Engine Building Thoughts

#1

Engine Building Thoughts

This will just be a collection of random thoughts on engine building. If you have random questions, I can answer those here too. In the future, I may expand on some of these ideas and create new threads as necessary, but for now it's just a jumble.

#2

fart on a friends head!!!

i have a question. . . ive always thought/heard that a half bridge isnt as reliable (in the long run) as a streetport. i know the reasoning, but is this only a half truth? what IS the average life expectancy of a half bridge motor?

#4

Apex Seals

We get asked a lot about apex seals. The long and short of it is that the only metallic apex seals we recommend for a quality street-performance rebuild are OEM seals, be they 2mm or 3mm. There are no aftermarket metallic seals that can match them for longevity, durability, sealing, friendliness to rotor housings, etc. NOTHING. Not even close.

A lot of aftermarket seals have a lot of hype written about them. One seal claims to be impossible to break...sure, but they WARP and you are expected to tear the engine down, straighten them with a hammer (!) and rebuild it again. Some have long end pieces...a design Mazda abandoned like a red-headed step child many years ago because of poor compression characteristics. Others are just replicas of the current Mazda seals, but none of the manufacturers have a millionth of the budget Mazda has for R&D. It appears to us, particularly after examining them under a scope, that some manufacturers just picked a cheap ductile iron out of a catalog, milled the seals and found they were 'good enough' to sell at a huge profit. It is abunantly clear to us that the testing was inadequate to prove long-term life. Many of the seals are only good for 30-50K miles, at best. While this may be good enough for the common 'floor-sweeper' rebuild that is lucky to get that far, it has no place on a quality street-performance rebuild that should last as long, if not longer, than the original engine.

The aftermarket metallic seals might suck for the street, but they do have racing applications, where the engines are not expected to last long and collateral damage needs to be minimized. Hurley seals, for example, which we have found very soft and abrasive, have the favorable characteristic of disintegrating into a fairly harmless powder, saving the rotors and housings from typical frag-damage when an apex seal is broken. That's great for a hard-running, short-life race engine, but not so good for a street car that need to last many years. The one exception is an ultra-high performance turbo motor that needs a lot of trial and error to find a safe tune. You build the engine with Hurley seals and if you break them, no big deal...just toss in new seals and try, try again, until the tune is good, then do a final freshening with the OEM metallic or aftermarket ceramic seals.

The Hurley seals are the only ones I mention by name because they are the only aftermarket metallic apex seals that we have any use for, even if that application is fairly limited. For any quality street-performance rebuild, nothing but OEM metallic seals are good enough. Ceramics are another story.

A lot of aftermarket seals have a lot of hype written about them. One seal claims to be impossible to break...sure, but they WARP and you are expected to tear the engine down, straighten them with a hammer (!) and rebuild it again. Some have long end pieces...a design Mazda abandoned like a red-headed step child many years ago because of poor compression characteristics. Others are just replicas of the current Mazda seals, but none of the manufacturers have a millionth of the budget Mazda has for R&D. It appears to us, particularly after examining them under a scope, that some manufacturers just picked a cheap ductile iron out of a catalog, milled the seals and found they were 'good enough' to sell at a huge profit. It is abunantly clear to us that the testing was inadequate to prove long-term life. Many of the seals are only good for 30-50K miles, at best. While this may be good enough for the common 'floor-sweeper' rebuild that is lucky to get that far, it has no place on a quality street-performance rebuild that should last as long, if not longer, than the original engine.

The aftermarket metallic seals might suck for the street, but they do have racing applications, where the engines are not expected to last long and collateral damage needs to be minimized. Hurley seals, for example, which we have found very soft and abrasive, have the favorable characteristic of disintegrating into a fairly harmless powder, saving the rotors and housings from typical frag-damage when an apex seal is broken. That's great for a hard-running, short-life race engine, but not so good for a street car that need to last many years. The one exception is an ultra-high performance turbo motor that needs a lot of trial and error to find a safe tune. You build the engine with Hurley seals and if you break them, no big deal...just toss in new seals and try, try again, until the tune is good, then do a final freshening with the OEM metallic or aftermarket ceramic seals.

The Hurley seals are the only ones I mention by name because they are the only aftermarket metallic apex seals that we have any use for, even if that application is fairly limited. For any quality street-performance rebuild, nothing but OEM metallic seals are good enough. Ceramics are another story.

#5

Originally Posted by rotorbrain

i have a question. . . ive always thought/heard that a half bridge isnt as reliable (in the long run) as a streetport. i know the reasoning, but is this only a half truth? what IS the average life expectancy of a half bridge motor?

Streetports can actually be made rather large, with only half the corner seal supported on the opening edge. We traditionally call these maximum-effort streetports "rally ports," because that was the usual application back in the day. Better torque than a bridge port and it still makes a lot of power.

Bridge ports, by the way, were originally used to get around racing rules prohibiting peripheral ports. They are inferior to peripheral ports in almost every way (other than cost), until you get into Megabridges, where the port volume exceeds that of a peripheral port. This is not to say we are against them, but they really are a compromise that is not always the best option. I have driven peripheral ports on the street (10,000 miles in one year alone) and find them wonderfully streetable with the right setup; no harder to drive than a bridge port. I even got 19.5 MPG on the freeway when not towing the trailer.

#6

Senior Member

whats the difference btwn a bridgeport, streetport, raceport, and peripheral port? all ive heard is that the perip port is the best bang for your buck but takes a toll on your engine.

#7

Originally Posted by sem7sem

Its is possile to join two (2) 1.3L 13brew engines to create a 2.6l 26b turbocharged 4 rotor motor. What kind of parts whould have to be fabricated??

Trending Topics

#8

Originally Posted by fcboy89

whats the difference btwn a bridgeport, streetport, raceport, and peripheral port? all ive heard is that the perip port is the best bang for your buck but takes a toll on your engine.

#9

Rotary Enthusiast

APEX Seal ??

A street 93 FD,, middle of the road street port, can I use single piece ceramic seal APEX , if so 2mm or 3mm,, rotors are bad dented on the face ,apex grooves are wallowed out, now I have 2- 87TII rotors, but what mods to them should be done to balance rotating assembly, and any recommends on what brand of ceramic APEXs I should look at. Am using a single GT4085, with V-mount, 850 Pri, 1600 sec. customer wants for it street use. also can we use a boost-cooler to make up for no race gas. help in this area would be appreciated? THX RON

#10

Ceramic Apex Seals

Ceramic apex seals, as opposed to metallic apex seals, are only available from the aftermarket. Unlike the case with metallic seals, the ceramics have significant advantages over metallics. When Mazda was pursuing Le Mans, they comissioned Dr. Francesco Ianetti to design ceramic seals for their racing motors. It worked well and Ianetti became the trusted supplier for ceramic apex seals, worldwide. More recently, a company in Canada called NRS started manufacturing high-quality ceramic apex seals at a more afforable price. We have worked with them to fine-tune the design and have been very happy with the results. At this point, we use both manufacturers, depending on the wishes of the customer. Ianetti has the long track record of sucess while NRS has a promising start and less expensive products.

Ceramic seals, which can cost around $2000 a set, are lighter than metallic seals and are extremely low friction. This makes them very rotor housing friendly, doubling or even tripling rotor housing life, while not wearing down like conventional metallic seals. Just based on longevity, there is an argument that they are cost effective over the life of the motor, simply because you can re-use them on rebuild after rebuild. Another advantage is that because of the low friction, you can increase apex seal spring pressure, thus improving sealing on the Major Axis of the engine. This translates to torque.

Ceramic apex seals are not indestructible but they are not particularly fragile either. When tuning on the edge, it is wise to build the engine with Hurley seals for break-in and tuning, as they cause minimal damage when they break and are cheap to replace. Once the final tune is known to be safe, you open the motor and swap in the ceramic seals.

Ceramic seals tend to be very hard on apex seal springs. NRS has developed a ceramic coated spring that reduced wear, for longer spring life. These "stinger" springs, as they are called, are highly recommended.

NRS, unlike Ianetti, sells seals in two grades of ceramic. One is called the "grey" and one is called the "black". The grey material is more equivalent to the Ianetti seals, and are intended for higher HP/Boost applications. The black material is far more inexpensive but is meant for non-turbo and low-boost applications.

2 piece/1 piece and 2mm/3mm arguments are basically the same for those of metallic seals. 2 piece seals cost more but seal better. 2mm seals make more power (better sealing, lower friction) but 3mm seals are definitely stronger.

As a price comparrison, we sell the 2mm, 2 PC factory apex seals for $450, including the springs. The 2mm, 2 PC NRS seals in the grey material, including "stinger" springs, sell for $2045.

Ceramic seals, which can cost around $2000 a set, are lighter than metallic seals and are extremely low friction. This makes them very rotor housing friendly, doubling or even tripling rotor housing life, while not wearing down like conventional metallic seals. Just based on longevity, there is an argument that they are cost effective over the life of the motor, simply because you can re-use them on rebuild after rebuild. Another advantage is that because of the low friction, you can increase apex seal spring pressure, thus improving sealing on the Major Axis of the engine. This translates to torque.

Ceramic apex seals are not indestructible but they are not particularly fragile either. When tuning on the edge, it is wise to build the engine with Hurley seals for break-in and tuning, as they cause minimal damage when they break and are cheap to replace. Once the final tune is known to be safe, you open the motor and swap in the ceramic seals.

Ceramic seals tend to be very hard on apex seal springs. NRS has developed a ceramic coated spring that reduced wear, for longer spring life. These "stinger" springs, as they are called, are highly recommended.

NRS, unlike Ianetti, sells seals in two grades of ceramic. One is called the "grey" and one is called the "black". The grey material is more equivalent to the Ianetti seals, and are intended for higher HP/Boost applications. The black material is far more inexpensive but is meant for non-turbo and low-boost applications.

2 piece/1 piece and 2mm/3mm arguments are basically the same for those of metallic seals. 2 piece seals cost more but seal better. 2mm seals make more power (better sealing, lower friction) but 3mm seals are definitely stronger.

As a price comparrison, we sell the 2mm, 2 PC factory apex seals for $450, including the springs. The 2mm, 2 PC NRS seals in the grey material, including "stinger" springs, sell for $2045.

#12

Originally Posted by ronbros3

A street 93 FD,, middle of the road street port, can I use single piece ceramic seal APEX , if so 2mm or 3mm,, rotors are bad dented on the face ,apex grooves are wallowed out, now I have 2- 87TII rotors, but what mods to them should be done to balance rotating assembly, and any recommends on what brand of ceramic APEXs I should look at. Am using a single GT4085, with V-mount, 850 Pri, 1600 sec. customer wants for it street use. also can we use a boost-cooler to make up for no race gas. help in this area would be appreciated? THX RON

So, are you asking about using Series 4 Turbo rotors in a 13B-REW engine? It can be done, but it's better to use S5 rotors, as they are very similar to S6 (13B-REW) rotors, except lacking apex seal groove hardening and a slight change in the bathtub. Your questions about which brand, etc. are answered in my previous post about ceramic apex seals (I was writing it while you posted your question).

As for the issue of race gas, don't focus too much on boost and look more closely at the output of the motor. With less boost, a big turbo can create more power. It is the power level that has a lot to do with what gas you need to run. This is assuming you are in an efficient boost range and the IC is adequate, otherwise you have a whole 'nuther set of problems. Anyway, around the 400RWHP level, you seriously need to consider using race gas, or at least a higher octane blend, regardless of boost.

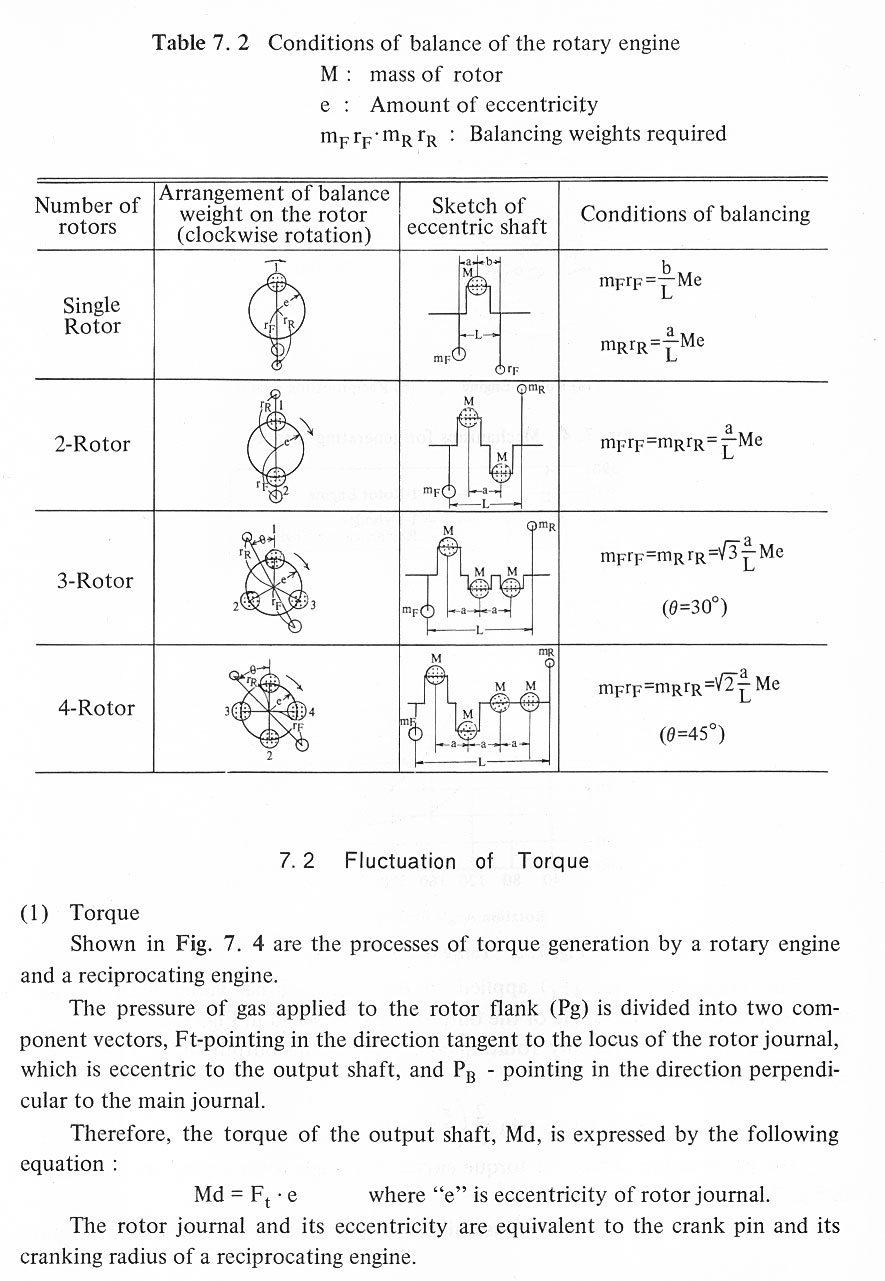

To answer the question of balancing, that gets a bit tricky. The S4 stuff is already about 150 grams heavier, which itself is not that big of a deal, but some of the Japanese stuff is even another 100 grams heavier than that, so you have the weight the parts and pay attention to the details. The usual way to do the swap is to use the S4 front counterweight and S4 flywheel, matched to the rotors. If you really want to balance the package with the -REW stuff, here is the chapter and verse:

Source: Rotary Engine by Kenichi Yamamoto

Last edited by Blake; 09-06-06 at 06:01 PM.

#13

Viton in various applications

Viton is a great material for many applications. We use it, in various grades, for water seals (tested for 7 years in multiple engines before we sold them to the public), rear stationary gear o-ring, dowel o-rings, oil filter pedistal o-rings, etc. BUT, in our experience Viton DOES NOT LAST as an oil control o-ring. I mention this because certain companies sell Viton oil control o-rings and we have seen many premature failures (20K or less). The stock oil control o-rings are a very expensive flourinated rubber, but they last 100K miles or more. This is not something to cut corners on! The aftermarket ones exist simply because the profit margin is so high.

Viton is one of those materials with a hyped reputation on the internet. While the reputation is deserved in many applications, it is rediculous to think it is superior in ALL applications. In this case, it's similar to Titanium and Carbon Fiber. Don't get hung up on the name; consider the application and weigh the costs and benefits.

Viton is one of those materials with a hyped reputation on the internet. While the reputation is deserved in many applications, it is rediculous to think it is superior in ALL applications. In this case, it's similar to Titanium and Carbon Fiber. Don't get hung up on the name; consider the application and weigh the costs and benefits.

#14

Engine Building Economics

You see a lot of $1,000 to $1,500 engine rebuilds being offered. You should be aware, however, that these engines are necessarily assembled from a lot of used parts. There is no way to build a motor capable of lasting as long as the original engine for much less that $2,000 in parts (at the builder's cost) plus labor.

The two highest wearing items in the engine are rotor housings and apex seals. A quality rebuild will replace both, plus a great many other parts. Rotor housings only last about 100K to as much as 150K before they are completely worn out, in the best of cases. Certainly, there are a handful of engines that last a bit beyond that, but even worn out housings and apex seals will let you putt around for quite a while before they utterly fail. Even if an engine dies at, say, 50K and you presume the life expectancy of the rotor housings is 100K to be safe, you can only expect 50K life of the rebuild. Now, of the two halves of the rotor housings life, which do you get? The better half or the worst half? Worn rotor housings just don't make the power of new housings. Now consider that there are very few 50K core motors around from which to salvage used rotor housings! With a 100K used rotor housing, you are really living on borrowed time and cannot possibly expect good results in the long haul...or even the medium haul. The engine would probably last long enough to make it out of the warrantee period of many builders, but it's not something to brag about.

The Mazda Spec on rotor housings is very loose. If you think about it, it makes perfect sense. Mazda is just trying to spec a rebuild to get you out of the warrantee; back where you would be if the engine did not fail prematurely. The Spec is not intended to give you a good-as-new engine but, rather, just give you back the balance of the original engine life. The spec permits up to 2mm of chrome flake, which is ludicrous in a quality engine rebuild. And if the chrome is intact, you can pretty much use it regardless of wear. Anyone building to "Mazda Specs" is not doing you any favors. New housings are as important as new apex seals to give you something more than a 30-50K rebuild. Of course, given the prevalence of aftermarket metallic apex seals that only last about that long, the picture becomes clear.

The retail price of a 13B-REW rotor housing is currently $815.05...EACH! While most established builders get a pretty nice discount from Mazda, you are still looking at over $1,100 per engine, just for the rotor housings on a 13B-REW. Added to the rest of the list if parts necessary to build a quality engine, the engine builder's cost is over $2,000 in parts, let alone all the hours of labor put into dissasembly, parts cleaning, refurbishing re-usable parts, and re-assembly. At $2,800 for a basic rebuild, if we spend more than 10 hours on an engine, we are losing money! This is not counting porting, oil mods, milling rotors or other extra services.

When you pay a premium for a quality rebuild, ALL the extra money is going into better parts! In fact, a cheepo rebuild is far more profitable for the builder. They may have to spend more hours tearing down countless cores and cleaning up nasty parts, but the cost is very, very minimal. We often build "floorsweepers" for ourselves out of the parts we discard from customer rebuilds, just for fun or for training an employee. We can do it for anywhere from $250-500. They run GREAT for a year or two and sometimes more. Even counting the labor we could make more profit selling those than our usual quality rebuild by selling them for $1,000 to $1,500. That's just not our game. We only build engines for those who see the sense in investing money in more new parts.

I will say, however, that I understand the mentality of wanting or needing to rebuild an engine cheaply, just to get yourself back on the road quickly at a minimal cost. I've done it myself. In those cases, you might as well rebuild the engine yourself! Rotary engines are relatively easy to rebuild and if you don't screw the pooch too bad, it would be unusual if the engine did not last a year or more. These things are much more forgiving than piston engines when it comes to rebuilding tolerances. Race engines, too, are a good candidate for cheepo rebuilds, since you are likely to pull them apart every year or two for freshening. In fact, "seasoned" parts are usually better in a race motor, provided they are not truly worn out.

All I'm saying is that you get what you pay for. The difference in cost between a cheap rebuild and a "premium" one is basically the cost of the additional new parts, and the new parts directly and positively impact the longevity of the engine. In the long run, the cheap rebuild costs you more (because you have to do it at least twice to match the longevity) and a greater proportion of the price is going into the pocket of the builder in terms of labor and profit.

If you want a premium rebuild, economics and logic suggest you are better paying a professional to do it for you. At Mazda retail prices, you would pay several hundred dollars more to simply buy the parts than to pay a pro for parts and labor to do the entire job. Even if you buy parts at a pretty decent discount yourself, the professional adds experience and more advanced tools and techniques, which are wise to invest in. The last thing you want to do is mess up a premium rebuild because you couldn't properly clearance a bearing or misinstalled a part. A cheap rebuild, however, is best done yourself. Tearing down cores, cleaning parts and tossing it all back together again for a few hundred dollars is far cheaper for an individual than a shop, which needs to make a pretty decent shop rate to pay the overhead, etc. And, if you do mess something up, you can do it again and still be ahead on money.

The two highest wearing items in the engine are rotor housings and apex seals. A quality rebuild will replace both, plus a great many other parts. Rotor housings only last about 100K to as much as 150K before they are completely worn out, in the best of cases. Certainly, there are a handful of engines that last a bit beyond that, but even worn out housings and apex seals will let you putt around for quite a while before they utterly fail. Even if an engine dies at, say, 50K and you presume the life expectancy of the rotor housings is 100K to be safe, you can only expect 50K life of the rebuild. Now, of the two halves of the rotor housings life, which do you get? The better half or the worst half? Worn rotor housings just don't make the power of new housings. Now consider that there are very few 50K core motors around from which to salvage used rotor housings! With a 100K used rotor housing, you are really living on borrowed time and cannot possibly expect good results in the long haul...or even the medium haul. The engine would probably last long enough to make it out of the warrantee period of many builders, but it's not something to brag about.

The Mazda Spec on rotor housings is very loose. If you think about it, it makes perfect sense. Mazda is just trying to spec a rebuild to get you out of the warrantee; back where you would be if the engine did not fail prematurely. The Spec is not intended to give you a good-as-new engine but, rather, just give you back the balance of the original engine life. The spec permits up to 2mm of chrome flake, which is ludicrous in a quality engine rebuild. And if the chrome is intact, you can pretty much use it regardless of wear. Anyone building to "Mazda Specs" is not doing you any favors. New housings are as important as new apex seals to give you something more than a 30-50K rebuild. Of course, given the prevalence of aftermarket metallic apex seals that only last about that long, the picture becomes clear.

The retail price of a 13B-REW rotor housing is currently $815.05...EACH! While most established builders get a pretty nice discount from Mazda, you are still looking at over $1,100 per engine, just for the rotor housings on a 13B-REW. Added to the rest of the list if parts necessary to build a quality engine, the engine builder's cost is over $2,000 in parts, let alone all the hours of labor put into dissasembly, parts cleaning, refurbishing re-usable parts, and re-assembly. At $2,800 for a basic rebuild, if we spend more than 10 hours on an engine, we are losing money! This is not counting porting, oil mods, milling rotors or other extra services.

When you pay a premium for a quality rebuild, ALL the extra money is going into better parts! In fact, a cheepo rebuild is far more profitable for the builder. They may have to spend more hours tearing down countless cores and cleaning up nasty parts, but the cost is very, very minimal. We often build "floorsweepers" for ourselves out of the parts we discard from customer rebuilds, just for fun or for training an employee. We can do it for anywhere from $250-500. They run GREAT for a year or two and sometimes more. Even counting the labor we could make more profit selling those than our usual quality rebuild by selling them for $1,000 to $1,500. That's just not our game. We only build engines for those who see the sense in investing money in more new parts.

I will say, however, that I understand the mentality of wanting or needing to rebuild an engine cheaply, just to get yourself back on the road quickly at a minimal cost. I've done it myself. In those cases, you might as well rebuild the engine yourself! Rotary engines are relatively easy to rebuild and if you don't screw the pooch too bad, it would be unusual if the engine did not last a year or more. These things are much more forgiving than piston engines when it comes to rebuilding tolerances. Race engines, too, are a good candidate for cheepo rebuilds, since you are likely to pull them apart every year or two for freshening. In fact, "seasoned" parts are usually better in a race motor, provided they are not truly worn out.

All I'm saying is that you get what you pay for. The difference in cost between a cheap rebuild and a "premium" one is basically the cost of the additional new parts, and the new parts directly and positively impact the longevity of the engine. In the long run, the cheap rebuild costs you more (because you have to do it at least twice to match the longevity) and a greater proportion of the price is going into the pocket of the builder in terms of labor and profit.

If you want a premium rebuild, economics and logic suggest you are better paying a professional to do it for you. At Mazda retail prices, you would pay several hundred dollars more to simply buy the parts than to pay a pro for parts and labor to do the entire job. Even if you buy parts at a pretty decent discount yourself, the professional adds experience and more advanced tools and techniques, which are wise to invest in. The last thing you want to do is mess up a premium rebuild because you couldn't properly clearance a bearing or misinstalled a part. A cheap rebuild, however, is best done yourself. Tearing down cores, cleaning parts and tossing it all back together again for a few hundred dollars is far cheaper for an individual than a shop, which needs to make a pretty decent shop rate to pay the overhead, etc. And, if you do mess something up, you can do it again and still be ahead on money.

#15

Tension bolt washers

Recently, a customer ordering a rebuild kit asked me about tension bolt washers and the need to replace them during a rebuild. To be honest, we've never seen one leak, no matter how ugly it was. In practice, we only recommend replacing them when they appear torn up, just to be safe, but don't lose any sleep over them. Some builders claim the neccessity of replacing them. I don't know why...perhaps because it looks like an "attention-to-detail" thing, inspiring confidence or whatever. Frankly, we suggest you put that money to work elsewhere.

#16

Cost cutting

Rebuilding an engine right is expensive, but there are costs that can be cut with little or no consequence. Remember, we do not recommend skimping on rotor housings unless you are just building yourself a floorsweeper to last a year or two.

First, side seals are great for re-use. They do not wear substantially in height; only in length. Since none of the grooves are exactly the same length, you can play musical chairs to fill up the shorter grooves and then fit a few new ones in the longer grooves. So, instead of buying 12 side seals, you can usually just get 4 or so, though having more on hand is a good idea in case you have trouble finding a good fit. The length can be reduced by sanding the ends with emery cloth. Make sure you get the angle right, so they fit the contour of the corner seal, and clearance them properly.

Corner seals can often be re-used as well by replacing just the rubber plugs (where applicable). Mazda retail on the corner seals with plugs are $7.75 each, or $93 for the twelve required. The plugs alone are $2.20 each, or $26.40 for a set of 12. There are times you want to replace corner seals, but most can be salvaged. The critical thing, beside free movement in their hole, is wear from the side seals. Whatever the case, you will be clearancing the side seals to their respective corner seals, so the endplay clearance will account for any minimal pre-existing wear. Do not re-use corner seal springs. And, if you don't already have them, be sure to upgrade to FD (3rd gen, 13B-REW) style corner seal springs (retail: $3.10 each). By re-using the corner seals and only replacing the plugs, you are freeing up money to invest in the FD corner seal springs, which offer a real benefit.

FD main bearings have a bunch of holes in them for better lubrication. These bearings cost a great deal more than the earlier bearings with the single hole. FD main bearings cost $63 each vs. $15 each for the earlier ones. That's a huge difference. You can actually use the earlier ones if you take the time to drill the extra holes. It takes some skill, but you can save serious money. The important thing is not to have any burrs. Note: the multi-window bearings are worthless on older engines because the stationary gears do not have an oil groove behind the bearings. However, you can modify the stationary gears with a die grinder if you want to upgrade.

Don't use an oil pan gasket. The gaskets cost money (obviously) but don't do as good of a job as simple silicone. In fact, once the factory oil pan gaskets start to leak, they spew oil at a prodigious rate. When the silicone leaks, it will at least be a relatively minor leak. I say "when" because it's not a case of "if". The stock pans always leak eventually due to the flexing of the engine. That's one of the reasons we developed aluminum oil pans for FCs and FDs, using an o-ring insetead of a gasket.

That's all I can think of at the moment, but I'm sure there are many things I am forgetting. You should not cut corners on rotor housings, apex seals, springs, bearings (new, even if you substitute), oil control o-rings (OEM only), water seals, dowel o-rings, etc.

First, side seals are great for re-use. They do not wear substantially in height; only in length. Since none of the grooves are exactly the same length, you can play musical chairs to fill up the shorter grooves and then fit a few new ones in the longer grooves. So, instead of buying 12 side seals, you can usually just get 4 or so, though having more on hand is a good idea in case you have trouble finding a good fit. The length can be reduced by sanding the ends with emery cloth. Make sure you get the angle right, so they fit the contour of the corner seal, and clearance them properly.

Corner seals can often be re-used as well by replacing just the rubber plugs (where applicable). Mazda retail on the corner seals with plugs are $7.75 each, or $93 for the twelve required. The plugs alone are $2.20 each, or $26.40 for a set of 12. There are times you want to replace corner seals, but most can be salvaged. The critical thing, beside free movement in their hole, is wear from the side seals. Whatever the case, you will be clearancing the side seals to their respective corner seals, so the endplay clearance will account for any minimal pre-existing wear. Do not re-use corner seal springs. And, if you don't already have them, be sure to upgrade to FD (3rd gen, 13B-REW) style corner seal springs (retail: $3.10 each). By re-using the corner seals and only replacing the plugs, you are freeing up money to invest in the FD corner seal springs, which offer a real benefit.

FD main bearings have a bunch of holes in them for better lubrication. These bearings cost a great deal more than the earlier bearings with the single hole. FD main bearings cost $63 each vs. $15 each for the earlier ones. That's a huge difference. You can actually use the earlier ones if you take the time to drill the extra holes. It takes some skill, but you can save serious money. The important thing is not to have any burrs. Note: the multi-window bearings are worthless on older engines because the stationary gears do not have an oil groove behind the bearings. However, you can modify the stationary gears with a die grinder if you want to upgrade.

Don't use an oil pan gasket. The gaskets cost money (obviously) but don't do as good of a job as simple silicone. In fact, once the factory oil pan gaskets start to leak, they spew oil at a prodigious rate. When the silicone leaks, it will at least be a relatively minor leak. I say "when" because it's not a case of "if". The stock pans always leak eventually due to the flexing of the engine. That's one of the reasons we developed aluminum oil pans for FCs and FDs, using an o-ring insetead of a gasket.

That's all I can think of at the moment, but I'm sure there are many things I am forgetting. You should not cut corners on rotor housings, apex seals, springs, bearings (new, even if you substitute), oil control o-rings (OEM only), water seals, dowel o-rings, etc.

#17

Resurfaced Rotor Housings

The Holy Grail of rotary engine rebuilding is an inexpensive and effective means to resurface rotor housings. With FD rotor housings retailing over $800 each, an alternative costing half as much with the similar durability would make someone rich. Unfortunately, despite numerous people trying, an effective method of re-chroming has not been demonstrated successful. Many claim success and are perfectly willing to sell you a nice looking product, but we have not seen any (yet) that hold up. We are still doing long-term testing on some promising attemts, but the jury is still out. When it comes to re-chroming, we are skeptics of the first magnitude. Even Mazda, with all the resources and motivation to salvage expensive parts, does not attempt it.

That said, there has been great success in resurfacing rotor housings with ceramic material, instead of chrome. There is only one company we trust for this: JHB in Canada. The catch? It costs about as much at buying new rotor housings. However, it really does have advantages. The ceramic material is Cermet, which is the same stuff Mazda used on the Le Mans winning 787B race car. They actually have two flavors of Cermet, A & B. A is the more expensive formula that is basically identical the the 787Bs coatings, while the B is a more economical formula. Ceramic coatings on rotor housings is actually a bit abrasive to metallic apex seals, but once they burnish-in the wear subsides. We have used both with good sucess.

That said, there has been great success in resurfacing rotor housings with ceramic material, instead of chrome. There is only one company we trust for this: JHB in Canada. The catch? It costs about as much at buying new rotor housings. However, it really does have advantages. The ceramic material is Cermet, which is the same stuff Mazda used on the Le Mans winning 787B race car. They actually have two flavors of Cermet, A & B. A is the more expensive formula that is basically identical the the 787Bs coatings, while the B is a more economical formula. Ceramic coatings on rotor housings is actually a bit abrasive to metallic apex seals, but once they burnish-in the wear subsides. We have used both with good sucess.

#18

Oh, I should say the rotor housing re-chroming process we are currently testing, which so far has been all positive, is the one by NRS. But, we still have more testing to do before giving it our stamp of approval. I think our next test is to run it in a pair of 600+ HP FDs and really thrash them.

#19

I've got a few questions. First, how long have you tested the cermet housings? I'm curious to see how they hold up over many tens of thousands of miles.

Also, you say that the p-port is streetable, but I had always heard they had a really rough idle. Did you get it to idle relatively normally? Also, what is the power band like? My car before it was rebuild several years ago had over 200k on the engine and wired open aux ports so I can deal with low torque. I'm just wondering where usable power starts and how high it goes. Also, what kind of life are you looking at from the engine?

Also, you say that the p-port is streetable, but I had always heard they had a really rough idle. Did you get it to idle relatively normally? Also, what is the power band like? My car before it was rebuild several years ago had over 200k on the engine and wired open aux ports so I can deal with low torque. I'm just wondering where usable power starts and how high it goes. Also, what kind of life are you looking at from the engine?

#20

Originally Posted by Sideways7

I've got a few questions. First, how long have you tested the cermet housings? I'm curious to see how they hold up over many tens of thousands of miles.

Also, you say that the p-port is streetable, but I had always heard they had a really rough idle. Did you get it to idle relatively normally? Also, what is the power band like? My car before it was rebuild several years ago had over 200k on the engine and wired open aux ports so I can deal with low torque. I'm just wondering where usable power starts and how high it goes. Also, what kind of life are you looking at from the engine?

Also, you say that the p-port is streetable, but I had always heard they had a really rough idle. Did you get it to idle relatively normally? Also, what is the power band like? My car before it was rebuild several years ago had over 200k on the engine and wired open aux ports so I can deal with low torque. I'm just wondering where usable power starts and how high it goes. Also, what kind of life are you looking at from the engine?

Peripheral ports don't idle very smoothly because of all the overlap. The same is true for bridgeports and, to a lesser extent, for larger streetports. My peripheral port idled around 1200 RPM and was pretty lopey, but that has NOTHING to do with driveability.

Typical peripheral port engines have fairly peaky powerbands, only starting to make real power over 7K RPM and done aroung 10K RPM. However, you don't have to have that powerband. I spent a lot of time tuning the exhaust to scavenge well everywhere and, with the timing retarded, made the same torque at 4K as it did at 9K RPM, with just a slight arc to max torque (~150 ft lbs) midway between. Very, very linear power delivery. With that setup, I was only making 225 HP to the rear wheels, but it was fun and easy to drive. With a race tune, it would have made a lot more power but I was very happy with it. I drove the car from Portland, Oregon to Gainesville, Florida and back, towing the "half RX-7" trailer. This was with 4.88 gears, 4-puck clutch, Weber 51IDA, etc.

The Peripheral Port 13B I had in the car rung up over 40K mile in various cars before I put it in my car. I took it out and we freshened it up after another 10K, at which point it was sold to someone else.

#21

I guess its more the p-port race engines that have driveability issues. I can deal with a high lopey idle. My car has a large street port and was lopey, plus it had a mysterious vac leak that I never found till I tore the engine down so it was even more lopey. In fact, most of the time I had to keep my foot a bit on the gas at stoplights. If I can find the money to do this, I might just contact you about details on how to work it out. If I can find a setup that would work, I would like to try to rig it up with an IDA throttle body kit and a standalone so I could run fuel injection, but I can iron that out if I ever decide to tackle a pp engine. Thanks for the useful info.

Also, I was jsut curious about your experiences with the JHB cermet. I know there's nothing wrong with cermet itself, but I had heard that the preperation for it is very important to its durability and I hadn't found anyone with first hand experience with long term use of their housings. Also good to know.

Also, I was jsut curious about your experiences with the JHB cermet. I know there's nothing wrong with cermet itself, but I had heard that the preperation for it is very important to its durability and I hadn't found anyone with first hand experience with long term use of their housings. Also good to know.

#22

Originally Posted by Sideways7

I guess its more the p-port race engines that have driveability issues. I can deal with a high lopey idle. My car has a large street port and was lopey, plus it had a mysterious vac leak that I never found till I tore the engine down so it was even more lopey. In fact, most of the time I had to keep my foot a bit on the gas at stoplights. If I can find the money to do this, I might just contact you about details on how to work it out. If I can find a setup that would work, I would like to try to rig it up with an IDA throttle body kit and a standalone so I could run fuel injection, but I can iron that out if I ever decide to tackle a pp engine. Thanks for the useful info.

My exhaust was tuned for a lower RPM range and the ignition timing was retarded, which gave me that nice, bold torque curve. Still, the 4.88 gears really helped with towing that 600 lbs trailer. The trade-off? NOISE. The car was indescribably LOUD. I was black-flagged at Portland International Raceway for exceeding 95 dB at 50 yards with the exhaust pointed the other way. Inside the car, it was over 105 dB. I had to wear ear plugs for the entire 8,000 mile round trip to Florida and I still had to stop periodically just to let the ringing in my ears subside. Every morning, I dreaded getting back inside that car. Keep in mind, it was stripped out, so there was not all the insulation to tone things down, but it would have worn me out anyway. Does it have to be that loud? No. A more restrictive exhaust can make a PP tolerable. Rob has a Rotary Truck with a PP13B which is not bad at all. It won't make the power of a race exhaust, but it gets out of its own way pretty good regardless.

Also, I was jsut curious about your experiences with the JHB cermet. I know there's nothing wrong with cermet itself, but I had heard that the preperation for it is very important to its durability and I hadn't found anyone with first hand experience with long term use of their housings. Also good to know.

#23

Originally Posted by Blake

You are right. The preparation and application are very demanding. JHB, however, has the process well in hand. Their products are meticulous.

I think I'm gonna put the pp engine on hold for a while until I get a better job, but its good to know they can be usable on the street. If/when I decide to do it I'll definately talk you about how to set up the exhaust. Thanks for all the help.

#24

Keep to the right.

iTrader: (10)

Join Date: Jul 2001

Location: Mascoutah, IL

Posts: 793

Likes: 0

Received 0 Likes

on

0 Posts

Blake, thanks for taking the time to do this. I'm learning a lot.

Have you experimented with:

-Anti-reversion steps in either the intake or exhaust.

-purposefully located, punched divots in the intake runners to create turbulence on the runner walls in locations where you've found fuel likes to fall out of the mixture and cling there.

-Porting intake runners so they have a "D-shape" section on turns, with the flat of the "D" on the inside.

Have you experimented with:

-Anti-reversion steps in either the intake or exhaust.

-purposefully located, punched divots in the intake runners to create turbulence on the runner walls in locations where you've found fuel likes to fall out of the mixture and cling there.

-Porting intake runners so they have a "D-shape" section on turns, with the flat of the "D" on the inside.

#25

Originally Posted by antiSUV

Blake, thanks for taking the time to do this. I'm learning a lot.

Have you experimented with:

-Anti-reversion steps in either the intake or exhaust.

Have you experimented with:

-Anti-reversion steps in either the intake or exhaust.

-purposefully located, punched divots in the intake runners to create turbulence on the runner walls in locations where you've found fuel likes to fall out of the mixture and cling there.

-Porting intake runners so they have a "D-shape" section on turns, with the flat of the "D" on the inside.

If you pick up the new issue of Mazdasport Magazine, they have the first part of a two-part article I wrote on porting. The first one is more theoretical and the second one will be a practical demonstration. There is also an article I wrote for New Zealand Performance Review about four years ago that is floating around on the internet.