NA -> TII knock sensor quesion

#1

I did a s4 na to s5 turbo swap. I'm running no emissions, 3 in straight exhaust, all s4 electronics except for injectors but I bypassed the resistor pack. No air intake temp sensor but it ran the same when I had it.

My car has a really bad hesitation right when I get on the gas, like a good 3 second hesitation. If I'm WOT or at least on it pretty good I don't really feel it but any other time I get it every time I shift and get back on the gas or let off and get back on it.

I keep hearing that pin 2m on the ecu is for the knock sensor but it's different on the na. Also that the s4's have a knock box or something and the s5's have it in the ecu. i have an s4 ecu.

My question is could that be my problem? i searched forever and got mixed feedback. Some said you had to have it, others said you didn't. Some people were saying it can retard the timing if I don't have it. So do I need to get a knock box and sensor or can I bypass it somehow? Or can i just not worry about it and the problem is somewhere else?

I've had this problem ever since I finished the swap 7 months ago and it's getting really old.

My car has a really bad hesitation right when I get on the gas, like a good 3 second hesitation. If I'm WOT or at least on it pretty good I don't really feel it but any other time I get it every time I shift and get back on the gas or let off and get back on it.

I keep hearing that pin 2m on the ecu is for the knock sensor but it's different on the na. Also that the s4's have a knock box or something and the s5's have it in the ecu. i have an s4 ecu.

My question is could that be my problem? i searched forever and got mixed feedback. Some said you had to have it, others said you didn't. Some people were saying it can retard the timing if I don't have it. So do I need to get a knock box and sensor or can I bypass it somehow? Or can i just not worry about it and the problem is somewhere else?

I've had this problem ever since I finished the swap 7 months ago and it's getting really old.

#2

Full Member

iTrader: (4)

Join Date: Apr 2007

Location: Strafford, MO

Posts: 153

Likes: 0

Received 0 Likes

on

0 Posts

Get the knock sensor! Yes it plugs in behind the kick panel (passenger side) above the computer. The s4 na didn't have the same box. I can't remember the exact plug, but it is definitely on the harness, assuming you used the s4 TII harness as well.

#4

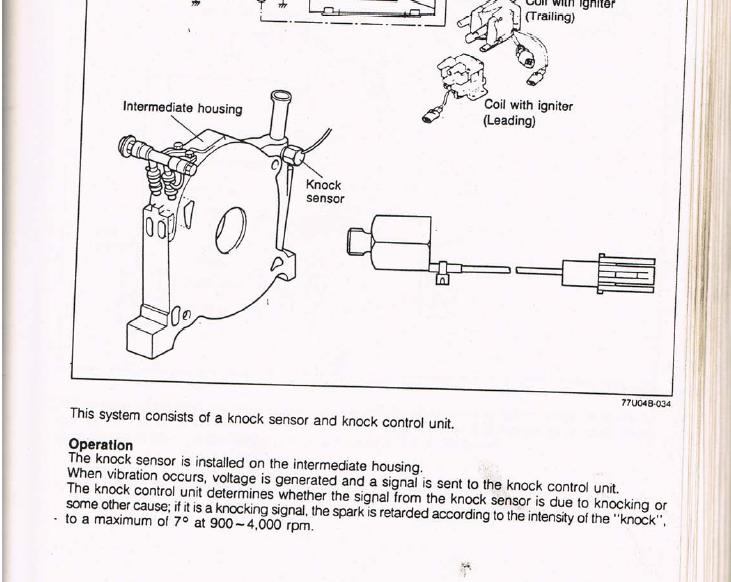

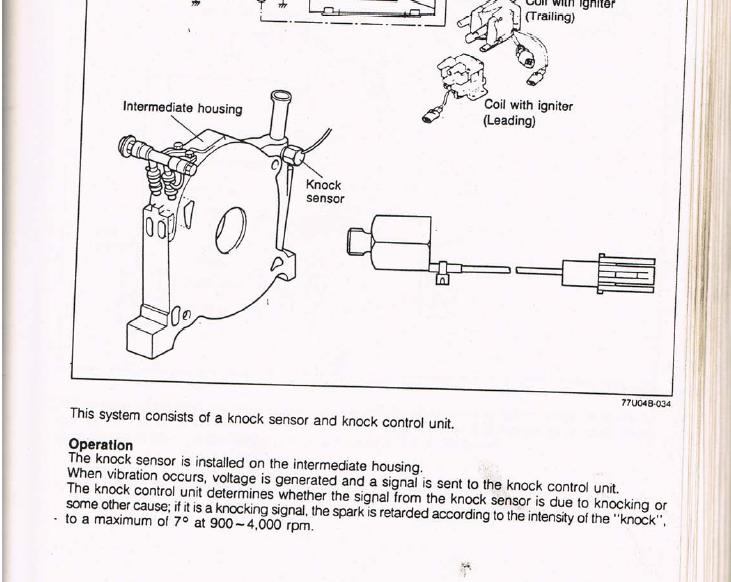

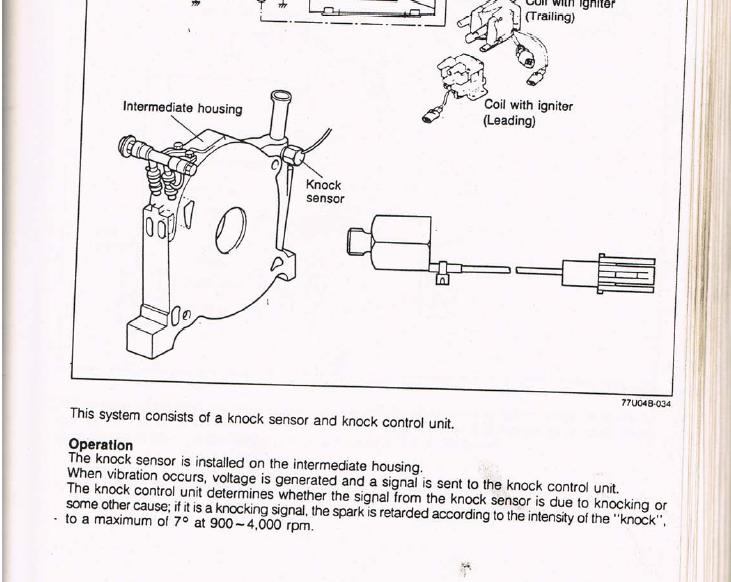

It's not your problem. The idea is that by leaving the wire connected to pin 2M, it *could* cause the ECU to see a signal that *could* be interpreted as a knock signal from the knock box. That signal would occur when the P/S is in operation (turning the wheel). Even so, the ECU would only retard to a maximum of 7* between 900 and 4000 RPM. This would reduce power, but not cause hesitation.

You also can't add the S4 knock system system very easily with NA wiring. The connections aren't there, but you could get creative and wire in a knock box if you wanted to. The wiring is in the FSM diagrams.

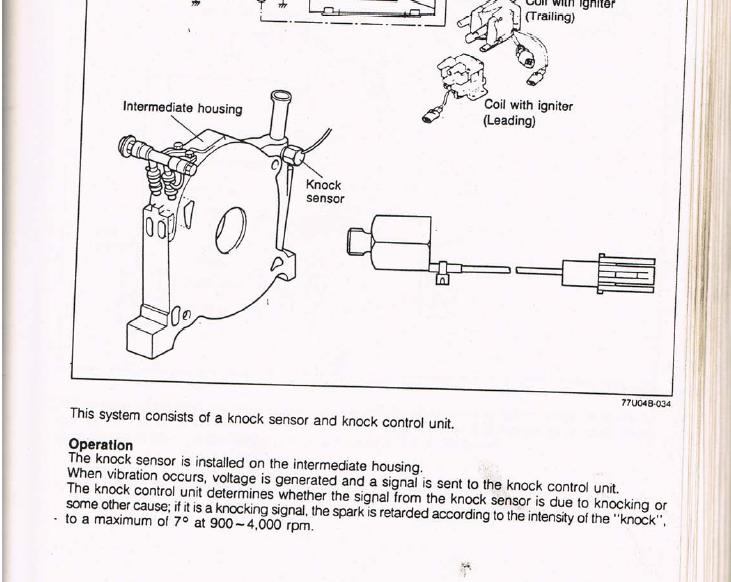

This is from the S4 TII training manual (courtesy of Arghx):

You also can't add the S4 knock system system very easily with NA wiring. The connections aren't there, but you could get creative and wire in a knock box if you wanted to. The wiring is in the FSM diagrams.

This is from the S4 TII training manual (courtesy of Arghx):

#6

talking head

that old aussie training supplement ( of mine ! ) has some interesting little tidbits in it

i scanned everything on the **** cause as you know everything is upside down over here

i scanned everything on the **** cause as you know everything is upside down over here

#7

It's not your problem. The idea is that by leaving the wire connected to pin 2M, it *could* cause the ECU to see a signal that *could* be interpreted as a knock signal from the knock box. That signal would occur when the P/S is in operation (turning the wheel). Even so, the ECU would only retard to a maximum of 7* between 900 and 4000 RPM. This would reduce power, but not cause hesitation.

You also can't add the S4 knock system system very easily with NA wiring. The connections aren't there, but you could get creative and wire in a knock box if you wanted to. The wiring is in the FSM diagrams.

This is from the S4 TII training manual (courtesy of Arghx):

You also can't add the S4 knock system system very easily with NA wiring. The connections aren't there, but you could get creative and wire in a knock box if you wanted to. The wiring is in the FSM diagrams.

This is from the S4 TII training manual (courtesy of Arghx):

something with the pin swapping(or rather i should say lack thereof) is causing the ECU to have a massive heart attack and fall on their faces. granted none of these cars i have personally worked on but they all have the same non turbo harness with turbo ECU in common, which leads me to believe that the knock sensor fed by power steering sensor is causing more than a simple timing retard hesitation, more like a fuel cut as well in conjunction.

it's honestly starting to irritate me, answering all of the questions on the phone regarding these swaps when i'm not doing the installs on them. people need to read up and do their homework instead of just slapping **** together and crossing their fingers.

in all honesty the knock sensor can be completely omitted from the system and you would never know it was gone. it has never saved a motor to date that i know of. if anything it might be better served if you could get a guage that could interpret the signal and have a knock gauge on your dash, because the ECU cannot compensate for it quick enough as it is not calibrated for the sensitivity that it should. but only a multimeter is sensitive enough to read the signal, or a standalone with knock sensor inputs.

keep in mind, adding a power signal to a circuit that is designed to only recieve a fraction of 1% of a volt(granted this is altered through the knock box and i haven't paid attention to the signal that the ECU actually gets, which may actually be a grounded switch input which is even worse) generally causes intermitting electronics failure, so in my assumptions the ECU is getting intermittently fried each time it gets this power steering signal which is causing the ECU to go offline temporarily and possibly killing the board slowly. eventually, if lucky, it may just kill the knock sensor tracer on the board and cure itself, worst case it burns up something else on the board resulting in a dead ECU.

at any rate, pull or cut the wire at the very least.

Last edited by RotaryEvolution; 09-13-11 at 11:15 AM.

Trending Topics

#8

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,780

Received 2,565 Likes

on

1,824 Posts

i'm pretty sure the knock box turns the knock sensors mV signal into a 0-5v signal, so its not going to fry anything, but feeding the ECU weird random voltages isn't a good idea! i bet there are parts of the map where pulling 7 degrees of timing would make it hesitate too.

so pull that wire!

so pull that wire!

#9

I don't have power steering or a power steering ecu. So I would assume it's just not plugged into anything. If pulling the wire out of the ecu should fix it though I'll do it. If that doesn't work I'm trying another ecu, and if that doesn't work I'm getting all s5 t2 electronics and ecu so it's not all mismatched and then it would have to fix this problem.

#10

i believe you're missing something, as i have had more than a few people have this exact issue when turboing their non turbo with non turbo harness lately than i care to comment on.

something with the pin swapping(or rather i should say lack thereof) is causing the ECU to have a massive heart attack and fall on their faces. granted none of these cars i have personally worked on but they all have the same non turbo harness with turbo ECU in common, which leads me to believe that the knock sensor fed by power steering sensor is causing more than a simple timing retard hesitation, more like a fuel cut as well in conjunction.

something with the pin swapping(or rather i should say lack thereof) is causing the ECU to have a massive heart attack and fall on their faces. granted none of these cars i have personally worked on but they all have the same non turbo harness with turbo ECU in common, which leads me to believe that the knock sensor fed by power steering sensor is causing more than a simple timing retard hesitation, more like a fuel cut as well in conjunction.

There unfortunately isn't any more detail on the inner workings of the ECU (unless the pocketlogger guys know), so all you can really say is that it *could* retard timing under 4000 RPM. Unless the difference in this signal is allowing the ECU to make more extreme timing changes in other parts of the map. But that's just guessing too.

The bottom line is cut the wire. The FSM does say that the knock sensor input (on pin 1R, not 2M by the way) should measure 3-5v with the key on or at idle. The NA portion says the P/S input would measure less than 1.5v with the wheel turned, and 10-12v with the wheel straight ahead. So who knows how that would be interpreted. It might do nothing since neither is within the expected 3-5v range, or it might retard timing in a new and creative way.

Originally Posted by mxrider914

I don't have power steering or a power steering ecu. So I would assume it's just not plugged into anything. If pulling the wire out of the ecu should fix it though I'll do it. If that doesn't work I'm trying another ecu, and if that doesn't work I'm getting all s5 t2 electronics and ecu so it's not all mismatched and then it would have to fix this problem.

You don't have S4 and S5 electronics mismatched do you?

Last edited by RotaryRocket88; 09-13-11 at 05:29 PM.

#12

I'm thinking it also might be my ecu. It has 2 chips that were put in back in '92 by like Autopride or something like that. One is a FCD and I couldn't figure out what the other was. I'm wondering if one of them is bad or if the chip is for bigger injectors or something and since I have stock it's messing something up. I was told I could plug my na ecu in and it will still run so I'm going to do that and if the problem stops then I'm going to another ecu.

#13

talking head

if you have the early wiring loom with the Br/B coloured strips for the earth wires on the MAP and the AFM

then there is factory bulletins to bridge on an extra earth to the engine from this wire

without it,, the hesitation issue creeps up when corrosion and loom joins age and now have earth potential between these devices and the pins 3G and 3A for earth at the ecu

issues also arise where all the device earths bundle together a little way up the loom from the ecu

resolder the brass crimps on the Br/B wiring here,, add another earth from here to the ecu case or to the engine block

redoing both these earths will remove all earth potential and so the devices should all read true

then there is factory bulletins to bridge on an extra earth to the engine from this wire

without it,, the hesitation issue creeps up when corrosion and loom joins age and now have earth potential between these devices and the pins 3G and 3A for earth at the ecu

issues also arise where all the device earths bundle together a little way up the loom from the ecu

resolder the brass crimps on the Br/B wiring here,, add another earth from here to the ecu case or to the engine block

redoing both these earths will remove all earth potential and so the devices should all read true

#14

Rotary Freak

If you have a turbo engine in a non turbo series four car, you should not run the knock sensors wire directly to pin 1R on the ECU. The knock wire should first go to a knock control unit then one of four wires off that unit goes to the pin 1R.

On a non turbo series four car, pin 1R is used for the power steering input to the ECU. That signal in not a voltage signal. You turn the steering wheel and a switch is made at the pwr steering unit up front and it puts a Ground on pin 1R if you HAVE power steering on the car. No power steering? You won't have a input on 1R then.

No knock sensor input to the ECU via the knock control unit has ........no effect on the car at all. Been driving this heap for ???? five/???? eight yrs with no knock sensor input at all.

If a person did a non turbo to turbo swap and DID have power steering then he'd depin the wire at 1R so the ECU would never see a gnd on .....pin 1R. Personally I've no idea what would happen if the 1R had a gnd put on it. For safety depin that wire. But the thread owner says he has no pwr steering so it's a moot point.

Some of the above makes sense.

On a non turbo series four car, pin 1R is used for the power steering input to the ECU. That signal in not a voltage signal. You turn the steering wheel and a switch is made at the pwr steering unit up front and it puts a Ground on pin 1R if you HAVE power steering on the car. No power steering? You won't have a input on 1R then.

No knock sensor input to the ECU via the knock control unit has ........no effect on the car at all. Been driving this heap for ???? five/???? eight yrs with no knock sensor input at all.

If a person did a non turbo to turbo swap and DID have power steering then he'd depin the wire at 1R so the ECU would never see a gnd on .....pin 1R. Personally I've no idea what would happen if the 1R had a gnd put on it. For safety depin that wire. But the thread owner says he has no pwr steering so it's a moot point.

Some of the above makes sense.

#15

Rotary Freak

Hesitation: I tried the extra gnd to the boost/pressure sensor. Did zip for me. So I resoldered and added yet another gnd to the ECU ground splice area described by BUMPSTART. Hesitation done gone south. Remove the new gnd I had added............hesitation done come back to visit..

NZCONVERTIBLE is one of many who had success adding another gnd at the splice area for the gnds located near the ECU. Others have not had success. Hit or miss evidently.

The trouble shooting bulletin that added the extra gnd at the pressure sensor, was done to help the grounding of the AFM. Several sensors in the engine bay use the same gnd wire so splicing into the boost sensor gnd wire is just a quick and easy way to add gnd to that circuit. It's a easily accessible area vs the other sensors.

Talking series four ONLY here.

NZCONVERTIBLE is one of many who had success adding another gnd at the splice area for the gnds located near the ECU. Others have not had success. Hit or miss evidently.

The trouble shooting bulletin that added the extra gnd at the pressure sensor, was done to help the grounding of the AFM. Several sensors in the engine bay use the same gnd wire so splicing into the boost sensor gnd wire is just a quick and easy way to add gnd to that circuit. It's a easily accessible area vs the other sensors.

Talking series four ONLY here.

#16

So what and where is the ecu ground splice? Do I just cut into one of the ground wires and solder on another ground and put it right to the body?

Also, if it was a ground issue with the harness and I'm using the same harness, wouldn't i have had the same problem with it when it was na?

Thanks for all the help guys.

Also, if it was a ground issue with the harness and I'm using the same harness, wouldn't i have had the same problem with it when it was na?

Thanks for all the help guys.

#17

talking head

Also, if it was a ground issue with the harness and I'm using the same harness, wouldn't i have had the same problem with it when it was na?

its also very easy ( and nearly free ! ) to fix and cross off the list

please ignore the obviously radical departure from some of your wiring colour schemes

i think this was a N327 NA aussie wiring loom

blacks and black /grey dash are earths

the orange /black is a power ( B/Y on US ) , do not solder an earth here, but resolder the crimp

peel the tape back a bit from the cu end of the plugs

look for the black /grey dash or other FC earth colour wire bundles

and also for where the shield for the lambda etc tie in

its not all that far in but you have to untape the square loom gatherers

the orange shown here will likely be black with yellow or other FC power colour

dont earth it,, but resolder the crimp,, this one is also a likely culprit for volt changes when staging

bottom pics shows its not all that far in

overall there is two earth bundles/ tie ins which you resolder and add a decent fresh earth back to the ecu from

there is also the power crimp which is neglected , so look out for it when in there

#18

i just found it strange that i have had about 3 people ask me about a severe hestitation as soon as the car hits boost regardless of engine RPMs with the non turbo-turbo swap with non turbo harness, the only thing all 3 had in common was that they all scratched their head at me when i asked them if they depinned the knock sensor wire to the ECU. i'm sure on some they may have also disregarded the pressure sensor but most were adamate that they did in fact replace it with the n318 sensor as well as AFM, so last thing i could think of was the knock input kicking the crap out of the ECU when it is just getting ready to read the signal.

no one ever really seems to get that you can't drop in a turbo motor and expect it to last if you don't read anything.

no one ever really seems to get that you can't drop in a turbo motor and expect it to last if you don't read anything.

Last edited by RotaryEvolution; 09-14-11 at 12:40 PM.

Thread

Thread Starter

Forum

Replies

Last Post

rgordon1979

3rd Generation Specific (1993-2002)

40

03-15-22 12:04 PM

mulcryant

2nd Generation Specific (1986-1992)

10

09-09-15 05:24 PM

83revival

New Member RX-7 Technical

4

09-03-15 10:42 PM