Cog/Gilmer Belt Drive for FD - Thoughts?

#26

Full Member

Thread Starter

Join Date: Jan 2003

Location: Gardena, CA

Posts: 222

Likes: 0

Received 0 Likes

on

0 Posts

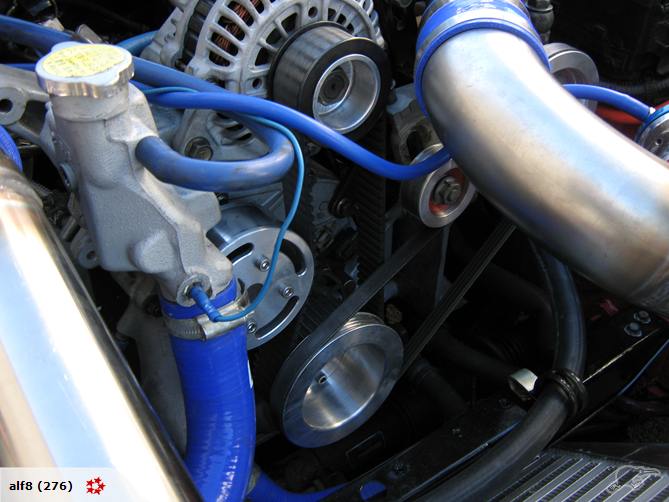

"found a pic of these gilmer kits, NZ$650 "

It's been stated earlier in this thread that it is made by Greene Brothers of NZ.

#27

#29

And there phone number is +64 7 5722710.

If they havnt change it the laste months..

#31

Full Member

Thread Starter

Join Date: Jan 2003

Location: Gardena, CA

Posts: 222

Likes: 0

Received 0 Likes

on

0 Posts

I agree that if someone designed a reversed water pump for the FD, there would probably be more options to eliminate slipping (i.e. a full cog/gilmer belt/pulley kit that includes the waterpump pulley). Who knows..... I believe at this point, that's just wishing for some things that don't exist....

#32

Original Gangster/Rotary!

iTrader: (213)

The bearings were new back when it was built in 2003, with approx. 20k miles use on the engine. This included a few road race days, a trip from TX back to NJ, and three trips to the DGRR event. Probably ran the Dragon about 20 times over those three years, which definitely puts a lot stress on the engine.

All four bearings look amazingly good. For the upcoming customer's build, I wouldn't hesitate to use them again, and we hardly ever do that at the shop. Of course, one rotor looks like a claymore mine detonated in close proximity to it, so that one prolly *won't* be reused

I'd also like to add that there was minimal wear on the iron housings and the rotors had next to no carbon buildup. I love my Idemitsu and Aquamist

#33

cog belts also aren't a good idea on a car that sees any decent amount of mileage. they are really only meant for drag cars. picture what happens when one of the ribs doesn't catch the groove just right while you are sitting in the middle of traffic... yup. now picture trying to find a replacement belt while your car is sitting on the side of the road... yup.

#34

Racecar - Formula 2000

What about all of the cog-belt-driven (timing-belt) camshafts on just about every modern car?

#35

#36

I was at the shop tonight tearing down an engine and remembered to inspect my old stationary gears and engine rotors.

The bearings were new back when it was built in 2003, with approx. 20k miles use on the engine. This included a few road race days, a trip from TX back to NJ, and three trips to the DGRR event. Probably ran the Dragon about 20 times over those three years, which definitely puts a lot stress on the engine.

All four bearings look amazingly good. For the upcoming customer's build, I wouldn't hesitate to use them again, and we hardly ever do that at the shop. Of course, one rotor looks like a claymore mine detonated in close proximity to it, so that one prolly *won't* be reused

I'd also like to add that there was minimal wear on the iron housings and the rotors had next to no carbon buildup. I love my Idemitsu and Aquamist

The bearings were new back when it was built in 2003, with approx. 20k miles use on the engine. This included a few road race days, a trip from TX back to NJ, and three trips to the DGRR event. Probably ran the Dragon about 20 times over those three years, which definitely puts a lot stress on the engine.

All four bearings look amazingly good. For the upcoming customer's build, I wouldn't hesitate to use them again, and we hardly ever do that at the shop. Of course, one rotor looks like a claymore mine detonated in close proximity to it, so that one prolly *won't* be reused

I'd also like to add that there was minimal wear on the iron housings and the rotors had next to no carbon buildup. I love my Idemitsu and Aquamist

#37

Full Member

Join Date: Jul 2006

Location: new zealand

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

#38

Full Member

Thread Starter

Join Date: Jan 2003

Location: Gardena, CA

Posts: 222

Likes: 0

Received 0 Likes

on

0 Posts

#39

#41

Ill put a 8 pack in after

Join Date: Dec 2011

Location: Rotorua, NZ

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

Video FD belt

Hi guys, seem like not many have one of theese. Bout $600 and 4 hours later at home= FD cogged belt drive. Had no probs with W/P or overheating/ slippage. Belt still looks new after 3000km. Trick its dont have to tight... or two loose . very easy to be tempted to make to tight thoughhttp://www.youtube.com/watch?v=93C_y...NFbXIpOUH68d_q

#42

Ill put a 8 pack in after

Join Date: Dec 2011

Location: Rotorua, NZ

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

The pump pulleys are quite a different size than the original ones = more contact area..... so in some ways its a good imoprovemnt for this. altho still small and runs on the back

#43

RX-7 Bad Ass

iTrader: (55)

While the Gilmer drive is pretty impressive looking, I really don't see the problem that it's supposedly fixing. Running a good idler pulley to get better belt contact on the airpump does the trick.

That's just a lot of money to solve a problem that doesn't exist.

Dale

That's just a lot of money to solve a problem that doesn't exist.

Dale

#46

cog belts also aren't a good idea on a car that sees any decent amount of mileage. they are really only meant for drag cars. picture what happens when one of the ribs doesn't catch the groove just right while you are sitting in the middle of traffic... yup. now picture trying to find a replacement belt while your car is sitting on the side of the road... yup.

when most cars have timing belts and drive over 200,000 miles with no issues

when most cars have timing belts and drive over 200,000 miles with no issues

#47

Ill put a 8 pack in after

Join Date: Dec 2011

Location: Rotorua, NZ

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

Supercharger

So you have all seend the super charged v8s around that make a 'whining' sound. Its not the charger its pretty much all the belt... made even louder by the mutiple pulleys and tight bends wide belts.

The air squesing out between the cogs makes that noise. The fd kits are only small belts but defantly make a distinctive whine, mine has very quiet exhaust and can hear it a mile away at revs... just something a little different.

I never had any colling issues, even if was minimal slippage at hard high reves... hard to tell, didint get it to fix a problem as souch, always had v8s and like the noise, makes people turn their heads a bit more.

With this set up I run the delt very loose, maybe 15mm defection in the middle, can twist belt about 90 degrees.

as far as slippage on new belt, the pulley has a little more contact around the circumfrence plus its over twice as wide as standard one....

End note...... user preferance, no slip, looks good, sounds better $600 NZD, chicken feed for cool factor

The air squesing out between the cogs makes that noise. The fd kits are only small belts but defantly make a distinctive whine, mine has very quiet exhaust and can hear it a mile away at revs... just something a little different.

I never had any colling issues, even if was minimal slippage at hard high reves... hard to tell, didint get it to fix a problem as souch, always had v8s and like the noise, makes people turn their heads a bit more.

With this set up I run the delt very loose, maybe 15mm defection in the middle, can twist belt about 90 degrees.

as far as slippage on new belt, the pulley has a little more contact around the circumfrence plus its over twice as wide as standard one....

End note...... user preferance, no slip, looks good, sounds better $600 NZD, chicken feed for cool factor

#49

While the Gilmer drive is pretty impressive looking, I really don't see the problem that it's supposedly fixing. Running a good idler pulley to get better belt contact on the airpump does the trick.

That's just a lot of money to solve a problem that doesn't exist.

Dale

That's just a lot of money to solve a problem that doesn't exist.

Dale

hell, these days it's difficult enough getting those lazy ***** to even special order anything or get any non model specific parts looked up. i get grief even asking for BUR7/9EQ spark plugs because they don't match their database...

/rant off

Last edited by RotaryEvolution; 01-01-12 at 01:33 PM.