infernosg's N/A build

#127

Full Member

Thread Starter

Yeah, a quick search shows it's most likely the lines. I'm using the standard CPE-lined stainless steel -6 AN lines and internet knowledge says they WILL permeate fuel over time. It looks like I'll be investing in PTFE-lined hoses in the future.

#128

I'm just using black nylon braided hose from Vibrant Performance. Nothing special. If your garage fills with the smell of gas you gotta have something leaking, not just a long term seepage. Poke around after you shut the car off and see if you can smell where it is coming from. A bad fitting, or leaking injectors dribbling fuel after you shut it off. Bad seal on the tank, filler tube, gas cap, or something. Maybe give the motor a good rev before you shut it off to ensure the intake is clear of fuel.

#129

Full Member

Thread Starter

I'm just using black nylon braided hose from Vibrant Performance. Nothing special. If your garage fills with the smell of gas you gotta have something leaking, not just a long term seepage. Poke around after you shut the car off and see if you can smell where it is coming from. A bad fitting, or leaking injectors dribbling fuel after you shut it off. Bad seal on the tank, filler tube, gas cap, or something. Maybe give the motor a good rev before you shut it off to ensure the intake is clear of fuel.

#130

Rotary Enthusiast

I dont know if there was a final consensus on injection angle, other than get it on a dyno, but here is a thread with a decent discussion.

https://www.rx7club.com/haltech-foru...inued-1101069/

https://www.rx7club.com/haltech-foru...inued-1101069/

#131

No. I would have to remove the bed of the truck to get to all of them. I was able to reach the line from the fuel pump to hardline which is the only "high pressure" line back there. I replaced that with a new rubber fuel line and clamps, and replaced the line between the fuel pump and fuel filter. Filter to tank, and return hardline to tank are original, as is the breather tube and everything connecting the expansion tank (don't think your car has one of these). On the engine side, I cut the flange off the feed and return hardlines and it's all AN fittings from there to the fuel rail. Gasoline evaporates quickly, so if your garage smells a day after you last drove it, you have something that is constantly leaking. Injectors, a fitting, the regulator, the fuel cell or tank or any hosing connecting it, that sort of thing. Something that keeps introducing a small amount of gas into the air over time.

#132

Full Member

Thread Starter

I dont know if there was a final consensus on injection angle, other than get it on a dyno, but here is a thread with a decent discussion.

https://www.rx7club.com/haltech-foru...inued-1101069/

https://www.rx7club.com/haltech-foru...inued-1101069/

No. I would have to remove the bed of the truck to get to all of them. I was able to reach the line from the fuel pump to hardline which is the only "high pressure" line back there. I replaced that with a new rubber fuel line and clamps, and replaced the line between the fuel pump and fuel filter. Filter to tank, and return hardline to tank are original, as is the breather tube and everything connecting the expansion tank (don't think your car has one of these). On the engine side, I cut the flange off the feed and return hardlines and it's all AN fittings from there to the fuel rail. Gasoline evaporates quickly, so if your garage smells a day after you last drove it, you have something that is constantly leaking. Injectors, a fitting, the regulator, the fuel cell or tank or any hosing connecting it, that sort of thing. Something that keeps introducing a small amount of gas into the air over time.

#133

Full Member

Thread Starter

Today I discovered my engine doesn't pull enough vacuum in front of the throttle butterflies in order to open the purge control valve. It only needs a couple in. Hg to open but I was only able to get that by shoving the source line of my vacuum gauge all the way into the throttle body, right in front of the butterfly. My plan B is to use a FD PCV valve. It works nearly the same way as the FC purge control valve. A line from the rear air filter to the top of the oil filler neck will serve as the crank case fresh air source. I'll reinstall the crankcase vent port in the center iron and connect that to my catch can. Then run a line from the catch can to a "T" that leads to the PCV valve, which connects to the vacuum manifold. The other side of the "T" connects to the charcoal canister, which has built-in fresh air source, and is connected to the fuel tank . It may seem complicated but it's actually pretty straightforward on the diagram I've drawn. It may not solve my fuel smell issue but it'll make me feel better having an evaporative emissions system again. Also, having an active crank case ventilation system should reduce the amount of condensation in the oil filler neck.

#134

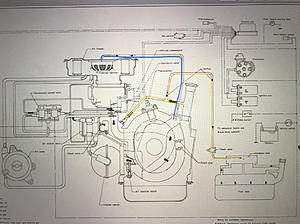

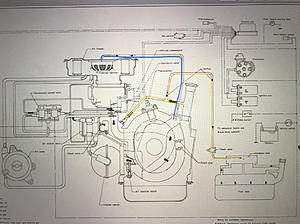

Here's the REPU diagram which is about as simple as you can get. It also shows arrows as to which way air is allowed to flow.

Vehicle off: if temperature changes and gas expands, gassy air is pushed through check valve into hardline to engine bay, it is pushed into the crank case via the top line, and further pushed out the bottom line to the charcoal canister.

Vehicle on: the ventilation valve allows a small amount of air to be pulled into the intake low on the manifold. The air comes from the upper filler tube line via the crank case lower line and through the charcoal canister. So a portion of your idle air is sucked through this way. Manual says if you block it off, engine speed should drop slightly, but if it stalls, replace the valve.

The 12a appears to employ the same system but uses a remote purge valve instead...but the line terminates below the throttle body to allow decent vacuum to constantly pull fresh air from the canister through the crank case and into the manifold. The diagram I'm looking at doesn't show the gas tank breather but I assume it's connected in the same manner.

The purge valve or ventilation valve serves two purposes: 1, don't allow positive pressure from the intake manifold side into the evap system and 2, restrict the amount of air that can be pulled into the intake manifold via vacuum. If you have a low vacuum signal, it may be fine, because the goal here is to release positive pressure from the crank case or gas tank. As long as you can blow through the purge valve and that air gets to below the throttle plates, you're good.

Vehicle off: if temperature changes and gas expands, gassy air is pushed through check valve into hardline to engine bay, it is pushed into the crank case via the top line, and further pushed out the bottom line to the charcoal canister.

Vehicle on: the ventilation valve allows a small amount of air to be pulled into the intake low on the manifold. The air comes from the upper filler tube line via the crank case lower line and through the charcoal canister. So a portion of your idle air is sucked through this way. Manual says if you block it off, engine speed should drop slightly, but if it stalls, replace the valve.

The 12a appears to employ the same system but uses a remote purge valve instead...but the line terminates below the throttle body to allow decent vacuum to constantly pull fresh air from the canister through the crank case and into the manifold. The diagram I'm looking at doesn't show the gas tank breather but I assume it's connected in the same manner.

The purge valve or ventilation valve serves two purposes: 1, don't allow positive pressure from the intake manifold side into the evap system and 2, restrict the amount of air that can be pulled into the intake manifold via vacuum. If you have a low vacuum signal, it may be fine, because the goal here is to release positive pressure from the crank case or gas tank. As long as you can blow through the purge valve and that air gets to below the throttle plates, you're good.

#135

Full Member

Thread Starter

The FC purge control valve operates a little differently from the 12A version. It only has three ports: one on top and two on the bottom. The smaller port on the bottom is connected to the intake manifold and always sees vacuum (except at WOT). The larger port on the bottom connects to the port on the oil filler neck. The port at the bottom of the oil filler neck in the center iron is connected to the charcoal canister. The online FSM also shows it being teed into a check valve that goes to the intake duct but my '89 hard copy FSM only shows that for the turbo model. In the latter case the fresh air supply is the bottom of the charcoal canister. When the purge control valve is open (above 2000 RPM according to the FSM) fuel vapor from the charcoal canister and crank case gases from the oil pan are sucked into the engine through the oil filler neck, into the large port and then out the small port. The port on top of the purge control valve connects to a port on the throttle body just in from of the butterflies. It's this port that controls when and how much the purge control valve is opened. When engine speed increases a small amount of vacuum is generated in front of the throttle butterflies. This pulls on a diaphragm and allows gases to flow through the large port and out the small port on the bottom of the valve. Without this small amount of vacuum no amount of engine vacuum will pull gases through the valve (I've tested it). Without vacuum on the top port the only way the valve will open is with positive pressure on the bottom port. Since the charcoal canister is vented pressure will always relieve there instead of at the purge control valve.

A PCV valve like what's in the early FDs and on other modern cars accomplishes the same without the need for two vacuum signals. Then again, the PCV valve is used solely for crank case gases and they have a separate, electronically-controlled purge valve for the evaporative emissions system. I don't see why I couldn't connect the two systems unless fuel vapor adversely affects the PCV valve in some way. It just seems like a more elegant solution. Where it gets interesting is understanding how the FD PCV valve works. I haven't been able to find any published pressure values only "it's opened slightly at idle and opens more as engine speed increases." I pull ~6.5 psi (~13.2 in. Hg) at idle, which I imagine is less than a stock FD. Therefore, the PCV will be more open at idle.

EDIT: If I really want to get fancy I could pick up a FD electronic purge control valve and use one of my switched outputs to activate it. There's not much information on its operation other than it's closed at idle. The FC FSM at least states the purge control valve is closed at idle and is open at 2000 RPM. I could easily program one of my spare DPO's to activate at like 1800 RPM and deactivate at 1600 RPM.

A PCV valve like what's in the early FDs and on other modern cars accomplishes the same without the need for two vacuum signals. Then again, the PCV valve is used solely for crank case gases and they have a separate, electronically-controlled purge valve for the evaporative emissions system. I don't see why I couldn't connect the two systems unless fuel vapor adversely affects the PCV valve in some way. It just seems like a more elegant solution. Where it gets interesting is understanding how the FD PCV valve works. I haven't been able to find any published pressure values only "it's opened slightly at idle and opens more as engine speed increases." I pull ~6.5 psi (~13.2 in. Hg) at idle, which I imagine is less than a stock FD. Therefore, the PCV will be more open at idle.

EDIT: If I really want to get fancy I could pick up a FD electronic purge control valve and use one of my switched outputs to activate it. There's not much information on its operation other than it's closed at idle. The FC FSM at least states the purge control valve is closed at idle and is open at 2000 RPM. I could easily program one of my spare DPO's to activate at like 1800 RPM and deactivate at 1600 RPM.

Last edited by infernosg; 05-23-18 at 12:38 PM.

#139

Full Member

Thread Starter

Thanks for the compliments. I haven't completely disappeared. Summer is a busy time for me. I did end up getting an emissions setup working: stock FC charcoal canister and a FD purge control solenoid which is operated by the PS1000. All appears to be working as intended but I still have a bad fuel smell in the garage. I'm not ruling out any leaks but I think it's just fuel vapor seeping through the braided fuel lines. Whenever I decide to update the setup I'll switch to PTFE-lined hoses. Other than that I took a break for most of July and August and just recently got back into trying to finish the tune. Most of the low-load stuff is sorted out except for the higher engine speeds, which are hard to hit on the street. I did try to do some WOT runs on a dyno a while back but the engine seemed to "run out of gas" at 7500 RPM for some reason. I wasn't behind the wheel but the dyno operator said it wouldn't go any higher. He said it felt like a mechanical restriction and noticed the car started to slightly pull vacuum again. My possible thoughts are: (1) there really isn't any issue and the operator misinterpreted something, (2) there's a mechanical restriction (my exhaust sucks), and/or (3) timing is too advanced. I didn't see anything weird in the run log or feel the car start to misfire or anything. It doesn't appear to have any problems spinning to 9000 RPM in gears 1-3 and I honestly thought ignition timing was conservative at around 20 degrees. In the end it was making almost 190 whp at 7200 RPM and 145 ft-lb at 6500 RPM. Not bad but I think this car is good for over 200 whp. I'm going to get the exhaust sorted out, continue to sort out the fuel map, and then get back on the dyno when it isn't nearly 100 degrees outside.

#141

Re: Gas smell. I'm guessing its a cracked fuel line, something by the tank perhaps? Anything you replaced already will be fine but check all the fittings and hose ends. As I said before, I didn't think it was the intake or lack of charcoal canister. If the garage always smells, there is an active leak on a fitting, barb, or damaged hose.

Do you have a dyno chart or log file from when the guy claimed it seemed to "run out of gas"? Did he mean literally, like it started to go lean? Or figuratively, like it wouldn't rev any more? I wouldn't be too worried about it pulling some vacuum at high rpms. Depending on where your vacuum lines are on the intake at high engine speed there could be a restriction. I doubt it's related to the exhaust. If you can rev the car to 9,000 in 2nd or 3rd on the street at full throttle and don't feel it falling apart, it's probably fine.

Do you have a dyno chart or log file from when the guy claimed it seemed to "run out of gas"? Did he mean literally, like it started to go lean? Or figuratively, like it wouldn't rev any more? I wouldn't be too worried about it pulling some vacuum at high rpms. Depending on where your vacuum lines are on the intake at high engine speed there could be a restriction. I doubt it's related to the exhaust. If you can rev the car to 9,000 in 2nd or 3rd on the street at full throttle and don't feel it falling apart, it's probably fine.

#143

Full Member

Thread Starter

Re: Gas smell. I'm guessing its a cracked fuel line, something by the tank perhaps? Anything you replaced already will be fine but check all the fittings and hose ends. As I said before, I didn't think it was the intake or lack of charcoal canister. If the garage always smells, there is an active leak on a fitting, barb, or damaged hose.

Do you have a dyno chart or log file from when the guy claimed it seemed to "run out of gas"? Did he mean literally, like it started to go lean? Or figuratively, like it wouldn't rev any more? I wouldn't be too worried about it pulling some vacuum at high rpms. Depending on where your vacuum lines are on the intake at high engine speed there could be a restriction. I doubt it's related to the exhaust. If you can rev the car to 9,000 in 2nd or 3rd on the street at full throttle and don't feel it falling apart, it's probably fine.

Do you have a dyno chart or log file from when the guy claimed it seemed to "run out of gas"? Did he mean literally, like it started to go lean? Or figuratively, like it wouldn't rev any more? I wouldn't be too worried about it pulling some vacuum at high rpms. Depending on where your vacuum lines are on the intake at high engine speed there could be a restriction. I doubt it's related to the exhaust. If you can rev the car to 9,000 in 2nd or 3rd on the street at full throttle and don't feel it falling apart, it's probably fine.

Regarding the dyno, honestly I didn't feel/see/hear anything unusual but I was staring at my computer at the time. The operator just said the car just stopped accelerating at 7500 RPM and that it felt like a mechanical restriction to him. I have a datalog of the run and I really don't see the engine hanging at 7500 RPM. If I zoom in really closely it maybe hung there for a 1/2 second before the operator let off. Nothing looks unusual. I was actually running a little rich by that point (around 12:1 - target is 12.5:1), the injector duty cycle was around 75%, and there were no major ignition corrections (it was pulling ~1 degree due to air temperature). Air temperature was high - around 150 but coolant and oil temperatures were good (less than 200). Manifold pressure started to drop (more vacuum) starting around 4000 RPM from +0.5 psi to -0.5 psi by 7500 RPM. I can't really hit 9000 RPM on the street in 3rd but I've done it several times in second with no issues. I do still see the manifold pressure drop, though.

In retrospect I'm actually wondering if my ignition timing is too retarded. At WOT it maxxes out at 21 degrees and most of what I've read says N/A cars like 20-30 degrees. I had dialed back the ignition map when I was breaking in the engine to keep it safe. Recently I added about half of the timing back in. Due to weather I've only been able to take the car out once since then but I haven't noticed any negative effects. I also found out my throttle pedal stop was preventing me from reaching 100% throttle position. I've fixed that but I don't think ~1 degree of throttle position would have that much of an impact. I haven't been able to get the car out since doing that, though.

I'm going to continue working on my street tune for another month or so to take advantage of the reasonable Fall temperatures. Once that's done I'll get it back on the dyno and really mess with timing to see if that fixes the 7500 RPM issue.

Way too much. I'm easily at the cost of a clean, stock FD at this point.

#145

Full Member

Thread Starter

Not really impressive at the moment. The car is only making 190 hp and 150 ft lb. It falls flat on its face after 7500 RPM. I'm also getting what feels like rear rotor misfire above 7500 RPM for some reason. It doesn't always happen though so maybe it's heat related? I think I have a fuel issue to track down too. The more pulls I make the leaner it gets no matter how much I increase the values in the fuel table. It's the worst at peak torque and almost feels like I'm running out of fuel. That doesn't make sense because I should in no way be maxxing out a 340 L/hr fuel pump with 190 hp and my injector duty cycle is ~70% at peak torque. I've been encouraged to log fuel pressure but I only have a mechanical gauge and no more inputs on my ECU. I think I can temporarily steal my oil pressure sender though. The other issue is hitting 7500+ RPM on the street. That's approaching 90 mi/hr in 3rd gear and I'm not sure if 2nd gear pulls are any good for this sort of thing. I need to get all this sorted out as well as rebuild my transmission and get a new exhaust made (larger diameter, better design, etc.). However, I've kind of taken a break from the car at the moment...

#146

Based on the details provided, it sounds like you are indeed running out of fuel. When I went to the dyno, I came across the exact same issue TWICE. First was the fuel pump (which you've solved, unless it's failing), and the second time I maxed out my (2) ID1000 injectors. Both times, the car climbed leaner and leaner after 5500 RPM and nothing we did could richen the mixture. I forget what you're running for injectors, but if your motor is heavily ported and you're only using two, you may need more fuel.

EDIT: If fuel is the problem, you'll be able to tell by watching the pressure gauge while a friend revs it at idle. Ideally, under load is better but if you're losing 10 PSI when free-reving the car, you know you have an issue (I was losing 20 PSI under load until I found my problem!!).

EDIT: If fuel is the problem, you'll be able to tell by watching the pressure gauge while a friend revs it at idle. Ideally, under load is better but if you're losing 10 PSI when free-reving the car, you know you have an issue (I was losing 20 PSI under load until I found my problem!!).

Last edited by djSL; 12-24-18 at 11:33 AM.

#147

Full Member

Thread Starter

Based on the details provided, it sounds like you are indeed running out of fuel. When I went to the dyno, I came across the exact same issue TWICE. First was the fuel pump (which you've solved, unless it's failing), and the second time I maxed out my (2) ID1000 injectors. Both times, the car climbed leaner and leaner after 5500 RPM and nothing we did could richen the mixture. I forget what you're running for injectors, but if your motor is heavily ported and you're only using two, you may need more fuel.

EDIT: If fuel is the problem, you'll be able to tell by watching the pressure gauge while a friend revs it at idle. Ideally, under load is better but if you're losing 10 PSI when free-reving the car, you know you have an issue (I was losing 20 PSI under load until I found my problem!!).

EDIT: If fuel is the problem, you'll be able to tell by watching the pressure gauge while a friend revs it at idle. Ideally, under load is better but if you're losing 10 PSI when free-reving the car, you know you have an issue (I was losing 20 PSI under load until I found my problem!!).

So I've got a few things to check/try out. I'm hoping to have everything resolved before DGRR next year. In reality, 190 hp at ~7000 RPM and 150 ft-lb at ~6500 RPM isn't bad. If I can fix the high end drop off it should be good for 200+ hp. Torque probably won't increase much but I'm hoping it won't drop off as drastically.

#148

When I was running stock ports, the 1000's were sufficient. IIRC, I maxed them out (90%-static) at 170whp with the peripheral port. Honestly, I think the efficiency side of things only counts when running four injectors. When using two injectors and with larger ports, standard rules don't seem to apply lol.

Bear in mind, this was my experience. After upgrading to a walbro 255 and ID1700X's, all my fuel issues were solved and I made 252whp (exhaust limited). FWIW, I'm running a base pressure of 50 psi (better atomization with larger injectors?).

Bear in mind, this was my experience. After upgrading to a walbro 255 and ID1700X's, all my fuel issues were solved and I made 252whp (exhaust limited). FWIW, I'm running a base pressure of 50 psi (better atomization with larger injectors?).

#149

If you are still having transient throttle issues....

I’d say it’s due to your injectors being too far away from the engine itself.

Lots of people who delete the OEM primary fuel rail/injectors report their cars are wayyy harder to tune because the ecu needs to anticipate when the arrival of the air/fuel mixture down a long intake tract.

The OEM stock location primary injectors have a super short and direct location for precise fuel control.

I’d say it’s due to your injectors being too far away from the engine itself.

Lots of people who delete the OEM primary fuel rail/injectors report their cars are wayyy harder to tune because the ecu needs to anticipate when the arrival of the air/fuel mixture down a long intake tract.

The OEM stock location primary injectors have a super short and direct location for precise fuel control.

#150

Just found this build thread off a facebook post, thanks for sharing your journey. Definitely a fan of the way the engine bay looks but I don't know how I would do without AC. Are you fully tuned now or still having some issues?