Alternator Relocation Brackets

#26

0000-09-0233

Join Date: Jun 2003

Location: Fort Wankel

Posts: 1,317

Likes: 0

Received 0 Likes

on

0 Posts

Blake,

I am down for atleast one too

Hopefully it will fit the 3....

Please PM me as soon as these are available.

I think for prototyping purposes.. I will opt to purchase both the flat-bar and the turn-buckle style....

I hope you are using a small sperical bushing sorta set-up.

Again, please PM me so I can get some funds your way.,

BTW, prototypes, and engineering model versions are fine with me.

I am down for atleast one too

Hopefully it will fit the 3....

Please PM me as soon as these are available.

I think for prototyping purposes.. I will opt to purchase both the flat-bar and the turn-buckle style....

I hope you are using a small sperical bushing sorta set-up.

Again, please PM me so I can get some funds your way.,

BTW, prototypes, and engineering model versions are fine with me.

#28

Rotary Enthusiast

Join Date: Jun 2002

Location: Yokosuka

Posts: 1,058

Likes: 0

Received 0 Likes

on

0 Posts

Can you use the stock v-belts, or do you need a different model?

This is really cool, man. I would really like one if the price is right. How much are you shooting for? $50-60 sounds pretty reasonable to me.

This is really cool, man. I would really like one if the price is right. How much are you shooting for? $50-60 sounds pretty reasonable to me.

#33

Originally Posted by SS124A

I think for prototyping purposes.. I will opt to purchase both the flat-bar and the turn-buckle style....

I hope you are using a small sperical bushing sorta set-up.

I hope you are using a small sperical bushing sorta set-up.

You take two rod ends, one threaded right hand (convensionally) and the other threaded left hand (back assward), then use a section of hex rod between them, threaded to match the rod ends at either side. So, you can adjust the length by turning the hex rod with a wrench...one way extends, the other retracts. Jam nuts are used to hold the ajustment.

Here is a picture of a 'supersized' version I made for the lower trailing links of the suspension on my old peripheral port 13B car.

The difference is that those rod ends cost over $30 each and the baby-sized ones for the tensioner would be a fraction of that. Actually, the retail value of the rod ends would be higher than the cost of the tensioner assembly, but I get WD (Warehouse Distributor) pricing so I can keep the cost reasonable.

I want to do the turnbuckle tensioner for my own vehicle because I like the precision of adjustment, as opposed to the pry and pray style flat bars. It also looks much cooler!

--

Blake Qualley

Pineapple Racing

#35

Originally Posted by Hades12

Will we have to cut off the Studs on the motor to use this?

#36

Originally Posted by wackyracer

Nice bracket. I want one and I prefer no tensioner. price please (I didnt see it).

Price will be between $50 and $85, including hardware and the belt. Variables in the cost include the finish (powder coating, cad plating, etc), type of tensioner, packaging, etc. I still have to make a welding jig, so that every one is exactly the same. One-offs are easy, but production is a PITA!

#37

Burning Oil-Grinding 3rd

Originally Posted by Blake

No, but you will have to remove them as the kit will come with some button-head bolts that use those threaded holes. Originally, I was going to just use nuts to fasten the bracket to the studs, but they stick out way too far and would force me to mount the alternator even farther out.

Stud Puller?

Two nuts pulled against each other?

Pipe wrench?

#38

Originally Posted by Hades12

I have never had a reason to take them out. Do they remove easy?

Stud Puller?

Two nuts pulled against each other?

Pipe wrench?

Stud Puller?

Two nuts pulled against each other?

Pipe wrench?

#39

Originally Posted by Blake

No tensioner at all...not even the flat one?

Price will be between $50 and $85, including hardware and the belt. Variables in the cost include the finish (powder coating, cad plating, etc), type of tensioner, packaging, etc. I still have to make a welding jig, so that every one is exactly the same. One-offs are easy, but production is a PITA!

Price will be between $50 and $85, including hardware and the belt. Variables in the cost include the finish (powder coating, cad plating, etc), type of tensioner, packaging, etc. I still have to make a welding jig, so that every one is exactly the same. One-offs are easy, but production is a PITA!

Im fine with krylon paint job. so count me in for 1 bracket.

thanks

#40

maybe i've missed it, but is this mod just for looks?? i know you mention about less water pump slippage, but i have had no problems whatsoever when i removed my air pump. it's been like this for the past 2 years and temps. are the way i would like them to be.

so is this form over function??

so is this form over function??

#41

Originally Posted by d0 Luck

maybe i've missed it, but is this mod just for looks?? i know you mention about less water pump slippage, but i have had no problems whatsoever when i removed my air pump. it's been like this for the past 2 years and temps. are the way i would like them to be.

so is this form over function??

so is this form over function??

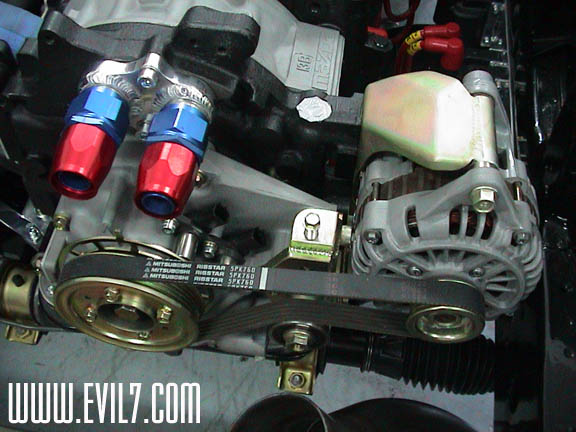

picture that bracket on this one.

Originally Posted by Hades12

#42

Originally Posted by d0 Luck

maybe i've missed it, but is this mod just for looks?? i know you mention about less water pump slippage, but i have had no problems whatsoever when i removed my air pump. it's been like this for the past 2 years and temps. are the way i would like them to be.

so is this form over function??

so is this form over function??

#43

Originally Posted by wackyracer

picture that bracket on this one.

Originally Posted by Blake

Any weight you move lower is benefitial to handling (lower CG) and it also allows you to use an electric water pump, so those are both good, functional reasons to relocate the alternator.

#46

Originally Posted by d0 Luck

yeah i actually saw it

question is: is it by a significant amount? i'm not detesting this mod in any way, i'm just really curious if it's worth spending my money on it in the future.

question is: is it by a significant amount? i'm not detesting this mod in any way, i'm just really curious if it's worth spending my money on it in the future.

#50

Rotary Enthusiast

iTrader: (14)

Join Date: May 2004

Location: Drifting a Roundabout near you!

Posts: 1,366

Likes: 0

Received 10 Likes

on

10 Posts

can you use your dual pulley you have now or go back to the single pulley. I like the CAD (gold) finish, easy to keep clean and less corrosion. Nice job Blake!