Which WI kits are best?

#1

Full Member

Thread Starter

Which WI kits are best?

Hi guys,

Just wondering which water injection kits are considered some of the better ones to choose from currently?

Thanks,

Mike

Just wondering which water injection kits are considered some of the better ones to choose from currently?

Thanks,

Mike

Last edited by mikey13b; 06-18-16 at 07:11 AM.

#2

Racing Rotary Since 1983

iTrader: (6)

if you plan to run water or water meth i recommend either the AEM 30-3350 with 30-3003 filter or Coolingmist.

AEM re-engineered their product and it now is significantly better than the previous offering.

should you want to do 100% meth i highly recommend the Alkycontrol system.

AI belongs on all turbo'd rotaries.

AEM re-engineered their product and it now is significantly better than the previous offering.

should you want to do 100% meth i highly recommend the Alkycontrol system.

AI belongs on all turbo'd rotaries.

#5

I've had good success with Coolingmist and I think I put it to a harder test than most. I tracked my car with their stage 1 trunk mount for over 5 years with water only. 20-30 min sessions where I'd use 1/2-3/4 of a gallon per session. Run 12 sessions on average per weekend and 6-8 times per year equals quite a bit of use.

Last year I finally had an issue where my pump was dying and pulsing the flow. I upgraded to their newer 200psi pump and super atomizing nozzles and it's good as new.

Last year I finally had an issue where my pump was dying and pulsing the flow. I upgraded to their newer 200psi pump and super atomizing nozzles and it's good as new.

#7

Personally, I love the simplicity of the mechanical setups. Here is one made by a member on here:

Mechanical Pre-Turbo Water Injection - Wannaspeed

Thread detailing how he developed the kit:

https://www.rx7club.com/auxiliary-in...wi-kit-807016/

Mechanical Pre-Turbo Water Injection - Wannaspeed

Thread detailing how he developed the kit:

https://www.rx7club.com/auxiliary-in...wi-kit-807016/

Trending Topics

#8

RX-7 Old Timer

I was exploring mechanical setups, and in the end I went with the AEM 30-3350 + filter that Howard suggested.

The mechanical complexity is similar, and there are a few advantages:

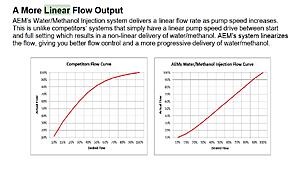

-Linear ramp up (the controller claims this, anyway)

-Flexibility to spay some pre-turbo and some post-intercooler

-Level sensor

I was also concerned with atomization at low pressures. With the controller, I can just spin dials and pick the injection window I want, and always get pretty good atomization.

The mechanical complexity is similar, and there are a few advantages:

-Linear ramp up (the controller claims this, anyway)

-Flexibility to spay some pre-turbo and some post-intercooler

-Level sensor

I was also concerned with atomization at low pressures. With the controller, I can just spin dials and pick the injection window I want, and always get pretty good atomization.

#9

The AEM pump, or any diaphragm pump, really, isn't actually linear. I own the AEM 30-3020 Water Methanol Failsafe gauge and thereís some good info in the literature. See attached for the typical flow curve of that pump and a 500cc nozzle. Iím using my ECU to PWM the pump and the 30-3020 to data log actual pump flow (it has a 0-5V output based on flow). If flow is out of range, it triggers my boost table switching input and drops the ECU back to WG pressure. Iíve tested the AEM nozzle down to 20% DC and atomization was really nice. Much below that and it wasnít great, but thatís pretty apparent in the flow curve as well.

#10

Racing Rotary Since 1983

iTrader: (6)

nice info Shainiac, thanks for sharing.

if you are concerned about an AI failure i will say that since we have around 40 or thereabouts power impulses per second safeguarding the motor using boost mgt isn't going to get it done.

as per John Pizzuto of J&S Electronics (http://www.jandssafeguard.com) Safeguard fame (both a rotary guy top top echelon elec engineer) you have to get it done on the next rotor face.

since elec travels at the speed of light ignition mgt must be the go-to safeguard defense.

of course there is nothing wrong w going to spring pressure and/or fuel but both will be too slow to save a detonating motor. ignition can.

again, thnx for the info.

Howard

if you are concerned about an AI failure i will say that since we have around 40 or thereabouts power impulses per second safeguarding the motor using boost mgt isn't going to get it done.

as per John Pizzuto of J&S Electronics (http://www.jandssafeguard.com) Safeguard fame (both a rotary guy top top echelon elec engineer) you have to get it done on the next rotor face.

since elec travels at the speed of light ignition mgt must be the go-to safeguard defense.

of course there is nothing wrong w going to spring pressure and/or fuel but both will be too slow to save a detonating motor. ignition can.

again, thnx for the info.

Howard

Last edited by Howard Coleman; 06-24-16 at 07:46 AM.

#11

Howard, I agree with you. I don't expect the system to save my butt if something all-out fails like a relay dying or line failure. The first reason

I added the failsafe gauge was because it provides a cost-effective way to data-log water-meth flow.

The gauge outputs a 0-5V signal that I can add to the datastream to my Megasquirt and hopefully make more informed tuning decisions.

It also shows you the general health of the water meth system.

I plan on running more water injection for the power I'm shooting for so that if I lost say ~10% of flow from a failing pump or partially clogged nozzle, the failsafe would catch it and bring it to my attention.

Meanwhile, I'm still flowing enough water to be safe, now I'm just more aware of how the system is holding up.

Proper knock sensing is on my list of upgrades, the only problem I've seen is that no-one can give you a square answer on what the actual safe knock threshold is on a certain engine with a certain setup. I don't want to break eggs to learn myself!

I added the failsafe gauge was because it provides a cost-effective way to data-log water-meth flow.

The gauge outputs a 0-5V signal that I can add to the datastream to my Megasquirt and hopefully make more informed tuning decisions.

It also shows you the general health of the water meth system.

I plan on running more water injection for the power I'm shooting for so that if I lost say ~10% of flow from a failing pump or partially clogged nozzle, the failsafe would catch it and bring it to my attention.

Meanwhile, I'm still flowing enough water to be safe, now I'm just more aware of how the system is holding up.

Proper knock sensing is on my list of upgrades, the only problem I've seen is that no-one can give you a square answer on what the actual safe knock threshold is on a certain engine with a certain setup. I don't want to break eggs to learn myself!

#13

Racing Rotary Since 1983

iTrader: (6)

"Proper knock sensing is on my list of upgrades, the only problem I've seen is that no-one can give you a square answer on what the actual safe knock threshold is on a certain engine with a certain setup. I don't want to break eggs to learn myself!"

it is one thing to have a monitor and response tool, such as my ViPEC V88, but quite another to correctly set it at the "threshold" of actual knock...

here's what ViPEC has to say re knock onset...

" Ideally these numbers should be about 20% above the highest Knock Level Cyl X for each of the load sites when the engine isn't knocking."

John Pizzuto was kind enough to PM me re the subject after my post...

"Over the years people have asked at what point does combustion become knock? In other words, how do you identify the start of knock? I didn't have an answer.

I found a paper a few months ago that defines it to be about 1.5 bar fluctuation of peak cylinder pressure. Say the peak combustion pressure is 85 bar, then the start of knock would be if the pressure was 85 bar with 1.5 bar oscillations riding on top of it. The oscillations are less than 2% of the peak pressure.

To see this, you have to run the pressure signal through a high pass filter. The result looks like a knock trace, without the mechanical interference.

Oscillations from heavy, audible knock can be 10% of the peak pressure.

This information starts at the bottom of page 57 of the document referenced in this thread:

http://www.aquamist.co.uk/forum2/vbu...ead.php?t=2872

It's a PHD Thesis by Emmanuel P. Kasseris, titled "Knock Limits in Spark Ignited Direct Injected Engines Using Gasoline/Ethanol Blends"

John Pizzuto

J&S Electronics"

i look forward to reading the link..

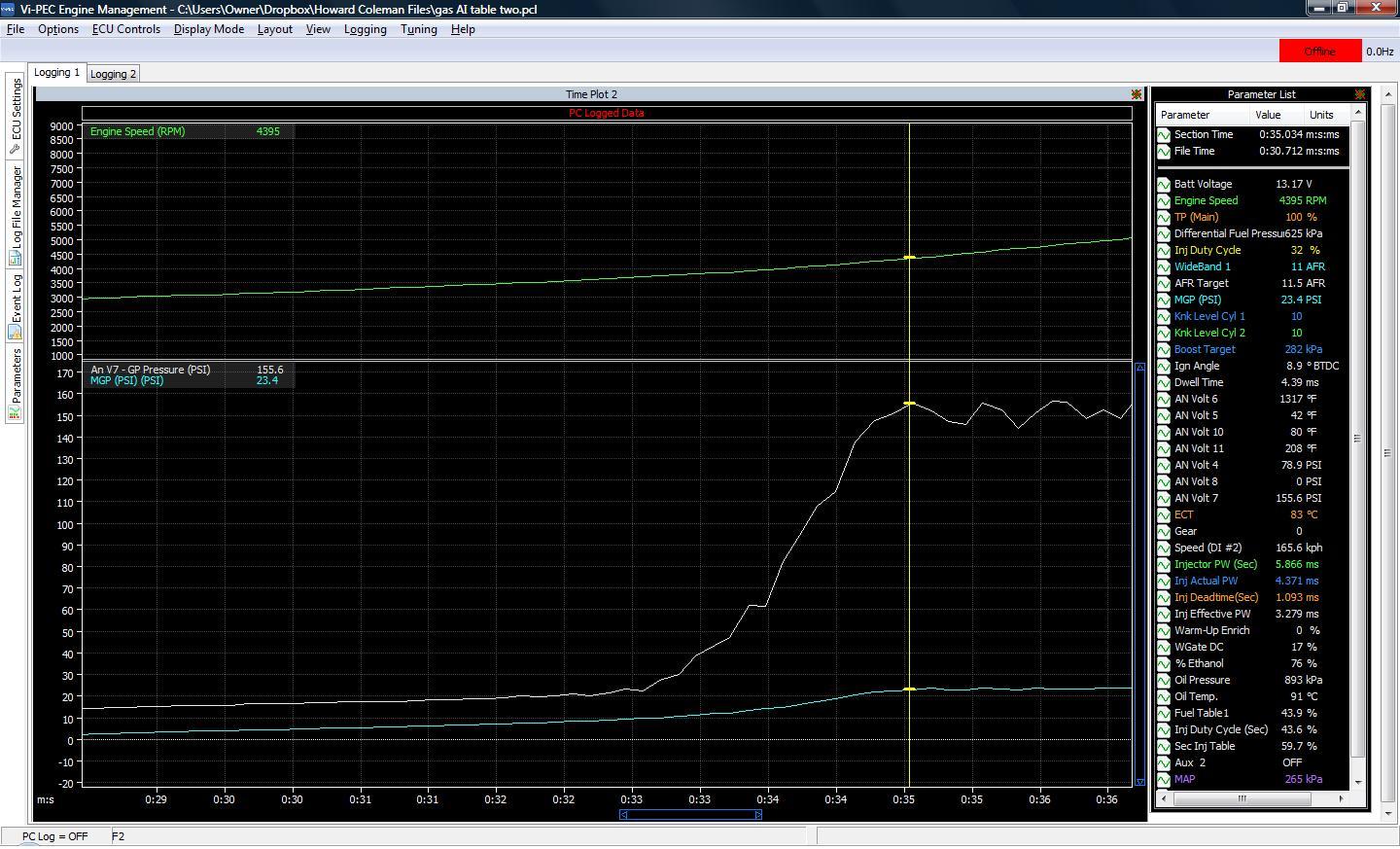

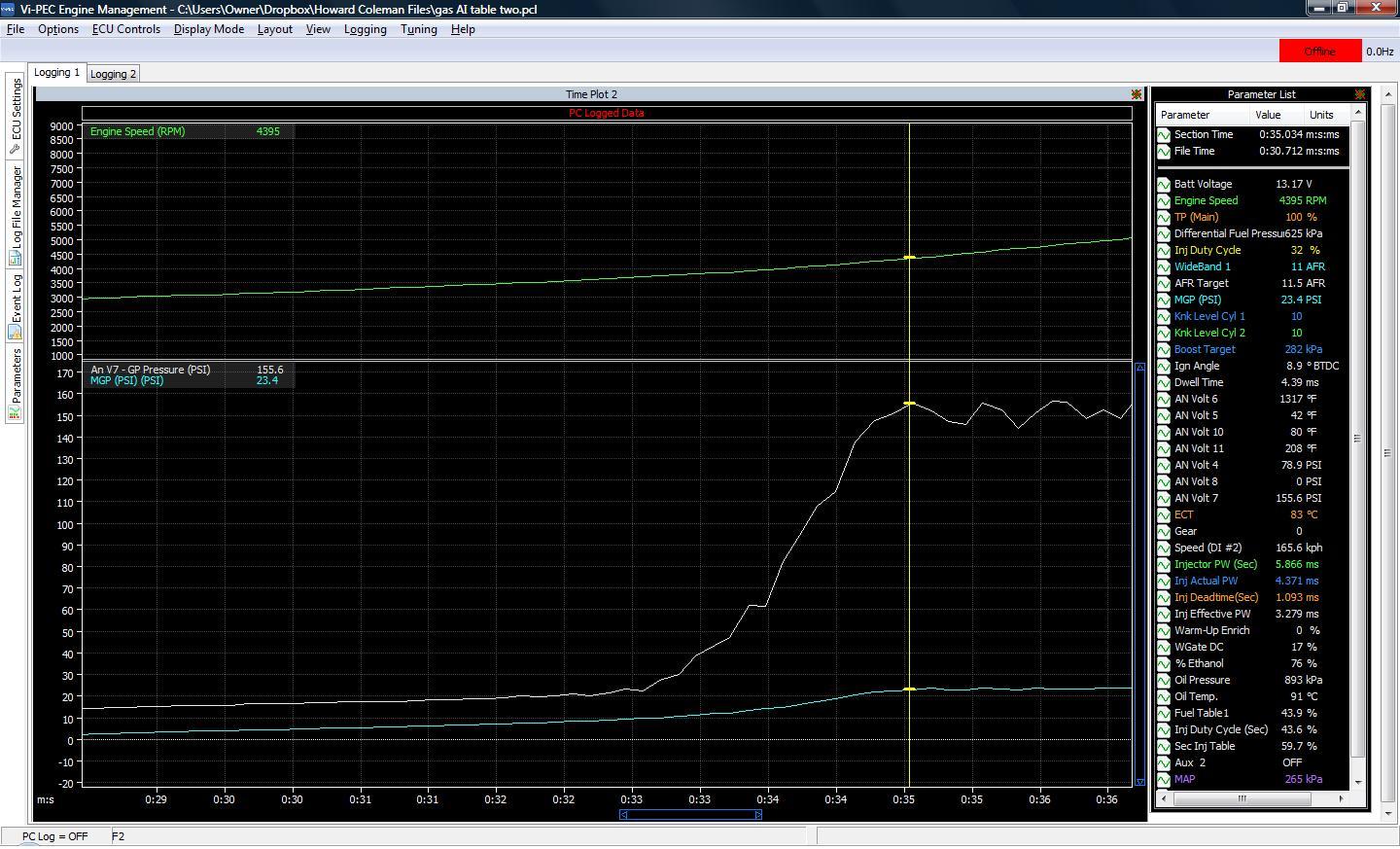

here's my AI system pressure data from one run thru 5 gears

the ramp aspect AI starts around 10 PSI and maxes w boost:

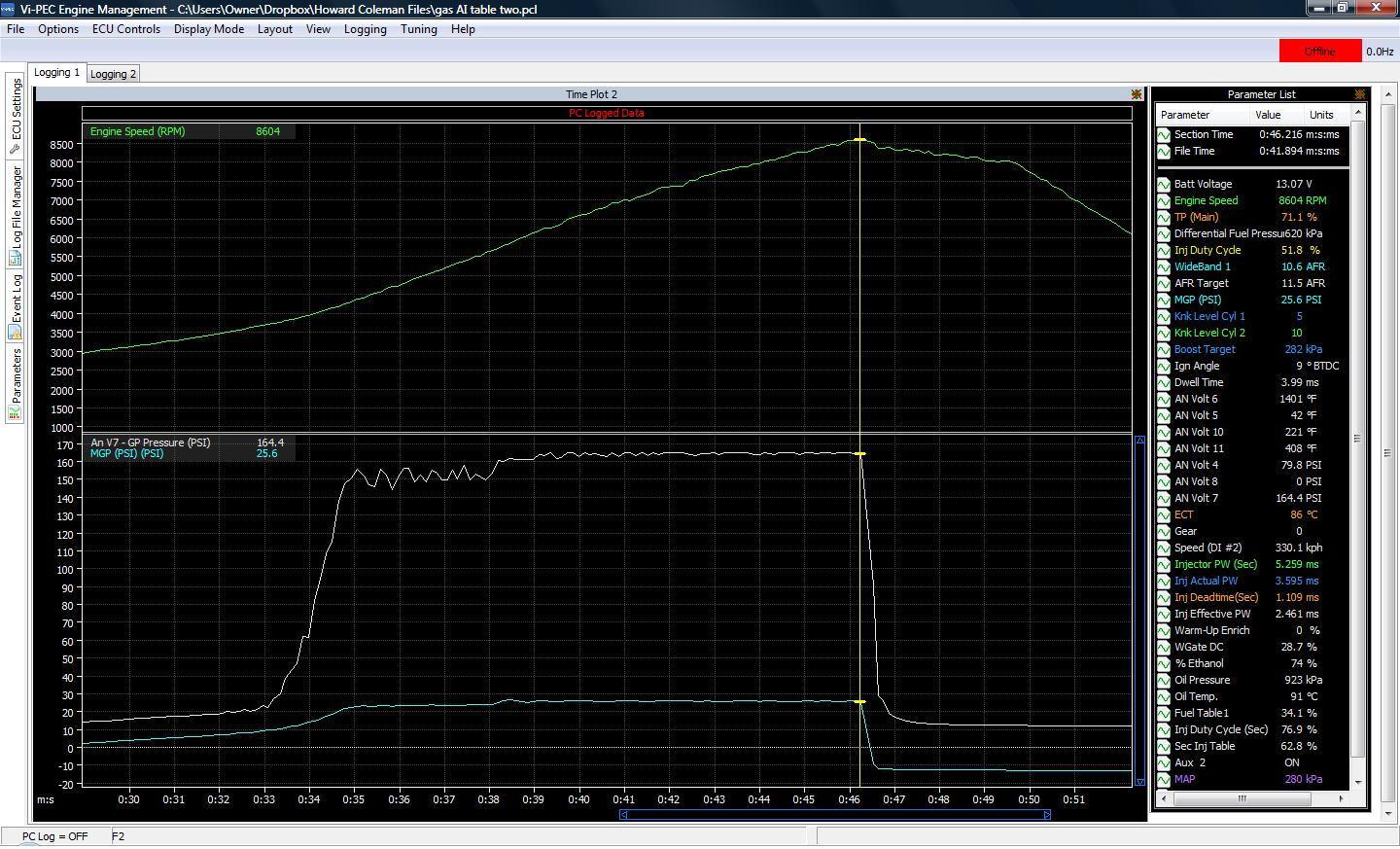

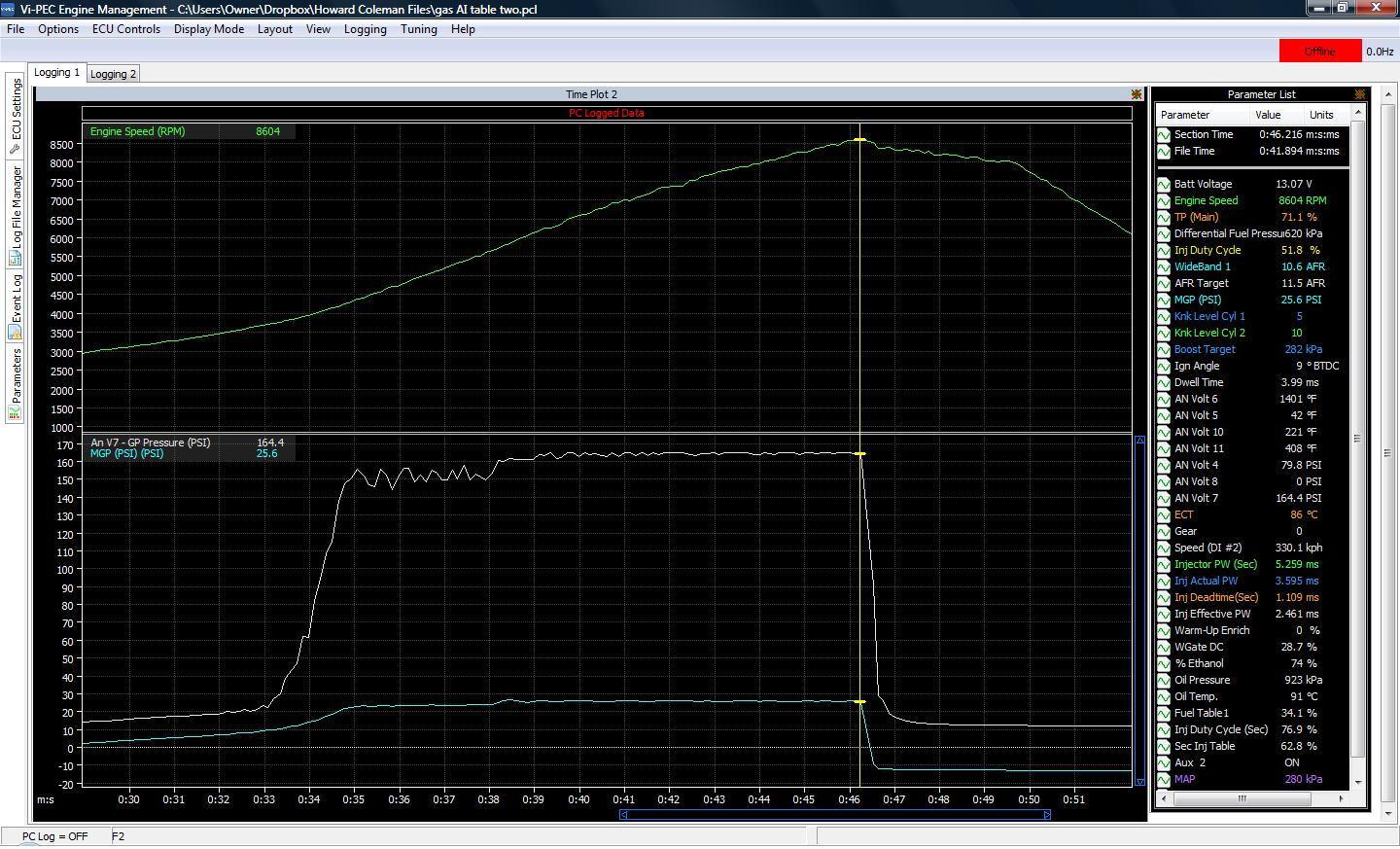

the bigger picture, same run, which was to 203 mph in fifth gear:

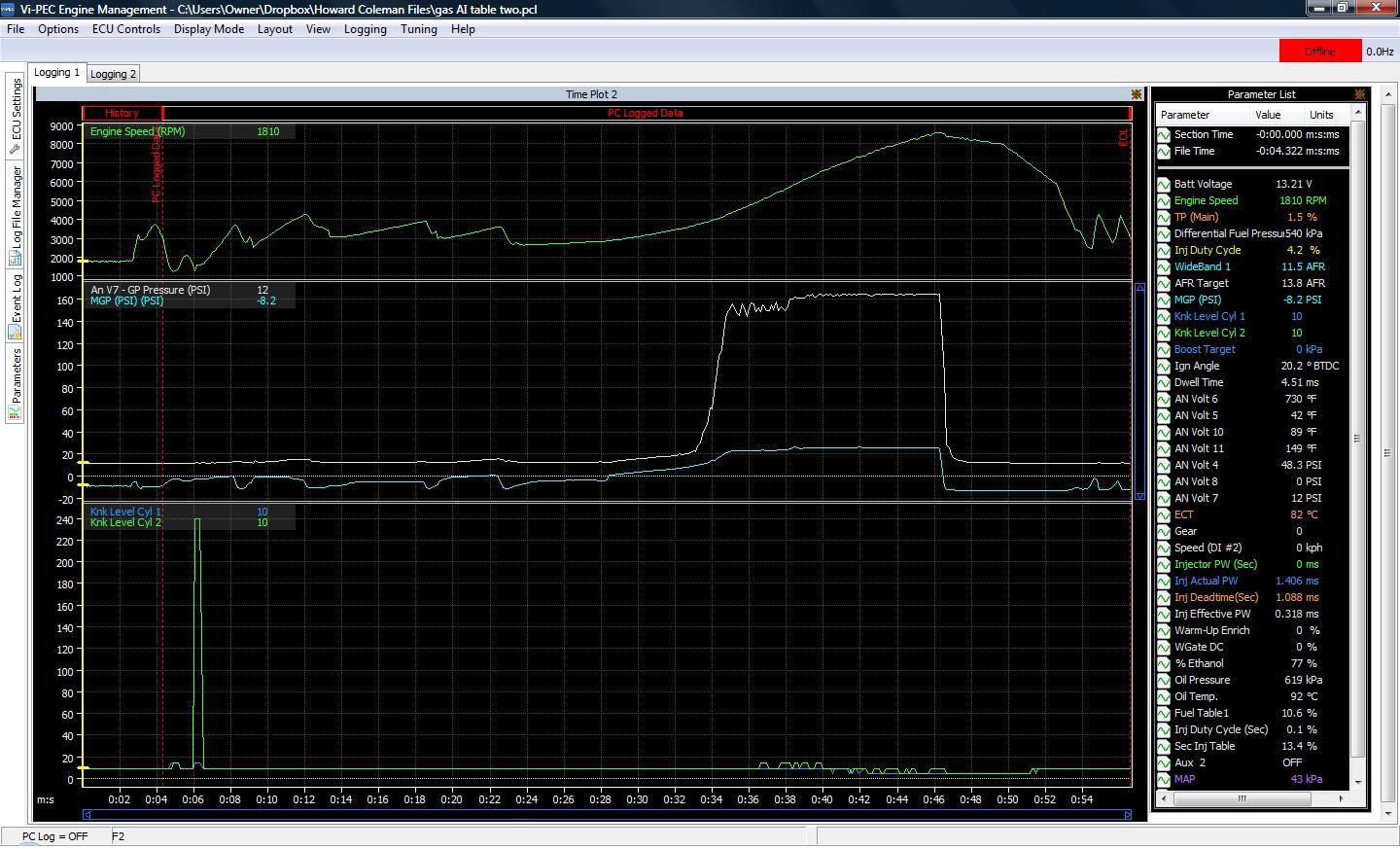

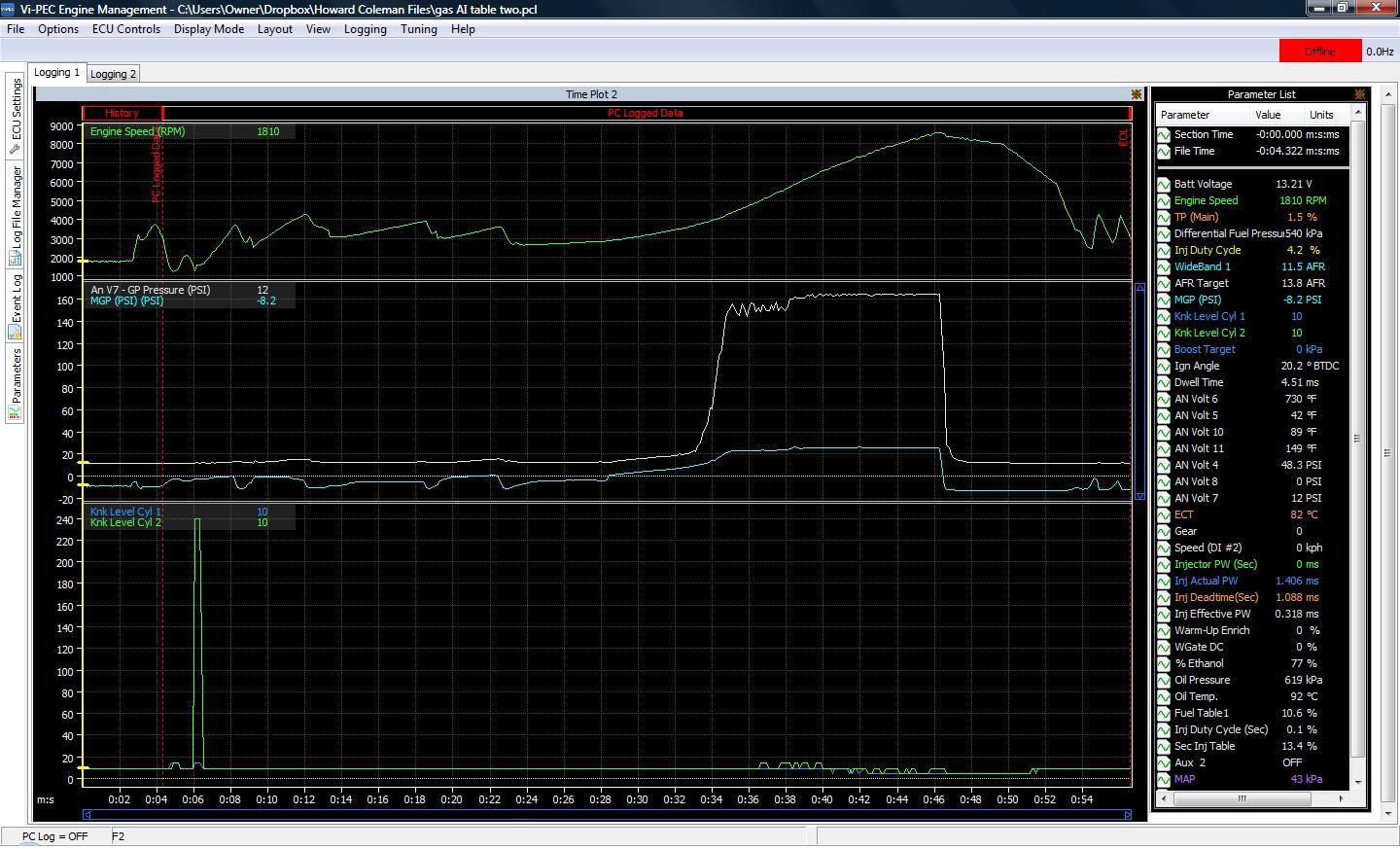

adding in the knock readings and looking at the whole run...

notice the knock spike to 240... registered only on the rear, the front was 15 (Bosch RX8 knock sensors) at 1325 rpm in first w 13% TPS, 18 degrees timing 13.3 AFR... probably a mechanical non combustion event. following that thru 5 gears knock only registered 10/15.

i have seen real knock register in the 600s. the key of course is where to I D the onset of real knock. where to set a reactive ignition response.

Howard

it is one thing to have a monitor and response tool, such as my ViPEC V88, but quite another to correctly set it at the "threshold" of actual knock...

here's what ViPEC has to say re knock onset...

" Ideally these numbers should be about 20% above the highest Knock Level Cyl X for each of the load sites when the engine isn't knocking."

John Pizzuto was kind enough to PM me re the subject after my post...

"Over the years people have asked at what point does combustion become knock? In other words, how do you identify the start of knock? I didn't have an answer.

I found a paper a few months ago that defines it to be about 1.5 bar fluctuation of peak cylinder pressure. Say the peak combustion pressure is 85 bar, then the start of knock would be if the pressure was 85 bar with 1.5 bar oscillations riding on top of it. The oscillations are less than 2% of the peak pressure.

To see this, you have to run the pressure signal through a high pass filter. The result looks like a knock trace, without the mechanical interference.

Oscillations from heavy, audible knock can be 10% of the peak pressure.

This information starts at the bottom of page 57 of the document referenced in this thread:

http://www.aquamist.co.uk/forum2/vbu...ead.php?t=2872

It's a PHD Thesis by Emmanuel P. Kasseris, titled "Knock Limits in Spark Ignited Direct Injected Engines Using Gasoline/Ethanol Blends"

John Pizzuto

J&S Electronics"

i look forward to reading the link..

here's my AI system pressure data from one run thru 5 gears

the ramp aspect AI starts around 10 PSI and maxes w boost:

the bigger picture, same run, which was to 203 mph in fifth gear:

adding in the knock readings and looking at the whole run...

notice the knock spike to 240... registered only on the rear, the front was 15 (Bosch RX8 knock sensors) at 1325 rpm in first w 13% TPS, 18 degrees timing 13.3 AFR... probably a mechanical non combustion event. following that thru 5 gears knock only registered 10/15.

i have seen real knock register in the 600s. the key of course is where to I D the onset of real knock. where to set a reactive ignition response.

Howard

#14

That's pretty neat. I imagine that is all done by the controller. The ramp rate in duty cycle between ON and FULL probably is the opposite of the natural pump flow curve to make it flatter. If it turns on at 10 and full at 20psi, 15 probably isn't 50% DC, but a duty cycle that gives you half flow.

#15

Racing Rotary Since 1983

iTrader: (6)

yes...

since i run only methanol as AI injectant i take system integrity very seriously and therefore my system is Alkycontrol... (since 04).

the controller does allow ramp and entry adjustment, which of course is crude compared to fuel injection but does get the job done. my guess is there is a bit of room for better adjustment.

since i run only methanol as AI injectant i take system integrity very seriously and therefore my system is Alkycontrol... (since 04).

the controller does allow ramp and entry adjustment, which of course is crude compared to fuel injection but does get the job done. my guess is there is a bit of room for better adjustment.

#17

I was exploring mechanical setups, and in the end I went with the AEM 30-3350 + filter that Howard suggested.

The mechanical complexity is similar, and there are a few advantages:

-Linear ramp up (the controller claims this, anyway)

-Flexibility to spay some pre-turbo and some post-intercooler

-Level sensor

I was also concerned with atomization at low pressures. With the controller, I can just spin dials and pick the injection window I want, and always get pretty good atomization.

The mechanical complexity is similar, and there are a few advantages:

-Linear ramp up (the controller claims this, anyway)

-Flexibility to spay some pre-turbo and some post-intercooler

-Level sensor

I was also concerned with atomization at low pressures. With the controller, I can just spin dials and pick the injection window I want, and always get pretty good atomization.

You should be able to use a level sensor with just about any setup.

What do you consider low pressure? Most people set the pressure switch to turn on at 10 psi or higher, otherwise you end up going through water or water/meth mix really fast. I don't know about low single digit pressures because I've never really looked into it, but anything in the double digits seems to produce great atomization.

In all honesty, people have had great results with all kinds of WI setups. Mechanical is my personal preference, but external pump setups like the AEM work great as well.

#18

if you plan to run water or water meth i recommend either the AEM 30-3350 with 30-3003 filter or Coolingmist.

AEM re-engineered their product and it now is significantly better than the previous offering.

should you want to do 100% meth i highly recommend the Alkycontrol system.

AI belongs on all turbo'd rotaries.

AEM re-engineered their product and it now is significantly better than the previous offering.

should you want to do 100% meth i highly recommend the Alkycontrol system.

AI belongs on all turbo'd rotaries.

Apart from that it works well on my set up with small nozzle, diluted boost juice on modest 400rwhp engine, but wondering if its worth upgrading.

#20

What are the improvements AEM made on their kit? Im running the previous version with the old controller, wondering if its worthwhile upgrading. Ive got a feeling it doesn't really ramp up but just starts spraying mist at full volume at the starting boost level. At least when i hold the nozzle up and press the "test" button that's what it looks like.

Apart from that it works well on my set up with small nozzle, diluted boost juice on modest 400rwhp engine, but wondering if its worth upgrading.

Apart from that it works well on my set up with small nozzle, diluted boost juice on modest 400rwhp engine, but wondering if its worth upgrading.

#22

I run a M5 nozzle of pure water without a re-tune on BUR-9 plugs all around, NGK standard wires, stock coils, and a HKS Twin Power. Never an issue.

#23

I agree with Smokey. I've been running a simple boost-activated WI system for several years. I sized my nozzle (M3) using Howard's formula in the stickys and have had zero issues on stock ignition, including stock plugs. It's set to come on between 1 and 2 psi. Nozzle is post-IC, pre-TB. No break-up and no discernable loss of power.

Thread

Thread Starter

Forum

Replies

Last Post

Monsterbox

Auxiliary Injection

46

05-26-20 01:50 AM

Chriz88DX

2nd Generation Specific (1986-1992)

6

05-08-16 11:05 AM