Oddball Weber IDA questions

#1

Oddball Weber IDA questions

Has anyone flowbenched a weber IDA to see what CFM it has?

And, with the RB IDA manifold, does anyone know the thread and pitch of the brake booster fitting, and the two fittings in the primary port runners?

Does the 2nd gen oil injectors thread into the RB IDA primary port runners?

And, with the RB IDA manifold, does anyone know the thread and pitch of the brake booster fitting, and the two fittings in the primary port runners?

Does the 2nd gen oil injectors thread into the RB IDA primary port runners?

#3

The brake booster fitting should be a 3/8" NPT, if the other 2 are for OMP lines, then they're probably 1/8" NPT.

I've never seen anyone use the FI oil injectors on a carb intake, interesting idea. If you go that route, keep in mind that the vacuum hose is not a vacuum line, it supplies filtered fresh air. Tap into the bottom of the filter box, inside the fitered air area for supply. I don't really see any advantage in using them. 1/8" NPT brass barbs have always worked well.

I've never seen anyone use the FI oil injectors on a carb intake, interesting idea. If you go that route, keep in mind that the vacuum hose is not a vacuum line, it supplies filtered fresh air. Tap into the bottom of the filter box, inside the fitered air area for supply. I don't really see any advantage in using them. 1/8" NPT brass barbs have always worked well.

#4

hi trochoid,

1/8" npt on the brake booster is very close, but does not quite thread in. i think it's still metric, and i've seen stock 12a carb brake booster hardware on there for that.

for the omp ports, i'm just looking for something that threads right in not involving retapping. it's a real oddball thread and their website says it's metric so a trip to the junkyard will find out if the FI oil injectors are a fit. if not then i'll just have to brass barb it.

1/8" npt on the brake booster is very close, but does not quite thread in. i think it's still metric, and i've seen stock 12a carb brake booster hardware on there for that.

for the omp ports, i'm just looking for something that threads right in not involving retapping. it's a real oddball thread and their website says it's metric so a trip to the junkyard will find out if the FI oil injectors are a fit. if not then i'll just have to brass barb it.

#7

thanks to the junkyard i now know a stock 1st gen banjo bolt threads into the new RB IDA manifold.

could not find any easily accessable 2nd gen oil injectors, didn't want to spend time taking intake manifold off the only 1 i found.

so for the omp fittings i'm gonna tap out to 1/8" NPT and use the traditional brass barb fitting.

could not find any easily accessable 2nd gen oil injectors, didn't want to spend time taking intake manifold off the only 1 i found.

so for the omp fittings i'm gonna tap out to 1/8" NPT and use the traditional brass barb fitting.

Trending Topics

#10

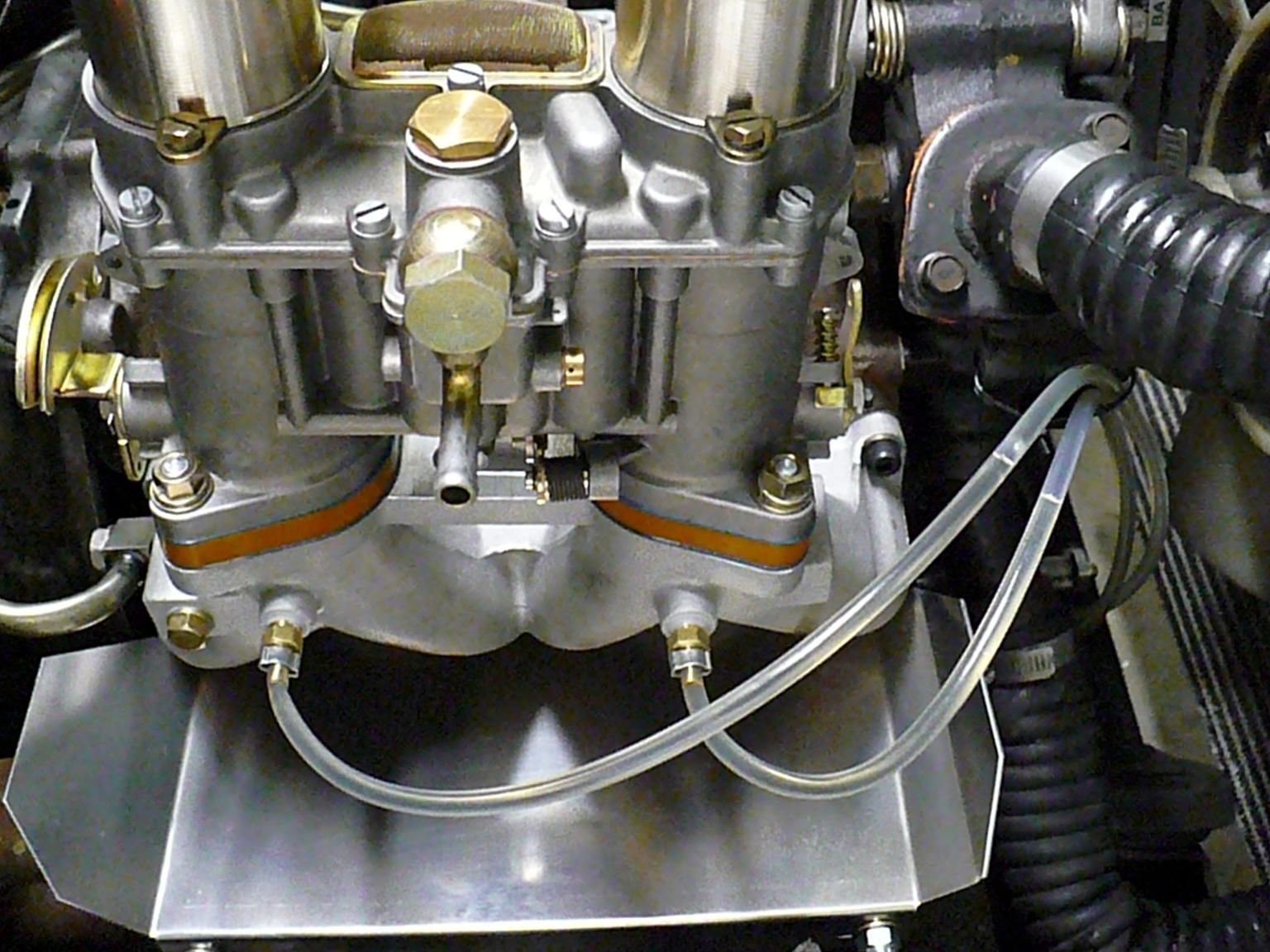

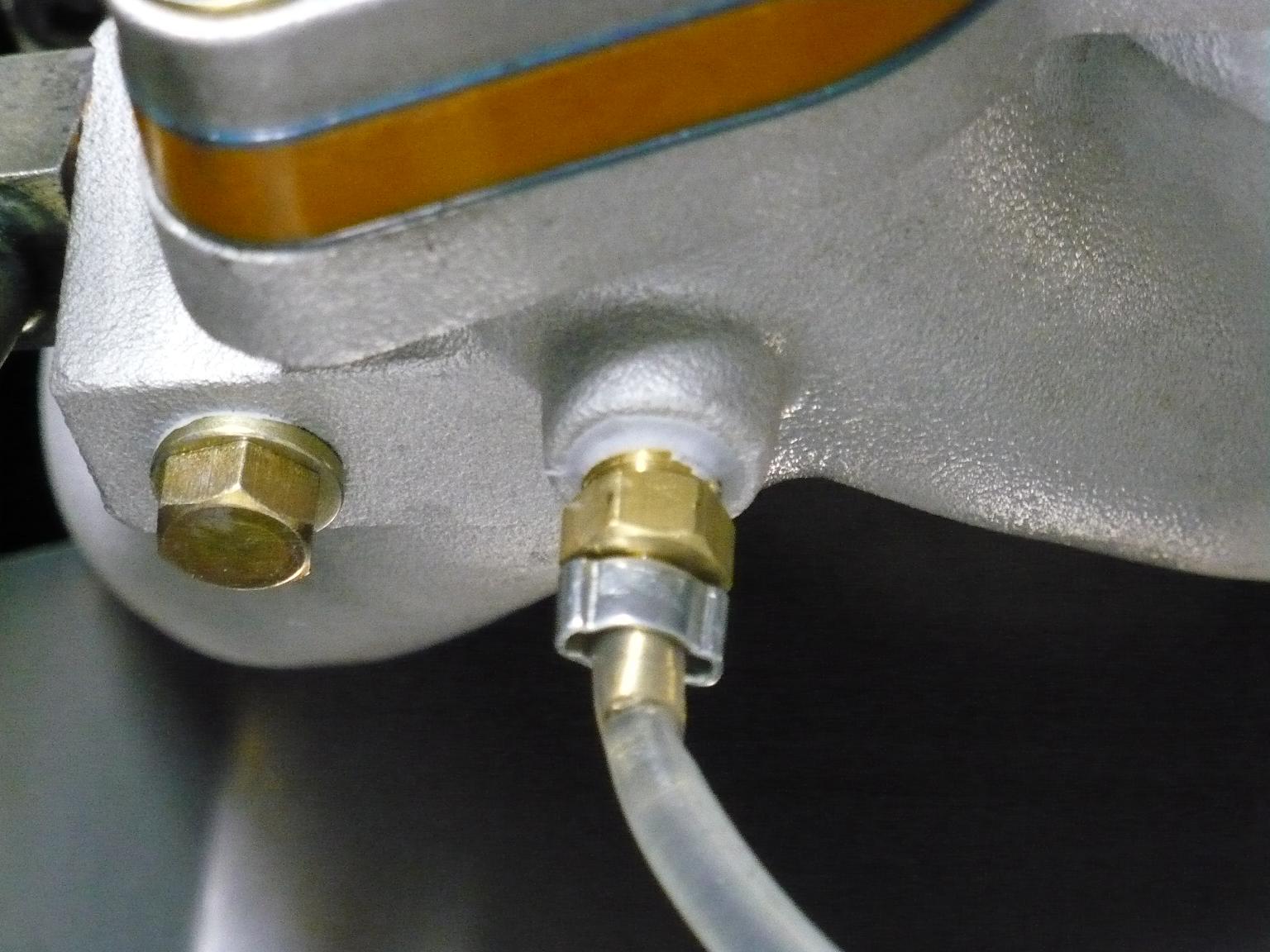

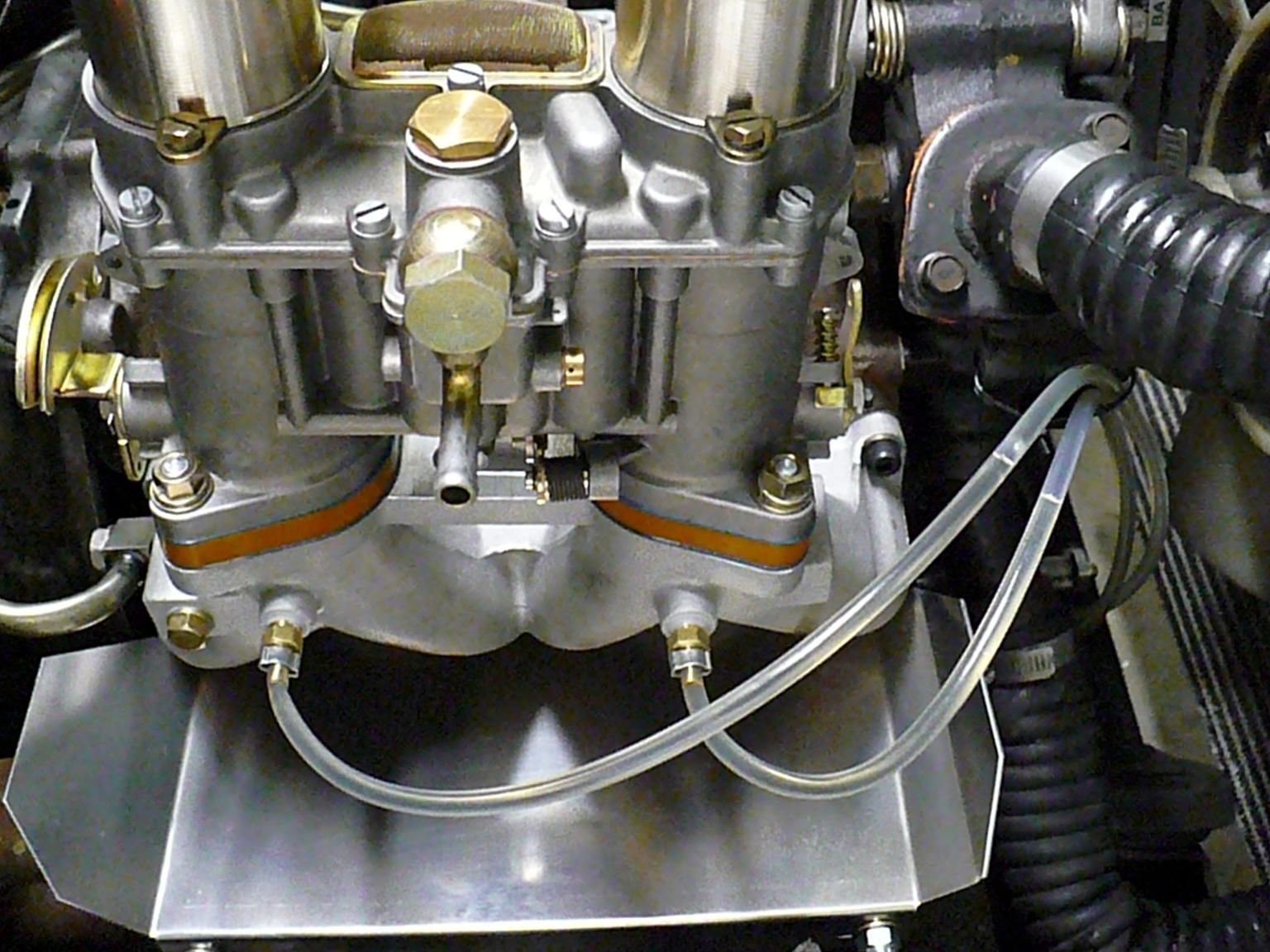

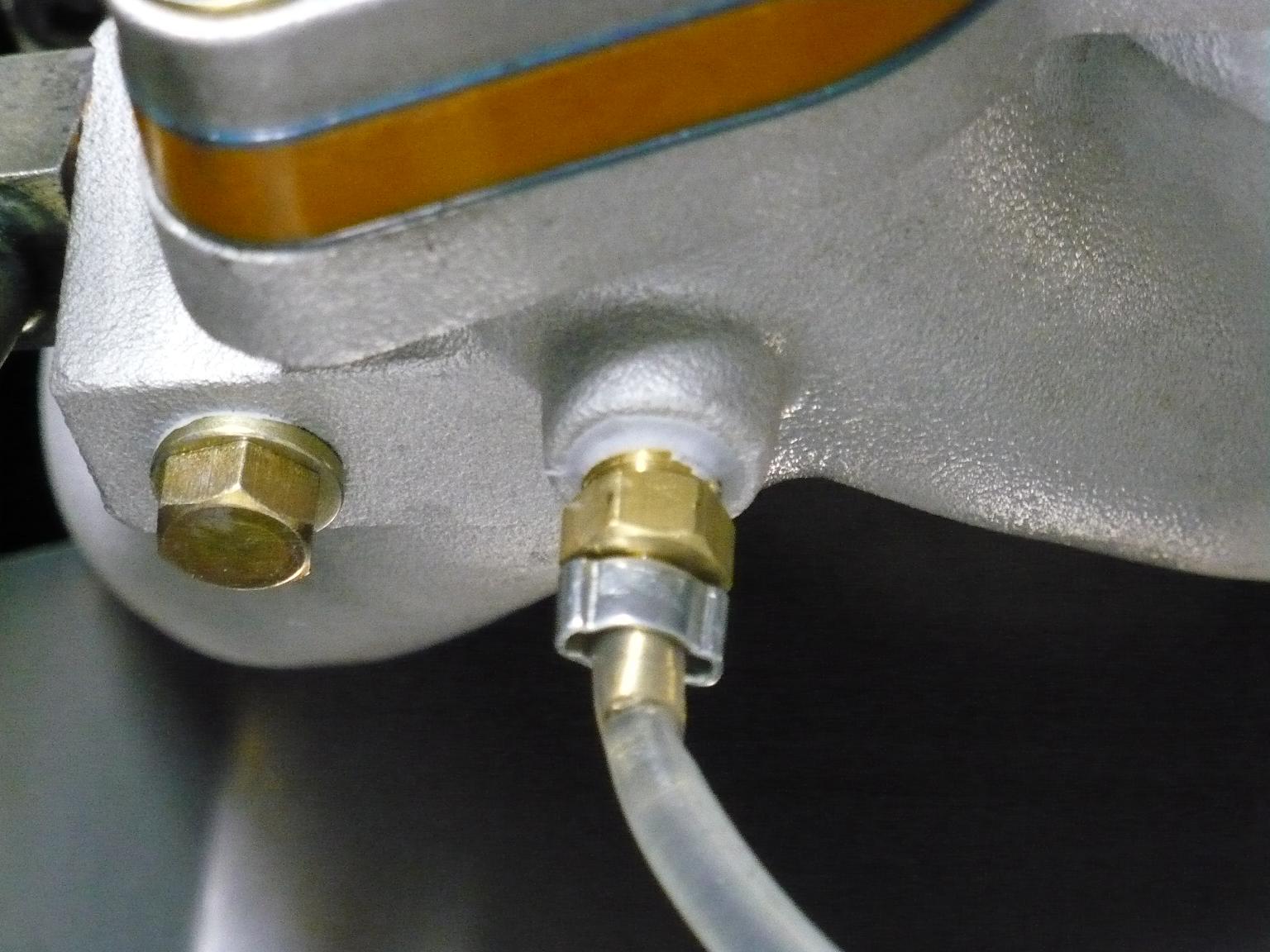

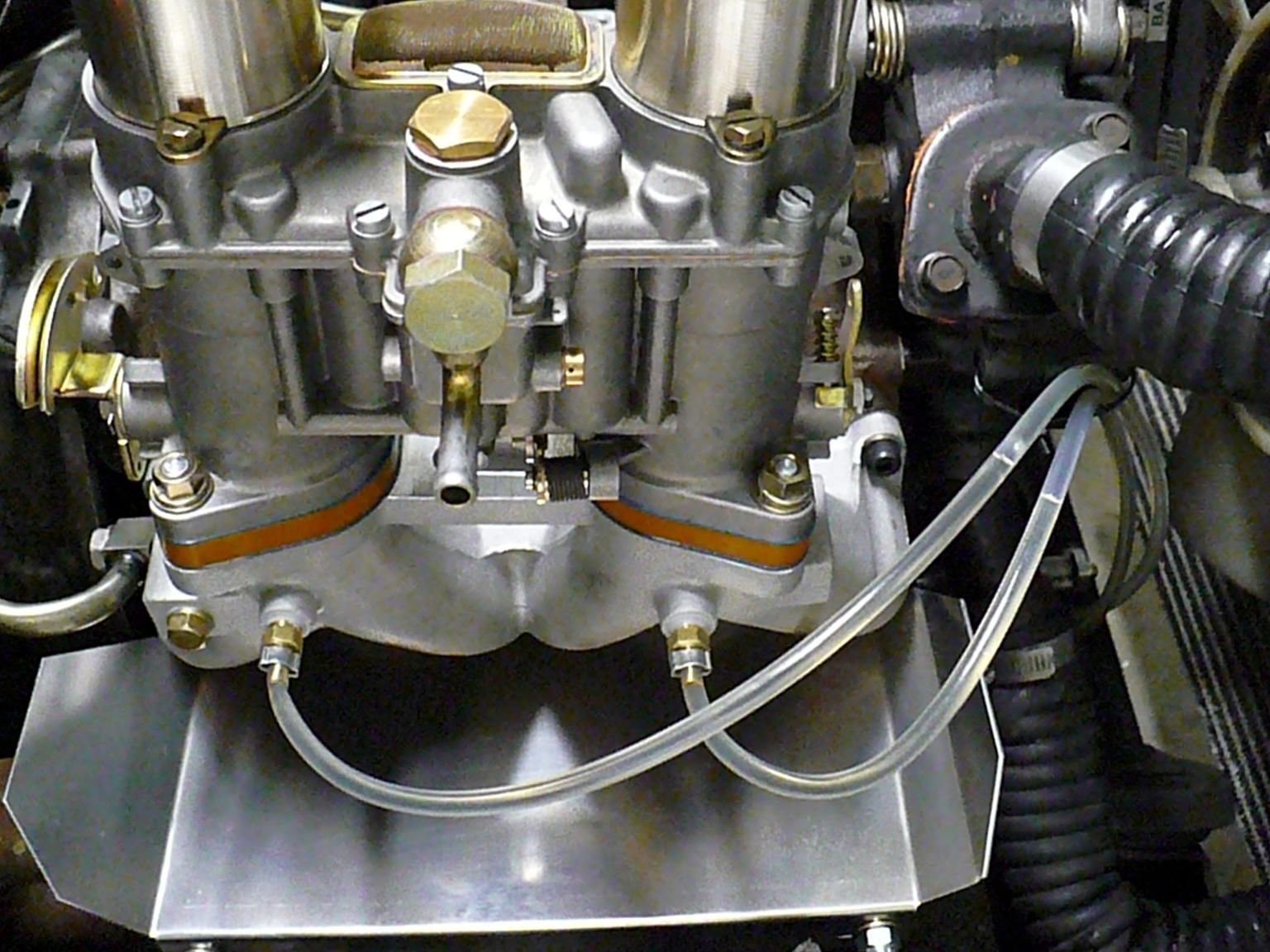

Ordered all this from McMasterCarr.com

5346K61 BRASS HOSE FITTING, BARB X MALE PIPE FOR 1/8" HOSE ID, 1/8" PIPE

5773K14 EXTREME-PURITY CLEAR PFA TUBING, 3/16" ID, 1/4" OD, 1/32" WALL THICKNESS, CLEAR

6541K34 DOUBLE PINCH ZINC-PLTD STL HOSE & TUBE CLAMP, 13/64" TO 9/32" CLAMP DIAMETER RANGE

Cost $25 shipped

Note that although the barb says it's for a 1/8 hose Inside Diameter, a 1/8 ID hose will not fit. The Outside Diameter of that barb is 3/16. Thus the 3/16" hose I ordered slides on like it belongs there.

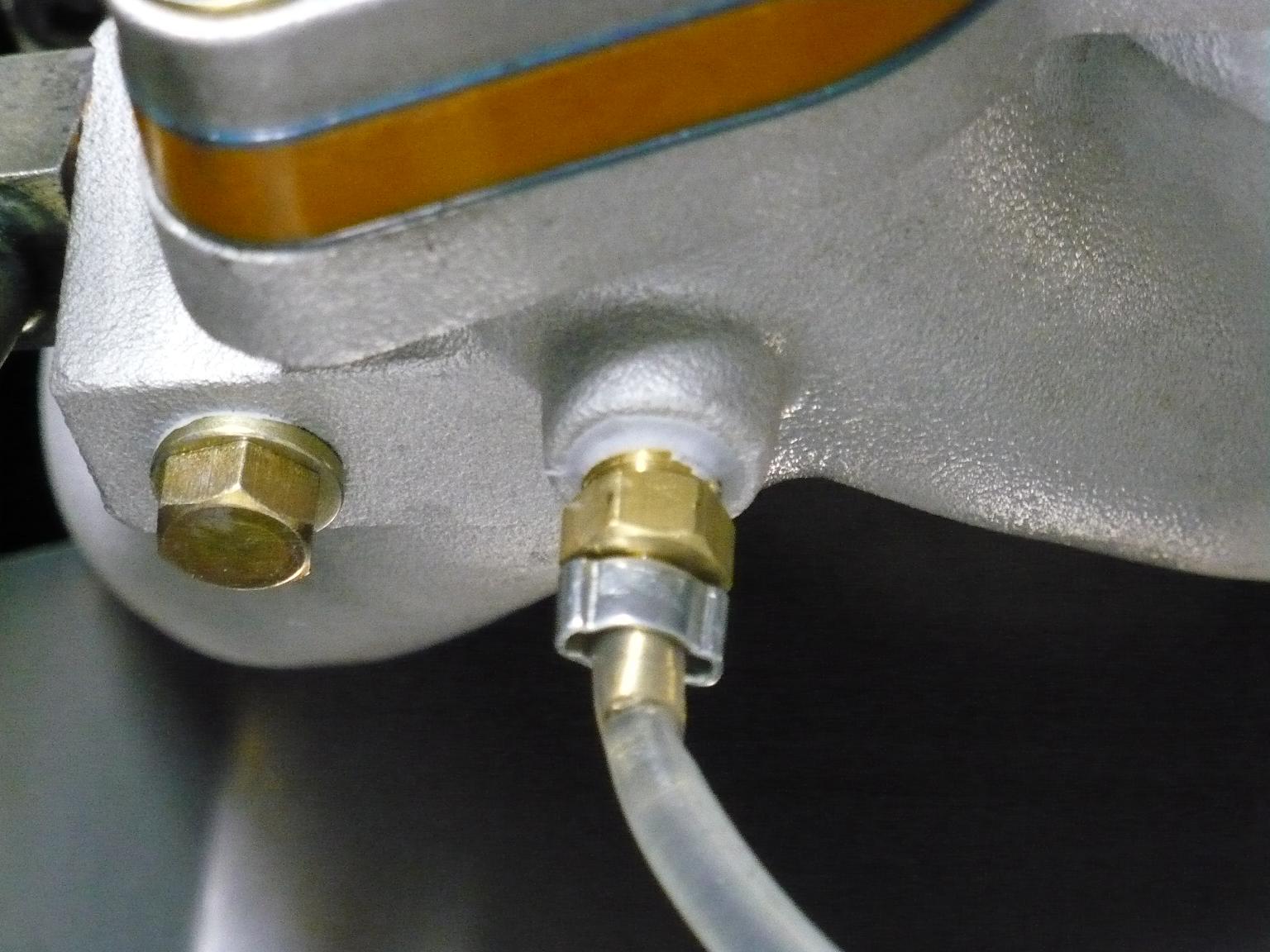

The two black allen head plugs in the Racing Beat Weber IDA manifold are metric pipe thread, and must be tapped to standard 1/8" NPT. Only takes a few minutes and the tap was five bucks. Tap it slowly, with lots of cutting oil or old man 3-in-1 Oil by WD40. I tapped 5.5 threads in there.

Put MotoSeal on the threads of the hose barb. MotoSeal is a gasoline impervious silicone sealant. Bought MotoSeal at the local Kragens. Then thread the barb in, let the manifold sit with the barbs facing up, threads facing down, overnight. That way excess MotoSeal will pool up where the manifold meets the barb, and make even more of a seal.

Cut the lines to length. Slide two of the clamps on there. Fill up the OMP lines with oil. I used an old man little black oilcan filled with castrol gtx 25/50 but would have used 2 stroke if I had any in the garage. Then put the lines on OMP. Crimp down the clamps with standard wire crimpers. Fill to the rim with oil, put other end of line on hose barb nipple and crimp that puppy.

Good to go.

#13

Thats how I first did my IDA's and it smoke a lot just like when you retain the oil feed injection on the rotor housings. Its best to premix it in the fuel bowl.

Ordered all this from McMasterCarr.com

5346K61 BRASS HOSE FITTING, BARB X MALE PIPE FOR 1/8" HOSE ID, 1/8" PIPE

5773K14 EXTREME-PURITY CLEAR PFA TUBING, 3/16" ID, 1/4" OD, 1/32" WALL THICKNESS, CLEAR

6541K34 DOUBLE PINCH ZINC-PLTD STL HOSE & TUBE CLAMP, 13/64" TO 9/32" CLAMP DIAMETER RANGE

Cost $25 shipped

Note that although the barb says it's for a 1/8 hose Inside Diameter, a 1/8 ID hose will not fit. The Outside Diameter of that barb is 3/16. Thus the 3/16" hose I ordered slides on like it belongs there.

The two black allen head plugs in the Racing Beat Weber IDA manifold are metric pipe thread, and must be tapped to standard 1/8" NPT. Only takes a few minutes and the tap was five bucks. Tap it slowly, with lots of cutting oil or old man 3-in-1 Oil by WD40. I tapped 5.5 threads in there.

Put MotoSeal on the threads of the hose barb. MotoSeal is a gasoline impervious silicone sealant. Bought MotoSeal at the local Kragens. Then thread the barb in, let the manifold sit with the barbs facing up, threads facing down, overnight. That way excess MotoSeal will pool up where the manifold meets the barb, and make even more of a seal.

Cut the lines to length. Slide two of the clamps on there. Fill up the OMP lines with oil. I used an old man little black oilcan filled with castrol gtx 25/50 but would have used 2 stroke if I had any in the garage. Then put the lines on OMP. Crimp down the clamps with standard wire crimpers. Fill to the rim with oil, put other end of line on hose barb nipple and crimp that puppy.

Good to go.

Ordered all this from McMasterCarr.com

5346K61 BRASS HOSE FITTING, BARB X MALE PIPE FOR 1/8" HOSE ID, 1/8" PIPE

5773K14 EXTREME-PURITY CLEAR PFA TUBING, 3/16" ID, 1/4" OD, 1/32" WALL THICKNESS, CLEAR

6541K34 DOUBLE PINCH ZINC-PLTD STL HOSE & TUBE CLAMP, 13/64" TO 9/32" CLAMP DIAMETER RANGE

Cost $25 shipped

Note that although the barb says it's for a 1/8 hose Inside Diameter, a 1/8 ID hose will not fit. The Outside Diameter of that barb is 3/16. Thus the 3/16" hose I ordered slides on like it belongs there.

The two black allen head plugs in the Racing Beat Weber IDA manifold are metric pipe thread, and must be tapped to standard 1/8" NPT. Only takes a few minutes and the tap was five bucks. Tap it slowly, with lots of cutting oil or old man 3-in-1 Oil by WD40. I tapped 5.5 threads in there.

Put MotoSeal on the threads of the hose barb. MotoSeal is a gasoline impervious silicone sealant. Bought MotoSeal at the local Kragens. Then thread the barb in, let the manifold sit with the barbs facing up, threads facing down, overnight. That way excess MotoSeal will pool up where the manifold meets the barb, and make even more of a seal.

Cut the lines to length. Slide two of the clamps on there. Fill up the OMP lines with oil. I used an old man little black oilcan filled with castrol gtx 25/50 but would have used 2 stroke if I had any in the garage. Then put the lines on OMP. Crimp down the clamps with standard wire crimpers. Fill to the rim with oil, put other end of line on hose barb nipple and crimp that puppy.

Good to go.

#14

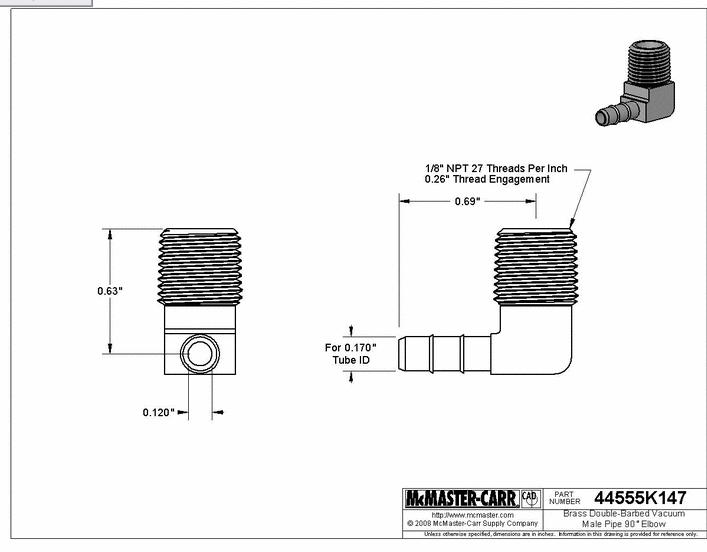

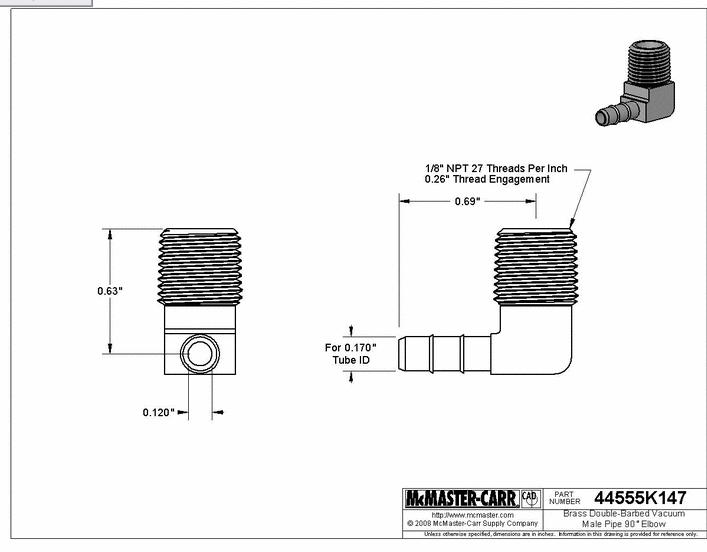

Turned out it was impossible to seal it entirely as the omp tube was hooked up to a source of constant vacuum. It was sucking air from around the brass fitting barbs. Poured water on the brass fitting and can see it get into the tube.

So now I'm considering buying two of these little 90* elbow fittings and screw them on top of the air cannister. Directly above the auxuliary venturi. Let the oil drip down into the carb. If the fitting is on the outside of the top of the air cannister then it can't fall in. Loctite in place.

Brass Double-Barbed Vacuum Tube Fitting 90 Deg Elbow for .17" Tube X 1/8" NPTF Male Pipe

So now I'm considering buying two of these little 90* elbow fittings and screw them on top of the air cannister. Directly above the auxuliary venturi. Let the oil drip down into the carb. If the fitting is on the outside of the top of the air cannister then it can't fall in. Loctite in place.

Brass Double-Barbed Vacuum Tube Fitting 90 Deg Elbow for .17" Tube X 1/8" NPTF Male Pipe

#16

Although.....for my other weber, I put the OMP in the manifold, and I get no smoke...

#20

Is it the threads in the intake that aren't sealing or the hose on the barb? If it's the threads, there are many different types of thread sealer that can fix that. If it's the hose on the barb, try heating the hose and see if it will shrink down and seal. If that doesn't work, there's a way to use fine wire twisted around the hose and barb to seal it. Something similar to the wire clamp that the stock mop lines use.

#22

Banned. I got OWNED!!!

brad, the weber carbs dont have a specified cfm rating because the venturies are interchangeable.. the bigger the venturies are the more cfm the carb will flow.

on the omp fittings i install the barbed brass fittings with silicone hose and never have a problem

on the omp fittings i install the barbed brass fittings with silicone hose and never have a problem

#24

No distributor? No thanks

iTrader: (6)

Join Date: Oct 2003

Location: Outskirts of Road Atlanta

Posts: 3,438

Likes: 0

Received 6 Likes

on

4 Posts

Hey DriveFast, what manifold are you using? I've always seen the IDAs turned around with the float bowl to thhe outside and fuel feed from the inside. That's how my 51 is set up. I've also got the OMP feeding the float bowl, tapped just below the air cleaner in the vertical face below the jet cover screen where RB adds their OMP barbs.