FD3S Rear "Euro" Washer/Fluid Tank

#601

Hey guys!

I've been holding off posting anything until there was something more substantial to share. Well, I got something substantial.

Where should I start? Ok, a few pics.

What you see is the first sample pulled from the production mold. We needed to make a few changes and will make a couple more before we get another and hopefully final sample in a couple weeks.

Ok. So quick rundown of what you are looking at.

1) We managed to tic the box on all the upgrades to the OEM Euro Washer Tank we set out to do. One piece design, increased capacity (about 2 gallons), sump to control slosh (more on that), bosses for installing sensors/nozzles, OEM fitment and molded cap and rubber mounts.

2) On the topic of the sump - we had to change the design slightly from the last 3D print. There was an issue with plastic filling the 90 degree corners fully, so it went to a more 'sloped' design. No biggie and should not effect performance at all. Also, please note the finish scuffs are just a artifact from modifying the mold, NOT an indication of what the production piece will look like.

3) This thing is a BEAST. I had originally gone through the thought exercise of figuring out how to protect this from getting damaged in transit. I now have ZERO worries about that.

4) The fill neck interior is a little ugly. Nothing that effects the threads, or sealing, or filling - just inconsistent (and ugly). I'm going to try to work with the factory on cleaning that up a bit. Maybe machine it after the fact.

5) The black material is just for the sample. The final (and next sample actually) will be white / opaque like OEM.

6) The supplied SBG cap OR the OEM cap fit no problem. Tank WILL include a SBG Cap. I have a few OEM caps if people are interested. PM me.

7) The tank in the pictures is ALREADY drilled so I could test fit the level sensor. You tank will NOT be drilled and won't include a grommet (pictured) unless you buy a kit from SakeBomb Garage.

Further Improvements from this sample to the next.

1) Relocated Sensor Boss. I didn't account for the pigtail part of the sensor when I placed the sensor boss on the front where I did. SO, I need to move it down a bit. No biggie.

2) Additional Sensor Boss. I am adding a sensor boss directly in the sump. I didn't know if there'd be room for it, bu there is, so I added it.

3) Drill Guides. When drilling the sensor/nozzle bosses, it was a little tough to center the drill bit, so I added centering 'divots' in order to help with that.

4) Finish. We will be adding a sandblasted finish to the entire tank and cap, EXCEPT to the lettering. It should look really nice.

I'm sure there's something I'm missing, but I will be sure to update this as I remember.

OH! Also, SBG will have updated on the brackets here soon. Sit tight on that.

...and finally, here's a video I took since it probably does a better job then any pictures or words:

I've been holding off posting anything until there was something more substantial to share. Well, I got something substantial.

Where should I start? Ok, a few pics.

What you see is the first sample pulled from the production mold. We needed to make a few changes and will make a couple more before we get another and hopefully final sample in a couple weeks.

Ok. So quick rundown of what you are looking at.

1) We managed to tic the box on all the upgrades to the OEM Euro Washer Tank we set out to do. One piece design, increased capacity (about 2 gallons), sump to control slosh (more on that), bosses for installing sensors/nozzles, OEM fitment and molded cap and rubber mounts.

2) On the topic of the sump - we had to change the design slightly from the last 3D print. There was an issue with plastic filling the 90 degree corners fully, so it went to a more 'sloped' design. No biggie and should not effect performance at all. Also, please note the finish scuffs are just a artifact from modifying the mold, NOT an indication of what the production piece will look like.

3) This thing is a BEAST. I had originally gone through the thought exercise of figuring out how to protect this from getting damaged in transit. I now have ZERO worries about that.

4) The fill neck interior is a little ugly. Nothing that effects the threads, or sealing, or filling - just inconsistent (and ugly). I'm going to try to work with the factory on cleaning that up a bit. Maybe machine it after the fact.

5) The black material is just for the sample. The final (and next sample actually) will be white / opaque like OEM.

6) The supplied SBG cap OR the OEM cap fit no problem. Tank WILL include a SBG Cap. I have a few OEM caps if people are interested. PM me.

7) The tank in the pictures is ALREADY drilled so I could test fit the level sensor. You tank will NOT be drilled and won't include a grommet (pictured) unless you buy a kit from SakeBomb Garage.

Further Improvements from this sample to the next.

1) Relocated Sensor Boss. I didn't account for the pigtail part of the sensor when I placed the sensor boss on the front where I did. SO, I need to move it down a bit. No biggie.

2) Additional Sensor Boss. I am adding a sensor boss directly in the sump. I didn't know if there'd be room for it, bu there is, so I added it.

3) Drill Guides. When drilling the sensor/nozzle bosses, it was a little tough to center the drill bit, so I added centering 'divots' in order to help with that.

4) Finish. We will be adding a sandblasted finish to the entire tank and cap, EXCEPT to the lettering. It should look really nice.

I'm sure there's something I'm missing, but I will be sure to update this as I remember.

OH! Also, SBG will have updated on the brackets here soon. Sit tight on that.

...and finally, here's a video I took since it probably does a better job then any pictures or words:

The following 3 users liked this post by MattGold:

The following users liked this post:

MattGold (11-12-18)

#604

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

The following users liked this post:

MiataRoadster (11-13-18)

The following users liked this post:

MattGold (11-13-18)

#609

The AEM sensor is the same one we're testing. BUT, we've been using the push-in style - whereas the AEM is threaded. Sooo, could you try it? Yeah. But I'd probably recommend the push-in style. I think it's included if you buy the SBG kit... and if not, will probably be less than $10 all in.

#610

)...

)...So let me take another crack at it.

1) Level Sensor. The AEM sensor is the same one we're testing. BUT, we've been using the push-in style - whereas the AEM is threaded. Sooo, could you try it? Yeah. But I'd probably recommend the push-in style. I think it's included if you buy the SBG kit... and if not, will probably be less than $10 all in.

2) Nozzle. The one we're using is the AEM one. Yes it will move over. Yes it will thread in.

The following users liked this post:

MattGold (11-13-18)

#614

#617

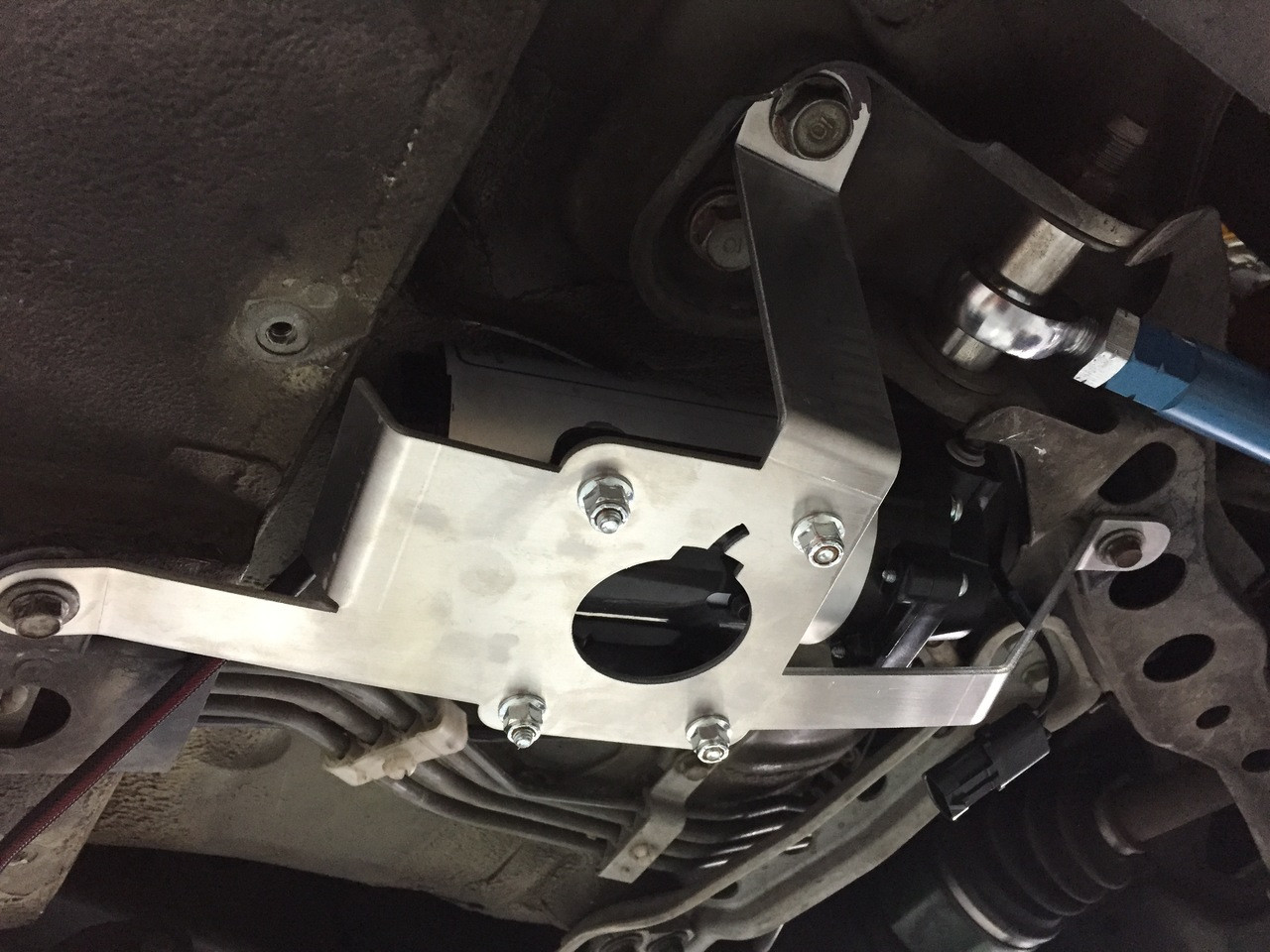

Might be a tad hard to see, but this bracket is holding the pump in that first picture.

[img]https://cdn1.bigcommerce.com/server5200/mjpwat6/products/651/images/2917/IMG_5379__74792.1541635435.1280.1280.JPG[/img]

[img]https://cdn1.bigcommerce.com/server5200/mjpwat6/products/651/images/2917/IMG_5379__74792.1541635435.1280.1280.JPG[/img]

#618

Rotary Enthusiast

iTrader: (32)

Weren't there some rubber isolation bushings shown in one of the earlier design images? Is there any transmitted noise or vibration noticeable with the solid mounting?

I already ordered a bracket, but I thought I would ask anyway...just wondering if additional isolation will be needed if it is really desired to dampen pump noise.

I already ordered a bracket, but I thought I would ask anyway...just wondering if additional isolation will be needed if it is really desired to dampen pump noise.

#619

Weren't there some rubber isolation bushings shown in one of the earlier design images? Is there any transmitted noise or vibration noticeable with the solid mounting?

I already ordered a bracket, but I thought I would ask anyway...just wondering if additional isolation will be needed if it is really desired to dampen pump noise.

I already ordered a bracket, but I thought I would ask anyway...just wondering if additional isolation will be needed if it is really desired to dampen pump noise.

Can you see them up there? Is that what you were thinking of?

#621

Hey guys! I had a forum member reach out the other day to try and get some more info on the tank production, specifically a revised ETA. I sent him as honest of a message as I could, and upon rereading it, figured there was no reason to not post this publicly so everyone can be in-the-loop...

<<The original ETA, has sadly come and gone. Some of it due to necessary changes, some due to incremental improvements. Most of it due to looking at ETAs as finite rather than fluid. At this point, there's nothing happening that isn't out of necessity anymore.

Ok, so where EXACTLY are we with the tanks? Lemme just revisit my original estimates and let you into my head a bit... opened the GB on July 10. I was working off a 30/30/30 day timeline - 30 days for mold production. 30 days for tank production. 30 days for shipping. That's how I got to my October/November ETA. What I didn't plan for was how incremental things have become...

Obviously you've seen the first samples from the mold. That means, the mold is made. That's a HUGE step. Did it take longer than the time frame we were quoted (30 days) to actually make the mold? Yeah. It did. Once we got that mold made, I didn't account for the time it would take to actually produce the first sample and get samples here. Not to mention revamping the design / mold. That has basically sapped an extra week or two weeks between each step.

Mold made... two weeks... first sample.

First sample... a week to ship... arrival.

Review sample... two weeks... design changes.

Design changes communicated... two weeks... design changes implemented.

Design changes implemented... one week... new mold made.

It's not like we're "stuck" per se, things are moving forward, nothing has stalled. But it's a process... an incremental process.

Ok, so where EXACTLY are we with the tanks? I'm waiting on the white/clear samples with the last round of changes (move boss, additional sump boss, drill guides) to be produced so I can approve it and green light tank production. THAT will be another 30 days (or so). Then another 30 days (or so) for shipping. We ARE dealing with an overseas manufacturer, so that's why the shipping time frame is so large.

So where does that bring us? Realistically? February delivery. Let's say I get the samples one week from today and give the green light. 60 days is January 26th. Is that what people want to hear? Probably not. Is it what I expected? Definitely not. But I think it's more accurate than any other ETA at the moment. If you are antsy to the point of wanting a refund - I don't *think* that's what you are asking - BUT, that's no problem at all.

Again, thanks for your support and Happy thanksgiving.>>

So that's where we are. If I'm being perfectly honest, I'm more excited for this project NOW then I ever have been - once I had the samples in hand, I had a "holy ****, this thing exists" moment. Truly invigorating. Anyhow, new samples are happening and I really, really think they will be perfect and will get the green light. From there, it's a waiting game.

Thanks for coming along with me on this adventure!

<<The original ETA, has sadly come and gone. Some of it due to necessary changes, some due to incremental improvements. Most of it due to looking at ETAs as finite rather than fluid. At this point, there's nothing happening that isn't out of necessity anymore.

Ok, so where EXACTLY are we with the tanks? Lemme just revisit my original estimates and let you into my head a bit... opened the GB on July 10. I was working off a 30/30/30 day timeline - 30 days for mold production. 30 days for tank production. 30 days for shipping. That's how I got to my October/November ETA. What I didn't plan for was how incremental things have become...

Obviously you've seen the first samples from the mold. That means, the mold is made. That's a HUGE step. Did it take longer than the time frame we were quoted (30 days) to actually make the mold? Yeah. It did. Once we got that mold made, I didn't account for the time it would take to actually produce the first sample and get samples here. Not to mention revamping the design / mold. That has basically sapped an extra week or two weeks between each step.

Mold made... two weeks... first sample.

First sample... a week to ship... arrival.

Review sample... two weeks... design changes.

Design changes communicated... two weeks... design changes implemented.

Design changes implemented... one week... new mold made.

It's not like we're "stuck" per se, things are moving forward, nothing has stalled. But it's a process... an incremental process.

Ok, so where EXACTLY are we with the tanks? I'm waiting on the white/clear samples with the last round of changes (move boss, additional sump boss, drill guides) to be produced so I can approve it and green light tank production. THAT will be another 30 days (or so). Then another 30 days (or so) for shipping. We ARE dealing with an overseas manufacturer, so that's why the shipping time frame is so large.

So where does that bring us? Realistically? February delivery. Let's say I get the samples one week from today and give the green light. 60 days is January 26th. Is that what people want to hear? Probably not. Is it what I expected? Definitely not. But I think it's more accurate than any other ETA at the moment. If you are antsy to the point of wanting a refund - I don't *think* that's what you are asking - BUT, that's no problem at all.

Again, thanks for your support and Happy thanksgiving.>>

So that's where we are. If I'm being perfectly honest, I'm more excited for this project NOW then I ever have been - once I had the samples in hand, I had a "holy ****, this thing exists" moment. Truly invigorating. Anyhow, new samples are happening and I really, really think they will be perfect and will get the green light. From there, it's a waiting game.

Thanks for coming along with me on this adventure!

The following users liked this post:

knotsonice (11-26-18)

#622

Hey guys! I had a forum member reach out the other day to try and get some more info on the tank production, specifically a revised ETA. I sent him as honest of a message as I could, and upon rereading it, figured there was no reason to not post this publicly so everyone can be in-the-loop...

<<The original ETA, has sadly come and gone. Some of it due to necessary changes, some due to incremental improvements. Most of it due to looking at ETAs as finite rather than fluid. At this point, there's nothing happening that isn't out of necessity anymore.

Ok, so where EXACTLY are we with the tanks? Lemme just revisit my original estimates and let you into my head a bit... opened the GB on July 10. I was working off a 30/30/30 day timeline - 30 days for mold production. 30 days for tank production. 30 days for shipping. That's how I got to my October/November ETA. What I didn't plan for was how incremental things have become...

Obviously you've seen the first samples from the mold. That means, the mold is made. That's a HUGE step. Did it take longer than the time frame we were quoted (30 days) to actually make the mold? Yeah. It did. Once we got that mold made, I didn't account for the time it would take to actually produce the first sample and get samples here. Not to mention revamping the design / mold. That has basically sapped an extra week or two weeks between each step.

Mold made... two weeks... first sample.

First sample... a week to ship... arrival.

Review sample... two weeks... design changes.

Design changes communicated... two weeks... design changes implemented.

Design changes implemented... one week... new mold made.

It's not like we're "stuck" per se, things are moving forward, nothing has stalled. But it's a process... an incremental process.

Ok, so where EXACTLY are we with the tanks? I'm waiting on the white/clear samples with the last round of changes (move boss, additional sump boss, drill guides) to be produced so I can approve it and green light tank production. THAT will be another 30 days (or so). Then another 30 days (or so) for shipping. We ARE dealing with an overseas manufacturer, so that's why the shipping time frame is so large.

So where does that bring us? Realistically? February delivery. Let's say I get the samples one week from today and give the green light. 60 days is January 26th. Is that what people want to hear? Probably not. Is it what I expected? Definitely not. But I think it's more accurate than any other ETA at the moment. If you are antsy to the point of wanting a refund - I don't *think* that's what you are asking - BUT, that's no problem at all.

Again, thanks for your support and Happy thanksgiving.>>

So that's where we are. If I'm being perfectly honest, I'm more excited for this project NOW then I ever have been - once I had the samples in hand, I had a "holy ****, this thing exists" moment. Truly invigorating. Anyhow, new samples are happening and I really, really think they will be perfect and will get the green light. From there, it's a waiting game.

Thanks for coming along with me on this adventure!

<<The original ETA, has sadly come and gone. Some of it due to necessary changes, some due to incremental improvements. Most of it due to looking at ETAs as finite rather than fluid. At this point, there's nothing happening that isn't out of necessity anymore.

Ok, so where EXACTLY are we with the tanks? Lemme just revisit my original estimates and let you into my head a bit... opened the GB on July 10. I was working off a 30/30/30 day timeline - 30 days for mold production. 30 days for tank production. 30 days for shipping. That's how I got to my October/November ETA. What I didn't plan for was how incremental things have become...

Obviously you've seen the first samples from the mold. That means, the mold is made. That's a HUGE step. Did it take longer than the time frame we were quoted (30 days) to actually make the mold? Yeah. It did. Once we got that mold made, I didn't account for the time it would take to actually produce the first sample and get samples here. Not to mention revamping the design / mold. That has basically sapped an extra week or two weeks between each step.

Mold made... two weeks... first sample.

First sample... a week to ship... arrival.

Review sample... two weeks... design changes.

Design changes communicated... two weeks... design changes implemented.

Design changes implemented... one week... new mold made.

It's not like we're "stuck" per se, things are moving forward, nothing has stalled. But it's a process... an incremental process.

Ok, so where EXACTLY are we with the tanks? I'm waiting on the white/clear samples with the last round of changes (move boss, additional sump boss, drill guides) to be produced so I can approve it and green light tank production. THAT will be another 30 days (or so). Then another 30 days (or so) for shipping. We ARE dealing with an overseas manufacturer, so that's why the shipping time frame is so large.

So where does that bring us? Realistically? February delivery. Let's say I get the samples one week from today and give the green light. 60 days is January 26th. Is that what people want to hear? Probably not. Is it what I expected? Definitely not. But I think it's more accurate than any other ETA at the moment. If you are antsy to the point of wanting a refund - I don't *think* that's what you are asking - BUT, that's no problem at all.

Again, thanks for your support and Happy thanksgiving.>>

So that's where we are. If I'm being perfectly honest, I'm more excited for this project NOW then I ever have been - once I had the samples in hand, I had a "holy ****, this thing exists" moment. Truly invigorating. Anyhow, new samples are happening and I really, really think they will be perfect and will get the green light. From there, it's a waiting game.

Thanks for coming along with me on this adventure!

#623

Hey guys! I had a forum member reach out the other day to try and get some more info on the tank production, specifically a revised ETA. I sent him as honest of a message as I could, and upon rereading it, figured there was no reason to not p....

...Thanks for coming along with me on this adventure!

...Thanks for coming along with me on this adventure!

We appreciate the communication. Thank you for keeping us in the loop. Also, I emailed sakebomb, via my order email that I have had a change of address since I placed my order. Anyway to verify that that has been received?

The following users liked this post:

iantboyd (11-28-18)