Haltech how do you safely induce knock?

#3

what he said

there is no safe method with the engine actually running, any knock is damaging unless in a diesel engine designed to handle the forces.

the problem with pairing random sensors with random ECUs is you have no idea how to accurately calibrate knock readings. that is why you should get a knock box with a readout and auxliary output to your ECU that you can match readings to. although knock boxes aren't cheap and some just suck, they still have a place in most tuner's tool sets. i don't use one because i have grown accustomed to feeling when an engine isn't happy, but if you have a hoopdie with unblanced wheels and solid engine mounts with straight exhaust, that can be a little difficult.

there is no safe method with the engine actually running, any knock is damaging unless in a diesel engine designed to handle the forces.

the problem with pairing random sensors with random ECUs is you have no idea how to accurately calibrate knock readings. that is why you should get a knock box with a readout and auxliary output to your ECU that you can match readings to. although knock boxes aren't cheap and some just suck, they still have a place in most tuner's tool sets. i don't use one because i have grown accustomed to feeling when an engine isn't happy, but if you have a hoopdie with unblanced wheels and solid engine mounts with straight exhaust, that can be a little difficult.

Last edited by RotaryEvolution; 03-04-17 at 12:23 PM.

#4

I thought he was joking lol. so seriously? knock on it with some brass hammer? I don't even have room to hit the engine directly.

Haltech has this function where it listens to the engine running and you listen through the installed knock sensor while you induce knock to listen to what the knock frequency is. You can record the knock frequency and use it for safeguard.. sounds good in theory... I like that method over a hammer personally haha. I'll leave this function alone for now..

Haltech has this function where it listens to the engine running and you listen through the installed knock sensor while you induce knock to listen to what the knock frequency is. You can record the knock frequency and use it for safeguard.. sounds good in theory... I like that method over a hammer personally haha. I'll leave this function alone for now..

#5

problem with that theory is that knock in rotaries comes on abruptly usually and with little control. the only way i know to induce knock is to advance the timing to the limit and jab the throttle, you will get a knock....

you don't have the factory engine lift bracket installed anymore?

you don't have the factory engine lift bracket installed anymore?

Last edited by RotaryEvolution; 03-04-17 at 12:58 PM.

#6

I removed it. I can hit on it with 3/8" socket extension... do I hit on the iron or the rotor housing? I guess i will try it out. it's better than nothing until my tuner is back at the shop. He wanted the knock sensors, so I'm guessing he has a preferred method of making them useful.

Trending Topics

#8

Old [Sch|F]ool

I always whack the engine with a hammer to make sure the knock sensor is working. If the computer uses a sensing window, it can be a real pain in the *** if you can't manually open the window up. "Okay, now hit the block with a hammer, but exactly when the piston is between 20BTDC and 20ATDC firing..."

On rotaries, I found that firing the trailing ignition 180 degrees out of phase will very reliably produce knock in vacuum. Oops.

On rotaries, I found that firing the trailing ignition 180 degrees out of phase will very reliably produce knock in vacuum. Oops.

#10

Old [Sch|F]ool

Try it sometime! When I did my first engine built, a mild streetport 12A, I had an MSD running two coils direct-fire on the leading and I stabbed the distributor in wrong. It ran okay since the leading was firing at the right time, but it meant the trailing was firing around 190 degrees BTDC give or take a few. Anything more than 1/3 throttle make it detonate so hard it felt like the engine was turning backwards, accompanied by black smoke out the exhaust.

But it idled with AUTHORITY with that much trailing advance, I tell you hwat!

But it idled with AUTHORITY with that much trailing advance, I tell you hwat!

Last edited by peejay; 03-04-17 at 10:05 PM.

#13

thanks for the replies. guys! I did the hammer method but not feeling too confident whether it's the correct frequency. trailing method just seems dangerous to me... i don't know... i prefer a transient knock... rather than full-time knock until I set it back to normal... I may try the low rpm and giving 30 degree advance on transient throttle timing advance in vacuum... that sounds reasonable.. what do you think?

#14

Full Member

Out of curiosity what frequency did you end up with? Factory manual I think is 3500Hz.

I did the HPAcademy course for tuning, and on piston methods he uses the ECU tunes to induce knock by temporarily over advancing the timing and sampling it on the ECU. But for rotaries, he routinely cautions that trying to set up knock detection on a rotary is risky as inducing knock may blow your seals out. Had never heard of the hammer method though, so might give that a go.

I did the HPAcademy course for tuning, and on piston methods he uses the ECU tunes to induce knock by temporarily over advancing the timing and sampling it on the ECU. But for rotaries, he routinely cautions that trying to set up knock detection on a rotary is risky as inducing knock may blow your seals out. Had never heard of the hammer method though, so might give that a go.

#15

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,802

Received 2,577 Likes

on

1,831 Posts

the Rx8 will knock a little, and my P port does the same so try it.

you need to be running around stoich AFR, rpm is low, 1800-2500rpm and timing around 18btdc. throttle is 30-60%

it makes a chirping sound, its more prevalent when the engine is cold.

you need to be running around stoich AFR, rpm is low, 1800-2500rpm and timing around 18btdc. throttle is 30-60%

it makes a chirping sound, its more prevalent when the engine is cold.

#16

actually my tuner had a genius idea. Don't make it knock. Just listen to normal operating frequency of the engine then set a frequency window higher than the normal operating sound to be interpreted as "knock". It works very well. I tripped knock once when I punched it one day on the freeway from 70mph. I hit a lean window in the fuel map (19 AFR @ 4-5 psi). Immediately threw a check engine light and automatically retarded timing by the set amount. Works awesome.

#17

actually my tuner had a genius idea. Don't make it knock. Just listen to normal operating frequency of the engine then set a frequency window higher than the normal operating sound to be interpreted as "knock". It works very well. I tripped knock once when I punched it one day on the freeway from 70mph. I hit a lean window in the fuel map (19 AFR @ 4-5 psi). Immediately threw a check engine light and automatically retarded timing by the set amount. Works awesome.

The idea of advanced knock detection is to to target the specific frequency where knock occurs and to IGNORE everything else. Knock will generate a noise within a very specific frequency range within a narrow range of crank position. This is what the knock filtering is setup to look for. Yes, there is a typical range of noises an engine makes, but those noises are dynamic and change with RPM and load. If you do not tell the ECU what frequency to target, you're effectively wasting it's ability to distinguish true knock from noise. So, the knock event that you logged, was it knock or a rouge noise? You're not sure, are you?

My guess and what I hope he actually told you, was to possible log the base dB trace during a free rev or low boost pull where you're confident no knock is occurring and use that to define the base dB table. Any noise with a higher dB is then defined as knock with the defined frequency range and defined crank window. A low boost, no knock pull is the way to define this dB value, not the knock frequency.

#19

Full Member

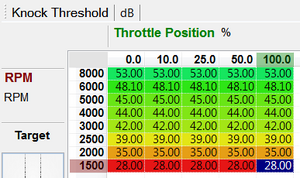

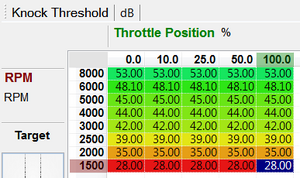

So curious as to what Knock Threshold dB limits people are running then.

Here is the Haltech base table:

Interesting to see that the threshold starts low and go up with rpm, given that I've found most of the "random noises" you see seem to happen at low rpm, not high rpm.

What do your maps look like?

Here is the Haltech base table:

Interesting to see that the threshold starts low and go up with rpm, given that I've found most of the "random noises" you see seem to happen at low rpm, not high rpm.

What do your maps look like?

#21

Banned. I got OWNED!!!

So curious as to what Knock Threshold dB limits people are running then.

Here is the Haltech base table:

Interesting to see that the threshold starts low and go up with rpm, given that I've found most of the "random noises" you see seem to happen at low rpm, not high rpm.

What do your maps look like?

Here is the Haltech base table:

Interesting to see that the threshold starts low and go up with rpm, given that I've found most of the "random noises" you see seem to happen at low rpm, not high rpm.

What do your maps look like?

#22

I think it's lower in the lower RPM because the background noise is lower at a lower RPM. Log the knock dB when you're driving around with conservative timing map, and you'll see what I mean. The background noise at 3500hz follows the rpm curve. Mine goes upto 39-40dB at 8500rpm @ 12psi. Doesn't matter if I retard timing by a few degrees. AFR is solid at 10.8 and I tried lower. I heard actual knock is lot louder. I wasn't logging the 3500hz band when I tripped the knock threshold last time. I hope it won't happen again but I'm logging it just in case.

#23

Banned. I got OWNED!!!

I think it's lower in the lower RPM because the background noise is lower at a lower RPM. Log the knock dB when you're driving around with conservative timing map, and you'll see what I mean. The background noise at 3500hz follows the rpm curve. Mine goes upto 39-40dB at 8500rpm @ 12psi. Doesn't matter if I retard timing by a few degrees. AFR is solid at 10.8 and I tried lower. I heard actual knock is lot louder. I wasn't logging the 3500hz band when I tripped the knock threshold last time. I hope it won't happen again but I'm logging it just in case.

Shoot, we should end up doing development collaborations on here. You're so far ahead of the majority of people on the other Rx7Club ECU forums...