RB Holley install

#1

RB Holley install

Installed the 79-85 RB holle kit for stock port 12a's. I have a high idle...about 2k. I just wanted to confirm that the idle speed screw is the one on the throttle lever...right next to where the cable attaches to the arm. Also, looking for insight for causes for this...possibly a bad seal? Manifold gasket appears well sealed...and carb to manifold is well sealed as well.

Thanks guys

Thanks guys

#2

ancient wizard...

Before you start adjusting things,look over your work. Are all unused ports on carb plugged off? Where(vacuum source) do you have your distributor vacuum advance hooked up? It should be a ported source(above throttle plate)that at idle speed has no vacuum until the passage in carb has air drawn past it by throttle plate opening. Manifold vacuum is present whenever engine is running and hooking distributor to this port will immediately advance the ignition timing by @20 degrees... which raises idle speed considerably. Without car running,look down carb throat at primary and secondary throttle plates. Secondary plates should be fully closed,if they're not,this could be cause of excessive idle speed. Primary plates should be cracked open,but just barely.

Does your throttle cable have freeplay(slack)? If not,it may be holding throttle open slightly. Looking down into carb(engine off),open and close throttle fully and watch action of throttle plates. Open throttle wot,using your fingers on secondary throttle linkage where secondary vacuum pod is attached,open and close secondary throttle shaft making sure it closes fully to throttle body. Once you've ruled out linkage hanging up,correct throttle cable play and no apparent vacuum leaks or unplugged ports,then try to adjust idle speed lower. Post some pics of your setup and adjustment screw(s) in question.

Does your throttle cable have freeplay(slack)? If not,it may be holding throttle open slightly. Looking down into carb(engine off),open and close throttle fully and watch action of throttle plates. Open throttle wot,using your fingers on secondary throttle linkage where secondary vacuum pod is attached,open and close secondary throttle shaft making sure it closes fully to throttle body. Once you've ruled out linkage hanging up,correct throttle cable play and no apparent vacuum leaks or unplugged ports,then try to adjust idle speed lower. Post some pics of your setup and adjustment screw(s) in question.

#4

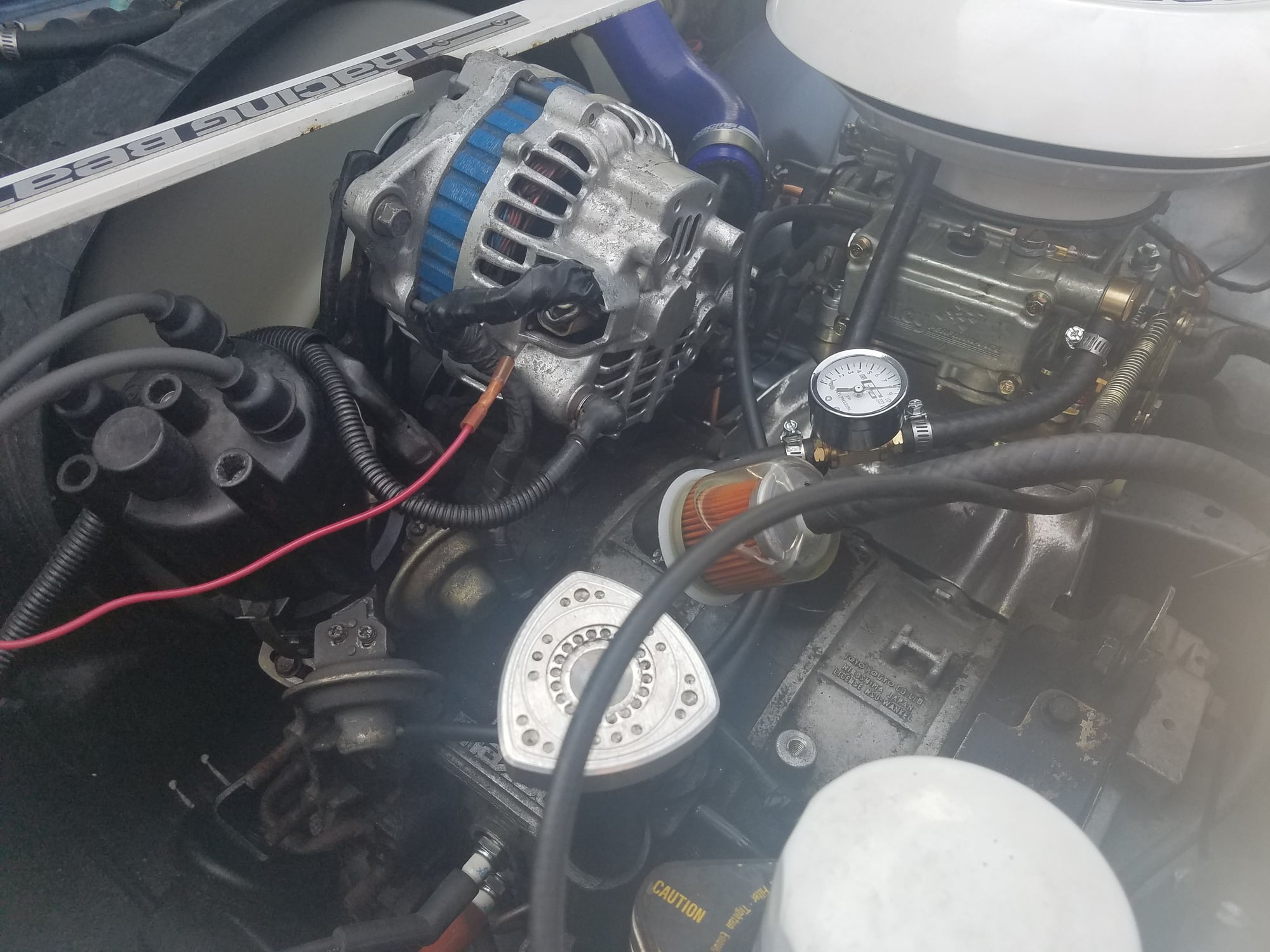

The screw in question is in the last picture above the throttle arm assy. The linkage has free play at idle, and appears to open up without an issue and return as well. The port I am using on the carb for the vacuum source for the trailing ignition is the port near the oil metering pump hookup on the primary float bowl (as shown above).

#5

ancient wizard...

In the last pic,that is the base idle speed adjusting screw. Looking in same pic,is that fuel puddled on manifold to left of carb,coolant. That would appear to be a ported source for dist vac advance. You say you have it hooked to trailing vacuum pod,shouldn't that be teed to both leading and trailing pods?

While running,if still excessively high,pull dist.vacuum advance hose from carb and feel for vacuum/see if idle speed is lowered somewhat. Carb should be adjusted close out of box,never perfect,some adjustments have to be made to mixture/idle speed-every engine is different in what it wants. Try turning base idle screw ccw and see if idle speed comes down.

Couple things,not a fan two of fuel filters with one in engine compartment,plastic or otherwise. Too much risk of fire. OE filter location by pump is fine. What kind of fuel pump do you have on the car,gauge is showing almost 9 lbs. pressure,seems excessive & could lead to flooding/driveability problems. Do you have a fuel pressure regulator installed,do install instructions dictate a min/max fuel pressure target?

While running,if still excessively high,pull dist.vacuum advance hose from carb and feel for vacuum/see if idle speed is lowered somewhat. Carb should be adjusted close out of box,never perfect,some adjustments have to be made to mixture/idle speed-every engine is different in what it wants. Try turning base idle screw ccw and see if idle speed comes down.

Couple things,not a fan two of fuel filters with one in engine compartment,plastic or otherwise. Too much risk of fire. OE filter location by pump is fine. What kind of fuel pump do you have on the car,gauge is showing almost 9 lbs. pressure,seems excessive & could lead to flooding/driveability problems. Do you have a fuel pressure regulator installed,do install instructions dictate a min/max fuel pressure target?

#6

In the last pic,that is the base idle speed adjusting screw. Looking in same pic,is that fuel puddled on manifold to left of carb,coolant. That would appear to be a ported source for dist vac advance. You say you have it hooked to trailing vacuum pod,shouldn't that be teed to both leading and trailing pods?

While running,if still excessively high,pull dist.vacuum advance hose from carb and feel for vacuum/see if idle speed is lowered somewhat. Carb should be adjusted close out of box,never perfect,some adjustments have to be made to mixture/idle speed-every engine is different in what it wants. Try turning base idle screw ccw and see if idle speed comes down.

Couple things,not a fan two of fuel filters with one in engine compartment,plastic or otherwise. Too much risk of fire. OE filter location by pump is fine. What kind of fuel pump do you have on the car,gauge is showing almost 9 lbs. pressure,seems excessive & could lead to flooding/driveability problems. Do you have a fuel pressure regulator installed,do install instructions dictate a min/max fuel pressure target?

While running,if still excessively high,pull dist.vacuum advance hose from carb and feel for vacuum/see if idle speed is lowered somewhat. Carb should be adjusted close out of box,never perfect,some adjustments have to be made to mixture/idle speed-every engine is different in what it wants. Try turning base idle screw ccw and see if idle speed comes down.

Couple things,not a fan two of fuel filters with one in engine compartment,plastic or otherwise. Too much risk of fire. OE filter location by pump is fine. What kind of fuel pump do you have on the car,gauge is showing almost 9 lbs. pressure,seems excessive & could lead to flooding/driveability problems. Do you have a fuel pressure regulator installed,do install instructions dictate a min/max fuel pressure target?

Currently, the idle speed screw is backed all the way off of the throttle lever so it is not influencing the idle speed (at least not to drive it up). I will be looking down the throat of the intake to check to see that the secondaries are closed, etc, at idle.

#7

ancient wizard...

Not certain why the instructions would say to hook up trailing only...doesn't make sense. Get about 6" of 3/16 vacuum hose and a 3/16 vacuum tee and connect both advance units with same hose. That's essentially how it was with the Nikki carb-no reason to change that. Regarding the base idle screw,do you have it backed out where it's not in contact with throttle shaft,what rpm is it idling now-still fast?

Trending Topics

#9

ancient wizard...

I read the posted instructions,makes no sense to me...Do you still have the high idle speed? Recommend you call Racing Beat and ask them about line 15 on install instructions. Were it me,i'd hook up Leading & Trailing advance units as i described in previous post. Regarding idle speed & adjustment,leave vacuum advance disconnected at carb for now and plug the port on carb. There should be no vacuum available at idle speed for advance,temporarily leaving vacuum source to advance disconnected and plugged will eliminate this as a cause for high idle eliminating that as a cause.

Can you post install instructions so to be able to see all of them?

Can you post install instructions so to be able to see all of them?

Last edited by GSLSEforme; 08-25-17 at 06:30 PM.

#11

Current status: Idle around 1600rpm at normal operating temperature. Choke butterfly wide open. Secondaries appear closed. Idle speed set screw is just touching the throttle lever/arm so the secondary butterflies dont hit the opening hard. Hooked up the vacuum advances (both) to the vacuum port on the carburetor which is located next to the primary float bowl. The idle was pretty smooth, and around 1600rpm.

Then I disconnected this vacuum port from the ignition advances and ran the car with the vacuum port OPEN. Idle got a little rough and didnt change rpm much. Then I ran the car with this vacuum port CAPPED and idle went down a little and was also a bit rougher (~1500rpm).

Butterflies APPEAR to be in appropriate positions when the car is running, so this leaves your guys' review of the instructions, everything Ive said, and I suppose a possible leak in the intake manifold gasket. I sprayed around with WD40 and found no change in idle speed. Thank you guys much.

Last edited by dankekong; 08-27-17 at 12:26 PM.

#12

ancient wizard...

Where is the base idle screw at,adjustment wise? Will turning it ccw lower idle speed?. Do you have a timing light,do you know if your base ignition timing is correct,have you checked it? Warm the engine, block off vacuum source to vacuum advance and put the timing light on engine and verify correct timing for leading and trailing ignition.Now hook up vac hose to both advance units and look at timing marks again. Pretty certain from what you're posting the timing will be advanced & idle rpm increased because of it. A ported vacuum source will(should)have no vacuum at idle with throttle closed- there should be no vacuum advance with throttle closed. Reasons for high idle,likely to least likely... base idle screw turned in too far-secondary throttle plates not fully closed-base ignition timing advanced too far- gasket issue between metering block and carb body and or gasket problem between throttle plate and carb body- problem with power valve(not certain it has one,but should). One more thing you could do,while car is running,pinch hose going from intake to brake booster shut with a pair of needle nose pliers and see if idle speed changes. If it does you have a leaky brake booster. I like to lightly spray carb cleaner around areas I suspect are vacuum leaks,it's less messy and more sensitive to help find smaller leaks.

Last edited by GSLSEforme; 08-27-17 at 02:14 PM.

#13

Will do more ignition timing/troubleshooting soon. Question: is there a gasket which is supposed to be used between the carburetor and the intake manifold?

Step #2: "Install the carburetor on the manifold, using flat washers, lock washers, and nuts supplied"

The gasket...which comes with the carburetor in the Holley box...is not mentioned. I just want to clarify. And for the record, this gasket is currently installed. I know it sounds odd, but I just want to make sure here considering the weird high idle and also the vagueness of some of the install instructions.

Also, the base idle screw is JUST in contact with the arm on the throttle shaft. Turning it CCW will lower engine speed by maybe 50rpms at this point. It is damn near backed all the way out/off.

Step #2: "Install the carburetor on the manifold, using flat washers, lock washers, and nuts supplied"

The gasket...which comes with the carburetor in the Holley box...is not mentioned. I just want to clarify. And for the record, this gasket is currently installed. I know it sounds odd, but I just want to make sure here considering the weird high idle and also the vagueness of some of the install instructions.

Also, the base idle screw is JUST in contact with the arm on the throttle shaft. Turning it CCW will lower engine speed by maybe 50rpms at this point. It is damn near backed all the way out/off.

Last edited by dankekong; 08-28-17 at 10:32 AM.

#14

ancient wizard...

Yes,a gasket is required.

Another thing to check is the choke and fast idle linkage and fast idle speed adjusting screw. If the linkage/screw is not adjusted properly it could hold throttle open enough to cause this problem. Easy enough to check,remove air cleaner and observe linkage and adjust screw behind black choke thermostat. Cold engine(not running)open throttle far enough to allow choke spring to pull choke plate shut and engage fast idle linkage on cam,i think the cam has two steps. This should prop throttle open slightly. Now push choke plate open against spring,open throttle while doing so and linkage should drop off fast idle cam and allow throttle to close to base idle adjustment. Warm engine,open choke plate, linkage should be such that adjusting screw is not touching cam it rides on. If any of this does not function as described, look into it further.

Another thing to check is the choke and fast idle linkage and fast idle speed adjusting screw. If the linkage/screw is not adjusted properly it could hold throttle open enough to cause this problem. Easy enough to check,remove air cleaner and observe linkage and adjust screw behind black choke thermostat. Cold engine(not running)open throttle far enough to allow choke spring to pull choke plate shut and engage fast idle linkage on cam,i think the cam has two steps. This should prop throttle open slightly. Now push choke plate open against spring,open throttle while doing so and linkage should drop off fast idle cam and allow throttle to close to base idle adjustment. Warm engine,open choke plate, linkage should be such that adjusting screw is not touching cam it rides on. If any of this does not function as described, look into it further.

Last edited by GSLSEforme; 08-28-17 at 12:30 PM.

#15

I checked out the choke assembly. All these checks perform as expected. I backed off the set screw as much as possible afterwards, and I even removed the choke spring assembly/housing. The engine still idles around 1500rpm with it removed and having no influence upon idle speed. I checked timing, checked for vacuum leaks (haven't found one yet) and also checked the set screw for the idle speed. I also have the fuel pressure dialed in to ~5psi.

I am at a loss now. I uninstalled the carb and manifold and will try to examine it bit by bit and reinstall. I am in contact with Racing Beat, hopefully they don't leave me hanging. Intake manifold gasket is perfectly installed, as well as the two o-rings for the coolant ports. Everything appeared installed properly and square.

I am at a loss now. I uninstalled the carb and manifold and will try to examine it bit by bit and reinstall. I am in contact with Racing Beat, hopefully they don't leave me hanging. Intake manifold gasket is perfectly installed, as well as the two o-rings for the coolant ports. Everything appeared installed properly and square.

#16

carb whisperer

Junk.

Call RB for help, they'll tell you your engine needs rebuilt.

Their "new RB465" needs a good bit of work out of the box to work properly, and then it's not great throttle response, pig rich idle (which needs adjusted almost daily), horrible MPG, secondaries that open at 5k, and lots of spitting and sputtering.

As for the idle speed, I promise you that it's leaking air around the throttle shafts (a lot).

you can close the secondaries further with a small screw driver UNDER the baseplate, but it negatively affects secondary transition.

adjusting the idle screw too far down on the primary also covers the transfer slot and results in very poor tip in.

You're about $3-400 in work away from getting your advertised carburetor, GL. This forum is lined with warnings about that product.

Reserve space under my post for the folks at RB to defend themselves and discount my 10 year nightmare with more than a couple of these.

Also reserve space for those that will say that because they had a good experience, that 100% of RB carbs are flawless.

Call RB for help, they'll tell you your engine needs rebuilt.

Their "new RB465" needs a good bit of work out of the box to work properly, and then it's not great throttle response, pig rich idle (which needs adjusted almost daily), horrible MPG, secondaries that open at 5k, and lots of spitting and sputtering.

As for the idle speed, I promise you that it's leaking air around the throttle shafts (a lot).

you can close the secondaries further with a small screw driver UNDER the baseplate, but it negatively affects secondary transition.

adjusting the idle screw too far down on the primary also covers the transfer slot and results in very poor tip in.

You're about $3-400 in work away from getting your advertised carburetor, GL. This forum is lined with warnings about that product.

Reserve space under my post for the folks at RB to defend themselves and discount my 10 year nightmare with more than a couple of these.

Also reserve space for those that will say that because they had a good experience, that 100% of RB carbs are flawless.

#17

At this point I reached out to them and have been very respectful and hopeful as well as deliberate with what I've done and tested/checked. I also witnessed the leaky/leaking throttle shafts as you've mentioned and I am just very hopeful that the folks at RB will be kind and fair enough to facilitate a return.

It is not fair to spend that much money on equipment and it not even be tested or guaranteed, even though they advertise it that way. I am hopeful.

It is not fair to spend that much money on equipment and it not even be tested or guaranteed, even though they advertise it that way. I am hopeful.

#18

carb whisperer

They refused to return mine, because I attempted to adjust it (just as you have) which violates their return policy.

In the end, I dealt with mine sucking for 2 years, and then purchased another new one. Which had the exact same issues as the first. They refused it's return too, telling me that they have been in business for 30 years and sold thousands of flawless kits blah blah blah.

I contacted the BBB and they banned me as a customer, even went as far as attempting to discredit my claims and issues here on this forum.

I took my "knows nothing about carburetors" self out there and starting building my own without issues while learning from their mistakes. The cost to perfect the Holley on the rotary was high, to the point megasquirt EFI was much cheaper.

I changed gears and followed Jeff20B in the development of racing nikki's, and I can tell you I finally have the perfect 4bbl. I may have spent 400 total on my first example including 10 cores, lathe work, a new dremel, polish, and hardware.

I'm still running it without issue 3 years later, and I only pop the hood when I want to.

In the end, I dealt with mine sucking for 2 years, and then purchased another new one. Which had the exact same issues as the first. They refused it's return too, telling me that they have been in business for 30 years and sold thousands of flawless kits blah blah blah.

I contacted the BBB and they banned me as a customer, even went as far as attempting to discredit my claims and issues here on this forum.

I took my "knows nothing about carburetors" self out there and starting building my own without issues while learning from their mistakes. The cost to perfect the Holley on the rotary was high, to the point megasquirt EFI was much cheaper.

I changed gears and followed Jeff20B in the development of racing nikki's, and I can tell you I finally have the perfect 4bbl. I may have spent 400 total on my first example including 10 cores, lathe work, a new dremel, polish, and hardware.

I'm still running it without issue 3 years later, and I only pop the hood when I want to.

#19

I had started some of the nikki mods, heading towards a performance nikki setup. I will be going back to that work and finishing it. I am still hopeful about the communications with Racing Beat, but we will see. I will post updates as I get them and get concrete answers from them. I don't want to step on toes before something actually happens. Your warnings/experiences are heeded and much appreciated.

I will be installing the stock manifold and carb (although both modified ) this week! That way I have a running car....

) this week! That way I have a running car....

I will be installing the stock manifold and carb (although both modified

) this week! That way I have a running car....

) this week! That way I have a running car....

#20

carb whisperer

I had started some of the nikki mods, heading towards a performance nikki setup. I will be going back to that work and finishing it. I am still hopeful about the communications with Racing Beat, but we will see. I will post updates as I get them and get concrete answers from them. I don't want to step on toes before something actually happens. Your warnings/experiences are heeded and much appreciated.

I will be installing the stock manifold and carb (although both modified ) this week! That way I have a running car....

) this week! That way I have a running car....

I will be installing the stock manifold and carb (although both modified

) this week! That way I have a running car....

) this week! That way I have a running car....Good luck, seriously. If people would actually be willing to pay something more than 150 bucks for a modified nikki I'd sell them. Every one I build is an improved version of the last.

#23

Far from a carb expert here, but I have had a decade+ to learn. I've also had my fair share of tough learning experiences with a holley that came on the car when I got it as a kid. One of the things that never sat right with rb's setup was that the omp went directly into a zone that was never supposed to have oil in it. I ended up re routing that to below the mounting flange. I can get a pic if you are interested. My setup. while having a bunch of the usual quirks... cutting out on left turns -> need cathedral bowls and different floats =$$$... no tip in response, almost an on off switch between 1/4 and 1/2 throttle and nothing else happens all the way up to full. Just overall weird behavior. I was at least able to get it to idle solid at 950-1000. The lope on my sp is really nice around there, any lower and the whole thing wants to stall any time I touch the gas, just hiccups and floods. I ended up driving my car 5 hours (NH to PA) on the primaries only because the secondaries would just not open, and that was on a brand new holley.

I'm in the process of collecting enough parts for a megasquirt conversion. Hoping that will take most of the guess work out of this. With the holley, I always have the sense of, did I change anything? It should have made it better... don't feel anything different. Hmm... repeat. It all seems just too mushy, if that makes any sense.

Should have learned how to modify a nikki when I still had one. Time for efi and tuning that I can see.

I'm in the process of collecting enough parts for a megasquirt conversion. Hoping that will take most of the guess work out of this. With the holley, I always have the sense of, did I change anything? It should have made it better... don't feel anything different. Hmm... repeat. It all seems just too mushy, if that makes any sense.

Should have learned how to modify a nikki when I still had one. Time for efi and tuning that I can see.

Last edited by swbtm; 10-28-17 at 09:03 PM.

#24

carb whisperer

^accurate to a tee. Careful though, making statements on this forum based on facts and experience is generally met with ridicule and disbelief. Someone will chime in and say "they have record breaking Holley in PR" or "Robert lives from rotary shack made 700 hp with one" or "racing beat says it won't need tuning", etc.