GFORCE Transmissions PA

#1

Stay tuned...

Thread Starter

iTrader: (3)

Join Date: Jul 1997

Location: West Islip, Long Island NY

Posts: 2,917

Likes: 0

Received 1 Like

on

1 Post

GFORCE Transmissions PA

Myself, SpeedNYC (Roan) and 13BRx3 (Allen) took a road trip to GFORCE Tranmissions on Friday. We left there with a few goodies. Big thanks to Roan for getting all the details, talking to Mike and helping both Allen and I get our transmissions. I could have called GFORCE myself but since Roan already had a great relationship with them, he took care of it for me.

Last year I broke 3rd gear, Roan spoke to them and worked it out and since he was buying another transmission (20K total so far) and they fixed my transmission for a great deal. If you have to get GFORCE, I would suggest going through SpeedNYC (Roan)

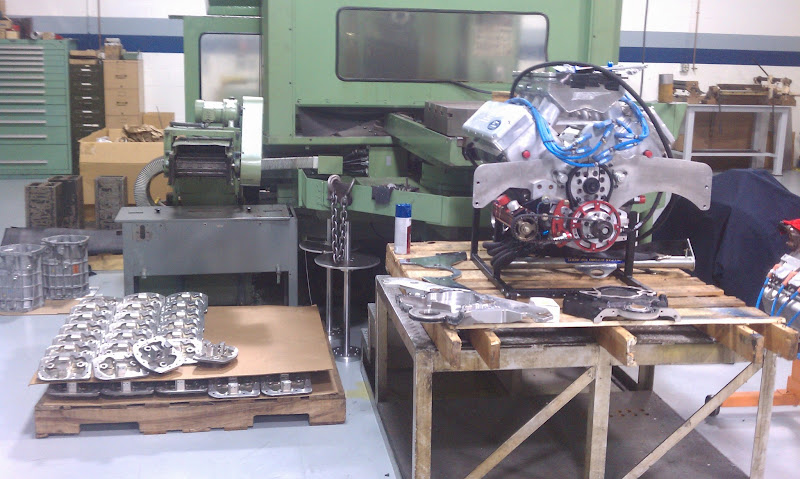

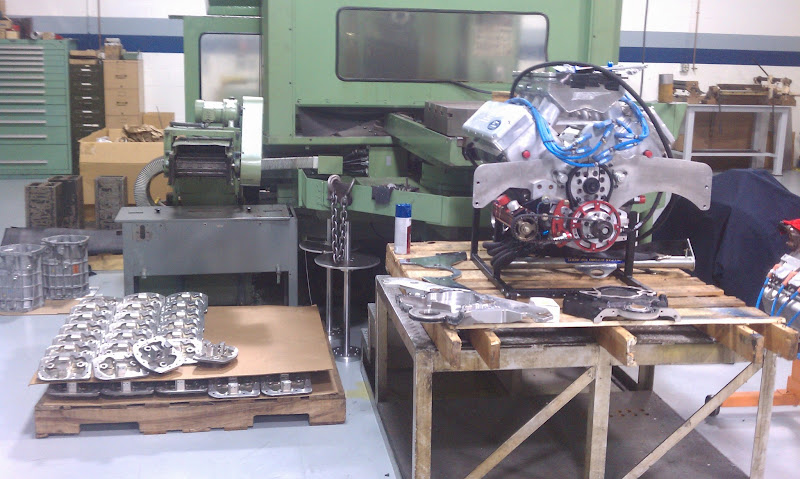

Big thanks to Mike@Gforce who rebuilt the tranny while we watched. He then gave us a tour of the facility which was huge. I really was amazed and how nice they were and the senior Mike made it a point to tell us they appreciate the rotary/import business and will support us. The rotor housings you see in the pic are in development and should be available shortly. Mike mentioned they designed these housings with the combined efforts of a select few of the top engine builders in the rotary drag racing community. These engine builders and tuners are the ones that are going to be testing the unit. The names that were mentioned have rotaries in the 6 sec/low 7 sec range all making over 1000HP.

Here are some pics...

Work Room

Rotor Housing they are developing...

My gearset

Another GF5R we bought...

Last year I broke 3rd gear, Roan spoke to them and worked it out and since he was buying another transmission (20K total so far) and they fixed my transmission for a great deal. If you have to get GFORCE, I would suggest going through SpeedNYC (Roan)

Big thanks to Mike@Gforce who rebuilt the tranny while we watched. He then gave us a tour of the facility which was huge. I really was amazed and how nice they were and the senior Mike made it a point to tell us they appreciate the rotary/import business and will support us. The rotor housings you see in the pic are in development and should be available shortly. Mike mentioned they designed these housings with the combined efforts of a select few of the top engine builders in the rotary drag racing community. These engine builders and tuners are the ones that are going to be testing the unit. The names that were mentioned have rotaries in the 6 sec/low 7 sec range all making over 1000HP.

Here are some pics...

Work Room

Rotor Housing they are developing...

My gearset

Another GF5R we bought...

#7

Stay tuned...

Thread Starter

iTrader: (3)

Join Date: Jul 1997

Location: West Islip, Long Island NY

Posts: 2,917

Likes: 0

Received 1 Like

on

1 Post

Housings are supposed to be much stronger. I wanted to ask if the housing was damaged can a new sleeve be pressed in, I assumed yes but I was too busy watching him build my tranny and did not want to distract him and these guys kept asking more questions!!!!

Trending Topics

#11

Stay tuned...

Thread Starter

iTrader: (3)

Join Date: Jul 1997

Location: West Islip, Long Island NY

Posts: 2,917

Likes: 0

Received 1 Like

on

1 Post

I thought the same thing but I guess at the HP levels we are at, we don't really know. Mike mentioned specific names on the guys that came to him and are currently testing and these are the top engine builders in PR and one rotary car in the US. I guess if they are coming to him it has to be worth it? All I was concerned about was if a sleeve can be pressed out and pressed back in. Maybe someone with more experience can chime in.

#12

most likely the housing was cast around the sleeve so probably not. i'm sure they could try but it may deform the new sleeve on installation.

i wasn't aware the housings were a weak link either unless the twisting forces are cracking the enlarged holes for the dowels/studs.

i wasn't aware the housings were a weak link either unless the twisting forces are cracking the enlarged holes for the dowels/studs.

Last edited by RotaryEvolution; 01-30-12 at 04:16 PM.

#15

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

Apex seals and e-shafts are already covered, side plates, its different story. Their breakage at dowel land is consequence of rotor housing deformation. Dowel pins should align parts of the engine, not transfer side loads created by housing deformation to side plates.

If anyone seen rotor housing design of wankel engines which were intended to be heavily turbocharged, then they would know how Mazda parts are subtle in comparsion with them. Mazda didnīt change casting strenght of production engines since 10A, they didnīt have to. But if someone is pushing 1300 HP and mainly very high torque levels, its understandable to move on to such components. Not only they will allow for even more power, but internal sealing at such levels will be better and so will be reliability.

If anyone seen rotor housing design of wankel engines which were intended to be heavily turbocharged, then they would know how Mazda parts are subtle in comparsion with them. Mazda didnīt change casting strenght of production engines since 10A, they didnīt have to. But if someone is pushing 1300 HP and mainly very high torque levels, its understandable to move on to such components. Not only they will allow for even more power, but internal sealing at such levels will be better and so will be reliability.

#16

Apex seals and e-shafts are already covered, side plates, its different story. Their breakage at dowel land is consequence of rotor housing deformation. Dowel pins should align parts of the engine, not transfer side loads created by housing deformation to side plates.

If anyone seen rotor housing design of wankel engines which were intended to be heavily turbocharged, then they would know how Mazda parts are subtle in comparsion with them. Mazda didnīt change casting strenght of production engines since 10A, they didnīt have to. But if someone is pushing 1300 HP and mainly very high torque levels, its understandable to move on to such components. Not only they will allow for even more power, but internal sealing at such levels will be better and so will be reliability.

If anyone seen rotor housing design of wankel engines which were intended to be heavily turbocharged, then they would know how Mazda parts are subtle in comparsion with them. Mazda didnīt change casting strenght of production engines since 10A, they didnīt have to. But if someone is pushing 1300 HP and mainly very high torque levels, its understandable to move on to such components. Not only they will allow for even more power, but internal sealing at such levels will be better and so will be reliability.

#17

Wow, I was there on Thursday afternoon. I got the "tour" but I'm disappointed I didn't spot the rotary parts in the workshop. It was my first time around there even though I work just 10min away. (My car doesn't have the power to need that kind of gearing)

I see you had a look at the new Ford race engine (and the Chevy labels they made for it as a gag).

If you noticed some boring cast iron parts in the back room you would have seen what I was there for.

I see you had a look at the new Ford race engine (and the Chevy labels they made for it as a gag).

If you noticed some boring cast iron parts in the back room you would have seen what I was there for.

#18

Banned. I got OWNED!!!

iTrader: (1)

Join Date: Sep 2003

Location: SoCal

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

Apex seals and e-shafts are already covered, side plates, its different story. Their breakage at dowel land is consequence of rotor housing deformation. Dowel pins should align parts of the engine, not transfer side loads created by housing deformation to side plates.

If anyone seen rotor housing design of wankel engines which were intended to be heavily turbocharged, then they would know how Mazda parts are subtle in comparsion with them. Mazda didnīt change casting strenght of production engines since 10A, they didnīt have to. But if someone is pushing 1300 HP and mainly very high torque levels, its understandable to move on to such components. Not only they will allow for even more power, but internal sealing at such levels will be better and so will be reliability.

If anyone seen rotor housing design of wankel engines which were intended to be heavily turbocharged, then they would know how Mazda parts are subtle in comparsion with them. Mazda didnīt change casting strenght of production engines since 10A, they didnīt have to. But if someone is pushing 1300 HP and mainly very high torque levels, its understandable to move on to such components. Not only they will allow for even more power, but internal sealing at such levels will be better and so will be reliability.

its always refreshing when someone with knowledge chimes in

thank you

thank you

#19

Banned. I got OWNED!!!

iTrader: (1)

Join Date: Sep 2003

Location: SoCal

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

that will never happen, low production parts made from billet are extremely costly for many reasons and should never go down in price but go up when people see the benefits from these custom made parts. this kind of stupid post reminds me of how many stupid people there are in this world!

[/QUOTE]

[/QUOTE]