How To: Dual Fuel Pump Wiring With Pump Fail Indicator Lights

#29

Make an assessment...

iTrader: (3)

I was wondering if it would be OK to use circuit breakers like these instead of fuses? I can't see why it wouldn't, but maybe there's something I'm not thinking about.

Also, I picked up the same type of relays and connectors that you used, but the ones I got seemed really cheap and the connectors were hard to press on and get off, so I got these Hella relays and connectors to use instead since they seemed to be higher quality...

http://www.amazon.com/HELLA-00779430...ds=hella+relay

http://www.amazon.com/HELLA-H8470900...xgy_auto_img_y

...the only problem is that the back side of the connector doesn't really allow for removing one of the wires to solder in the extra wire. Is there another way I can wire it to achieve the same results? I was planning on splicing it but I'm a little confused on this. I've never been a fan of wiring and schematics or diagrams. Any help would be appreciated. Oh, and to be clear, I'm trying to wire them together according to the first iteration, because I don't yet have pressure sensors to wire in, but I'd like to add those someday.

*******

Also, I picked up the same type of relays and connectors that you used, but the ones I got seemed really cheap and the connectors were hard to press on and get off, so I got these Hella relays and connectors to use instead since they seemed to be higher quality...

http://www.amazon.com/HELLA-00779430...ds=hella+relay

http://www.amazon.com/HELLA-H8470900...xgy_auto_img_y

...the only problem is that the back side of the connector doesn't really allow for removing one of the wires to solder in the extra wire. Is there another way I can wire it to achieve the same results? I was planning on splicing it but I'm a little confused on this. I've never been a fan of wiring and schematics or diagrams. Any help would be appreciated. Oh, and to be clear, I'm trying to wire them together according to the first iteration, because I don't yet have pressure sensors to wire in, but I'd like to add those someday.

*******

#31

Make an assessment...

iTrader: (3)

I followed the dual pressure sensor diagram (second schematic in post #12) and I finally got to the point of trying to start the car after my rebuild. I initially had a lot of fuel leaks at the filters/check valves/pressure sensors due to a bad fitting and not having some of the fittings cranked down, but once I got all that sorted out I ran into some other issues.

First, I had an unrelated problem with the car cranking slow, but we got that sorted out. While we were working on that, during slow cranking I noticed the indicator lights were going crazy. The light for pump 1 was staying on and the light for pump 2 was flickering. However, it's misleading because I was getting pressure to the fuel rails. Maybe I just wasn't getting enough. Another thing I noticed is that my fuel pressure dropped way faster than it used to once the pumps weren't on anymore. The fuel pressure used to take about an hour or so to drop to 0psi at the fuel rails, and now it's down in about 5-10 minutes. The only thing I changed from the stock setup was I flared the stock hardlines and put AN fittings on them and ran -6 line from the hardline to the return fitting on the fuel hanger. So I don't think that would make that much of a difference.

The car wouldn't start unless we sprayed starting fluid in, and it would die right away, so we figured the injectors might not be opening, even though I just had them cleaned and flow tested a few months ago at ID and they were good. We swapped from the Adaptronic Select that I haven't run on yet to the old PFC that I was using before. After this we noticed that I'm not getting any power to the pumps at all, and the indicator lights are off also. I checked to make sure I was getting 12v from the battery to the relays and I am, but I don't think I'm getting anything from the white/red stock wire. Looking at the schematic, it looks like that would keep the lights from turning on and also the pumps, since they're not being told to. But maybe I'm reading this wrong. Is that correct?

I'm leaving country soon and I'd like to drive this thing at least once in 2014 lol.

First, I had an unrelated problem with the car cranking slow, but we got that sorted out. While we were working on that, during slow cranking I noticed the indicator lights were going crazy. The light for pump 1 was staying on and the light for pump 2 was flickering. However, it's misleading because I was getting pressure to the fuel rails. Maybe I just wasn't getting enough. Another thing I noticed is that my fuel pressure dropped way faster than it used to once the pumps weren't on anymore. The fuel pressure used to take about an hour or so to drop to 0psi at the fuel rails, and now it's down in about 5-10 minutes. The only thing I changed from the stock setup was I flared the stock hardlines and put AN fittings on them and ran -6 line from the hardline to the return fitting on the fuel hanger. So I don't think that would make that much of a difference.

The car wouldn't start unless we sprayed starting fluid in, and it would die right away, so we figured the injectors might not be opening, even though I just had them cleaned and flow tested a few months ago at ID and they were good. We swapped from the Adaptronic Select that I haven't run on yet to the old PFC that I was using before. After this we noticed that I'm not getting any power to the pumps at all, and the indicator lights are off also. I checked to make sure I was getting 12v from the battery to the relays and I am, but I don't think I'm getting anything from the white/red stock wire. Looking at the schematic, it looks like that would keep the lights from turning on and also the pumps, since they're not being told to. But maybe I'm reading this wrong. Is that correct?

I'm leaving country soon and I'd like to drive this thing at least once in 2014 lol.

#32

Make an assessment...

iTrader: (3)

If I jump f/p to gnd in the diagnostic box I get fuel pressure, and it starts and runs on that.

And the slow cranking problem seems to be back.

Also, the lights stay on with fuel pressure, and go off when you touch the wires together. Relays 3&4 were also clicking a lot at first but that went away.

And the slow cranking problem seems to be back.

Also, the lights stay on with fuel pressure, and go off when you touch the wires together. Relays 3&4 were also clicking a lot at first but that went away.

#33

Did you do the bypass the resistor that controls the stock fuel pump speed? I can't remember if I mentioned that in this write up or not. I'm wondering if that is what is causing your problem since the signal that used to control the stock fuel pump is now being used to turn on the 12V relays. Sometimes relays can be finicky when the voltage is low. As far as the fuel pressure bleeding off quickly, if you didn't manage to get all of the debris out of your new lines from when you cut them, you may have some injectors that are semi clogged, and unable to close completely which would allow the pressure to bleed off.

Just a few ideas.

Just a few ideas.

#34

Make an assessment...

iTrader: (3)

I tried a couple different things. I tried jumping the high speed relay and the connector to the fuel pump resistor. I swapped the Adaptronic back in and it fixed the fuel issue. I guess it was just something with the Power FC.

I still have the issue with the fuel pressure dropping, with the indicator light flashing (but I figured that one out I think), and relays three and four clicking. I swapped the wires on the pressure sensors and the problem went to the other light, so whatever the problem is, it's with the pressure sensor. I looked in the instructions that came with it and it says it's adjustable to what pressure you want it to activate. I wonder if it's adjustable enough to make the light go off until pressure drops. If not, I might need to get different ones. For the fuel pressure dropping, I really hope debris in the lines and clogged injectors is not the case lol.

I also discovered a couple new problems. The wideband and EGT gauges shut off while cranking, and oil is spraying from one of the engine mount bolts and spraying onto the turbo manifold.

We're still working with the fuel map but we're getting closer to getting it started.

I still have the issue with the fuel pressure dropping, with the indicator light flashing (but I figured that one out I think), and relays three and four clicking. I swapped the wires on the pressure sensors and the problem went to the other light, so whatever the problem is, it's with the pressure sensor. I looked in the instructions that came with it and it says it's adjustable to what pressure you want it to activate. I wonder if it's adjustable enough to make the light go off until pressure drops. If not, I might need to get different ones. For the fuel pressure dropping, I really hope debris in the lines and clogged injectors is not the case lol.

I also discovered a couple new problems. The wideband and EGT gauges shut off while cranking, and oil is spraying from one of the engine mount bolts and spraying onto the turbo manifold.

We're still working with the fuel map but we're getting closer to getting it started.

#35

You will definitely need to adjust the pressure sensors. I haven't done this myself, but here are the steps that I would take to adjust them properly. Someone else may have a better idea, but this is how I would approach it. Since I haven't actually been through this myself as of yet, I may be missing something. I'm sorry I can't give you more absolute advice...

1. Look at the documentation that came with the pressure sensors to figure out which way to turn the adjustment screw in order to increase or decrease the setting.

2. Set your pressure on your regulator to where you're base fuel pressure should be.

3. You'll need to determine what your lowest normal/acceptable pressure is. I'm not an expert on this part, so maybe someone else may want to chime in, but I would think it would be as simple as finding a hill to drive down, down shifting a gear, and letting the engine "brake" the car without applying any throttle. I think this will give you your largest (smallest depending on how you look at it) vacuum reading. Take note of your fuel pressure at the given vacuum.

4. While idling the engine, adjust your fuel pressure regulator to give you the same pressure that was noted in the previous step.

5. Starting with the low fuel pressure light on, adjust the pressure sensors until the light just goes out for each pump.

6. Return the fuel pressure regulator to the proper base fuel pressure at idle & you should be good to go.

1. Look at the documentation that came with the pressure sensors to figure out which way to turn the adjustment screw in order to increase or decrease the setting.

2. Set your pressure on your regulator to where you're base fuel pressure should be.

3. You'll need to determine what your lowest normal/acceptable pressure is. I'm not an expert on this part, so maybe someone else may want to chime in, but I would think it would be as simple as finding a hill to drive down, down shifting a gear, and letting the engine "brake" the car without applying any throttle. I think this will give you your largest (smallest depending on how you look at it) vacuum reading. Take note of your fuel pressure at the given vacuum.

4. While idling the engine, adjust your fuel pressure regulator to give you the same pressure that was noted in the previous step.

5. Starting with the low fuel pressure light on, adjust the pressure sensors until the light just goes out for each pump.

6. Return the fuel pressure regulator to the proper base fuel pressure at idle & you should be good to go.

#36

Make an assessment...

iTrader: (3)

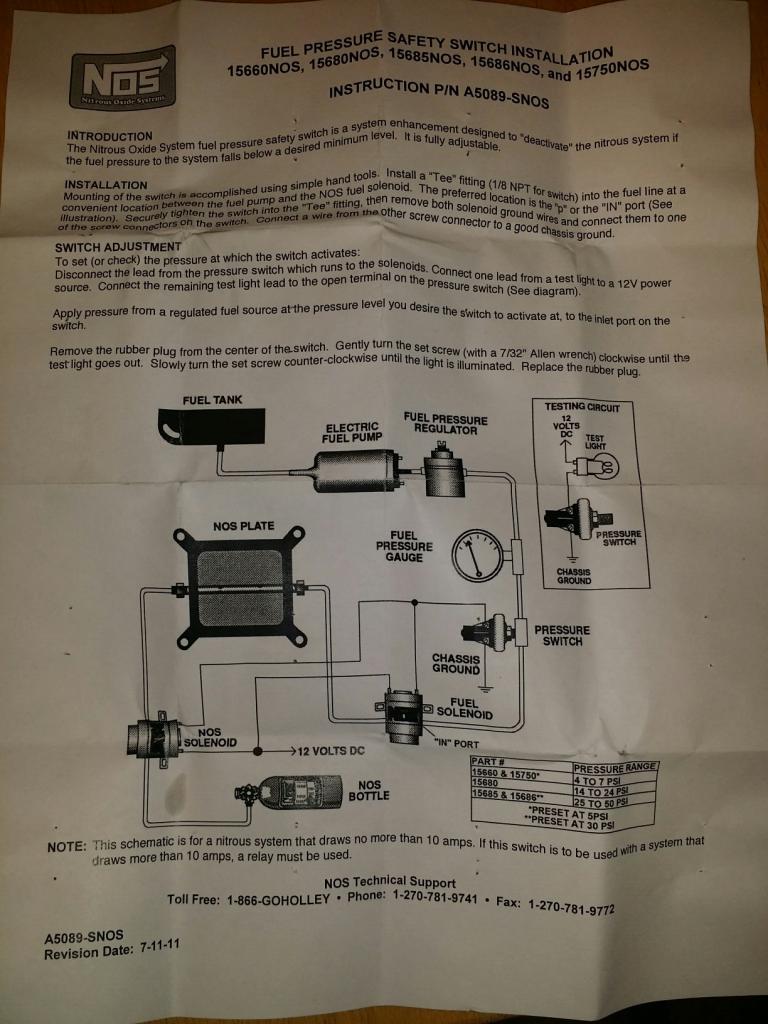

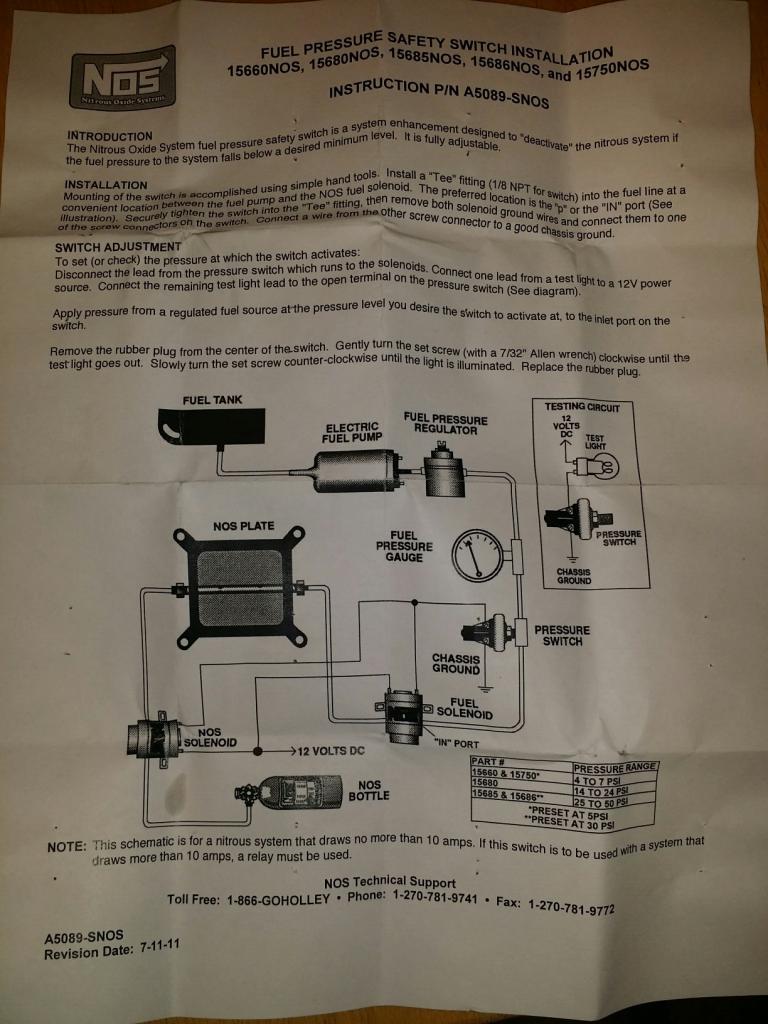

I wanted to go back and edit my post to add this pic, but it wouldn't let me, so here it is.

Will those steps work, though? I've been under the impression that the light will stay on until pressure is lost. I removed the wires from the sensor and the light didn't go out until I touched them together. So I would think the light stays on while the sensor is open, but once it closes the light goes off. I want it the opposite way.

Or maybe I'm not understanding your steps lol.

It just won't work the way it is now because the lights will stay on until I lose pressure, but if I lose power to the pumps the lights will...stay on lol. So if I lose power to the pumps the light will be on, at the same time it would be off because I lost fuel pressure.

I'll still try your steps, but I have to get it on the road first lol.

Will those steps work, though? I've been under the impression that the light will stay on until pressure is lost. I removed the wires from the sensor and the light didn't go out until I touched them together. So I would think the light stays on while the sensor is open, but once it closes the light goes off. I want it the opposite way.

Or maybe I'm not understanding your steps lol.

It just won't work the way it is now because the lights will stay on until I lose pressure, but if I lose power to the pumps the lights will...stay on lol. So if I lose power to the pumps the light will be on, at the same time it would be off because I lost fuel pressure.

I'll still try your steps, but I have to get it on the road first lol.

#37

The circuit is designed to use a normally open/held closed pressure switch, which I'm pretty sure is what you got.

When you have fuel pressure, the contacts on the pressure switches close which energizes relays 3 & 4. When those relays energize, the normally closed contacts (between 30 & 87a in the diagram) open which turns the light off. This way you're not driving around with a light on on your dash. If you lose fuel pressure, or if you lose power to the pump, the light will turn on indicating a problem with that pump. So in short, the LED should be off when everything is operating normally.

I looked up the PNs on the sheet that you attached, and they all appear to be the correct type of pressure switch, although some have too low of a pressure range. Which P/N did you get, is it the 15685 or 15686?

Try turning the adjustment screw on the switches counter-clockwise until the LEDs go out. Note that the test light in the diagram that you posted will operate exactly opposite of the LEDs in the circuit diagram you are using from post #12 (2nd schematic) due to the way relays 3 & 4 are wired in. If you turn them fully counter clockwise and the light is still on, then you may want to double check that your LEDs are actually wired to terminal 87a on relays 3 & 4 and not terminal 87.

When you have fuel pressure, the contacts on the pressure switches close which energizes relays 3 & 4. When those relays energize, the normally closed contacts (between 30 & 87a in the diagram) open which turns the light off. This way you're not driving around with a light on on your dash. If you lose fuel pressure, or if you lose power to the pump, the light will turn on indicating a problem with that pump. So in short, the LED should be off when everything is operating normally.

I looked up the PNs on the sheet that you attached, and they all appear to be the correct type of pressure switch, although some have too low of a pressure range. Which P/N did you get, is it the 15685 or 15686?

Try turning the adjustment screw on the switches counter-clockwise until the LEDs go out. Note that the test light in the diagram that you posted will operate exactly opposite of the LEDs in the circuit diagram you are using from post #12 (2nd schematic) due to the way relays 3 & 4 are wired in. If you turn them fully counter clockwise and the light is still on, then you may want to double check that your LEDs are actually wired to terminal 87a on relays 3 & 4 and not terminal 87.

#38

Make an assessment...

iTrader: (3)

After looking at the schematic more I understood how it worked, but I still thought maybe I should have gotten normally closed sensors. The part number on the ones I got is 15685, so I got the right ones.

I adjusted the fuel pressure sensors and my buddy watched the lights to tell me when they turned off. I tried to test it by taking out the circuit opening (green) relay and cranking the car, but I think by removing the power of the whole system, the results of the test don't mean anything lol. The lights do click on for a split second when you first turn the key to run though, so I guess that's something. I also need to test the power loss to the pumps to make sure the lights come on. Also, by adjusting the sensors, it got rid of the clicking noise from relays three and four. As soon as the lights went off the clicking stopped for the most part. After adjusting them the first time, I turned the ignition over and the light for pump 1 still clicked on a bit, so I adjusted it out a little more. I also tested it by letting the system prime and letting the fuel pressure drop to about 20psi and the lights didn't come on so I was a bit worried about that. I guess we'll see what happens though.

I adjusted the fuel pressure sensors and my buddy watched the lights to tell me when they turned off. I tried to test it by taking out the circuit opening (green) relay and cranking the car, but I think by removing the power of the whole system, the results of the test don't mean anything lol. The lights do click on for a split second when you first turn the key to run though, so I guess that's something. I also need to test the power loss to the pumps to make sure the lights come on. Also, by adjusting the sensors, it got rid of the clicking noise from relays three and four. As soon as the lights went off the clicking stopped for the most part. After adjusting them the first time, I turned the ignition over and the light for pump 1 still clicked on a bit, so I adjusted it out a little more. I also tested it by letting the system prime and letting the fuel pressure drop to about 20psi and the lights didn't come on so I was a bit worried about that. I guess we'll see what happens though.

#39

When you first turn the key to the ACC position, you will see the lights flicker because the power is momentarily cut from the fuel system. However, when you initially start cranking the engine you might see the lights flicker again due to the injectors beginning to function before the pump has had a chance to fully pressurize the system. It sounds like you're on the right track. Maybe you should try priming the system, allow it to bleed down to the point where you want the low pressure lights to illuminate, then adjust the sensors until the lights turn on. Then start the car and see if everything seems stable.

#40

Make an assessment...

iTrader: (3)

Yeah I figured that was probably the case, so I'm hopeful it will work like it's supposed to. The way I have them adjusted right now is where the lights won't flicker while cranking either. Since I'm still having the issue where the fuel pressure drops off quickly, I used that to see at what point the lights would come on. I let it get down to 20psi but they still didn't come on. I'll have to come up with another way. Also, I haven't been able to start the car yet on the new ECU, but I'll test everything when I'm finished.

Also, I was thinking about it yesterday...should I have the check valves right on the end of the pressure sensors, or should I put them in the engine bay right before the two fuel lines go into the Y? That way the fuel doesn't even get a chance to flow back into the line all the way to the rear and it stops it right at the end.

Also, I was thinking about it yesterday...should I have the check valves right on the end of the pressure sensors, or should I put them in the engine bay right before the two fuel lines go into the Y? That way the fuel doesn't even get a chance to flow back into the line all the way to the rear and it stops it right at the end.

#42

Make an assessment...

iTrader: (3)

Ok cool, I'll leave them like they are, then.

We started to do that last night, but the no fuel pressure problem is back so we troubleshot that and ended up confused. I'm not getting power even at the fuel pump resistor, and it's pointing to the green circuit opening relay but we tried three different known good ones and nothing worked. I also removed the relay and jumped it with a wire, that's the only way I get power to the pumps. I'm going to post a separate thread on that so I don't keep gunking up your thread. Sorry.

We started to do that last night, but the no fuel pressure problem is back so we troubleshot that and ended up confused. I'm not getting power even at the fuel pump resistor, and it's pointing to the green circuit opening relay but we tried three different known good ones and nothing worked. I also removed the relay and jumped it with a wire, that's the only way I get power to the pumps. I'm going to post a separate thread on that so I don't keep gunking up your thread. Sorry.

Thread

Thread Starter

Forum

Replies

Last Post

LunchboxSA22

2nd Generation Specific (1986-1992)

37

10-26-15 10:53 AM

immanuel__7

2nd Generation Specific (1986-1992)

89

09-05-15 10:23 AM

befarrer

Microtech

3

08-22-15 05:52 PM