The Monsterbox 4 Rotor

#1632

rewired entire front chassis harness, tucked up over suspension inside wheel wells, simply wireless engine bay once and for all

fans, pumps, lights everything. Worked from 5pm to 4am then get to job at 830am this morning. Day before, 7pm to 3am, same deal. And will do it again tonight. Time to step it up

The following 4 users liked this post by Monsterbox:

#1637

Few notes,

new engine sounds insane. Was alone of work. Nearly 55hrs from last Friday to Monday trying to finish it up for that first start-up. Engine feels a good bit different. Uses alot more throttle to rev fully. The turbine/runners are so much larger that the exhaust velocity just isnt there anymore and it doesnt make any spool/boost at free rev in the safe 6k rpm break in range. This tells me the flow is going to be outstanding world of difference on boost. Finally would be nice to have a solid boost curve from 6500 to 9500rpm with minimal back pressure

had some drama with the external oil pump not providing enough pressure. Turns out the pump manufacture makes different size bypass springs. Overnighted a new spring, now it makes 90psi idle, and 125psi over 4k+ rpm.

no leaks anywhere.

the only "issue" is the mechanical pump keeps vapor locking after shutting down hot. It wont restart or reprime until it cools down. The heat from the oil pump transfers across the swivel flange and into the fuel pump, cavitating the non pressurized scavenge line.

I refused to give up on the mechanical pump, so I decided to stop ******* around and get serious. Ordered a NASCAR cable drive conversion. I'm literally going to mount the bump off the rear crash bar, right off the tank sump, and drive it with a NASCAR stock car cable flex hex driveshaft. This allows the mechanical pump to have literally no heat interference, completely eliminated priming, and positions the pump so that the pump is always 100% gravity fed never having to pull upstream. The absolute, hands down, ultimate fuel pump solution with rock solid reliability. I cannot think of a single con. The cable will supposedly outlast the life of the pump.

body panels cut and buff this week then assembly with aero, fuel pump relocation, move over to ethanol, then drive/tune!

thanks

new engine sounds insane. Was alone of work. Nearly 55hrs from last Friday to Monday trying to finish it up for that first start-up. Engine feels a good bit different. Uses alot more throttle to rev fully. The turbine/runners are so much larger that the exhaust velocity just isnt there anymore and it doesnt make any spool/boost at free rev in the safe 6k rpm break in range. This tells me the flow is going to be outstanding world of difference on boost. Finally would be nice to have a solid boost curve from 6500 to 9500rpm with minimal back pressure

had some drama with the external oil pump not providing enough pressure. Turns out the pump manufacture makes different size bypass springs. Overnighted a new spring, now it makes 90psi idle, and 125psi over 4k+ rpm.

no leaks anywhere.

the only "issue" is the mechanical pump keeps vapor locking after shutting down hot. It wont restart or reprime until it cools down. The heat from the oil pump transfers across the swivel flange and into the fuel pump, cavitating the non pressurized scavenge line.

I refused to give up on the mechanical pump, so I decided to stop ******* around and get serious. Ordered a NASCAR cable drive conversion. I'm literally going to mount the bump off the rear crash bar, right off the tank sump, and drive it with a NASCAR stock car cable flex hex driveshaft. This allows the mechanical pump to have literally no heat interference, completely eliminated priming, and positions the pump so that the pump is always 100% gravity fed never having to pull upstream. The absolute, hands down, ultimate fuel pump solution with rock solid reliability. I cannot think of a single con. The cable will supposedly outlast the life of the pump.

body panels cut and buff this week then assembly with aero, fuel pump relocation, move over to ethanol, then drive/tune!

thanks

#1638

The Ancient

I've run out of superlatives. Keeps getting better. And I'm glad you are almost done with this phase of your life and will have some fun with the damned thing!

#1640

The bsfc of the 4 rotor pport is quite heavy. Calculations on last engine injector duty/flow shows around 0.85 on 93 octane. Moving up to e85 will likely put this over 1.15. A typical rotary on 93 is around 0.65. So as you can see it's around 45%+ more fuel consumption from the overlap + e85. The projected fuel demand comes in around 275 gallons per hour at 1100-1200rwhp to run e85 on this engine.

with such a high overlap, and such large intake runner for maximal flow, the consequence is low velocity intake speed at lower rpm. Much of the higher bsfc is attributed to the slower intake velocity causing inferior air charge atomization. There are two ways to improve efficiency, one is to move the injector directly to the port (which mazda did on the 787b), however this is way to much effort vs reward, and seemingly impossible to fit. Two, is to run significantly higher fuel pressire. Formula 1 runs over 90+psi base fuel pressures as this has a tremendous affect on atomization which vastly improved bsfc and makes for a cleaner/better power.

So here we arrive at two goals,

1. 250gph+

2. 90psi base pressure potential (110psi with 20psi boost)

with these two goals, we must find a pump that can meet the requirements,

there is simply nothing on the market short of using two massive weldon/aeromotive etc brushless electronic pumps. Costs become very high. 1300 per pump. Risk becomes high, more than one pump to fail. Control becomes difficult, staging pumps / pulse width modulation etc. Not to mention complex plumbing to draw these off of a surge tank or sump. And also the amperage/fuel heat/alternator demand aspects.

with these details in mind, the easy choice is mechanical. Mechanical pump ramps up on demand, rpm based. Will never fail, poses little drag on the engine, does not require complex plumbing or electrical systems. And is much more cost effective in the long run. The current pump on my setup can flow 400gph at 9k rpm. And it will flow 50gph at idle. And if more is desired, the shaft gearing inside can easily and cheaply be upgraded for 800gph etc

the downside is a mechanical pump needs a drive apparatus. Most will use a belt or camshaft. There is no room on my car, so I converted the oil pump to have a rear hex drive that will drive the hex input on the fuel pump in reverse rotation, whereby you flip the pump upside down driving it backwards but achieving the necessary 50% drive ratio, using the already in place wet sump r4 pump.

The beauty (hopefully) at this point is that the end all be all of all fuel systems is the remote mount mechanical, and to achieve this you need to design a hex drive system up front firstly. But here we already have the converted oil pump, so it's simply one last step to complete the design and move the pump to the rear.

in short,

We should see instant prime, no head suction to pull against, no heat to cavitate, no electrical draw, no demand return flow issues, and should have 275+Gph

The following 3 users liked this post by Monsterbox:

#1642

The Ancient

Is there any question about the hex drive takeoff from the oil pump being able to easily drive the fuel pump?

#1643

I notice better mpg, ability to achieve the same AFR with less injector duty, ability to idle lower and leaner, and better tip in response with greater base pressure. If you YouTube test videos of injector spray pattern on high pressure you can see such a tremendous difference in atomization. It definitely cant hurt to try it on a more traditional engine/porting. The downside is that most electric pumps cant support high base pressures, because of the flow/pressure drop

The following users liked this post:

gmonsen (09-08-18)

#1645

Junior Member

I barely ever post here, but still read quite a lot. I will always love the 7, and 4-rotors have fascinated me for almost 20 years now.

I just want to say that for whatever it's worth coming from some no-name lurker - thank you for this thread and for what you're doing here. You have been so engaged, so positive, so open in sharing your ideas and your results, and so welcoming and kind in the face of advice and suggestions from others - it's really a remarkable thing to see. The pace you've been going at and the results you're getting are fantastic for sure, but I hope you're not paying too high of a personal price for that.

I don't do car projects anymore, but I am still into motorcycles, and this thread is one of my big inspirations about trying to always aim for the best possible outcome - to pursue the perfect expression of the dreamed outcome. Keep doing what you're doing!

I just want to say that for whatever it's worth coming from some no-name lurker - thank you for this thread and for what you're doing here. You have been so engaged, so positive, so open in sharing your ideas and your results, and so welcoming and kind in the face of advice and suggestions from others - it's really a remarkable thing to see. The pace you've been going at and the results you're getting are fantastic for sure, but I hope you're not paying too high of a personal price for that.

I don't do car projects anymore, but I am still into motorcycles, and this thread is one of my big inspirations about trying to always aim for the best possible outcome - to pursue the perfect expression of the dreamed outcome. Keep doing what you're doing!

The following users liked this post:

gmonsen (09-10-18)

#1647

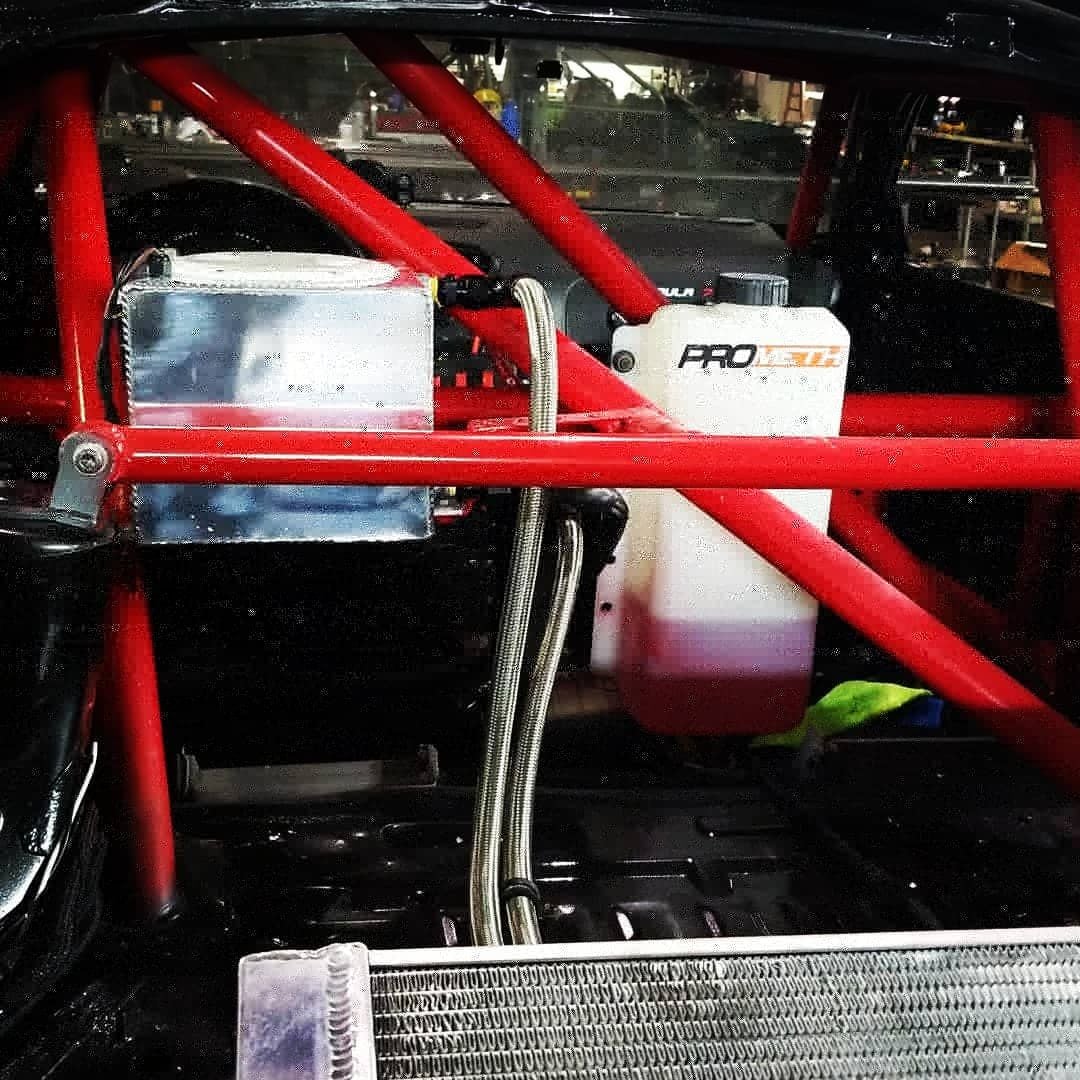

getting heat cavitation from oil temp transfer across oil pump to fuel pump. Working on NASCAR hex cable remote driven fuel pump setup directly off the sump, and using a 250 micron pre filter fitting in the sump. Should solve all priming and heat transfer issues making for the most reliable setup possible regarding fuel system.

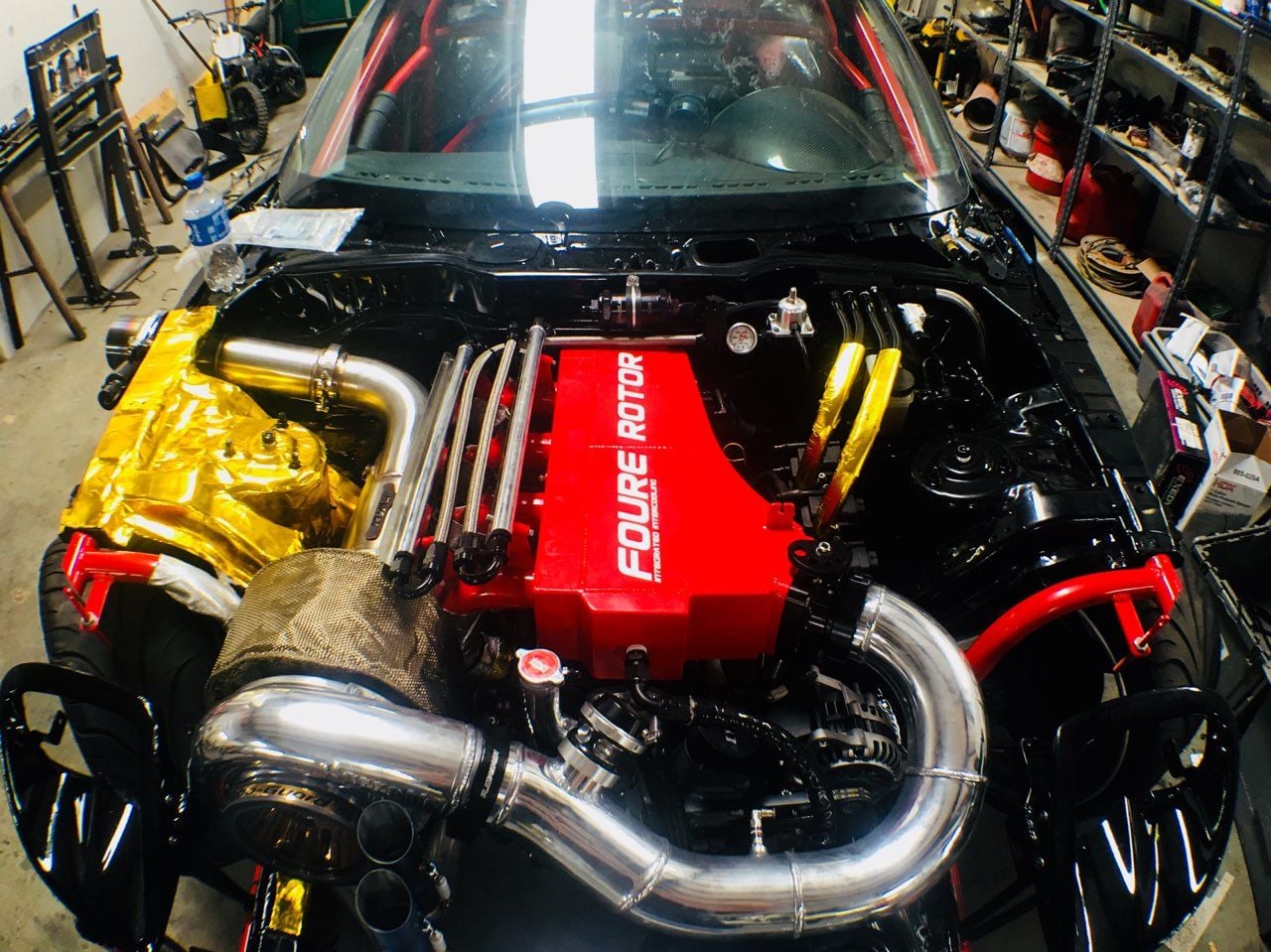

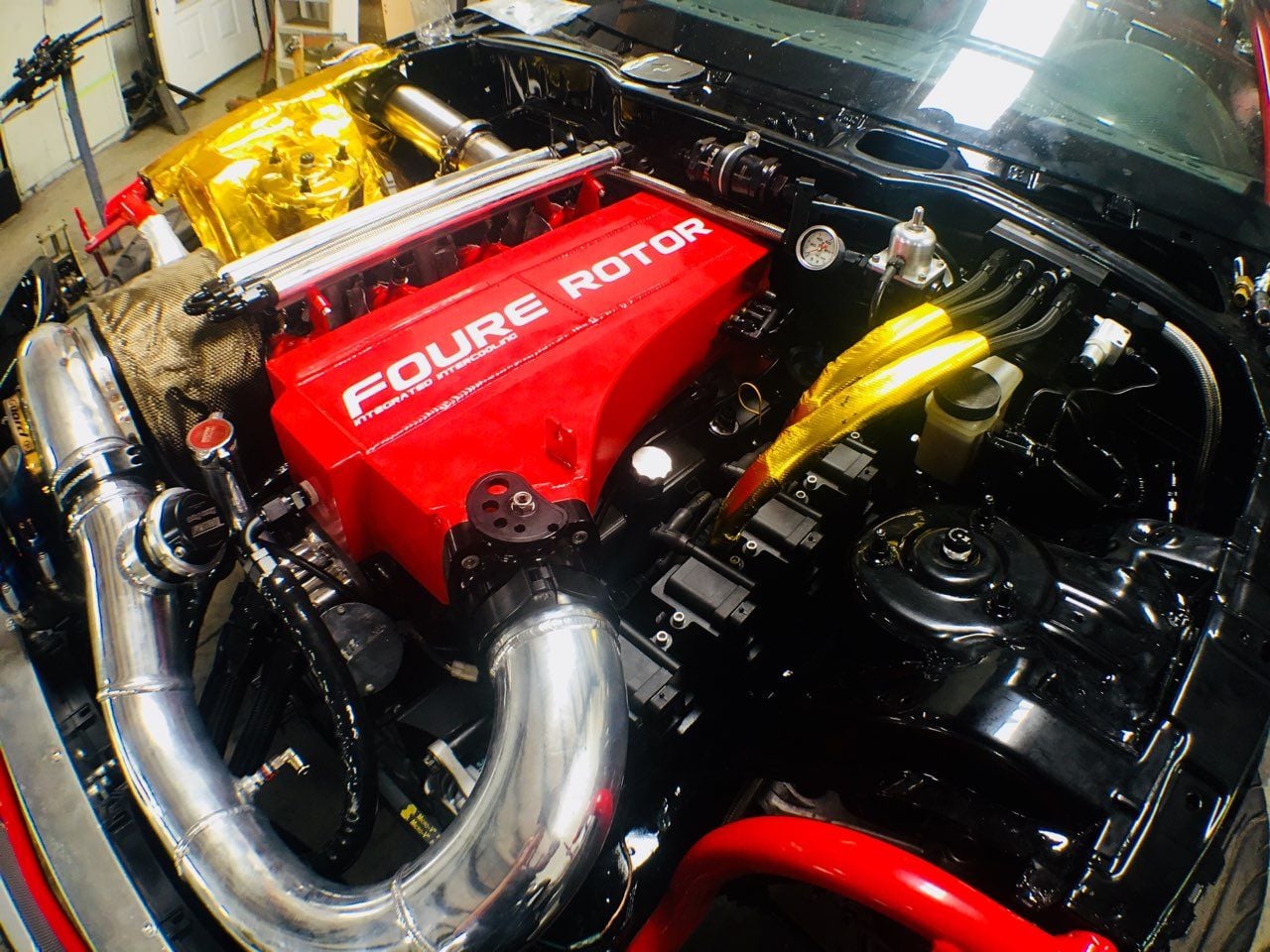

finished up intercooler plumbing and mounting

buffed and cut passenger door, paint is flawless with a good deep cut and buff

keep pushing

The following users liked this post:

gmonsen (09-13-18)

Me likey

Me likey