12a Disassembly Question?

#1

ok, so im trying to tear down the "spare" motor i got with my car, but im having a bit of a time with the front bolt. my buddy's impact that is rated to 750 ft-lbs wouldnt budge it... actually we tried spinning it both ways, nothing.

the plan now is a locked flywheel and a really long pipe... should i find someone with a stronger impact? should i heat it?

i guess its a dumb question, but is it a regular right-handed thread? i would think that it is, but i dont want to tighten it trying to loosen it. haha

the plan now is a locked flywheel and a really long pipe... should i find someone with a stronger impact? should i heat it?

i guess its a dumb question, but is it a regular right-handed thread? i would think that it is, but i dont want to tighten it trying to loosen it. haha

#2

It is a normal right hand thread.

The front pulley bolt is a royal bitch to get off. Most people put a thread locker on there, some put too much or use a permanent type. Try heating it with a Mapp torch until nice and hot. Or a propane torch if that's all you have will take a long time to heat it.

I had one motor where the shop put a green threadlocker on there and it was horrible to get off. I ended up locking the flywheel and using a I **** you not 6 foot cheater pipe over my breaker bar.

The front pulley bolt is a royal bitch to get off. Most people put a thread locker on there, some put too much or use a permanent type. Try heating it with a Mapp torch until nice and hot. Or a propane torch if that's all you have will take a long time to heat it.

I had one motor where the shop put a green threadlocker on there and it was horrible to get off. I ended up locking the flywheel and using a I **** you not 6 foot cheater pipe over my breaker bar.

#3

Lefty loosy on the front 19mm bolt. You have to lock the flywheel to have any chance at front bolt removal. Also heat it up with a MAPP gas torch. Propane can work. You're supposed to burn off the locktite that some engines had. Others come off just fine at 70 to 90 foot pounds of tightness which is factory spec even with supposed loctite. It's a gamble - some engines are easy and others make you want to grab your BFH. Usually the ones assembled by idiots - you know who you are.

Speaking of my BFH, I had a couple of insane FD engines. These normally are tightened to 200 foot pounds. Yeah that's what I said. But they still can come off with a normal impact, but not these two. I tried everything I could think of. No budge. So I grabbed an old craftsman 3/4" wrench, made sure the flywheel was locked, and with the bolt basically still glowing, I'd beat on the wrench like an abusive character is a William S Burroughs... anyway it would move a tiny bit with each hit until you swear the shaft was twisting, and only then would it start to show signs of loosening up. I might have bent the shaft on those two so I picked up a set of v-blocks to check for run out.

Speaking of my BFH, I had a couple of insane FD engines. These normally are tightened to 200 foot pounds. Yeah that's what I said. But they still can come off with a normal impact, but not these two. I tried everything I could think of. No budge. So I grabbed an old craftsman 3/4" wrench, made sure the flywheel was locked, and with the bolt basically still glowing, I'd beat on the wrench like an abusive character is a William S Burroughs... anyway it would move a tiny bit with each hit until you swear the shaft was twisting, and only then would it start to show signs of loosening up. I might have bent the shaft on those two so I picked up a set of v-blocks to check for run out.

#4

lol i have access to some very long cheater pipe, but i figured that impact would do it... i have seen it take off bolts that have broken breaker bars before, literally.

my crappy lil electric craftsman impact took off the flywheel nut but wouldnt touch anything else lol

my crappy lil electric craftsman impact took off the flywheel nut but wouldnt touch anything else lol

Last edited by bikeordie092; 03-29-13 at 12:56 AM.

#7

I just opened up two 12a's this week. I got a IR 3/4 drive impact turned on 5 and it's pop pop pop popp vrrooom ... Never had a problem with either of them. I tap the bolt with a hammer a couple times and it came right off. Hell even the 54mm flywheel nut acted like it wasn't even there. But I've used this gun on a Mack trucks pinion bolts and they're at 800-900 lbs.

Trending Topics

#11

#12

There are a few locking tools out there from places like Mazdatrix.

The one I use is essentially a 3-foot piece of 1.5" x 0.25" rolled steel bar stock with two holes drilled in it, allowing it to be bolted to the flywheel at a tangent. This is then braced on the floor or a suitable strong rest that the engine is on.

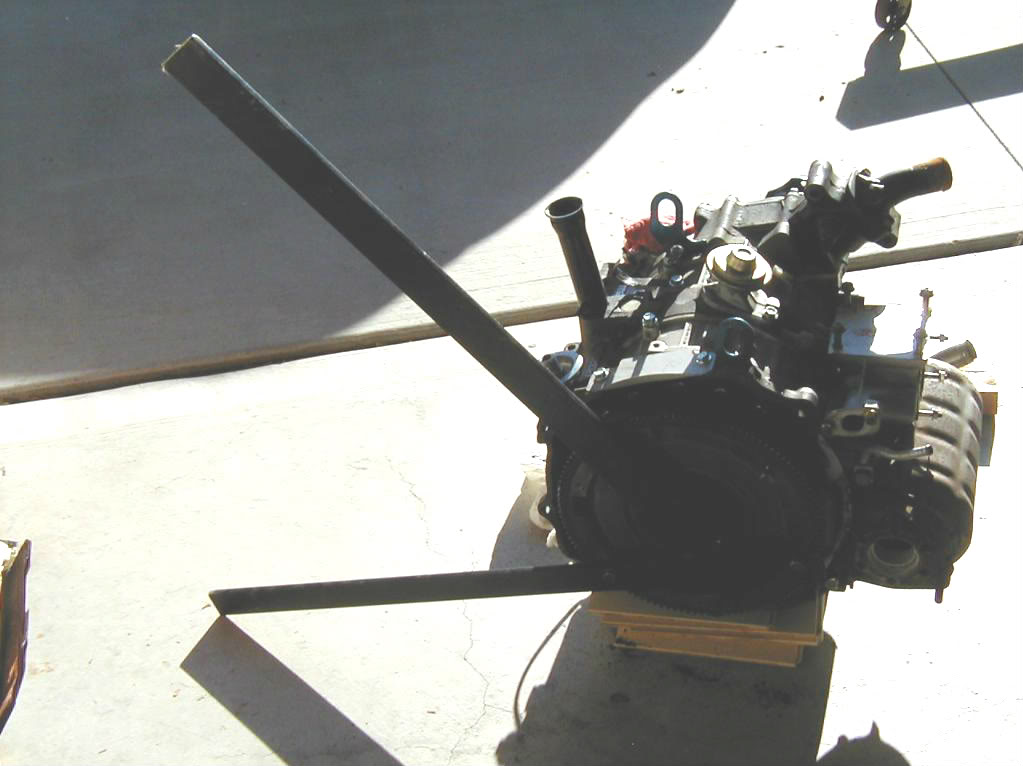

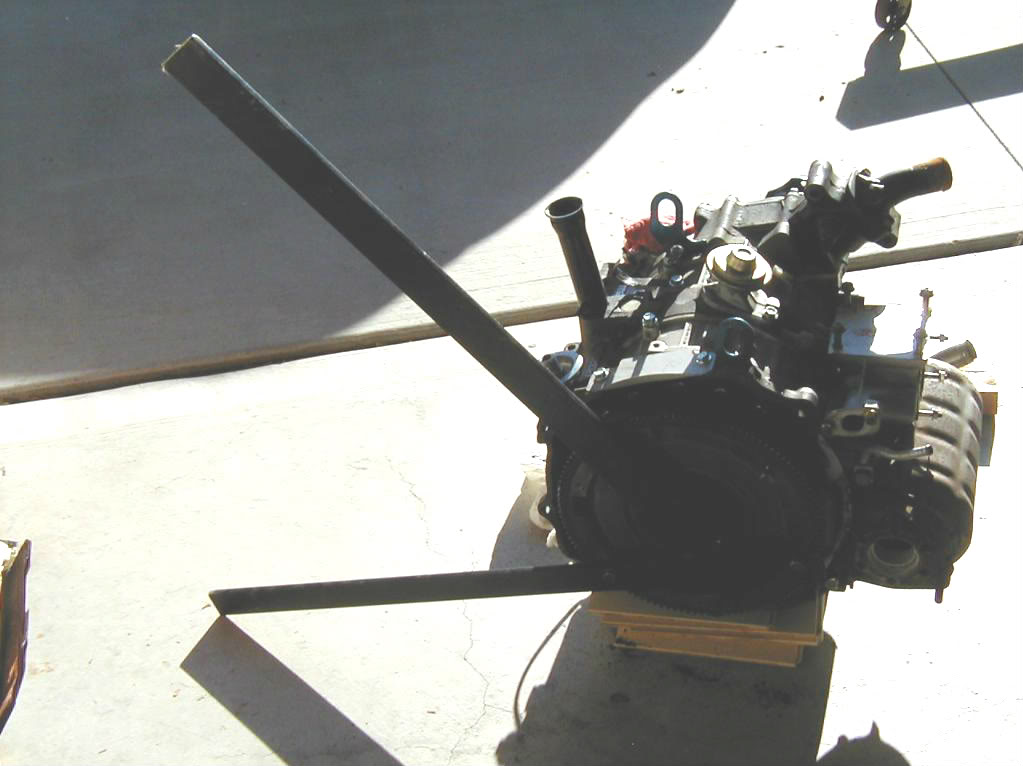

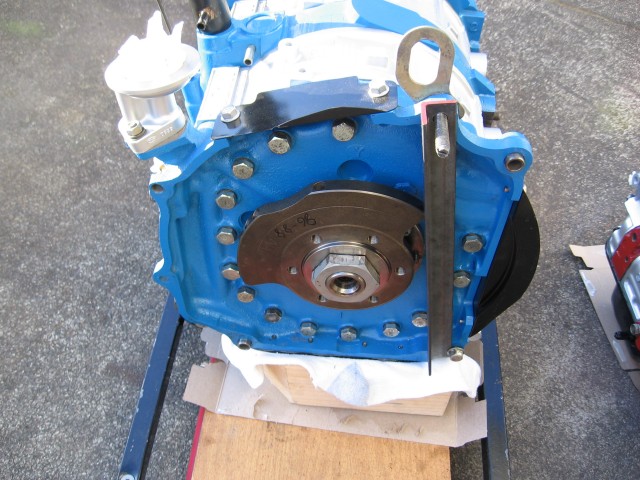

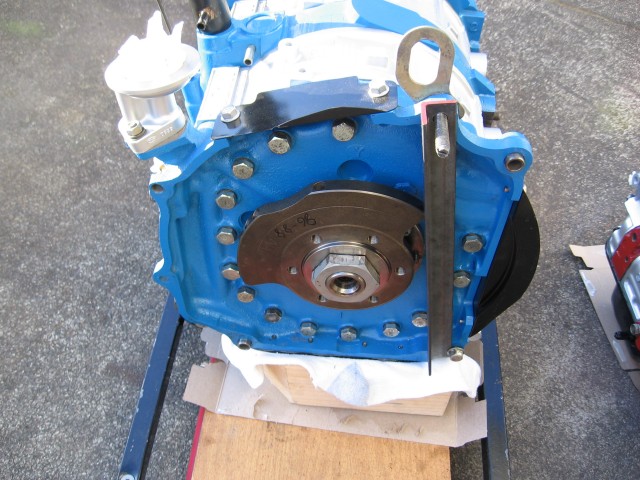

Pictures of the process:

Removing flywheel nut:

Installing flywheel nut:

Removing or Installing front pulley bolt:

The one I use is essentially a 3-foot piece of 1.5" x 0.25" rolled steel bar stock with two holes drilled in it, allowing it to be bolted to the flywheel at a tangent. This is then braced on the floor or a suitable strong rest that the engine is on.

Pictures of the process:

Removing flywheel nut:

Installing flywheel nut:

Removing or Installing front pulley bolt:

#14

Those are some awesome pics DD, I will look into making something along those lines. Not much can go wrong with flat steel.

In the TII engine I've been working on I went out and bought one of these from Autozone:

and held the front pulley tight with it resting on the water pump pulley and she came off without much hassle.

In the TII engine I've been working on I went out and bought one of these from Autozone:

and held the front pulley tight with it resting on the water pump pulley and she came off without much hassle.

#15

Worked on two engines today. Both needed some sort of stock flywheel or a rear CW and an aftermarket flywheel.

As mentioned earlier, I have the early version of what Mazdatrix sells. It's just a flywheel starter ring gear they chopped and welded a couple steel tubes to, then had it plated.

It's a little off but works well enough.

And not to leave the rear CW folks out, I came up with an angle iron that works perfectly for these.

As mentioned earlier, I have the early version of what Mazdatrix sells. It's just a flywheel starter ring gear they chopped and welded a couple steel tubes to, then had it plated.

It's a little off but works well enough.

And not to leave the rear CW folks out, I came up with an angle iron that works perfectly for these.

#18

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,592 Likes

on

1,841 Posts

RX7 1975-1985: Flywheels: Flywheel Stopper Bar Tool -

Thread

Thread Starter

Forum

Replies

Last Post

t-von

3rd Generation Specific (1993-2002)

9

09-10-15 01:56 PM

Nosferatu

2nd Generation Specific (1986-1992)

7

09-05-15 02:13 PM