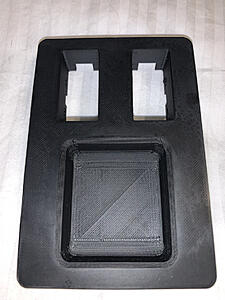

84-85 1st Gen Window Switch panel

The following 4 users liked this post by kutukutu1:

#4

3D Printed

Nice job once again, it looks great.

I've had the same color issues as well; the black looks grey for many of the more hardy filaments (except PETG which ends up as a glossy/oily black).

Your material looks to be some sort of ABS? Nice idea on making the bottom of the cup a separate part so it doesn't need support/keeps the surface smooth. What sort of glue are you using to attach the two pieces? CA works very well on PETG, although I haven't experimented with gluing ABS/ASA just yet. Have you ever tried solvent welding on ABS using acetone? Pardon the questionnaire barrage, not too many people document 3D printed automotive interior parts. This reminds me that I should go update my thread as well .

.

I've had the same color issues as well; the black looks grey for many of the more hardy filaments (except PETG which ends up as a glossy/oily black).

Your material looks to be some sort of ABS? Nice idea on making the bottom of the cup a separate part so it doesn't need support/keeps the surface smooth. What sort of glue are you using to attach the two pieces? CA works very well on PETG, although I haven't experimented with gluing ABS/ASA just yet. Have you ever tried solvent welding on ABS using acetone? Pardon the questionnaire barrage, not too many people document 3D printed automotive interior parts. This reminds me that I should go update my thread as well

.

.

#5

Originally Posted by Benjamin4456

Nice job once again, it looks great.

I've had the same color issues as well; the black looks grey for many of the more hardy filaments (except PETG which ends up as a glossy/oily black).

Your material looks to be some sort of ABS? Nice idea on making the bottom of the cup a separate part so it doesn't need support/keeps the surface smooth. What sort of glue are you using to attach the two pieces? CA works very well on PETG, although I haven't experimented with gluing ABS/ASA just yet. Have you ever tried solvent welding on ABS using acetone? Pardon the questionnaire barrage, not too many people document 3D printed automotive interior parts. This reminds me that I should go update my thread as well .

.

I've had the same color issues as well; the black looks grey for many of the more hardy filaments (except PETG which ends up as a glossy/oily black).

Your material looks to be some sort of ABS? Nice idea on making the bottom of the cup a separate part so it doesn't need support/keeps the surface smooth. What sort of glue are you using to attach the two pieces? CA works very well on PETG, although I haven't experimented with gluing ABS/ASA just yet. Have you ever tried solvent welding on ABS using acetone? Pardon the questionnaire barrage, not too many people document 3D printed automotive interior parts. This reminds me that I should go update my thread as well

.

.

#6

3D Printed

Thanks. Yeah it's abs for the moment. I've heard ASA is the new ABS but everywhere I look it's sold out. Putting them together with crazy glue is the best way for abs. Bonds like it was printed together. I think ideally nylon would be a better material, but the printing troubles and upgrades needed don't seem to be worth it unless I find that the abs is not holding up. Just today I made some design mods to strengthen the switch tabs as repeated testing caused one to snap at the layer line.

In my opinion straight nylon isn't worth messing with except for gears or things that need to survive friction, in which case it's amazing. Dying natural nylon is possible, although when I experimented with this it caused the residual tension in the parts to warp them. Glass filled nylon is the next logical step but it requires a hardened steel nozzle which doesn't work as well for other materials if you switch often (worse thermal conductivity). Carbon fiber nylon is amazing stuff though. My carb hat(s) are printed from it and are still in top condition, as well as my secondary venturis which I've been driving around with for a few weeks.

Honestly I'm just using a couple lightly modified Ender 3 Pro's and I run 260C frequently on a Micro Swiss all metal hot end clone paired to the stock heater cartridge and thermistor with no issues. Not sure what your setup is, but I'd definitely consider looking into filled nylons for higher heat/chemical resistant parts, although perhaps not interior parts.

Oh, and a note on ASA. I've been using Raise3D's ASA recently and it's fine, nothing too special. 3DXTech also supposedly makes good ASA which I may try next. Matterhackers is my go-to for higher priced filaments as anything over $35 ships free to the contiguous US. They also have Raise3D ASA in stock as of writing this

.

.

Last edited by Benjamin4456; 10-04-21 at 04:03 PM.

#7

Rotary Enthusiast

Maybe you can turn one into a single drink holder for those of us that don't have PW.

Very nice work on this piece, so many things are unobtanium these days.

Very nice work on this piece, so many things are unobtanium these days.

Trending Topics

#8

Originally Posted by Ckforker

Maybe you can turn one into a single drink holder for those of us that don't have PW.

Very nice work on this piece, so many things are unobtanium these days.

Very nice work on this piece, so many things are unobtanium these days.

#9

Originally Posted by Benjamin4456

I've never actually printed with ABS and only have ASA, although I imagine they print almost identically. Best thing about ASA is that it is naturally UV and weather resistant while retaining everything good about ABS. The layer adhesion is the only thing I really do not like with ABS, as like you mentioned with the tabs breaking, I keep having the same issues. That's why I left my interior parts that need to bend as PETG, although as I've recently discovered, if they are under high load they will eventually deflect when heated.

In my opinion straight nylon isn't worth messing with except for gears or things that need to survive friction, in which case it's amazing. Dying natural nylon is possible, although when I experimented with this it caused the residual tension in the parts to warp them. Glass filled nylon is the next logical step but it requires a hardened steel nozzle which doesn't work as well for other materials if you switch often (worse thermal conductivity). Carbon fiber nylon is amazing stuff though. My carb hat(s) are printed from it and are still in top condition, as well as my secondary venturis which I've been driving around with for a few weeks.

Honestly I'm just using a couple lightly modified Ender 3 Pro's and I run 260C frequently on a Micro Swiss all metal hot end clone paired to the stock heater cartridge and thermistor with no issues. Not sure what your setup is, but I'd definitely consider looking into filled nylons for higher heat/chemical resistant parts, although perhaps not interior parts.

Oh, and a note on ASA. I've been using Raise3D's ASA recently and it's fine, nothing too special. 3DXTech also supposedly makes good ASA which I may try next. Matterhackers is my go-to for higher priced filaments as anything over $35 ships free to the contiguous US. They also have Raise3D ASA in stock as of writing this .

.

In my opinion straight nylon isn't worth messing with except for gears or things that need to survive friction, in which case it's amazing. Dying natural nylon is possible, although when I experimented with this it caused the residual tension in the parts to warp them. Glass filled nylon is the next logical step but it requires a hardened steel nozzle which doesn't work as well for other materials if you switch often (worse thermal conductivity). Carbon fiber nylon is amazing stuff though. My carb hat(s) are printed from it and are still in top condition, as well as my secondary venturis which I've been driving around with for a few weeks.

Honestly I'm just using a couple lightly modified Ender 3 Pro's and I run 260C frequently on a Micro Swiss all metal hot end clone paired to the stock heater cartridge and thermistor with no issues. Not sure what your setup is, but I'd definitely consider looking into filled nylons for higher heat/chemical resistant parts, although perhaps not interior parts.

Oh, and a note on ASA. I've been using Raise3D's ASA recently and it's fine, nothing too special. 3DXTech also supposedly makes good ASA which I may try next. Matterhackers is my go-to for higher priced filaments as anything over $35 ships free to the contiguous US. They also have Raise3D ASA in stock as of writing this

.

.That's awesome to hear about the carb hats with the CF nylon. I've been wanting to do that, but obviously upgrading to an all metal hot end causing printing issues with pla,abs and flex material and up to a few days ago I only had one printer so maybe I'll upgrade one. Have you tried the CF nylon on moving/stressed parts? How does it hold up?

Raise3D makes good stuff. Their printers are nice, but way out of budget for me. I buy my abs from MatterHackers too. I did find a Chinese brand called eryone that seems to make a decent product for $20/kg so been trying them for test pieces and quick Proto so I don't waste the good stuff.

#10

Originally Posted by Ckforker

Maybe you can turn one into a single drink holder for those of us that don't have PW.

Very nice work on this piece, so many things are unobtanium these days.

Very nice work on this piece, so many things are unobtanium these days.

#12

Originally Posted by VA RX7

How do you take these out without breaking them in the first place?

#13

Yeah, def agree with mazdaverx713B. It looks nice! I have the burgundy interior. I think if I gently sand it/scuff it, it would take paint pretty well. I believe Lowes has a burgundy paint in a spray can that's pretty close for those of us that have the burgundy.

#17

Thanks! Took much longer than expected. Printing that ASA was a lot tougher to dial in the printer than any other material ive worked with. CF nylon prints like a dream in comparison to ASA. I might try the CF nylon for this parts, those tabs wont be going anywhere if i do. That thing is tough as hell. I found another material by ninjaflex called armadillo TPU. I really wish the thermal properties could hold up to being inside a car. The material is practically unbreakable, but it only holds 60C before softening.

#18

If anyone wants to test one out, send me a pm. Ill ship you a cupholder or oem style one, just report back with feedback and some pictures. My FB has been a gutted track car for a long time so full interior install pictures would be nice to see.

Will send out at most 3. Thanks

Will send out at most 3. Thanks

#19

3D Printed

Thanks! Took much longer than expected. Printing that ASA was a lot tougher to dial in the printer than any other material ive worked with. CF nylon prints like a dream in comparison to ASA. I might try the CF nylon for this parts, those tabs wont be going anywhere if i do. That thing is tough as hell. I found another material by ninjaflex called armadillo TPU. I really wish the thermal properties could hold up to being inside a car. The material is practically unbreakable, but it only holds 60C before softening.

I would happily test one of your parts and provide feedback, although my car won't be on the road for quite some time yet. The part looks good though and I'm glad to see you got ASA working well.

#20

If anyone wants to test one out, send me a pm. Ill ship you a cupholder or oem style one, just report back with feedback and some pictures. My FB has been a gutted track car for a long time so full interior install pictures would be nice to see.

Will send out at most 3. Thanks

Will send out at most 3. Thanks

#21

Originally Posted by Benjamin4456

Ah yeah, the ninjaflex stuff is good, but it's spendy for what you get. I wanted to use the armadillo TPU for the push-in screw covers but have yet to do so. Recently I've started printing in polycarbonate and results are so far impressive. It's crazy stiff and impact resistant compared to other plastics with great layer adhesion, and my particular variant has a Tg of 113C (PolyMax PC). I don't think it'll have many uses, but things in the engine bay will certainly benefit from it. I actually need to get my ASA printer running again to get some parts rolling here - just ordered some chrome wrap earlier today to start experimenting with the chrome dash accents.

I would happily test one of your parts and provide feedback, although my car won't be on the road for quite some time yet. The part looks good though and I'm glad to see you got ASA working well.

I would happily test one of your parts and provide feedback, although my car won't be on the road for quite some time yet. The part looks good though and I'm glad to see you got ASA working well.

Send me a pm with your address.

#23

3D Printed

I've actually found the ninja flex products to be fairly priced, but the prices in Amazon can fluctuate from 34 to 56/ kg. I tried polycarbonate a long time ago, but it was so stiff it was hard to use on anything that needed some flex. Let me know how the chrome wrap goes. That would be awesome to see.

Send me a pm with your address.

Send me a pm with your address.

So far all I've used polycarbonate for is brackets, which it does a wonderful job at. I'm also experimenting with it for some push clips as it has much better layer adhesion and heat resistance than ABS. I'll be sure to post updates in my thread whenever I get my printer running again (waiting on a new mainboard).

#24

Senior Member