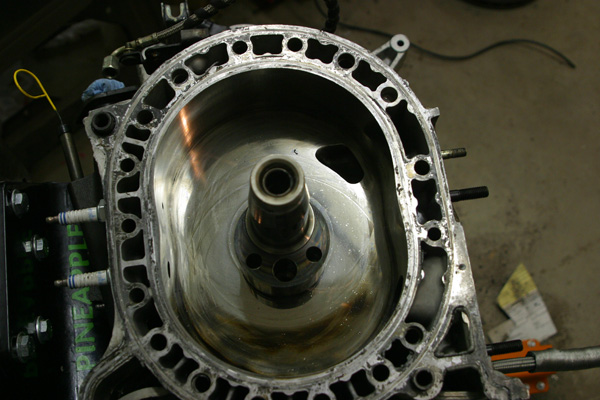

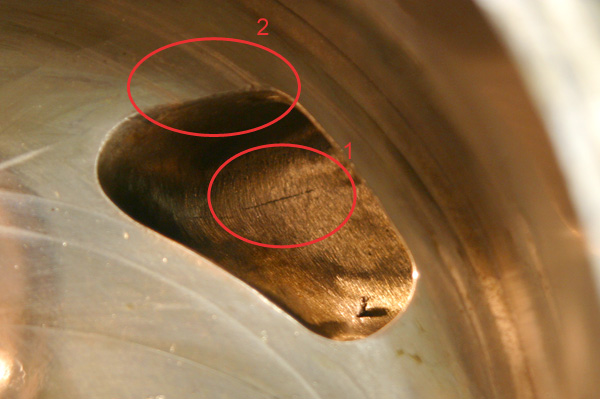

1) Overview of the rear rotor

Full Size Pic

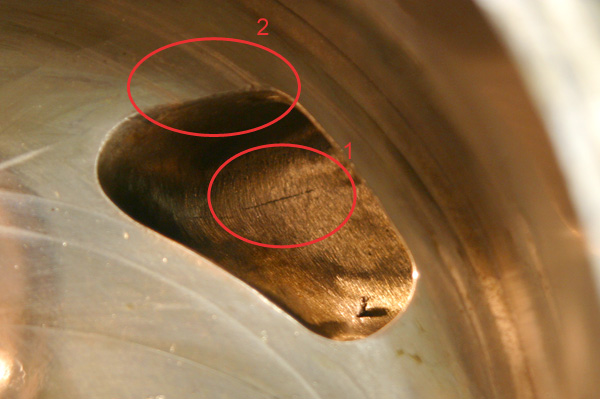

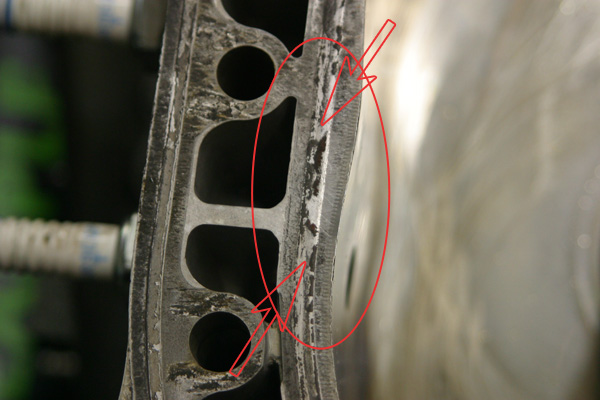

2) Port Issues

Full Size Pic

Issue 1 you can see is what looks like a hairline crack. Motor builder says this is probably just a remnant of the porting process and nothing to be worried about. I can't imagine this happened while the motor was installed, so I'm inclined to believe him. Update: I just found this pic: http://www.dekoning.net/images/rx7/s...s/IMG_7099.JPG

which shows the same line. So that I'm going to ignore.

Issue 2 is the slight marks you can see leading away from the port trailing edge. Probably caused by the broken side seals. I'm going to try to clean up the port edge, but the marks will have to stay. Over time I'm guessing they will be worn away.

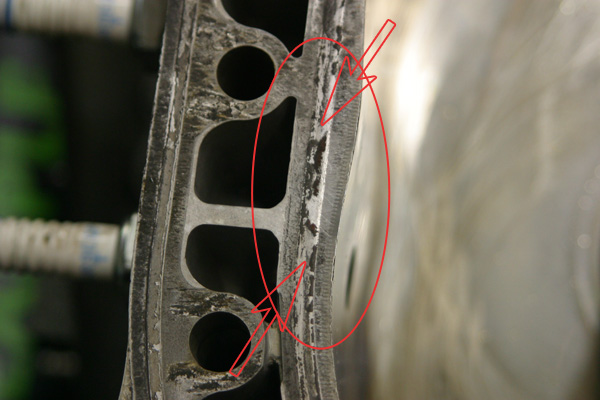

3) Water Seal Issue

Full Size Pic

If you look closely, you can see the mark from the seal imbetween the two edges of where the iron mates with the housing. However the line stops at the point of the arrows. This is where the o-ring was deformed. It was aparently still sealing, but there is a small dent there that I'm going to work out, and I bought a replacement o-ring.

1) Overview of the rear rotor

Full Size Pic

2) Port Issues

Full Size Pic

Issue 1 you can see is what looks like a hairline crack. Motor builder says this is probably just a remnant of the porting process and nothing to be worried about. I can't imagine this happened while the motor was installed, so I'm inclined to believe him. Update: I just found this pic: http://www.dekoning.net/images/rx7/s...s/IMG_7099.JPG

which shows the same line. So that I'm going to ignore.

Issue 2 is the slight marks you can see leading away from the port trailing edge. Probably caused by the broken side seals. I'm going to try to clean up the port edge, but the marks will have to stay. Over time I'm guessing they will be worn away.

3) Water Seal Issue

Full Size Pic

If you look closely, you can see the mark from the seal imbetween the two edges of where the iron mates with the housing. However the line stops at the point of the arrows. This is where the o-ring was deformed. It was aparently still sealing, but there is a small dent there that I'm going to work out, and I bought a replacement o-ring.

#22

edit; just saw your latest post. EEK.

edit2: why is there RTV where the irons meet the housings? he used RTV to hold the freakin water orings in???

i know you're supposed to use RTV to seal up where the dowels and legs are to hold oil in, but i've never seen anybody RTV around the entire block......

edit2: why is there RTV where the irons meet the housings? he used RTV to hold the freakin water orings in???

i know you're supposed to use RTV to seal up where the dowels and legs are to hold oil in, but i've never seen anybody RTV around the entire block......

Last edited by jacobcartmill; 09-01-06 at 06:38 PM.

#23

Original Gangster/Rotary!

iTrader: (213)

GooRoo,

regarding #2 of the port issues, one way to avoid this is to bevel/smooth out the sharp edge to make it less harsh and give a more gradual transition for the side seal which is sliding over that portion of the intake port.

regarding the coolant o-rings, ideally hylomar should be used. I have heard of silicone being used in some cases with no ill effects but it's not something I would use.

question, what is that in the lower right hand corner of the intake port? a small piece of silicone from the engine disassembly?

also, did you just buy one coolant o-ring? I have always bought new ones for each rebuild.

Rich

regarding #2 of the port issues, one way to avoid this is to bevel/smooth out the sharp edge to make it less harsh and give a more gradual transition for the side seal which is sliding over that portion of the intake port.

regarding the coolant o-rings, ideally hylomar should be used. I have heard of silicone being used in some cases with no ill effects but it's not something I would use.

question, what is that in the lower right hand corner of the intake port? a small piece of silicone from the engine disassembly?

also, did you just buy one coolant o-ring? I have always bought new ones for each rebuild.

Rich

#24

Full Member

iTrader: (1)

Join Date: Mar 2001

Location: Newark, CA, USA

Posts: 213

Likes: 0

Received 0 Likes

on

0 Posts

...I would put it back together first and run a gallon or so of water thru the intake vacuum lines and steam out most of the carbon build up first before trying the seafoam or MMO...

This is what I did after first trying the over night trans fluid trick ....and it finally freed up a stuck corner seal that I had...although it was not as bad as yours..it was more like 105,75,75...this actually brang it up to something like 110,95,95 and it wasn't until I added premix and ran it full throttle on the freeway a few times that it finally freed up completely. This was on a motor that was also running too rich, then sat for a couple years.

This is what I did after first trying the over night trans fluid trick ....and it finally freed up a stuck corner seal that I had...although it was not as bad as yours..it was more like 105,75,75...this actually brang it up to something like 110,95,95 and it wasn't until I added premix and ran it full throttle on the freeway a few times that it finally freed up completely. This was on a motor that was also running too rich, then sat for a couple years.