Aluminum Flywheel WTF?

#1

Magnet Boy

Thread Starter

Just received my long awaited high performance lightweight aluminum flywheel for my FD to be used with an ACT XT clutch. The flywheel utilizes a replaceable friction surface. When I handed it to my mechanic, he said WTF? How come this surface isn't machined? It is clearly a rough stock finish. The texture appears to have pores on the order of 5 to 10 mils deep.

I discussed this with the vendor (who shall remain nameless for the time being) who explained that all of their flywheels look like this. I said WTF? every flywheel I've ever seen has a machined surface. I expected this surface as delivered to be turned on a lathe or ground. My mechanic and I are concerned that this will eat the hell out of my clutch disk while causing overheating, hot spots, chattering, etc. The vendor said they've always made them this way and it is completely normal and not a problem.

My mechanic purchased the same exact setup approximately four years ago. He noticed that his friction plate has 10 fasteners while mine has 16 fasteners. Apparently they have made changes over the years. My mechanic still has in hand the original friction plate from four years ago (since replaced) and this original plate appears to be machined has he rememered it was when he got it. About a year ago, he bought a new friction plate from the same vendor and remembers the same quality machined surface, unlike mine.

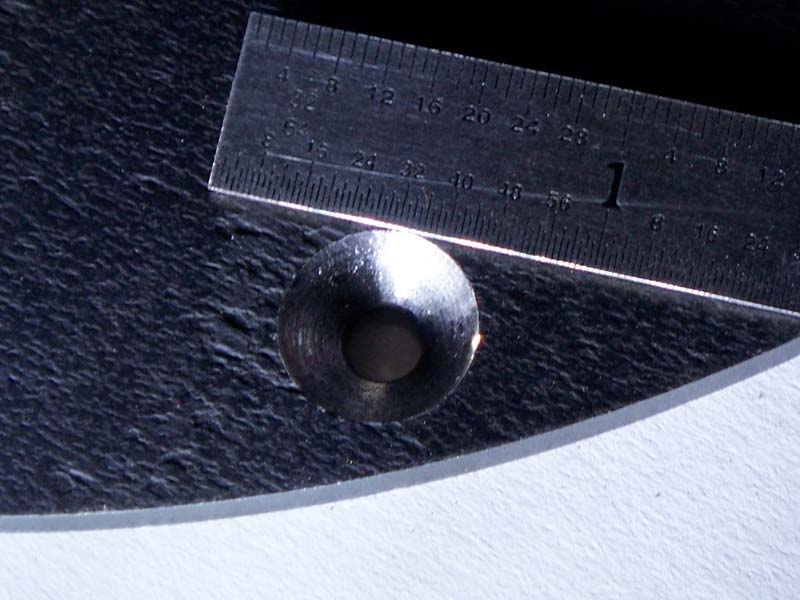

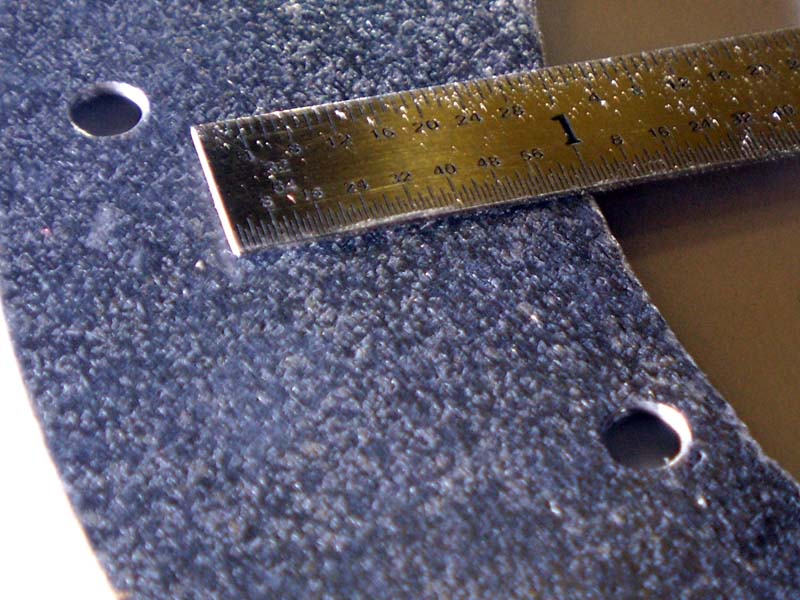

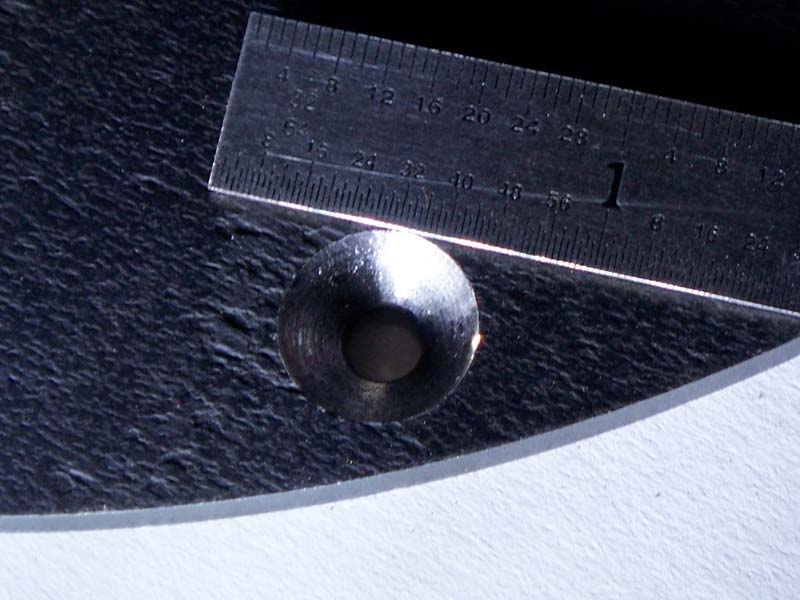

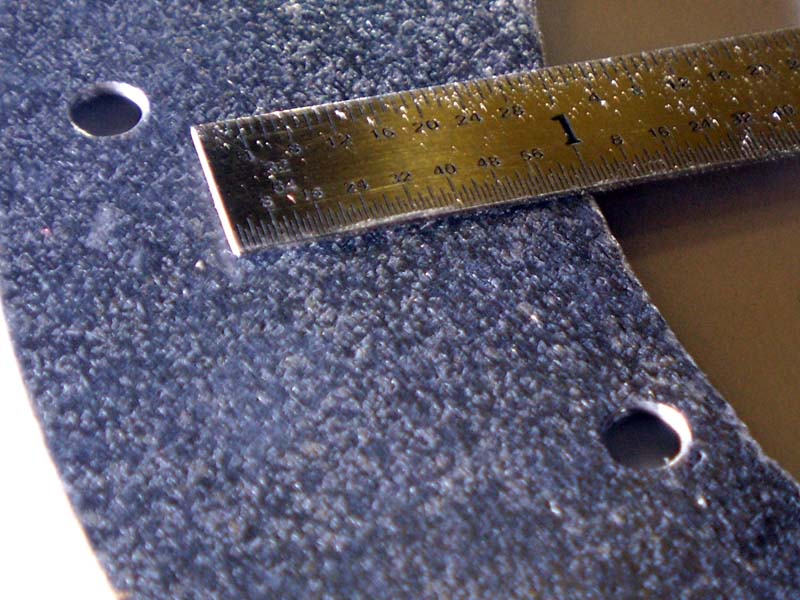

What do you think? See attach photos of the replaceable friction surface from my flywheel. I have attempted to highlight the texture of the surface with side lighting. #1 overall plate, #2 close up of front surface, #3 front surface showing scale, #4 rear surface.

I discussed this with the vendor (who shall remain nameless for the time being) who explained that all of their flywheels look like this. I said WTF? every flywheel I've ever seen has a machined surface. I expected this surface as delivered to be turned on a lathe or ground. My mechanic and I are concerned that this will eat the hell out of my clutch disk while causing overheating, hot spots, chattering, etc. The vendor said they've always made them this way and it is completely normal and not a problem.

My mechanic purchased the same exact setup approximately four years ago. He noticed that his friction plate has 10 fasteners while mine has 16 fasteners. Apparently they have made changes over the years. My mechanic still has in hand the original friction plate from four years ago (since replaced) and this original plate appears to be machined has he rememered it was when he got it. About a year ago, he bought a new friction plate from the same vendor and remembers the same quality machined surface, unlike mine.

What do you think? See attach photos of the replaceable friction surface from my flywheel. I have attempted to highlight the texture of the surface with side lighting. #1 overall plate, #2 close up of front surface, #3 front surface showing scale, #4 rear surface.

#4

Magnet Boy

Thread Starter

Originally Posted by Aeka GSR

is that replacement peice aluminum too? If not i would imagine it wouldnt be machined.

The odd thing is the way the vendor claims "we've always made them this way" and "we have probably thousands in service and they are all like this" whereas my mechanic's friction plate from one year ago seemed to be machined. The vendor seems to be either lying or intentionally misrepresenting what is going on. Maybe the vendor has made a change to reduce the cost based on a theory that the unmachined surface is FINE. OK. But why not say so? Why claim "we always made them this way" if in fact this is not true (since they used to be machined)?

Most steel or chromemoly flywheels are cast or forged and then turned on a lathe, so of course the friction surface will be a flat machined surface, just like a brake rotor. The question I am posing to the Rx-7 community here is: should a replaceable steel friction surface on an aluminum flywheel also be machined? Or is it OK that is kind of rough? Will this extra roughness result in undue and premature wear and tear on the clutch disk?

#5

Magnet Boy

Thread Starter

Originally Posted by mono4lamar

looks completely normal to me... its the fidanza flywheel right? i have a fidanza on my fd and it looked the same as the last one on my mx6. its just the way the replacement friction surface looks.

But this raises exactly the information I want to see:

Is this how a Fidanza aluminum flywheel replaceable friction surface looks?

Is this how a Racing Beat aluminum flywheel replaceable friciton surface looks?

#7

This is normal for a replacement surface, it just needs to be mounted up and turned. The reason for this it to compensate for the variances of each flywheel. If they sent it to you pre machined it would not be true and you would not get the best mating surface for the clutch disk.

Hope this helps,

Dan

Hope this helps,

Dan

Trending Topics

#8

Originally Posted by Chadwick

This is normal for a replacement surface, it just needs to be mounted up and turned. The reason for this it to compensate for the variances of each flywheel. If they sent it to you pre machined it would not be true and you would not get the best mating surface for the clutch disk.

Hope this helps,

Dan

Hope this helps,

Dan

#9

Magnet Boy

Thread Starter

Originally Posted by tmiked

Looks to me like someone just decided to save on manufacturing costs.

#10

Magnet Boy

Thread Starter

Originally Posted by Chadwick

This is normal for a replacement surface, it just needs to be mounted up and turned. The reason for this it to compensate for the variances of each flywheel. If they sent it to you pre machined it would not be true and you would not get the best mating surface for the clutch disk.

Hope this helps,

Dan

Hope this helps,

Dan

THIS IS NOT A REPLACEMENT INSERT. THIS IS A BRAND NEW FLYWHEEL. IT CAME LIKE THIS. I removed the insert so I could inspect the back side and so I could show pictures without revealing the vendor. I wanted an unbiased opinion.

I agree the new insert ought to be installed on the flywheel and THEN turned, right? That is what I am going to do. This vendor is claiming I ought to just throw it on there AS IS and let my new clutch wear away the stock rough surface. WTF?

#11

Originally Posted by rxcited2

Dan,

THIS IS NOT A REPLACEMENT INSERT. THIS IS A BRAND NEW FLYWHEEL. IT CAME LIKE THIS. I removed the insert so I could inspect the back side and so I could show pictures without revealing the vendor. I wanted an unbiased opinion.

I agree the new insert ought to be installed on the flywheel and THEN turned, right? That is what I am going to do. This vendor is claiming I ought to just throw it on there AS IS and let my new clutch wear away the stock rough surface. WTF?

THIS IS NOT A REPLACEMENT INSERT. THIS IS A BRAND NEW FLYWHEEL. IT CAME LIKE THIS. I removed the insert so I could inspect the back side and so I could show pictures without revealing the vendor. I wanted an unbiased opinion.

I agree the new insert ought to be installed on the flywheel and THEN turned, right? That is what I am going to do. This vendor is claiming I ought to just throw it on there AS IS and let my new clutch wear away the stock rough surface. WTF?

#15

Lives on the Forum

Originally Posted by Chadwick

This is normal for a replacement surface, it just needs to be mounted up and turned.

#16

Magnet Boy

Thread Starter

Agreed ^ it needs to be mounted and turned. But is it right that a new flywheel ought to come this way? Is it right that the vendor lied about changes to the way he ships his flywheels? Is it right that the vendor suggests to use it AS IS?

#17

Full Member

Join Date: Jan 2005

Location: Calgary, AB, Canada

Posts: 104

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by rxcited2

NO. This is NOT a Fidanza flywheel.

But this raises exactly the information I want to see:

Is this how a Fidanza aluminum flywheel replaceable friction surface looks?

Is this how a Racing Beat aluminum flywheel replaceable friciton surface looks?

But this raises exactly the information I want to see:

Is this how a Fidanza aluminum flywheel replaceable friction surface looks?

Is this how a Racing Beat aluminum flywheel replaceable friciton surface looks?

nope. my racing beat insert was smooth not all pitted like that one...

#18

Originally Posted by rxcited2

Agreed ^ it needs to be mounted and turned. But is it right that a new flywheel ought to come this way? Is it right that the vendor lied about changes to the way he ships his flywheels? Is it right that the vendor suggests to use it AS IS?

#19

Originally Posted by rxcited2

Dan,

THIS IS NOT A REPLACEMENT INSERT. THIS IS A BRAND NEW FLYWHEEL. IT CAME LIKE THIS. I removed the insert so I could inspect the back side and so I could show pictures without revealing the vendor. I wanted an unbiased opinion.

I agree the new insert ought to be installed on the flywheel and THEN turned, right? That is what I am going to do. This vendor is claiming I ought to just throw it on there AS IS and let my new clutch wear away the stock rough surface. WTF?

THIS IS NOT A REPLACEMENT INSERT. THIS IS A BRAND NEW FLYWHEEL. IT CAME LIKE THIS. I removed the insert so I could inspect the back side and so I could show pictures without revealing the vendor. I wanted an unbiased opinion.

I agree the new insert ought to be installed on the flywheel and THEN turned, right? That is what I am going to do. This vendor is claiming I ought to just throw it on there AS IS and let my new clutch wear away the stock rough surface. WTF?

#20

Lives on the Forum

Originally Posted by rxcited2

This vendor is claiming I ought to just throw it on there AS IS and let my new clutch wear away the stock rough surface. WTF?

#22

Passenger

Posts: n/a

WOW..... cant wait until more information is revealed!!! both my origional SR flywheel that i bought in 02 and the replacement friction plate i bought from SR in 06 were BOTH machined....

while on this topic, my SR flywheel has the lesser ammount of rivits and you say you have the more ammount of rivits, and my question is if you can use the RB replacement friction plate with the more modern SR flywheels because the replacement plate from SR is $150 and is only $75 from RB.......

while on this topic, my SR flywheel has the lesser ammount of rivits and you say you have the more ammount of rivits, and my question is if you can use the RB replacement friction plate with the more modern SR flywheels because the replacement plate from SR is $150 and is only $75 from RB.......