Lightweight rotors=less torque?!

#76

Originally Posted by TT_Rex_7

It's not like im playing a hit and miss game here. I have specific software that aids in the strength after being machined down or while designing something that we use for military, and bridgeston/firestone work. I'm not doing this to the motor I currently have in my car, i'm just buying a used motor to tinker with. Not to be cocky, but I dont dick around with jobs, I get them done, and I get them done the right way the first time. Granted I've never machined ANY automotive parts in my life, but I'm positive with the aid of knowledgable people about this subject and my shop, it can get done right. It might sound silly to some and not to others, I'm just doing it in spare time to keep myself occupied. There has been several cars in japan that have had the rotor faces and pockets machined. Theres a guy here in the US that can lighten rotors, but alot of tuners havn't done that either so that doesn't really say anything. All that says is its damn expensive for someone that can't do it themselves. if I recall right there are specific coating treatments on the rotors, anyone know where I can look them up or does anyone know off hand what the coatings are so I can check into who can do them in my area. I really appreciate everyones help and responces and Daryls also as soon as he responds to my e-mail lol.

-Alex

-Alex

Dave

#77

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by dgeesaman

Even with FEA and knowledgeable engineers, I still think you're going to have a hard time improving on Mazda's R&D. It may be enlightening to investigate the design of the Renesis rotors.

Dave

Dave

-Alex

#78

Rotary Enthusiast

Originally Posted by TT_Rex_7

It would atleast create more power though correct, since its allowing more air to be put in the motor? If machining the face/pocket will not effect displacement then what could be done to create a larger displacement short of changing eccentric shaft offset for obvious reasons?

-Alex

-Alex

in theory, increased dish will allow more power as you suspected, but not by more displacement.

Assuming peak compression pressure of the charge is limted to xx psi by knock, a deep dish and resulting lower CR allows a higher boost level to hit xx psi at say tdc. More boost at same displacement means more power. The deeper dish may also improve flame front activity, which allows xx psi limit to be raised ... allowing even more boost and power. The larger pocket with higher boost will also deliver torque deeper into the power cycle, as the chamber expands.

Unless your aids are very talented in fea, specifically transient heat transfer, dynamics, and related stress runs on a complex casting, with a lot of unknowns, I would not stray far from existing mazda rotor designs, as others have cautioned.

Lower CR for an FD has a lot more useful hp/torque potential then risky rotor weight savings that only show up in first few gears (as I stated pg 2)

#79

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by KevinK2

as I said on pg 2, deeper pocket does not change disp't. displacement is directly proportional to the eccentic radius, the rotor radius (center to apex seal contact), and the chamber width. thats it. actual value is 3 x e x Ap, where Ap is projected area of a face ... apex seal to apex seal.

in theory, increased dish will allow more power as you suspected, but not by more displacement.

Assuming peak compression pressure of the charge is limted to xx psi by knock, a deep dish and resulting lower CR allows a higher boost level to hit xx psi at say tdc. More boost at same displacement means more power. The deeper dish may also improve flame front activity, which allows xx psi limit to be raised ... allowing even more boost and power. The larger pocket with higher boost will also deliver torque deeper into the power cycle, as the chamber expands.

Unless your aids are very talented in fea, specifically transient heat transfer, dynamics, and related stress runs on a complex casting, with a lot of unknowns, I would not stray far from existing mazda rotor designs, as others have cautioned.

Lower CR for an FD has a lot more useful hp/torque potential then risky rotor weight savings that only show up in first few gears (as I stated pg 2)

in theory, increased dish will allow more power as you suspected, but not by more displacement.

Assuming peak compression pressure of the charge is limted to xx psi by knock, a deep dish and resulting lower CR allows a higher boost level to hit xx psi at say tdc. More boost at same displacement means more power. The deeper dish may also improve flame front activity, which allows xx psi limit to be raised ... allowing even more boost and power. The larger pocket with higher boost will also deliver torque deeper into the power cycle, as the chamber expands.

Unless your aids are very talented in fea, specifically transient heat transfer, dynamics, and related stress runs on a complex casting, with a lot of unknowns, I would not stray far from existing mazda rotor designs, as others have cautioned.

Lower CR for an FD has a lot more useful hp/torque potential then risky rotor weight savings that only show up in first few gears (as I stated pg 2)

Anywho though, as far as the complications you've stated with altering the pockets into a new design, that would just be the beginning and I'm not going to waste that kind of money/time and what not on an idea. So as far as straying away into the unknowns, I don't plan on doing that.

I'm not sure if you read my last post but would be curious to know your opinion. Altering the face pockets to the pervious designs isn't really changing mazdas designs. If I can modify them to the older style rotors on the 86-88 I really dont see any complications within reason. I'm not looking into lightening the rotors for extra power nor do I think anyone is.

As far as completly altering the pockets to whatever, it was simply an idea brought up and was questioned for facts.

-Alex

#80

Rotary Enthusiast

Originally Posted by edmcguirk

There is one big difference between reciprocating angines and rotary engines. The reciprocating engine has to stop and start the weight of rods and pistons every revolution and that work is directly subtracted from torque/HP. That loss starts small at low RPM but increases at the square of the RPM (or is it cubed?).....

Most of work done to accelerate the recipricating mass is gained back during deceleration as the inertial load helps turn the crank.

#81

Rotary Enthusiast

Originally Posted by turbojeff

Your wrong here Jim.

Torque available at the axles is NOT the reason you accelerate much more slowly in 4th gear than you do it 1st.

Look at your own "losses" graph and see that there is a dramtically increasing drag force, [I]that[I] is why you accelerate much more slowly in 4th vs. 1st. Weight/rolling resistance increases roughly linearly.

HP is what moves the car. Torque does not move anything. POWER moves things.

Like I said, torque at the rear wheels is less in the higher gears, HP available at the wheels doesn't change much at higher speeds.

Torque available at the axles is NOT the reason you accelerate much more slowly in 4th gear than you do it 1st.

Look at your own "losses" graph and see that there is a dramtically increasing drag force, [I]that[I] is why you accelerate much more slowly in 4th vs. 1st. Weight/rolling resistance increases roughly linearly.

HP is what moves the car. Torque does not move anything. POWER moves things.

Like I said, torque at the rear wheels is less in the higher gears, HP available at the wheels doesn't change much at higher speeds.

as you know hp=ft*lbs/sec, it also equals an applied force at some velocity, or lbs * ft/sec. you also know f=ma for inertial acceleration.

hp= f x v

hp= m x a x v

so if you have a constant hp available, the faster you are going, the slower you will be able to accelerate, even with no wind drag.

Last edited by KevinK2; 12-28-04 at 01:48 AM.

#82

Rotary Enthusiast

Originally Posted by jimlab

....If we converted torque at the axles to horsepower at the axles, you'd still see the same drop in POWER in higher gears.

This is not true. Hp at the axles will not drop with higher gears, as the torque (or force) curves do. ie for say 5k rpm, 2x wheel speed begets 1/2 wheel torque, for same hp.

What you do get if you plot hp vs mph, instead of wheel torque, is the same exact shift points at the intersections. My excel ss has both type curves.

#83

Super Snuggles

Originally Posted by KevinK2

This is not true. Hp at the axles will not drop with higher gears, as the torque (or force) curves do. ie for say 5k rpm, 2x wheel speed begets 1/2 wheel torque, for same hp.

What you do get if you plot hp vs mph, instead of wheel torque, is the same exact shift points at the intersections. My excel ss has both type curves.

#84

Senior Member

Join Date: Jul 2003

Location: Wayne, NJ 07470

Posts: 416

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by KevinK2

then Jimlab better put his rotary back in .... not.

Most of work done to accelerate the recipricating mass is gained back during deceleration as the inertial load helps turn the crank.

Most of work done to accelerate the recipricating mass is gained back during deceleration as the inertial load helps turn the crank.

I got stresses and power loss confused.

#85

Alex,

Mazda engineers have been working for decades to develop a rotor that will provide optimal power and durability. While you may be able to reduce weight, it is likely that there will be a significant sacrifice elsewhere. It appears that the lightened rotors produced by Daryl are for racing applications. Those parts are going to be put in race engines with very short lifespans. They are not expected to last very long.

My recommendation would be for you to obtain rotors from as many different "generations" of the 13b as possible, including the RX8 rotors. Measure, and weigh all of them. This would allow you to see what Mazda has done to improve the design, and drop weight. I think it would be very helpful. Who knows, maybe you will design the next lightweight (and durable) rotor for them

Mazda engineers have been working for decades to develop a rotor that will provide optimal power and durability. While you may be able to reduce weight, it is likely that there will be a significant sacrifice elsewhere. It appears that the lightened rotors produced by Daryl are for racing applications. Those parts are going to be put in race engines with very short lifespans. They are not expected to last very long.

My recommendation would be for you to obtain rotors from as many different "generations" of the 13b as possible, including the RX8 rotors. Measure, and weigh all of them. This would allow you to see what Mazda has done to improve the design, and drop weight. I think it would be very helpful. Who knows, maybe you will design the next lightweight (and durable) rotor for them

#86

Rotary Enthusiast

looks like only real advantage for light rotors is for high rpm use or extending the redline ... less e-shaft flex.

Rotor inertia is based on mass center .6" off spin axis, at shaft rpm, and rotor spinning at 1/3 shaft rpms. assuming 12.5 lbs rotors, with mass distributed like a 5" dia cylinder, the total wk^2 inertia for the rotors is about 61 lb-in^2, mostly from rotor spinning at 1/3 shaft speed. This is only 15% of the stock flywheel, which I measured at 413 lb-in^2.

Note stock pressure plate assembly was about 50% of the stock fw inertia. Rotors are a very small part of the total rotating assembly that drives the rear axle.

Rotor inertia is based on mass center .6" off spin axis, at shaft rpm, and rotor spinning at 1/3 shaft rpms. assuming 12.5 lbs rotors, with mass distributed like a 5" dia cylinder, the total wk^2 inertia for the rotors is about 61 lb-in^2, mostly from rotor spinning at 1/3 shaft speed. This is only 15% of the stock flywheel, which I measured at 413 lb-in^2.

Note stock pressure plate assembly was about 50% of the stock fw inertia. Rotors are a very small part of the total rotating assembly that drives the rear axle.

#87

Super Snuggles

Originally Posted by adam c

My recommendation would be for you to obtain rotors from as many different "generations" of the 13b as possible, including the RX8 rotors. Measure, and weigh all of them.

http://www.mazdatrix.com/faq/rotorwgt.htm

The only 13B rotor not on the chart is the Renesis, but from the published statements that an 11-14% (depending on who you believe) decrease in rotor weight was achieved, we can deduce that the Renesis rotors (10.0:1) weigh about 8.2-8.5 lbs. If it were possible to machine the Renesis rotors to drop the compression ratio to ~9.0:1, you might have something.

However, removing material from rotors is one thing, but re-balancing them afterward is another. That's why people pay others for the service.

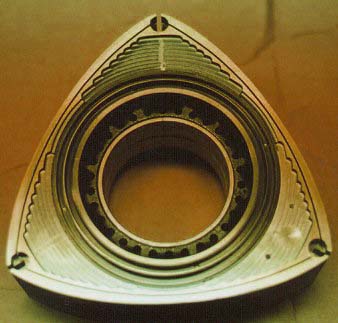

Here are a few pictures of lightened rotors...

#88

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by jimlab

The only 13B rotor not on the chart is the Renesis, but from the published statements that an 11-14% (depending on who you believe) decrease in rotor weight was achieved, we can deduce that the Renesis rotors (10.0:1) weigh about 8.2-8.5 lbs. If it were possible to machine the Renesis rotors to drop the compression ratio to ~9.0:1, you might have something.

-Alex

#89

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Well I looked up prices on the rotor assembly on the rx8 and the prices really arnt that bad...about $420 bux for each rotor. Quite interesting, if anyone knows if it will work in our motors, then i'll def. be ordering them.

-Alex

-Alex

#90

Originally Posted by jimlab

All 13B rotors must be of the same overall dimensions or they wouldn't work in a 13B housing, and the weighing has already been done for us.

I was referring to a detailed group of measurements to see what small changes have been made over the years. While the overall outer dimensions will be the same, the design of the face of the rotors has changed. In addition, the internal configuration has likely changed to a more efficient shape. I believe that it would be useful to cut open these different rotors, and take note of the internal differences.

#91

Super Snuggles

Originally Posted by adam c

I was referring to a detailed group of measurements to see what small changes have been made over the years. While the overall outer dimensions will be the same, the design of the face of the rotors has changed. In addition, the internal configuration has likely changed to a more efficient shape. I believe that it would be useful to cut open these different rotors, and take note of the internal differences.

Short of finding out if the lighter Renesis rotors can be machined for lower compression and will work with the 13B-REW stationary gears and eccentric shaft, there's no further research to be done, because there's no possible benefit. We know that the '93-'95 rotors were the lightest until the Renesis, so we can rule out all previous 13B rotors. We know that the '93-'95 rotors had 9.0:1 compression, so we know that any rotor that replaces them should be the same or lower. You either make the '93-'95 rotors lighter, change the Renesis rotors to 9.0:1 compression, or you give it up and spend your time and money elsewhere.

#92

I wouldn't do it

However, Alex seems bound and determined to pursue this project. Its very unlikely, but not impossible, that he will come up with anything useful. Doing research on past rotor design would be a good way for him to see how the design has changed and improved over the years. At some point "someone" will design an improvement to the RX8 rotor. We just don't know who will do it, or how long it will take.

However, Alex seems bound and determined to pursue this project. Its very unlikely, but not impossible, that he will come up with anything useful. Doing research on past rotor design would be a good way for him to see how the design has changed and improved over the years. At some point "someone" will design an improvement to the RX8 rotor. We just don't know who will do it, or how long it will take.

#93

There's nothing wrong with having high compression rotors. People have been using the S4 NA rotors with REW's for years to increase compression. People have also used Turbo II rotors to lower compression and run more boost on pump gas and lower the chance of detonation.

#94

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by adam c

I wouldn't do it

However, Alex seems bound and determined to pursue this project. Its very unlikely, but not impossible, that he will come up with anything useful. Doing research on past rotor design would be a good way for him to see how the design has changed and improved over the years. At some point "someone" will design an improvement to the RX8 rotor. We just don't know who will do it, or how long it will take.

However, Alex seems bound and determined to pursue this project. Its very unlikely, but not impossible, that he will come up with anything useful. Doing research on past rotor design would be a good way for him to see how the design has changed and improved over the years. At some point "someone" will design an improvement to the RX8 rotor. We just don't know who will do it, or how long it will take.

What I had brought up earlier was taking the rotors from 93-95 and machining the pockets to the same specs as the 86-88 turbo rotors for the lower compression to run more boost on pump gas. That would give 1 lower compression and 2 less weight. Or I can buy the renisis rotor and machine down pocket to the same as the 93-95 with the same benefits. Only problem with the renesis rotors is its unsure if they will work. But at 420 bux its not that huge of an investment, if it fails, i'll make it into a nice base for a lamp of some sort lol. The only thing left is to find someone that has their motor torn down already to fit it in there and see if it will work. Anyone up for that?!

If it will not work in the 13b-rew i'll go back to machining the rotors that originally came in it.

If it will not work in the 13b-rew i'll go back to machining the rotors that originally came in it.-Alex

#95

$420 ea right?

You might do a little research on rotor faces denting. It is my experience, and Jim's pics show that the material removed for lightening purposes is not removed from the rotor face, rather the side of the rotor.

I'd section a few junk rotors before you machine the pocket on a good one. YOu might end up with a very thin section on combustion face of the newer rotors if you cut a deeper pocket.

IIRC Max Cooper had some pics of dented rotors from his motor.

You might do a little research on rotor faces denting. It is my experience, and Jim's pics show that the material removed for lightening purposes is not removed from the rotor face, rather the side of the rotor.

I'd section a few junk rotors before you machine the pocket on a good one. YOu might end up with a very thin section on combustion face of the newer rotors if you cut a deeper pocket.

IIRC Max Cooper had some pics of dented rotors from his motor.

#96

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by turbojeff

$420 ea right?

You might do a little research on rotor faces denting. It is my experience, and Jim's pics show that the material removed for lightening purposes is not removed from the rotor face, rather the side of the rotor.

I'd section a few junk rotors before you machine the pocket on a good one. YOu might end up with a very thin section on combustion face of the newer rotors if you cut a deeper pocket.

IIRC Max Cooper had some pics of dented rotors from his motor.

You might do a little research on rotor faces denting. It is my experience, and Jim's pics show that the material removed for lightening purposes is not removed from the rotor face, rather the side of the rotor.

I'd section a few junk rotors before you machine the pocket on a good one. YOu might end up with a very thin section on combustion face of the newer rotors if you cut a deeper pocket.

IIRC Max Cooper had some pics of dented rotors from his motor.

-Alex

#98

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

So then it shouldn't effect anything but the compression ratio if I was to machine the pocket wider and not go any deeper? Obviously if theres not really enough material to go deeper, only option is to make the pocket wider in all directions to get rid of the material for a lower compression.

-Alex

-Alex

#99

Rotary Enthusiast

Thread Starter

Join Date: Jun 2004

Location: Gallatin, TN

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Does anyone by any chance have a bum 93-95 rotor laying around that they are willing to sell or anything so I can get some measurements of the pockets?

-Alex

-Alex

#100

Rotary Enthusiast

http://www.mazdatrix.com/faq/cutaways.htm

they have a rotor pic in the rx8 section.

wonder if the cut rotor in link has a core hole along the pocket side, as suggested by image?

dropping rx8 rrotor from 10:1 to 9:1, for example, would require 1.1 in^3 removed per face, for about .9 lb total per rotor. Thats a lot off just the pocket sides.

This would be about a 7.5 lb rotor, vs 9.5 for the FD. e-shaft with c'weights would require dynamic rebalancing.

hope it works for you .... only logical benefit would be potential higher rev limit, as fw is better place to drop 4 lbs of rotating weight for less drivetrain rotational inertia.

they have a rotor pic in the rx8 section.

wonder if the cut rotor in link has a core hole along the pocket side, as suggested by image?

dropping rx8 rrotor from 10:1 to 9:1, for example, would require 1.1 in^3 removed per face, for about .9 lb total per rotor. Thats a lot off just the pocket sides.

This would be about a 7.5 lb rotor, vs 9.5 for the FD. e-shaft with c'weights would require dynamic rebalancing.

hope it works for you .... only logical benefit would be potential higher rev limit, as fw is better place to drop 4 lbs of rotating weight for less drivetrain rotational inertia.