Oil catch can setup on my race car.

#51

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

The setup is litterly identical to damian's. I was just wondering if anyone has use this same setup on a fairly quick right hand track with a decent set of semi's or slicks and had the same issues?

#52

Yeah, post pics of the setup if you can.

I am betting there is either some difference to my setup or somthing wrong like a hose line is kinked up preventing proper venting, allowing pressure to push oil into the can.

Post things like:

- what size lines and fittings did you use (this is a VERY important one)

- what kind of catch can did you use

- are the fitting placements locations all the same as my setup?

I am betting there is either some difference to my setup or somthing wrong like a hose line is kinked up preventing proper venting, allowing pressure to push oil into the can.

Post things like:

- what size lines and fittings did you use (this is a VERY important one)

- what kind of catch can did you use

- are the fitting placements locations all the same as my setup?

#53

>>I was just wondering if anyone has use this same setup on a fairly quick right hand track with a decent set of semi's or slicks and had the same issues?

I do every race season :-)

I know you mean other people :-)

During the season I am on tracks that offer every type of turn, and even the big tests to the catch can setup, like RoadAmerica carousel, a high speed sustained right hand turn, and MAM that has a high speed sustained left hand turn. And the other tracks take car of every other speed and radius corner for putting the setup to the test.

The only time I ever had the can fill up after making this setup was when one of the lines kinked, stopping the proper venting.

I do every race season :-)

I know you mean other people :-)

During the season I am on tracks that offer every type of turn, and even the big tests to the catch can setup, like RoadAmerica carousel, a high speed sustained right hand turn, and MAM that has a high speed sustained left hand turn. And the other tracks take car of every other speed and radius corner for putting the setup to the test.

The only time I ever had the can fill up after making this setup was when one of the lines kinked, stopping the proper venting.

#54

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

Wow thats interesting. How much power/boost are you making. This is a very new motor that will still seal up with some more Ks, but I still feel that it shouldn't be pushing this much oil out. Its had a beating on the dyno and not a drop in the catch can so its definitly related to slosh.

Heres some pics:

I dont actually have a pic anywhere I can find of the catch can itself, but its just a 1Litre can with two inlets and a filter. I cant really see how the can itself could make all that much difference?? Even if it had baffled inlets, if the oil has still made it that far, how is it going to get back?

I think part of the issue could be because the line from the filler neck goes straight down and any oil that sloshes up the filler neck will just drain down it. I could try and move the filler neck fitting to on top of the cap maybe and see if that helps??

The lines are all -10 and braided and nice smooth bends so they cant kink.

Heres some pics:

I dont actually have a pic anywhere I can find of the catch can itself, but its just a 1Litre can with two inlets and a filter. I cant really see how the can itself could make all that much difference?? Even if it had baffled inlets, if the oil has still made it that far, how is it going to get back?

I think part of the issue could be because the line from the filler neck goes straight down and any oil that sloshes up the filler neck will just drain down it. I could try and move the filler neck fitting to on top of the cap maybe and see if that helps??

The lines are all -10 and braided and nice smooth bends so they cant kink.

#55

>>Wow thats interesting. How much power/boost are you making.

I typically run around 15psi (380 to 390 RWHP).

Good info you posted, this will help to debug what the problem is.

I do not think it is the catch can, however I am not sure on the fitting you use here:

Not the AN fitting itself, but the hard line that goes down to the block. How large is hole where it mates to the engine?

That fitting is pretty critical, you want the hole to be as large as possible, ideally as large as the actual hole in the engine block.

I typically run around 15psi (380 to 390 RWHP).

Good info you posted, this will help to debug what the problem is.

I do not think it is the catch can, however I am not sure on the fitting you use here:

Not the AN fitting itself, but the hard line that goes down to the block. How large is hole where it mates to the engine?

That fitting is pretty critical, you want the hole to be as large as possible, ideally as large as the actual hole in the engine block.

#56

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

The ID of the pipe is at least as big as the hole in the block, and its much bigger then the ID of the -10 hose. The problem was never and issue on road tyres. Its only since I went to 265 semi slicks all round and started pushing the car that its reared its head.

Failing being able to stop oil making its was to the catch can, I might either look at a return, a 2L catch can, or running a second can that the breather can run to so it catches any slosh/overflow and stops oil going everywhere.

One other thing to note, is when i got the car back, they forgot to put that breather line from the turbo return on and the issue was exactly the same. I reinstalled that second breather and it improved, but did not fix it. So it looks like the oil is definitly traveling up the filler neck and out that breather. I wonder if installing some downward angled plates on the inside of the filler on oposite sides and stagered as a kind of baffle to slow down oil traveling up the neck itself might help?

I can definitly see why you got stick of an oily race car > .

.

Failing being able to stop oil making its was to the catch can, I might either look at a return, a 2L catch can, or running a second can that the breather can run to so it catches any slosh/overflow and stops oil going everywhere.

One other thing to note, is when i got the car back, they forgot to put that breather line from the turbo return on and the issue was exactly the same. I reinstalled that second breather and it improved, but did not fix it. So it looks like the oil is definitly traveling up the filler neck and out that breather. I wonder if installing some downward angled plates on the inside of the filler on oposite sides and stagered as a kind of baffle to slow down oil traveling up the neck itself might help?

I can definitly see why you got stick of an oily race car >

.

.

#57

This may be your problem! In your extreme heavy right turning condition, you may need to swap vents to the front and move the turbo drain to the back. The factory engine is actually slightly angled upwards. So with the rear half being a little lower, your right rear vent is actually almost submerged in oil on level ground. Remember the oil full line is about 1/2" above the top portion of the oil pan. It's obvious slosh is causing you problems based on your driving condition. Accelerating and turning right pushes all the oil to the right rear corner of the engine. This is the same location you have your vent so the oil WILL travel up the line (vented or not). Ideally you want your vent in a location the oil can't reach it. You wont have these problems if you relocate to the front drain.

#59

The differences all depends on the sealing abilities of the oil control o-rings and boost levels. The more blow-by you get, the more crankcase positive pressure you will get (therefore more venting is needed). Even the factory engine gets very oiley under normal conditions. The factory oil pan can seal from leakage pretty well. It's just as the crankcase presurizes, the oil pan will try to separate from is mounting surface. Every time you go into boost this happens (more boost increases the chances of more blow-by). Then you have a slight contraction once the pressure is vented. Think about it, is expanding and contracting thing is done over and over and over so you will eventually loose the sealing ability. With really good venting, this wont happen.

#60

Just wanted to add that I too have done this mod and after about 5 track events on R888's I have only accumulated about 2oz of oil... so it's working great so far.

I used an adapter similar to pic below for the unused rear oil drain, a 3/8" brass 90 degree barb fitting, 3/8" Goodyear fuel injection hose and a small Jazz catch can pictured below. Stock oil filler neck.

(hose not connected in yet in this pic...)

I used an adapter similar to pic below for the unused rear oil drain, a 3/8" brass 90 degree barb fitting, 3/8" Goodyear fuel injection hose and a small Jazz catch can pictured below. Stock oil filler neck.

(hose not connected in yet in this pic...)

#61

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

This may be your problem! In your extreme heavy right turning condition, you may need to swap vents to the front and move the turbo drain to the back. The factory engine is actually slightly angled upwards. So with the rear half being a little lower, your right rear vent is actually almost submerged in oil on level ground. Remember the oil full line is about 1/2" above the top portion of the oil pan. It's obvious slosh is causing you problems based on your driving condition. Accelerating and turning right pushes all the oil to the right rear corner of the engine. This is the same location you have your vent so the oil WILL travel up the line (vented or not). Ideally you want your vent in a location the oil can't reach it. You wont have these problems if you relocate to the front drain.

Have you guys that track your cars with this setup got baffled sumps by any chance?

#62

Are any of you guys using this catch can?

http://www.saikoumichi.com/OCC_page.htm

Seems like a really nice design

http://www.saikoumichi.com/OCC_page.htm

Seems like a really nice design

#64

Are any of you guys using this catch can?

http://www.saikoumichi.com/OCC_page.htm

Seems like a really nice design

http://www.saikoumichi.com/OCC_page.htm

Seems like a really nice design

To be a truly good design, it would need the two inlet barbs plus some kind of vent/breather (like the one on Damian's car), so that it could relieve pressure from either side of the motor when oil is covering one of the two vent holes on the block.

EDIT: This one is more suited to track use....but still uses barbs rather than -AN fittings.

http://www.saikoumichi.com/Orb3_Breather_Tank.htm

#65

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

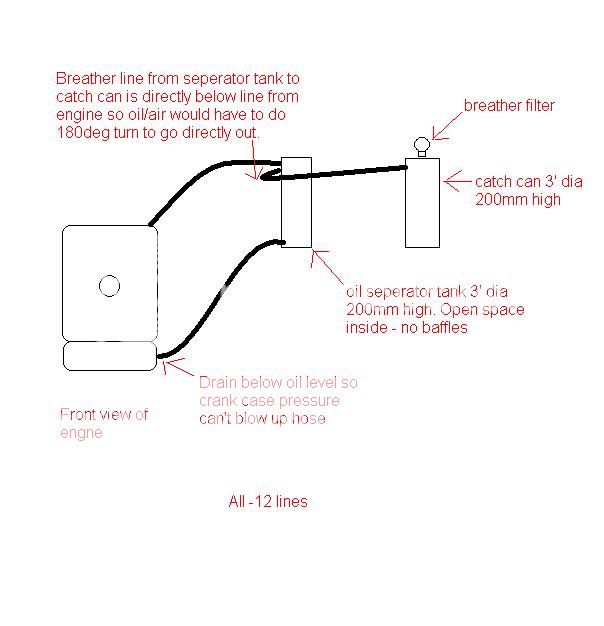

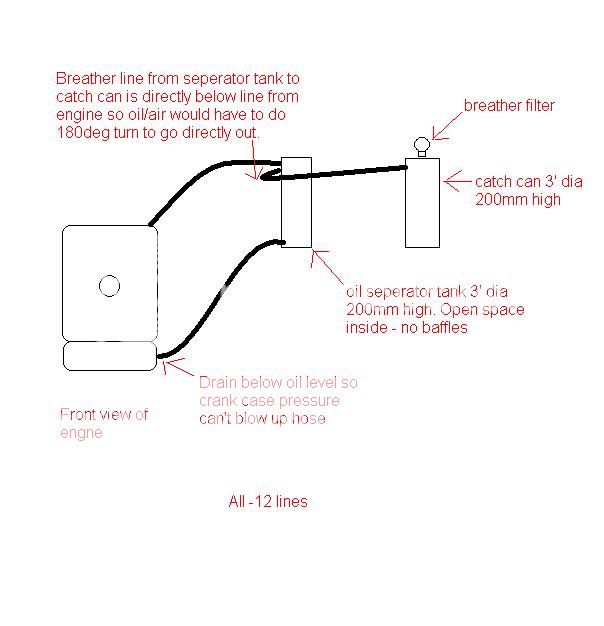

I got the following reply on another forum and was considering giving it a try. What are your thoughts on this design?

The attached maybe of some assistance, I did a lot of research into this...

Basically any oil in suspension (in air) is blown out the engine block vents under boost - which inturn fills up our catch tanks.

I'm not running alot of boost ~14psi, so I have only used one catch tank with a breather filter, but draining the catch tank back to the sump.

Baffles in the catch tank create more restrictions, and speed up the air - similar to using small breather hoses (see below..)

So far this has worked successfully, and on a number Rotary engines.

People may disagree, saying the crank case is being pressurised and will push oil from the sump into the catch tank.... But the pressure differential is the same,

ie. the same pressure trying to push the sump oil to the catch tank is also trying to push air/oil from the catch tank back to the sump - therefore the pressure is equal, remembering Oil in suspension is lighter than the volume of oil in the sump.

The Peterson dry sump pump catalogue, makes mention of oil in suspension:

Breather Cans

When plumbing in a breather can, to breath the engine, you should use at least a - 12 AN hose. The hose should run slightly up hill to the can so that any oil reaching the hose can run back down the hose to the tank. Be sure that the hose does not have any dips where oil can accumulate. Remember- The air coming from the oil tank to the breather is a result of having multiple scavenge sections which pump a lot of air from the engine. If the breather hose is too small, the velocity of the air will increase over what it would be with a larger hose. This increase in velocity will tend to carry more oil droplets to the breather can. This is why a larger hose is better.

Basically any oil in suspension (in air) is blown out the engine block vents under boost - which inturn fills up our catch tanks.

I'm not running alot of boost ~14psi, so I have only used one catch tank with a breather filter, but draining the catch tank back to the sump.

Baffles in the catch tank create more restrictions, and speed up the air - similar to using small breather hoses (see below..)

So far this has worked successfully, and on a number Rotary engines.

People may disagree, saying the crank case is being pressurised and will push oil from the sump into the catch tank.... But the pressure differential is the same,

ie. the same pressure trying to push the sump oil to the catch tank is also trying to push air/oil from the catch tank back to the sump - therefore the pressure is equal, remembering Oil in suspension is lighter than the volume of oil in the sump.

The Peterson dry sump pump catalogue, makes mention of oil in suspension:

Breather Cans

When plumbing in a breather can, to breath the engine, you should use at least a - 12 AN hose. The hose should run slightly up hill to the can so that any oil reaching the hose can run back down the hose to the tank. Be sure that the hose does not have any dips where oil can accumulate. Remember- The air coming from the oil tank to the breather is a result of having multiple scavenge sections which pump a lot of air from the engine. If the breather hose is too small, the velocity of the air will increase over what it would be with a larger hose. This increase in velocity will tend to carry more oil droplets to the breather can. This is why a larger hose is better.

#66

Here's the problem I see. The pressure in the oil separator will not be the same as that in the crank case. The pressure in the hose to the catch can will be greater than the pressure in the oil separator because the volume is so much greater in the oil separator. So you should see a large pressure drop between the two. Couple this to the fact that the oil separator is connected to the catch can/breather, which is at atmospheric pressure. This means that the compressed air/oil mixture has somewhere else to go, rather than back towards the sump. This is thinking in a transient state....at a constant system pressure, the oil separator can would reach some equilibrium pressure that would translate back to the sump.

I would have to do a full calculation to make sure, but at first thought, that is what I see.

I would have to do a full calculation to make sure, but at first thought, that is what I see.

#67

Besides, that setup will still push oil under cornering on-boost situations as oil will block the path of gases that need to be vented.

Vent the other side of the engine along with the typical vented route through the oil fill tube or whatever to one vented can (or one to each side would also work) and be done with it. You will eliminate the push of oil altogether and have a simpler, more compact design. All you will see in your catch can is a very, very small amount of gasoline after a long time running.

#68

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

The -12 lines part I was going to ignore, as I already have -10 ones run so hear you on that one!

This is exactly what I have currently and I am filling a 1L catch can after about 8 laps! Im not overly fussed about the amount of oil the motor is loosing (topping it up with clean oil cant be that bad and its not getting low enough to cause oil surge), but MAN am I getting sick of cleaning oil off my nice clean engine!!!

Vent the other side of the engine along with the typical vented route through the oil fill tube or whatever to one vented can (or one to each side would also work) and be done with it. You will eliminate the push of oil altogether and have a simpler, more compact design. All you will see in your catch can is a very, very small amount of gasoline after a long time running.

#69

In the second pic, the tube penetrating into the oil filler tube is butted up against the ID of the filler neck. That is also a chock point and undermines the larger lines ability to vent the air.

To correct my previous statement about the -12an line being way to big, there are some drag racers that run monster amounts of boost that use/benefit from that setup you posted, though I imagine it may also be remedied by venting the other side of the engine enabling smaller lines to be run.

#70

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

The steel pipe might look a bit crap, put inside it is bigger then a -10 hose and is a cleen smooth flow. Where it meets the flange is the only real bend, but due to where the wastgate is, there is NO other way of doing this. An AN fitting will not fit so theres nothing that can be done here other then moving the wastgate = MISSION.

The tubing in the second one is under cut on the bottom about half the width of the filler neck back so it is wide open to breath. Its more of a baffle to stop oil flowing down the breather when topping the car up. I could try blocking that off a bit more to stop oil that sloshes up the filler neck running down it.

Would oil slosh around to the point that it would reach right up to the filler cap though? Or would it just be oil that is brought up as pressure is relieved?

The tubing in the second one is under cut on the bottom about half the width of the filler neck back so it is wide open to breath. Its more of a baffle to stop oil flowing down the breather when topping the car up. I could try blocking that off a bit more to stop oil that sloshes up the filler neck running down it.

Would oil slosh around to the point that it would reach right up to the filler cap though? Or would it just be oil that is brought up as pressure is relieved?

#71

There has got to be a restriction somewhere in your system.

Is your breather filter large enough?

How about the hole it fits into?

How much are you overfilling it? Just fill it to normal levels from now on.

Perhaps try tapping an additional vent line into the front cover. Of course the oil pan would have to come off for that though. In that position, you will never have oil in the way under boost as all the oil will be at the back of the pan and below the level of that vent. It would work even better than the rear oil return. I did this six years ago or so and never had another drop of oil in the catch can.

https://www.rx7club.com/showpost.php...&postcount=205

https://www.rx7club.com/showpost.php...&postcount=210

https://www.rx7club.com/showpost.php...&postcount=211

Is your breather filter large enough?

How about the hole it fits into?

How much are you overfilling it? Just fill it to normal levels from now on.

Perhaps try tapping an additional vent line into the front cover. Of course the oil pan would have to come off for that though. In that position, you will never have oil in the way under boost as all the oil will be at the back of the pan and below the level of that vent. It would work even better than the rear oil return. I did this six years ago or so and never had another drop of oil in the catch can.

https://www.rx7club.com/showpost.php...&postcount=205

https://www.rx7club.com/showpost.php...&postcount=210

https://www.rx7club.com/showpost.php...&postcount=211

#72

The wankel way!!

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the pics, thats an idea I might have a look into. I am going to take the sump off at some point to install a baffle plate between the motor and the sump so I might install this port at the same time, even just to have it there if I need it should the sump baffle not help. If the problem is fixed with the baffle plate, I will just block this off.

Just to answer the above though, the breather filter and port are about -12 size, maybe larger, and I can exhale a whole breath into the catch can without it pressurising so i think this should be fine, and I only ever fill the car to the top mark on the dip stick. I havnt ever over filled it. The car usually comes back off the track with about 2/3rds between the marks on the stick.

Just to answer the above though, the breather filter and port are about -12 size, maybe larger, and I can exhale a whole breath into the catch can without it pressurising so i think this should be fine, and I only ever fill the car to the top mark on the dip stick. I havnt ever over filled it. The car usually comes back off the track with about 2/3rds between the marks on the stick.

#73

Damian - I've been busy trying to retrofit an existing catch can to work, but I find myself going back and forth with wrong fitting sizes and having to go through trouble to install a breather, so I think I'm just going to start over and get the Jegs can that you got. A few questions:

How did you install the view finder thing? I can't seem to find what the official name of it is or what parts to get to make it work.

It looks like you used the 21oz. version of the can, but to save space and with some track time on the setup, do you think the 7oz. version would also work?

It looks like your catch can is installed beneath the IC piping, is that right? You wouldn't happen to have the dimensions of the bracket that used to install it there, wouldja?

Thanks much for your contributions!

Allen

How did you install the view finder thing? I can't seem to find what the official name of it is or what parts to get to make it work.

It looks like you used the 21oz. version of the can, but to save space and with some track time on the setup, do you think the 7oz. version would also work?

It looks like your catch can is installed beneath the IC piping, is that right? You wouldn't happen to have the dimensions of the bracket that used to install it there, wouldja?

Thanks much for your contributions!

Allen