dual digital egt gauges for a dummys.

#1

dual digital egt gauges for a dummys.

I have been looking around and trying to research EGT gauges and how they work. I have read a few threads and guys get very technical on this subject. HOWARD COLEMAN has some good thread on this as well. although i understand 45% of it i need this technical mumbo jumbo broken down to dummy language...

I see some gauges with just one line read out like this one.

and others with a dual read out (assuming it reads both rotor chambers)

elaboration please!!!!!!

I see some gauges with just one line read out like this one.

and others with a dual read out (assuming it reads both rotor chambers)

elaboration please!!!!!!

#2

Alright, let me see if I can clear a couple things up. Let me explain the components of an EGT system (probe, signal, gauge or logging equipment) and what people mean by "fast acting" "response time" or "digital EGT." An "EGT gauge" really consists of a couple things:

1. The probe. These are normally called "K-type thermocouples." There are different places to get these. Some are threaded into a bung, others are installed with a special clamp. There is some level of tradeoff between the response of the instrument and its durability.

There are two types of "response" we deal with regarding EGT systems: response of the probe and response of the instrument. Response of the probe refers to how fast the signal from the probe changes relative to changes in exhaust temperature. So if our exhaust temperature suddenly spikes from 1500F to 2000F, how long until the thermocouple's signal will reflect that? I will discuss response of the actual instrument in a bit.

2. The signal. Your typical K type thermal probe has two wires coming out of it which produces some kind of signal (I'm not too familiar with the details). A lot of actual EGT gauges (the kind you mount in your car) will directly accept this signal. There's often a yellow and red wire.

But there is another type of 'signal' that people use when logging any kind of sensor. It is the 0-5V linear analog signal. So 0 volts could be say 500 degrees and 5 volts would be 2200 degrees, or some other range like that. It's the same way with a TPS: fully closed is close to 0 volts, and fully open is close to 5 volts, and then the signal will vary linearly between the two as the throttle plate opens and closes.

Now here's the deal: whatever signal comes out of a K type thermocouple (EGT probe), it is NOT a 0-5V analog signal. It is this other signal that most datalogging instruments (Power FC Datalogit being the most popular around here) can't accept. So if I want to see a graph of my exhaust temperatures, and my logging equipment can only handle 0-5v inputs, I need to convert the themocouple signal to the 0-5v linear signal.

To do this, we can use something like the FJO signal converter:

the signals from the probes connect to those yellow plugs. Then the FJO box outputs two analog 0-5V signals that can be read by a Datalogit or some other device.

This is NOT the same type of signal that most advertised EGT gauges use. The "dual digital EGT's" most people are talking about are not actual gauges. It refers to converting the thermal probe signal to a loggable analog signal. I hope that clears up some confusion. I currently have the FJO converter box on my car.

3. Gauge. I'm talking about an externally mounted gauge that you would put in your car somewhere. Usually it accepts the signal directly from the thermal probe(s), just like my old autometer. There are single gauges that you can install in a downpipe or dual gauges that you can install on each runner of the exhaust manifold.

Now let's talk about "response" again. Before, I was talking about how quickly the probe can adjust to changes in temperature. Now let's talk about how quickly the gauge can adjust to changes in the signal. On analog gauges, is the needle "lazy" ? Sometimes the gauge is "buffered" so that the needle moves slowly and smoothly. Autometer single EGT gauges are pretty slow responding, and they don't have a high max temperature. I know pineapple racing sells a dual EGT kit with two analog needles. I have used Autometer but I haven't used Pineapple Racing.

Any external gauge with a digital display (like you posted) will also be subject to sample rate issues. How fast can the display update? How many frames per second? Is it like watching a slide show?

Ok that was probably a lot. Just to review: an EGT system all starts with the probe. The probe produces its own signal. That signal can either go right to an externally mounted gauge, or it can go to a signal converter. The externally mounted gauges come in a bunch of varieties (analog or digital display, different max temps). The signal converter will produce a 0-5v output that requires a Datalogit or other logging software to read, but it is very useful for actual self tuning.

1. The probe. These are normally called "K-type thermocouples." There are different places to get these. Some are threaded into a bung, others are installed with a special clamp. There is some level of tradeoff between the response of the instrument and its durability.

There are two types of "response" we deal with regarding EGT systems: response of the probe and response of the instrument. Response of the probe refers to how fast the signal from the probe changes relative to changes in exhaust temperature. So if our exhaust temperature suddenly spikes from 1500F to 2000F, how long until the thermocouple's signal will reflect that? I will discuss response of the actual instrument in a bit.

2. The signal. Your typical K type thermal probe has two wires coming out of it which produces some kind of signal (I'm not too familiar with the details). A lot of actual EGT gauges (the kind you mount in your car) will directly accept this signal. There's often a yellow and red wire.

But there is another type of 'signal' that people use when logging any kind of sensor. It is the 0-5V linear analog signal. So 0 volts could be say 500 degrees and 5 volts would be 2200 degrees, or some other range like that. It's the same way with a TPS: fully closed is close to 0 volts, and fully open is close to 5 volts, and then the signal will vary linearly between the two as the throttle plate opens and closes.

Now here's the deal: whatever signal comes out of a K type thermocouple (EGT probe), it is NOT a 0-5V analog signal. It is this other signal that most datalogging instruments (Power FC Datalogit being the most popular around here) can't accept. So if I want to see a graph of my exhaust temperatures, and my logging equipment can only handle 0-5v inputs, I need to convert the themocouple signal to the 0-5v linear signal.

To do this, we can use something like the FJO signal converter:

the signals from the probes connect to those yellow plugs. Then the FJO box outputs two analog 0-5V signals that can be read by a Datalogit or some other device.

This is NOT the same type of signal that most advertised EGT gauges use. The "dual digital EGT's" most people are talking about are not actual gauges. It refers to converting the thermal probe signal to a loggable analog signal. I hope that clears up some confusion. I currently have the FJO converter box on my car.

3. Gauge. I'm talking about an externally mounted gauge that you would put in your car somewhere. Usually it accepts the signal directly from the thermal probe(s), just like my old autometer. There are single gauges that you can install in a downpipe or dual gauges that you can install on each runner of the exhaust manifold.

Now let's talk about "response" again. Before, I was talking about how quickly the probe can adjust to changes in temperature. Now let's talk about how quickly the gauge can adjust to changes in the signal. On analog gauges, is the needle "lazy" ? Sometimes the gauge is "buffered" so that the needle moves slowly and smoothly. Autometer single EGT gauges are pretty slow responding, and they don't have a high max temperature. I know pineapple racing sells a dual EGT kit with two analog needles. I have used Autometer but I haven't used Pineapple Racing.

Any external gauge with a digital display (like you posted) will also be subject to sample rate issues. How fast can the display update? How many frames per second? Is it like watching a slide show?

Ok that was probably a lot. Just to review: an EGT system all starts with the probe. The probe produces its own signal. That signal can either go right to an externally mounted gauge, or it can go to a signal converter. The externally mounted gauges come in a bunch of varieties (analog or digital display, different max temps). The signal converter will produce a 0-5v output that requires a Datalogit or other logging software to read, but it is very useful for actual self tuning.

#3

so basically i can run dual probes on each runner (fast acting probes= k probes) and monitor them in my PFC via FJO translator box for accurate readings and still run a single "autometer digital egt gauge" off ether probe? Being that the autometer gauge is digital it will update temp numbers faster than the needle gauges?

what is your exact EGT setup?

what is your exact EGT setup?

#4

Turd Ferguson

iTrader: (1)

Join Date: Jul 2006

Location: Sherman Oaks, California

Posts: 2,047

Likes: 0

Received 1 Like

on

1 Post

I would just emphasize that digital is late too. Digital information is late in the amount of time it takes a device to convert the voltage pulsations to digital (AD Converter).

Whether or not the digital autometer is any faster really depends on the gauge's conversion speed,refresh rate and any buffering to make the readout smooth. I'd guess it's just pretty pretty.

I don't think you'd want to use the gauge in tuning due to the increased potential for any number of latency issues.

Whether or not the digital autometer is any faster really depends on the gauge's conversion speed,refresh rate and any buffering to make the readout smooth. I'd guess it's just pretty pretty.

I don't think you'd want to use the gauge in tuning due to the increased potential for any number of latency issues.

#5

i see that you when with this set up.

2x EGT Probes

http://tscsensors.com/egtep0720001ssnexhau.html

2372°F

200milisecond response time

2x Digital Gauges with ability to route to 5v logger

http://tscsensors.com/pmdrd0000000ao0anal.html

Analog retransmission output (to Data Logger)

Visible high temperature alarm LED

Display Peak Hold Button

2 Weld in Stainless Steel Sensor Bungs

http://tscsensors.com/bngad0000000180.html

did you install it?

2x EGT Probes

http://tscsensors.com/egtep0720001ssnexhau.html

2372°F

200milisecond response time

2x Digital Gauges with ability to route to 5v logger

http://tscsensors.com/pmdrd0000000ao0anal.html

Analog retransmission output (to Data Logger)

Visible high temperature alarm LED

Display Peak Hold Button

2 Weld in Stainless Steel Sensor Bungs

http://tscsensors.com/bngad0000000180.html

did you install it?

#6

Turd Ferguson

iTrader: (1)

Join Date: Jul 2006

Location: Sherman Oaks, California

Posts: 2,047

Likes: 0

Received 1 Like

on

1 Post

I just realized that your Autometer picture is a kit of some sort. The problem with a kit is that rotaries run VERY hot compared to piston engines which a kit is likely to be built around.

You'd want to make sure that:

1) the EGT probes can run up to 2000 degrees (you shouldn't reach that on a rotary but you'll be within 500degrees of it).

2) That the probes are very fast in responding. In the 200-300 millisecond range.

----------------------------

EDIT: HA! That's what i just posted. I haven't installed it yet. Still got to get the manifold over to my welder. I didn't purchase the gauge or the converter yet since the car isn't currently running. The probes and 2 bungs were ~124.00 shipped . Converters will be another 80?

I couldn't find a price for the FJO converter. Horsepowerfreaks.com supposedly sells them (they have a picture of the box) but I couldn't figure out the cost on it. It's probably the better way to go b/c of the company reputation.

Howard Coleman, I believe, runs these as converters:

http://www.simplecircuitboards.com/S...le%20Board.pdf

You'd want to make sure that:

1) the EGT probes can run up to 2000 degrees (you shouldn't reach that on a rotary but you'll be within 500degrees of it).

2) That the probes are very fast in responding. In the 200-300 millisecond range.

----------------------------

EDIT: HA! That's what i just posted. I haven't installed it yet. Still got to get the manifold over to my welder. I didn't purchase the gauge or the converter yet since the car isn't currently running. The probes and 2 bungs were ~124.00 shipped . Converters will be another 80?

I couldn't find a price for the FJO converter. Horsepowerfreaks.com supposedly sells them (they have a picture of the box) but I couldn't figure out the cost on it. It's probably the better way to go b/c of the company reputation.

Howard Coleman, I believe, runs these as converters:

http://www.simplecircuitboards.com/S...le%20Board.pdf

Trending Topics

#8

You know, I said in my previous post that the dual EGT gauge is very useful for tuning. I dunno, I think I'm still on the fence about that. For example, my engine is peaking at over 1700F preturbo (rear rotor). Some say that's too hot, but I haven't had any real problems and haven't changed anything as a result of those readings. I think I looked at the EGT readings at first, then I was like "ok that's cool" and didn't bother with it much after that. And then I burnt out my probes and so far haven't replaced them because I have had other priorities.

Now some have mentioned that you can use the dual gauges to tell whether your EGT's are too cool during spool up. But if you are not comfortable acting on that and advancing the timing, then how useful was that EGT gauge really?

Now some have mentioned that you can use the dual gauges to tell whether your EGT's are too cool during spool up. But if you are not comfortable acting on that and advancing the timing, then how useful was that EGT gauge really?

#9

Racing Rotary Since 1983

iTrader: (6)

it is always great to see another EGT thread. thanks all for contributing.

as mentioned, you have the probe which puts out a tiny signal that get amplified by some sort of converter box. at that point it can go to an analog gauge or remain digital and be logged thru the Datalogit of something similar.

IMO a gauge is only modestly useful. if you are going to use the EGT readings to tune you need to be able to LOG them.

can you imagine tuning your map w an analog gauge that referenced Ms of injector ontime?

you need to look at your EGT in each of the 400 PFC tuning cells. for instance, most reference EGTs at the top of their RPM.

nothing wrong w that but you also need to reference EGTs from zero to one bar boost. by tuning to 1400 F in this area you will gain turbo spool. it will generally be working w your timing in this area. there is alot to gain and you won't get it w a gauge.

generally EGTs rise w RPM often due to backpressure. ideally you want them stable from 6000 up. i would say that i would prefer not to see 1700....

howard

as mentioned, you have the probe which puts out a tiny signal that get amplified by some sort of converter box. at that point it can go to an analog gauge or remain digital and be logged thru the Datalogit of something similar.

IMO a gauge is only modestly useful. if you are going to use the EGT readings to tune you need to be able to LOG them.

can you imagine tuning your map w an analog gauge that referenced Ms of injector ontime?

you need to look at your EGT in each of the 400 PFC tuning cells. for instance, most reference EGTs at the top of their RPM.

nothing wrong w that but you also need to reference EGTs from zero to one bar boost. by tuning to 1400 F in this area you will gain turbo spool. it will generally be working w your timing in this area. there is alot to gain and you won't get it w a gauge.

generally EGTs rise w RPM often due to backpressure. ideally you want them stable from 6000 up. i would say that i would prefer not to see 1700....

howard

#10

You know, I said in my previous post that the dual EGT gauge is very useful for tuning. I dunno, I think I'm still on the fence about that. For example, my engine is peaking at over 1700F preturbo (rear rotor). Some say that's too hot, but I haven't had any real problems and haven't changed anything as a result of those readings. I think I looked at the EGT readings at first, then I was like "ok that's cool" and didn't bother with it much after that. And then I burnt out my probes and so far haven't replaced them because I have had other priorities.

To add more info to this thread, another good thing about multiple probes is you can adjust the injector trims of each injector to even out the combustion temps. The rear rotor runs hotter for two reasons. The rear secondary runner is shorter/straighter and the coolant is hotter by the time it gets back their. On 20b's it's the center rotor that gets hottest. They have straight shot runners in the middle plus combustion heat from both front and rear rotors. The heat difference is one of the main reasons the rear rotor blows 1st on 13b's and center rotor on 20b's. So with multiple probes, you can add more fuel to the individual rotors to compensate for the differences in combustion temps.

#17

Racing Rotary Since 1983

iTrader: (6)

post turbo is.... useless.

depending on your turbo(s) the EGT can vary greatly from the pre to post. i have seen estimates that you have to add 200 F to post turbo but that can be wildly off the mark.

you may not accurately conclude that your preturbo egt is 200 F hotter than post readings.

in addition i have digitally logged pre and post turbo at the same time and find the difference between them swings significantly w throttle position.

you want to know the temp as close to the flange/engine as possible.

hc

depending on your turbo(s) the EGT can vary greatly from the pre to post. i have seen estimates that you have to add 200 F to post turbo but that can be wildly off the mark.

you may not accurately conclude that your preturbo egt is 200 F hotter than post readings.

in addition i have digitally logged pre and post turbo at the same time and find the difference between them swings significantly w throttle position.

you want to know the temp as close to the flange/engine as possible.

hc

#19

Just replied to a much older thread on this topic. I found probes and signal conditioners for a dual setup totaling about $135. See here: https://www.rx7club.com/showpost.php...0&postcount=21

My question is: Where do you install the probes with a stock twins setup? I am guessing drilling and tapping the 1/4 NPT holes into the bottom of the manifold? This would send the probes out into the least congested space for a stock twins setup, no?

My question is: Where do you install the probes with a stock twins setup? I am guessing drilling and tapping the 1/4 NPT holes into the bottom of the manifold? This would send the probes out into the least congested space for a stock twins setup, no?

#20

Sard EGT logging

Hi,

I have my old Sard EGT gauge and at the back it has some extra wire. I look up for the manual and ask Inukai to translate it. (Thanks Inukai)

From the manual it said "Green wiring ; The sensor output (Analog output 0 - 5 V) output resistance 2K ohm"

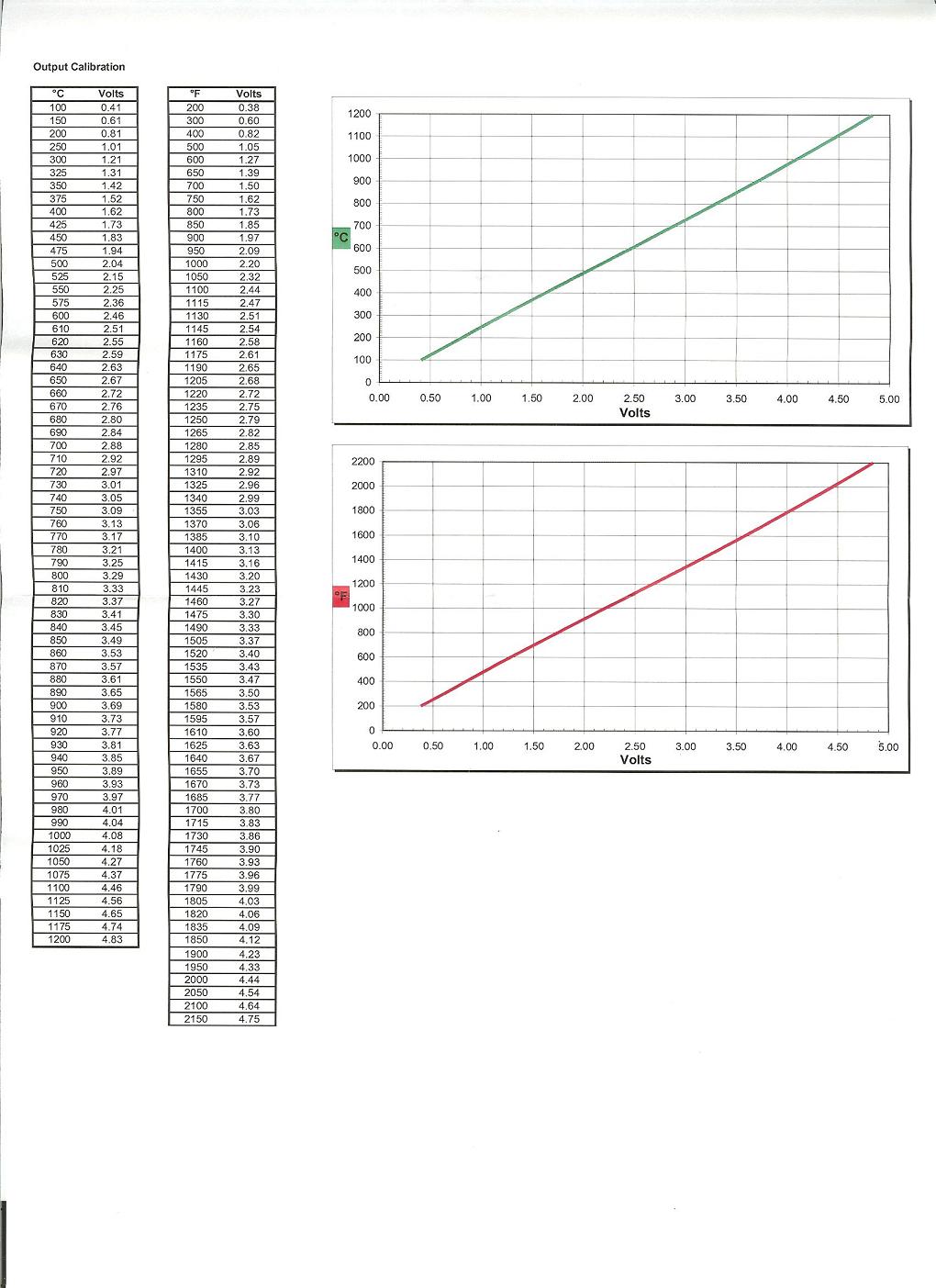

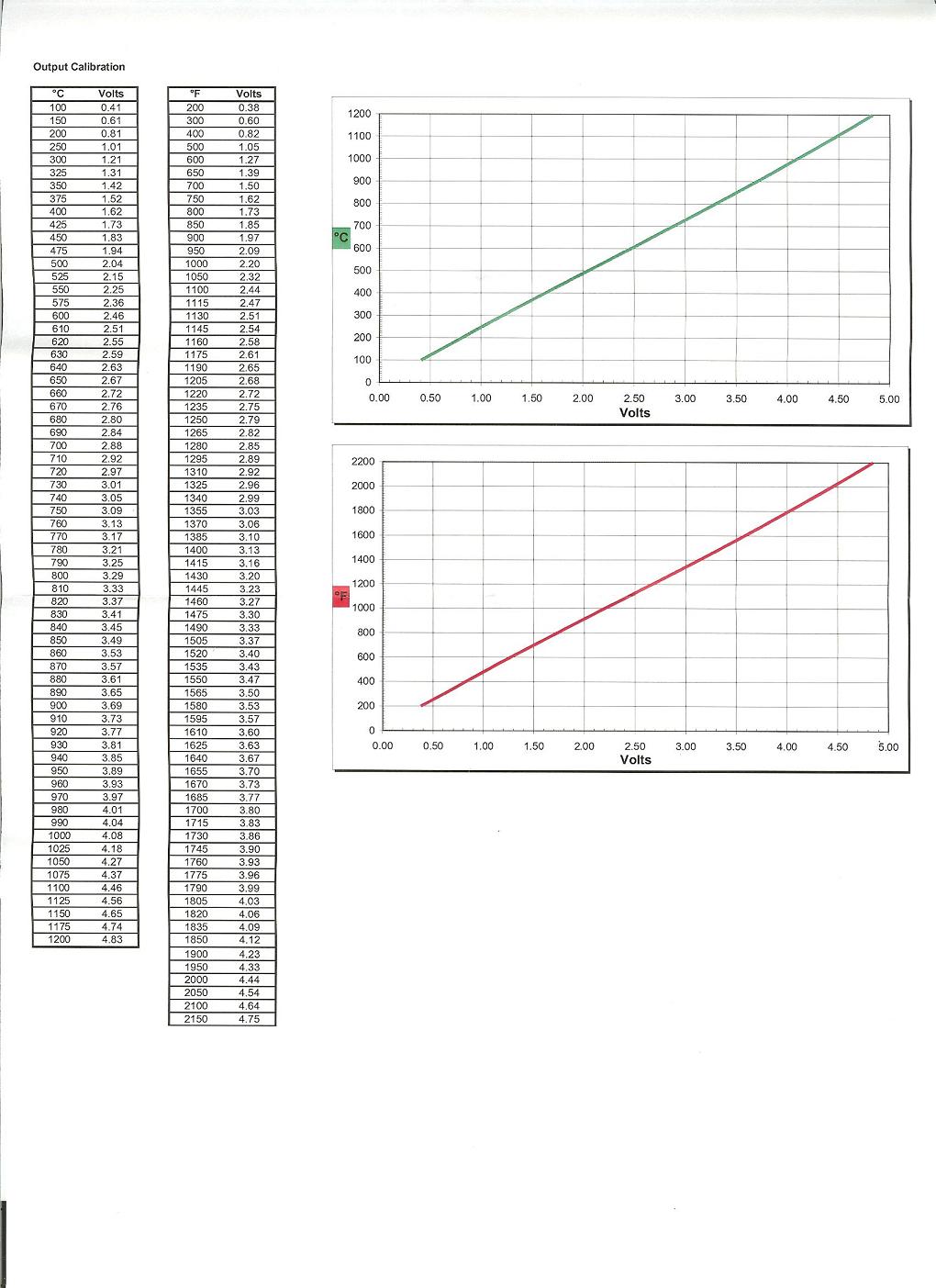

From what I understand I can connect this wire to AN input from the FC-datalogit box and key in value for 0V-200c (min) and 5V-1200c (max).

My question is what is the meaning of "output resistance 2K ohm" from the manual?

Please educate me.

Thanks.

I have my old Sard EGT gauge and at the back it has some extra wire. I look up for the manual and ask Inukai to translate it. (Thanks Inukai)

From the manual it said "Green wiring ; The sensor output (Analog output 0 - 5 V) output resistance 2K ohm"

From what I understand I can connect this wire to AN input from the FC-datalogit box and key in value for 0V-200c (min) and 5V-1200c (max).

My question is what is the meaning of "output resistance 2K ohm" from the manual?

Please educate me.

Thanks.

#21

That is the source resistance (or impedance, if you prefer) present in the output amplifier of the unit and will affect the calibration/scaling of the unit when connected to a low impedance load.

In most cases, the input resistance of the data logger or display device will be >>2k ohms, in which case the affect of the series output resistance will be negligible.

In most cases, the input resistance of the data logger or display device will be >>2k ohms, in which case the affect of the series output resistance will be negligible.

#22

REPU Garage

iTrader: (17)

Join Date: Jun 2007

Location: Northern Colorado

Posts: 623

Likes: 0

Received 0 Likes

on

0 Posts

This is the EGT display I am a fan of :

http://www.exhaustgas.com/ProductDet...sketID=&RepID=

They have it in single and dual probes. The display isn't the sexiest thing ever, but it works fantastically. It reads up to 2,000*F and is VERY fast acting. I can't go back to analog EGT gauges because they all seem to have high latency after using the Koso gauge.

http://www.exhaustgas.com/ProductDet...sketID=&RepID=

They have it in single and dual probes. The display isn't the sexiest thing ever, but it works fantastically. It reads up to 2,000*F and is VERY fast acting. I can't go back to analog EGT gauges because they all seem to have high latency after using the Koso gauge.

#23

That is the source resistance (or impedance, if you prefer) present in the output amplifier of the unit and will affect the calibration/scaling of the unit when connected to a low impedance load.

In most cases, the input resistance of the data logger or display device will be >>2k ohms, in which case the affect of the series output resistance will be negligible.

In most cases, the input resistance of the data logger or display device will be >>2k ohms, in which case the affect of the series output resistance will be negligible.

So, if the input resistance on the AN input fcdatalogit is =>2k ohms , it is ok to connect as is without any affect.

But if <2k ohms, the output range value will be smaller? I must put resistor between the connection? hmm, how do I check the AN input resistance?

Thanks a lot Speed of light.