EFR7670 and AI: Pre or Post turbo?

#1

EFR7670 and AI: Pre or Post turbo?

Up until a few hours ago, I had no idea there was an auxiliary injection section of this forum. It has about 20 stickies at the top and I've read through most of them. I'd have posted this in that section but it's clear no one really posts in there anymore and it's more of a helpful archive.

So I'm hot on the trail of my new build and I have a Turbosource EFR7670 (IWG) kit with the shorty cast manifold, an ASP Large IC, and a variety of other goodies going in when I finally get this rebuild started at the end of the month. Hoping for 400whp or more with an extremely hearty power band. Yes, I could do this on a 8374 on pump but the boost response wouldn't be as good. Originally, I was looking to E85 as a way to run increased boost to help get me there but the more I read about AI, the more I like it. So thank you to those of you who posted in previous threads of mine telling me to consider AI.

I want to check my understanding of what AI can actually do for me. I'm under the impression it will reduce detonation considerably to the point that pump 93+AI will yield numbers similar to E85 or race gas. The second thing I'm seeing is the considerable reduction in IATs which for me in Texas, is a huge deal.

During my AI binge reading I read a quote from Howard that stated...

as many are aware, the concept behind the pre-turbo location is pretty simple. a compressor, any compressor, is governed by physical laws. there is a point where additional pressure creates heat/expansion to the point that no more oxygen molecules can be packed into the space.

power is all about oxygen. more oxygen, more power. period.

at that (rightward) point on a compressor map the RPM line ceases to rise and the line goes static. no more RPM gain.

ballgame. all because of the heat of compression. brick wall.

the pre-turbo concept is to introduce cooling BTUs (latent heat) and thus allow for additional oxygen to be able to enter the compressor volume.

more oxygen molecules, more power. that's the concept.

I'm trying to interpret that statement but what I THINK it means, is a smaller turbo that runs out of steam (pun intended) up top might see benefits from AI that is pre-turbo. It would appear these "improvements" would essentially yield better efficiency for the turbo allowing it to make more power. Correct? The main reason I'm asking is because I know the 7670 is a small turbo and I'm having to balance the want for killer boost response you get from a small turbo, with the want for larger power numbers that obviously come from a larger turbo. Am I right in thinking that pre-turbo injection might be a way to get the best of both worlds to a point?

So I'm hot on the trail of my new build and I have a Turbosource EFR7670 (IWG) kit with the shorty cast manifold, an ASP Large IC, and a variety of other goodies going in when I finally get this rebuild started at the end of the month. Hoping for 400whp or more with an extremely hearty power band. Yes, I could do this on a 8374 on pump but the boost response wouldn't be as good. Originally, I was looking to E85 as a way to run increased boost to help get me there but the more I read about AI, the more I like it. So thank you to those of you who posted in previous threads of mine telling me to consider AI.

I want to check my understanding of what AI can actually do for me. I'm under the impression it will reduce detonation considerably to the point that pump 93+AI will yield numbers similar to E85 or race gas. The second thing I'm seeing is the considerable reduction in IATs which for me in Texas, is a huge deal.

During my AI binge reading I read a quote from Howard that stated...

as many are aware, the concept behind the pre-turbo location is pretty simple. a compressor, any compressor, is governed by physical laws. there is a point where additional pressure creates heat/expansion to the point that no more oxygen molecules can be packed into the space.

power is all about oxygen. more oxygen, more power. period.

at that (rightward) point on a compressor map the RPM line ceases to rise and the line goes static. no more RPM gain.

ballgame. all because of the heat of compression. brick wall.

the pre-turbo concept is to introduce cooling BTUs (latent heat) and thus allow for additional oxygen to be able to enter the compressor volume.

more oxygen molecules, more power. that's the concept.

#2

RX-7 Bad Ass

iTrader: (55)

I'm not sure what the long term would be of running pre-turbo - that could prematurely erode the compressor blade of the turbo over time.

Post IC is where most people put the WI nozzles. I've been running the AEM setup for years and have been really happy with it. Drops air intake temps very quickly.

If you have a decent IC setup, an efficient turbo, a somewhat cool air intake, and WI, you'll be in really good shape.

Dale

Post IC is where most people put the WI nozzles. I've been running the AEM setup for years and have been really happy with it. Drops air intake temps very quickly.

If you have a decent IC setup, an efficient turbo, a somewhat cool air intake, and WI, you'll be in really good shape.

Dale

The following users liked this post:

ItalynStylion (06-17-19)

#3

I'm not sure what the long term would be of running pre-turbo - that could prematurely erode the compressor blade of the turbo over time.

Post IC is where most people put the WI nozzles. I've been running the AEM setup for years and have been really happy with it. Drops air intake temps very quickly.

If you have a decent IC setup, an efficient turbo, a somewhat cool air intake, and WI, you'll be in really good shape.

Dale

Post IC is where most people put the WI nozzles. I've been running the AEM setup for years and have been really happy with it. Drops air intake temps very quickly.

If you have a decent IC setup, an efficient turbo, a somewhat cool air intake, and WI, you'll be in really good shape.

Dale

I'm also looking at the AEM setup in conjunction with the Sakebomb rear mounted tank. I like that tank because it's fairly large and I wouldn't have to fill it as often.

#4

To achieve your goal of 400+ HP w the EFR7670, you'll need boost greater than 20 psi. Pre-turbo injection will help improve your turbo efficiency greatly at this elevated boost. With the correct injection setup & nozzle atomization, I wouldn't worry as much w turbo compressor wear.

However, I would be worried about the lack of failsafes incorporated. If I recall, you're running a PFC, correct? If so, you have zero knock suppression/minimization/detection at present. For that reason alone, I'd consider a secondary injection nozzle post-IC. You won't need to spray a lot, but it'd be nice to have some added protection should the pre-turbo injection ever get wacky at WOT.

However, I would be worried about the lack of failsafes incorporated. If I recall, you're running a PFC, correct? If so, you have zero knock suppression/minimization/detection at present. For that reason alone, I'd consider a secondary injection nozzle post-IC. You won't need to spray a lot, but it'd be nice to have some added protection should the pre-turbo injection ever get wacky at WOT.

#5

To achieve your goal of 400+ HP w the EFR7670, you'll need boost greater than 20 psi. Pre-turbo injection will help improve your turbo efficiency greatly at this elevated boost. With the correct injection setup & nozzle atomization, I wouldn't worry as much w turbo compressor wear.

However, I would be worried about the lack of failsafes incorporated. If I recall, you're running a PFC, correct? If so, you have zero knock suppression/minimization/detection at present. For that reason alone, I'd consider a secondary injection nozzle post-IC. You won't need to spray a lot, but it'd be nice to have some added protection should the pre-turbo injection ever get wacky at WOT.

However, I would be worried about the lack of failsafes incorporated. If I recall, you're running a PFC, correct? If so, you have zero knock suppression/minimization/detection at present. For that reason alone, I'd consider a secondary injection nozzle post-IC. You won't need to spray a lot, but it'd be nice to have some added protection should the pre-turbo injection ever get wacky at WOT.

I would run a mix of methanol post turbo on a 500ish cc jet and call it a day. Pre turbo does work better, but it takes some time to figure it out. I chewed up 3 wheels before sorting it out.

#6

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,764

Received 2,556 Likes

on

1,819 Posts

#7

To achieve your goal of 400+ HP w the EFR7670, you'll need boost greater than 20 psi. Pre-turbo injection will help improve your turbo efficiency greatly at this elevated boost. With the correct injection setup & nozzle atomization, I wouldn't worry as much w turbo compressor wear.

However, I would be worried about the lack of failsafes incorporated. If I recall, you're running a PFC, correct? If so, you have zero knock suppression/minimization/detection at present. For that reason alone, I'd consider a secondary injection nozzle post-IC. You won't need to spray a lot, but it'd be nice to have some added protection should the pre-turbo injection ever get wacky at WOT.

However, I would be worried about the lack of failsafes incorporated. If I recall, you're running a PFC, correct? If so, you have zero knock suppression/minimization/detection at present. For that reason alone, I'd consider a secondary injection nozzle post-IC. You won't need to spray a lot, but it'd be nice to have some added protection should the pre-turbo injection ever get wacky at WOT.

And my EMS has yet to be decided. I ran a PFC on the last car because I was on stock twins. This one I'm leaning towards Link or Adaptronic. It will be one of those two but I haven't decided yet. I'm sure either will be fine. Pretty much going to let my tuner decide.

Myself and a few of my other dealers have made 400rwhp around 16 psi on the cast 7670 kit. Just depends on how the dyno reads, and what type of port. Bigger the port easier it is to make the power. The water alone isn't going to help with making power, the meth will.

I would run a mix of methanol post turbo on a 500ish cc jet and call it a day. Pre turbo does work better, but it takes some time to figure it out. I chewed up 3 wheels before sorting it out.

I would run a mix of methanol post turbo on a 500ish cc jet and call it a day. Pre turbo does work better, but it takes some time to figure it out. I chewed up 3 wheels before sorting it out.

Trending Topics

#8

You're going about things in a very good manner; thoughtful decisions, modest mods, asking the right questions, etc. I recently went a similar path as you by letting the tuner pick the ecu (Syvecs), and incorporating auxiliary injection to sweeten the failsafe pot (pre-turbo & post-IC).

In hindsight, I should've stuck it out w the 7670 a little longer to at least experiment its overall performance coupled w AI. But I ended up going 8374 for the new setup. In either case, shifting the compressor map to a more favorable operating zone via liquid injection is helpful for long term turbo performance at elevated boost levels.

In hindsight, I should've stuck it out w the 7670 a little longer to at least experiment its overall performance coupled w AI. But I ended up going 8374 for the new setup. In either case, shifting the compressor map to a more favorable operating zone via liquid injection is helpful for long term turbo performance at elevated boost levels.

#9

Racing Rotary Since 1983

iTrader: (6)

"You're going about things in a very good manner; thoughtful decisions, modest mods, asking the right questions"

i second that...

wherever possible i think "simple" wins. sure you can possibly shift flow to a higher level.. maybe. but you then are running water through your intercooler (BTW, my favorite) which tends to increase heatsoak so there are probably + and minuses to preturbo BUT you can accomplish everything you want with a single nozzle in your elbow or the silicone coupler immediately in front of the elbow. i do recommend for any injectant other than 100% methanol the newer AEM 30-3300 and filter 30-3003. simple, well engineered, effective.

as to ECU... as has been stated, the primary drawback of the Power FC/Datalogit is the fact it does not have an ACTIVE knock system. the PFC does monitor knock and if carefully used will help you reach a final tune. i still love the PFC/Datalogit.

considering it is a computer and was designed around the time our cars were rolling off the assembly line the fact that it still works well when computers were doing "Pong" as a game is amazing.

that said, time has passed and ECUs have evolved. Haltech has gone from dreadful to excellent. AEM has gone from beyond dreadful to excellent. when i made my switch from my Power FC (2012) neither the Elite 2500 or the Infinity were available. my options were Motec or ViPEC/Link. i am delighted w my ViPEC V88.

but i digress: the initial important question to ask re ECU selection is:

does the ECU have an ACTIVE KNOCK SYSTEM

if you have a system failure and knock occurs understand that at peak torque (where knock is most likely as it is max cylinder fill) there are approx 40 combustion events per second.

you need a fix on the next rotor face!

of course things like cutting boost or fuel, which take seconds, aren't going to get it done.

you need timing to go to zero on the next rotor face and that's what an active knock system can do.

there also needs to be:

Windowing-- knock only happens in 30 to 40 degrees of crank rotation so the system needs to be windowed, i e only active for 40 degrees per rotation so as to avoid false signals

Throttle Position Qualified---- the system should be able to allow you to enable it so it goes active only when the throttle position sensor is above a particular number, say 25%, again avoiding false signals

Response Definable--- custom user input as to the amount of timing reduction

one final note... i recommend you run two knock sensors and you buy the actual (Bosch) RX8 knock sensor as there will be no question it is tuned to the proper specific resonance for the rotary block.

Mazda p/n N3H118921

accurate knock readings are central to the construction of a proper timing map.

fuel quality is a moving target and knock response and AI are the answers

i second that...

wherever possible i think "simple" wins. sure you can possibly shift flow to a higher level.. maybe. but you then are running water through your intercooler (BTW, my favorite) which tends to increase heatsoak so there are probably + and minuses to preturbo BUT you can accomplish everything you want with a single nozzle in your elbow or the silicone coupler immediately in front of the elbow. i do recommend for any injectant other than 100% methanol the newer AEM 30-3300 and filter 30-3003. simple, well engineered, effective.

as to ECU... as has been stated, the primary drawback of the Power FC/Datalogit is the fact it does not have an ACTIVE knock system. the PFC does monitor knock and if carefully used will help you reach a final tune. i still love the PFC/Datalogit.

considering it is a computer and was designed around the time our cars were rolling off the assembly line the fact that it still works well when computers were doing "Pong" as a game is amazing.

that said, time has passed and ECUs have evolved. Haltech has gone from dreadful to excellent. AEM has gone from beyond dreadful to excellent. when i made my switch from my Power FC (2012) neither the Elite 2500 or the Infinity were available. my options were Motec or ViPEC/Link. i am delighted w my ViPEC V88.

but i digress: the initial important question to ask re ECU selection is:

does the ECU have an ACTIVE KNOCK SYSTEM

if you have a system failure and knock occurs understand that at peak torque (where knock is most likely as it is max cylinder fill) there are approx 40 combustion events per second.

you need a fix on the next rotor face!

of course things like cutting boost or fuel, which take seconds, aren't going to get it done.

you need timing to go to zero on the next rotor face and that's what an active knock system can do.

there also needs to be:

Windowing-- knock only happens in 30 to 40 degrees of crank rotation so the system needs to be windowed, i e only active for 40 degrees per rotation so as to avoid false signals

Throttle Position Qualified---- the system should be able to allow you to enable it so it goes active only when the throttle position sensor is above a particular number, say 25%, again avoiding false signals

Response Definable--- custom user input as to the amount of timing reduction

one final note... i recommend you run two knock sensors and you buy the actual (Bosch) RX8 knock sensor as there will be no question it is tuned to the proper specific resonance for the rotary block.

Mazda p/n N3H118921

accurate knock readings are central to the construction of a proper timing map.

fuel quality is a moving target and knock response and AI are the answers

Last edited by Howard Coleman; 06-17-19 at 06:50 PM.

The following 3 users liked this post by Howard Coleman:

#10

Just to clarify, this is the AEM kit everyone talks about being quite good?

https://www.rx7store.net/AEM_V2_Wate...%2030-3302.htm

https://www.rx7store.net/AEM_V2_Wate...%2030-3302.htm

#11

www.AusRotary.com

A major advantage of pre-turbo is that allows the use of a mechanical WI system. Setup and tuning on a mechanical system is vastly simplified. Plus it removes the pump as a potential failure point. You just select the correctly sized air-atomising nozzle, set up a MAC valve to trigger WI to operate at a specified boost (around 8psi or higher) and the boost pressure from the turbo compressor does the rest. You can incorporate additional failsafes if the water reservoir runs low or the MAC valve fails (anomalous pressure reading in the WI system). On mine, a tank level sender will trigger a separate boost target table and effectively run the engine at wastegate pressure levels until the water reservoir is refilled.

I got my kit through Green Brothers Racing in NZ (username JZG on here), but you could equally put together your own very cheaply, or get the one made by Wannaspeed

I have my doubts about the benefits of knock control on a high powered rotary. As the guys at HP Academy point out, if you're getting knock on a rotary it is probably already too late. IMO, much better to (a) tune conservatively and assume the possibility of poorer quality fuel (plus noting there isn't much to be gained from aggressive ignition advance on a rotary); (b) incorporate other engine protection measures based on low oil pressure, low fuel pressure, excessive EGT, over-boost, lean-out and over-rev, which IMO are going to be more effective than knock control. Of course you can have all of these things plus active knock control and no doubt knock is useful to have as part of your data set, but personally I'd prefer not to run so close to the ragged edge and assume knock control will save it.

I got my kit through Green Brothers Racing in NZ (username JZG on here), but you could equally put together your own very cheaply, or get the one made by Wannaspeed

I have my doubts about the benefits of knock control on a high powered rotary. As the guys at HP Academy point out, if you're getting knock on a rotary it is probably already too late. IMO, much better to (a) tune conservatively and assume the possibility of poorer quality fuel (plus noting there isn't much to be gained from aggressive ignition advance on a rotary); (b) incorporate other engine protection measures based on low oil pressure, low fuel pressure, excessive EGT, over-boost, lean-out and over-rev, which IMO are going to be more effective than knock control. Of course you can have all of these things plus active knock control and no doubt knock is useful to have as part of your data set, but personally I'd prefer not to run so close to the ragged edge and assume knock control will save it.

Last edited by KYPREO; 06-17-19 at 10:12 PM.

The following users liked this post:

FFR818 (02-10-23)

#12

All good advice.

This will be a street port engine so I'll have help there. Not going bridge port or anything crazy though. I'm planning to run typical windshield washer fluid in the tank since it's available at most gas stations making it a no brainer when I need to fill up in a pinch.

This will be a street port engine so I'll have help there. Not going bridge port or anything crazy though. I'm planning to run typical windshield washer fluid in the tank since it's available at most gas stations making it a no brainer when I need to fill up in a pinch.

Poster by Supernaut some time ago.

+20 F Washer Fluid - Contains approximately 7% methanol.

0 F Washer Fluid - Contains approximately 23% methanol.

-10 F Washer Fluid - Contains approximately 28% methanol.

-20 F Washer Fluid - Contains approximately 35% methanol.

-25 F Washer Fluid - Contains approximately 38% methanol.

-50 F Washer Fluid - Contains approximately 62% methanol.

#13

I haven't come across anything stronger than +20 up here in North Dallas. With summit being 'local', I just ordered boost juice from them instead.

Poster by Supernaut some time ago.

+20 F Washer Fluid - Contains approximately 7% methanol.

0 F Washer Fluid - Contains approximately 23% methanol.

-10 F Washer Fluid - Contains approximately 28% methanol.

-20 F Washer Fluid - Contains approximately 35% methanol.

-25 F Washer Fluid - Contains approximately 38% methanol.

-50 F Washer Fluid - Contains approximately 62% methanol.

Poster by Supernaut some time ago.

+20 F Washer Fluid - Contains approximately 7% methanol.

0 F Washer Fluid - Contains approximately 23% methanol.

-10 F Washer Fluid - Contains approximately 28% methanol.

-20 F Washer Fluid - Contains approximately 35% methanol.

-25 F Washer Fluid - Contains approximately 38% methanol.

-50 F Washer Fluid - Contains approximately 62% methanol.

I do have another question/concern about the pre-turbo injection. Since I live here in Texas I need the most cooling possible which is why the pre-turbo injection is so appealing. However, part of living here is that our winters are mild to the point that I could drive the car almost year round. And that has me thinking....in the colder months when there is extremely cold air (20-35F) moving over the intercooler, do you have to worry about the water/meth condensing on the inside of the intercooler? Last thing I want is to have the intercooler slowly filling up with water just waiting on some serious boost to come flood the engine.

Am I overthinking it or is that something to be concerned about?

#14

Racing Rotary Since 1983

iTrader: (6)

suggested AI systems:

AEM re-engineered their offering a few years ago and it works fine. the 30-3300 has a tank and the 30-3302 does not. take your pick

Snow Performance is the largest AI provider in terms of sales and has an excellent product line

Coolingmist offers a broad range of excellent systems. the founder had an FD and was a vendor on the RX7club site for a number of years

if you choose to run 100% methanol as injectant Alkycontrol is your system

whether you go pump or pumpless... of course the most important thing is that you use something. all our motors benefit greatly from both knock avoidance and internal cleanliness from AI.

each system has it's pluses and minuses.

the losing-the-pump-worry is not a worry for 95% of us since the amount of BTUs from the 50% meth (w water meth) is not enough to move the AFR needle.

if you are wanting to spend time in the 500 to 600 hp range and running either 91 or 93 octane you should be running around 900 CC/Min of 100% meth.

500 rotary rw hp (RRWHP) requires 3946 NET CC/Min of gasoline

550 requires 4341

600 requires 4736

therefore

500 rrwhp requires 120,733 BTUs from fuel

550 requires 133,503

600 requires 145,112

900 CC/Min of methanol provides 13740 BTUs

if you tune to 10.3 AFR a loss of the 900 CC of meth would move AFR to:

at 500 11.4

at 550 11.3

at 600 11.2

i have run 100% meth as AI since 2003 using the Alkycontrol system and it has never failed. i doubt i would have a problem if it were to fail as the fallback AFRs are not life threatening. Of course running higher power levels entails higher risk as well as requiring better quality systems and prep. if you are running water or water meth you have no risk as far as system failure. in the case of water meth the water's negative BTUs cancels the meth BTUs so you are really tuning almost like you have no AI system.

if you are wanting to run a mix of water and methanol you do have a few options:

the Oberbuchner brothers that founded FJO and later sold to Holly had a 1500 hp twin turbo Camaro as a house project car and they ran "bug juice" windshield wiper solvent as injectant for years. i asked Fred O about it (he is a Chemist) and he said that there are 4 components, meth, water, coloring and a very small amount of soap. they had zero issues with it for years.

a second option is to buy "Boost Cooler" from Snow Performance.

a third option is simply to buy methanol (approx $2.50 gallon) and mix it with distilled water. i did that briefly as a test.

a few comments re post 11

"have my doubts about the benefits of knock control on a high powered rotary" " if you're getting knock on a rotary it is probably already too late"

while i agree that knock control does not guarantee a get out of jail card my experience is the opposite. a properly set up knock system WILL generally save your motor from collapsed corner seal springs or broken apex seals by cutting timing immediately. it will also, if you monitor log data, alert you to developing issues.

i am a fan of any type of instrumentation as you mention: "incorporate other engine protection measures based on low oil pressure, low fuel pressure, excessive EGT, over-boost, lean-out and over-rev"

"I'd prefer not to run so close to the ragged edge and assume knock control will save it" totally agree with you. if you want to make bigger power, stay conservative on the timing and AFR and raise the boost.

there is a significant lack of appreciation for just how stressed our turbo'd motors are. most people think a 350 rwhp rotary is a conservative tune...

from my website:

"Don’t believe me?

Let’s look at a number of the absolute cutting edge 21st century supercomputer designed boosted active knock control 2018 engines in comparison.

Rear Wheel Horse Power Per Cubic Inch

2018 Corvette ZR1 1.71

2018 Corvette ZO6 1.47

2018 Porsche Turbo S 2.23

2018 McLaren 570S 2.06

2018 Merc Benz AMG GT C 1.91

2018 Accura NSX 2.0

2018 Nissan GTR NISMO 2.2

2019 Aston Martin Superleggara 1.91

2018 Ferrari Superfast 1.69

Average Rear Wheel Power per Cubic Inch 1.91

Now that we have a frame of reference let’s take a look at our turbo rotary:

Rear Wheel Power

(Mazda lists displacement at 80 cubic inches. There are a couple of legitimate ways to derive displacement. In order to be conservative I am going to use 160 cubic inches so as to better compare apples to apples.)

1993 Mazda RX7 OE 217 hp 160 cubic inches 1.36

1993 Mazda RX7 350 hp 160 cubic inches 2.19

1993 Mazda RX7 400 hp 160 cubic inches 2.5

1993 Mazda RX7 450 hp 160 cubic inches 2.81

1993 Mazda RX7 500 hp 160 cubic inches 3.13

1993 Mazda RX7 550 hp 160 cubic inches 3.44

1993 Mazda RX7 600 hp 160 cubic inches 3.75

This is profound. A “lowly” 350 rwhp RX7 is within spitting distance of the highest output boosted motors offered for 2018!.......

2.19 V 2.23

The second profundity is that unlike the above four cycle motors the rotary does not enjoy a cooling cycle after a power cycle. The rotary is a two cycle motor and as such it makes power every time the rotor passes the spark plug!

these metrics are CENTRAL to understanding the amount of respect our motors require as to their care and feeding.

AEM re-engineered their offering a few years ago and it works fine. the 30-3300 has a tank and the 30-3302 does not. take your pick

Snow Performance is the largest AI provider in terms of sales and has an excellent product line

Coolingmist offers a broad range of excellent systems. the founder had an FD and was a vendor on the RX7club site for a number of years

if you choose to run 100% methanol as injectant Alkycontrol is your system

whether you go pump or pumpless... of course the most important thing is that you use something. all our motors benefit greatly from both knock avoidance and internal cleanliness from AI.

each system has it's pluses and minuses.

the losing-the-pump-worry is not a worry for 95% of us since the amount of BTUs from the 50% meth (w water meth) is not enough to move the AFR needle.

if you are wanting to spend time in the 500 to 600 hp range and running either 91 or 93 octane you should be running around 900 CC/Min of 100% meth.

500 rotary rw hp (RRWHP) requires 3946 NET CC/Min of gasoline

550 requires 4341

600 requires 4736

therefore

500 rrwhp requires 120,733 BTUs from fuel

550 requires 133,503

600 requires 145,112

900 CC/Min of methanol provides 13740 BTUs

if you tune to 10.3 AFR a loss of the 900 CC of meth would move AFR to:

at 500 11.4

at 550 11.3

at 600 11.2

i have run 100% meth as AI since 2003 using the Alkycontrol system and it has never failed. i doubt i would have a problem if it were to fail as the fallback AFRs are not life threatening. Of course running higher power levels entails higher risk as well as requiring better quality systems and prep. if you are running water or water meth you have no risk as far as system failure. in the case of water meth the water's negative BTUs cancels the meth BTUs so you are really tuning almost like you have no AI system.

if you are wanting to run a mix of water and methanol you do have a few options:

the Oberbuchner brothers that founded FJO and later sold to Holly had a 1500 hp twin turbo Camaro as a house project car and they ran "bug juice" windshield wiper solvent as injectant for years. i asked Fred O about it (he is a Chemist) and he said that there are 4 components, meth, water, coloring and a very small amount of soap. they had zero issues with it for years.

a second option is to buy "Boost Cooler" from Snow Performance.

a third option is simply to buy methanol (approx $2.50 gallon) and mix it with distilled water. i did that briefly as a test.

a few comments re post 11

"have my doubts about the benefits of knock control on a high powered rotary" " if you're getting knock on a rotary it is probably already too late"

while i agree that knock control does not guarantee a get out of jail card my experience is the opposite. a properly set up knock system WILL generally save your motor from collapsed corner seal springs or broken apex seals by cutting timing immediately. it will also, if you monitor log data, alert you to developing issues.

i am a fan of any type of instrumentation as you mention: "incorporate other engine protection measures based on low oil pressure, low fuel pressure, excessive EGT, over-boost, lean-out and over-rev"

"I'd prefer not to run so close to the ragged edge and assume knock control will save it" totally agree with you. if you want to make bigger power, stay conservative on the timing and AFR and raise the boost.

there is a significant lack of appreciation for just how stressed our turbo'd motors are. most people think a 350 rwhp rotary is a conservative tune...

from my website:

"Don’t believe me?

Let’s look at a number of the absolute cutting edge 21st century supercomputer designed boosted active knock control 2018 engines in comparison.

Rear Wheel Horse Power Per Cubic Inch

2018 Corvette ZR1 1.71

2018 Corvette ZO6 1.47

2018 Porsche Turbo S 2.23

2018 McLaren 570S 2.06

2018 Merc Benz AMG GT C 1.91

2018 Accura NSX 2.0

2018 Nissan GTR NISMO 2.2

2019 Aston Martin Superleggara 1.91

2018 Ferrari Superfast 1.69

Average Rear Wheel Power per Cubic Inch 1.91

Now that we have a frame of reference let’s take a look at our turbo rotary:

Rear Wheel Power

(Mazda lists displacement at 80 cubic inches. There are a couple of legitimate ways to derive displacement. In order to be conservative I am going to use 160 cubic inches so as to better compare apples to apples.)

1993 Mazda RX7 OE 217 hp 160 cubic inches 1.36

1993 Mazda RX7 350 hp 160 cubic inches 2.19

1993 Mazda RX7 400 hp 160 cubic inches 2.5

1993 Mazda RX7 450 hp 160 cubic inches 2.81

1993 Mazda RX7 500 hp 160 cubic inches 3.13

1993 Mazda RX7 550 hp 160 cubic inches 3.44

1993 Mazda RX7 600 hp 160 cubic inches 3.75

This is profound. A “lowly” 350 rwhp RX7 is within spitting distance of the highest output boosted motors offered for 2018!.......

2.19 V 2.23

The second profundity is that unlike the above four cycle motors the rotary does not enjoy a cooling cycle after a power cycle. The rotary is a two cycle motor and as such it makes power every time the rotor passes the spark plug!

these metrics are CENTRAL to understanding the amount of respect our motors require as to their care and feeding.

Last edited by Howard Coleman; 06-19-19 at 07:31 AM.

The following 3 users liked this post by Howard Coleman:

#15

@Howard Coleman CPR your posts are insightful as always. Not sure I'm totally equipped to understand 100% of them yet but I get the majority of it.

To answer your questions, the goal I'm shooting for is about 400whp+. I'd like to have a very meaty power band with the upper end being just north of 400 if possible. I'm not looking for bragging numbers. I want a power band that is simply insane to drive at any RPM. Power under the curve is key. My eyes were opened to this as a result of my last vehicle; a 2017 VW Golf R with a Stage 2 APR treatment. It made about 400hp and 400tq at the crank. But what was unique about that car was HOW it delivered the power and WHERE that power was made. The low end torque was staggering. Although it didn't have huge peak numbers, the car pulled like a freight train no matter what RPM you were at. Not having to wait for the power, in my opinion, made the car more fun more often. It's a fact that we will spend very little time north of 5000rpm so doesn't it make sense to make 2000-5000rpm extremely fun too? That's the logic I'm using for this build.

And yes I'm aware this will be tough for the engine. We are building the engine for the purpose at the end of this month. I bought this car "running" on it's last leg (price was right) so I have the opportunity to do everything all at once.

I expect to run 93 pump since that's readily available in my area and supplement with the water/meth. I don't think my actual meth requirements will be too extreme since I'll be largely limited by compressor flow capability.

To answer your questions, the goal I'm shooting for is about 400whp+. I'd like to have a very meaty power band with the upper end being just north of 400 if possible. I'm not looking for bragging numbers. I want a power band that is simply insane to drive at any RPM. Power under the curve is key. My eyes were opened to this as a result of my last vehicle; a 2017 VW Golf R with a Stage 2 APR treatment. It made about 400hp and 400tq at the crank. But what was unique about that car was HOW it delivered the power and WHERE that power was made. The low end torque was staggering. Although it didn't have huge peak numbers, the car pulled like a freight train no matter what RPM you were at. Not having to wait for the power, in my opinion, made the car more fun more often. It's a fact that we will spend very little time north of 5000rpm so doesn't it make sense to make 2000-5000rpm extremely fun too? That's the logic I'm using for this build.

And yes I'm aware this will be tough for the engine. We are building the engine for the purpose at the end of this month. I bought this car "running" on it's last leg (price was right) so I have the opportunity to do everything all at once.

I expect to run 93 pump since that's readily available in my area and supplement with the water/meth. I don't think my actual meth requirements will be too extreme since I'll be largely limited by compressor flow capability.

#16

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,764

Received 2,556 Likes

on

1,819 Posts

#18

www.AusRotary.com

Howard Coleman thanks for taking the time to respond. I always appreciate your posts and have learnt a lot from them over the years.

I actually think with the OP's power goals, he should be going with an 8374 if sticking with the EFR range. It will make 400rwhp much more comfortably, at lower boost levels (provided it doesn't boost creep), and in reality the lag difference with the 7670 will be fairly trivial. W/M injection is then the icing on the cake for extra protection and cleaner internals.

I actually think with the OP's power goals, he should be going with an 8374 if sticking with the EFR range. It will make 400rwhp much more comfortably, at lower boost levels (provided it doesn't boost creep), and in reality the lag difference with the 7670 will be fairly trivial. W/M injection is then the icing on the cake for extra protection and cleaner internals.

#19

Racing Rotary Since 1983

iTrader: (6)

" I'm shooting for is about 400whp+"

no problem... 400 is 53 pounds per minute... the turbo maxes out around 460 at 34 psi. as you can see 53 pounds can be had at 2.2 pressure ratios which is 17.6 psi. this assumes the motor can drive the turbo to that spot of course.

i have no experience w the 7670 and perhaps it may be the single turbo answer to those who want lower rpm power. i do know that last year when i swapped from my SX-E 62 to my EFR 9180 my EGTs dropped by 100 F and my exhaust back pressure dropped 20% even though the turbine was doing more work! 585 V 545..

that was going from a 6.30 square inch turbine wheel SX-E 62 to a 7.14 EFR 9180.

the 7670 is 5.24 which is the same (5.25) area as the total of the two OE hotside wheels.

i am really big on decreasing drag from the exhaust port to the driven wheel. the less backpressure the less exhaust gets sucked into the incoming charge air and the lower the EGTs.

do we have some EGT and backpressure data for the 7670 around 400 hp?

no problem... 400 is 53 pounds per minute... the turbo maxes out around 460 at 34 psi. as you can see 53 pounds can be had at 2.2 pressure ratios which is 17.6 psi. this assumes the motor can drive the turbo to that spot of course.

i have no experience w the 7670 and perhaps it may be the single turbo answer to those who want lower rpm power. i do know that last year when i swapped from my SX-E 62 to my EFR 9180 my EGTs dropped by 100 F and my exhaust back pressure dropped 20% even though the turbine was doing more work! 585 V 545..

that was going from a 6.30 square inch turbine wheel SX-E 62 to a 7.14 EFR 9180.

the 7670 is 5.24 which is the same (5.25) area as the total of the two OE hotside wheels.

i am really big on decreasing drag from the exhaust port to the driven wheel. the less backpressure the less exhaust gets sucked into the incoming charge air and the lower the EGTs.

do we have some EGT and backpressure data for the 7670 around 400 hp?

Last edited by Howard Coleman; 06-19-19 at 07:36 AM.

#20

I do have another question/concern about the pre-turbo injection. Since I live here in Texas I need the most cooling possible which is why the pre-turbo injection is so appealing. However, part of living here is that our winters are mild to the point that I could drive the car almost year round. And that has me thinking....in the colder months when there is extremely cold air (20-35F) moving over the intercooler, do you have to worry about the water/meth condensing on the inside of the intercooler? Last thing I want is to have the intercooler slowly filling up with water just waiting on some serious boost to come flood the engine.

Am I overthinking it or is that something to be concerned about?

Am I overthinking it or is that something to be concerned about?

I have never tested what you are describing, however I have worked on the car right after boosting it, and no noticeable (NONE) condensation was found inside the intercooler, or pipe between turbo and intercooler. I would guess that the amount of pre-turbo injection is not high enough, so the alky evaporates before it gets a chance to get to the outlet of the turbo.

Something to keep in mind, you will NOT notice a drop in IAT with a pre turbo water injection, unlike a post turbo setup, where people report IAT drops. I know this because I wanted to set a ecu failsafe, so that boost would drops if IAT got past a target point.

#22

With a pre turbo injection (water OR 50/50 alky mix), I have noticed ZERO IAT temp drops, as logged by the haltech ecu. I've read others stating IAT drops when running POST intercooler injection, I wodner if the readings are skewed, because the IAT sensor gets wet? Regardless, in my experience, running Rice Racing pre turbo kit, and set/adjusted per his instructions, I see zero IAT drops when injecting.

#23

Racing Rotary Since 1983

iTrader: (6)

while i have never run water, so i cannot speak from experience, it is generally held that water does it's thing in the combustion chamber rather than cooling the IAT.

methanol definitely chills the charge air. one of the ways we used to confirm methanol flow on the dyno was to touch the UIM. if it was cold to the touch the methanol was flowing. not so with water. ( this doesn't mean water is a bad choice, it is just different as to delivering antiknock )

now that i log IAT w a thermocouple as well as AI pressure i just look at the log. as the AI pressure builds the IAT drops. a few years back Jose Le Duc was running 14 1680 injectors on methanol as base fuel and after a run if you were to lay your hand on the UIM you would not be able to remove it until the ice melted.

the very different flash characteristics between water and methanol need to be recognized as to nozzle location. methanol needs to be a bit upstream so it can work it's magic by cooling the intake charge whereas water can be added closer to the throttle body.

i am convinced that knowing actual IAT may be up there with AFRs and fuel pressure. many of us log IATs but very few use a thermocouple. many have upgraded to a "fast" open air sensor and take the output as the real deal. i have searched (and searched) for an actual disclosure as to how "fast" the fast sensor is. the point being... a thermocouple gives accurate readings four times a second... so it is "fast." if the "fast" sensor is faster than the stock sensor which runs at turtle speed... how fast is it? things happen in the blink of an eye on a pull. if there is any lag on a fast sensor you will be thinking your IAT is a bunch cooler than it is. and IAT is VERY important.

i have a suspicion that engine bays might look a bit different if everyone was using a thermocouple.

does anyone have data on the "fast" sensor?i

methanol definitely chills the charge air. one of the ways we used to confirm methanol flow on the dyno was to touch the UIM. if it was cold to the touch the methanol was flowing. not so with water. ( this doesn't mean water is a bad choice, it is just different as to delivering antiknock )

now that i log IAT w a thermocouple as well as AI pressure i just look at the log. as the AI pressure builds the IAT drops. a few years back Jose Le Duc was running 14 1680 injectors on methanol as base fuel and after a run if you were to lay your hand on the UIM you would not be able to remove it until the ice melted.

the very different flash characteristics between water and methanol need to be recognized as to nozzle location. methanol needs to be a bit upstream so it can work it's magic by cooling the intake charge whereas water can be added closer to the throttle body.

i am convinced that knowing actual IAT may be up there with AFRs and fuel pressure. many of us log IATs but very few use a thermocouple. many have upgraded to a "fast" open air sensor and take the output as the real deal. i have searched (and searched) for an actual disclosure as to how "fast" the fast sensor is. the point being... a thermocouple gives accurate readings four times a second... so it is "fast." if the "fast" sensor is faster than the stock sensor which runs at turtle speed... how fast is it? things happen in the blink of an eye on a pull. if there is any lag on a fast sensor you will be thinking your IAT is a bunch cooler than it is. and IAT is VERY important.

i have a suspicion that engine bays might look a bit different if everyone was using a thermocouple.

does anyone have data on the "fast" sensor?i

Last edited by Howard Coleman; 06-26-19 at 09:08 AM.

#24

Understanding water vs meth requires some understanding of thermodynamics and latent heat of vaporization. Water actually has a greater ability to absorb heat (970 BTU/lb) than meth (473), but has a much higher boiling point (212 vs 149). Under pressure the boiling point increases even more. If water is not vaporizing, it's not absorbing any heat. There may be some heat transfer simply due to the temperature difference of the water vs the air, but that would be minimal compared to the vaporization potential.

Also, the Triumph fast acting IAT sensor appears to be a thermocouple vs say a thermistor

High school physics aside, i'm interested in how the 7670 is working out

Also, the Triumph fast acting IAT sensor appears to be a thermocouple vs say a thermistor

High school physics aside, i'm interested in how the 7670 is working out

Last edited by TomU; 06-26-19 at 12:00 PM.

#25

Racing Rotary Since 1983

iTrader: (6)

"things happen in the blink of an eye on a pull. if there is any lag on a fast sensor you will be thinking your IAT is a bunch cooler than it is. and IAT is VERY important."

here's a recent log proving the point.

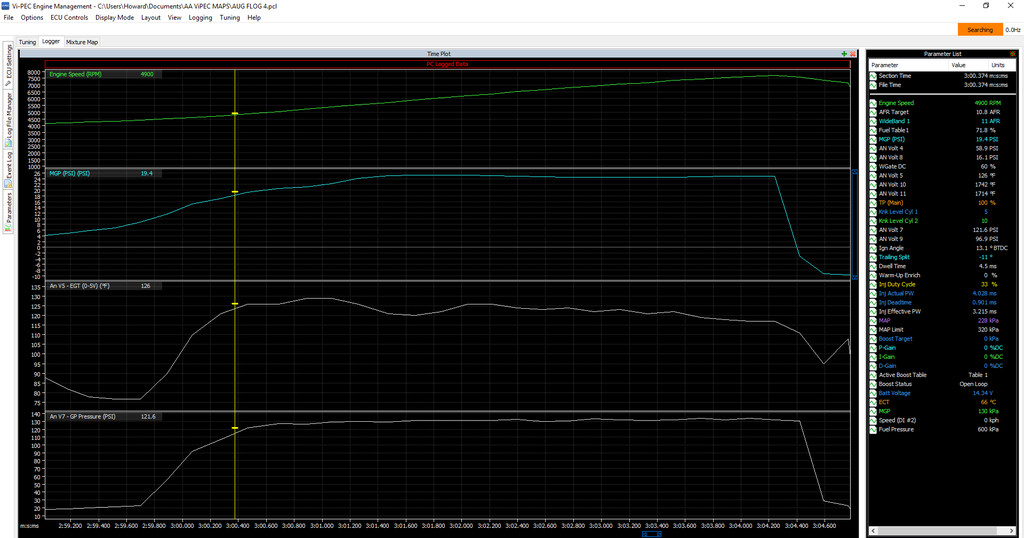

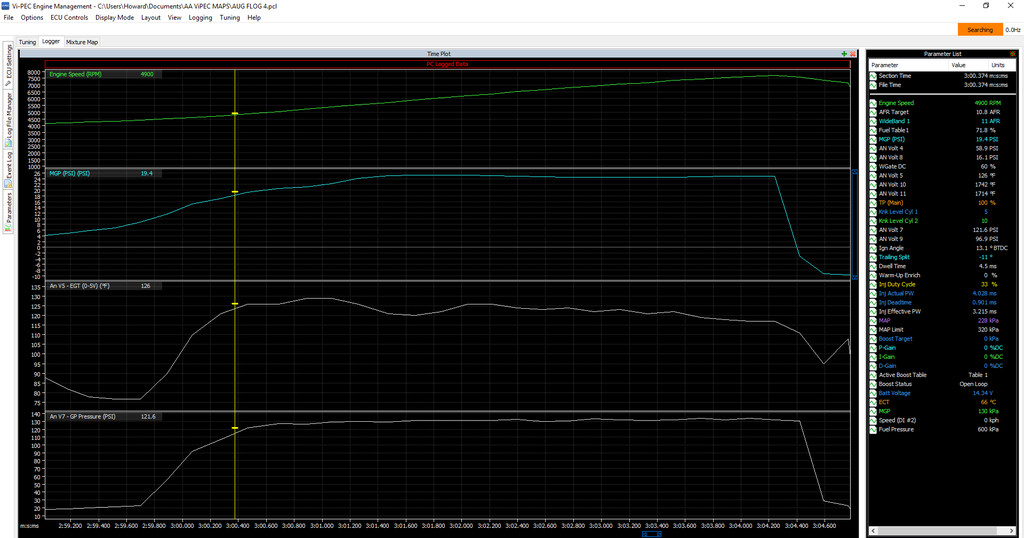

boost went from 8.9 psi at 2:59.790 to 19.4 at 3.00.374

just over a half second!

IAT went from 77 F to 126 F according to my thermocouple.

here's 8.9 psi:

here's the log at 3 minutes and .374 seconds:

IAT rose from 77 F to 126 F in less than three quarters of a second. note the bottom section of the log... that's my 100% methanol pressure log. AI pressure rose from 23.2 psi to 121.6 psi. i can't imagine where my IAT would be without it. i do plan to add a bit more meth to drop my IAT below ambient.

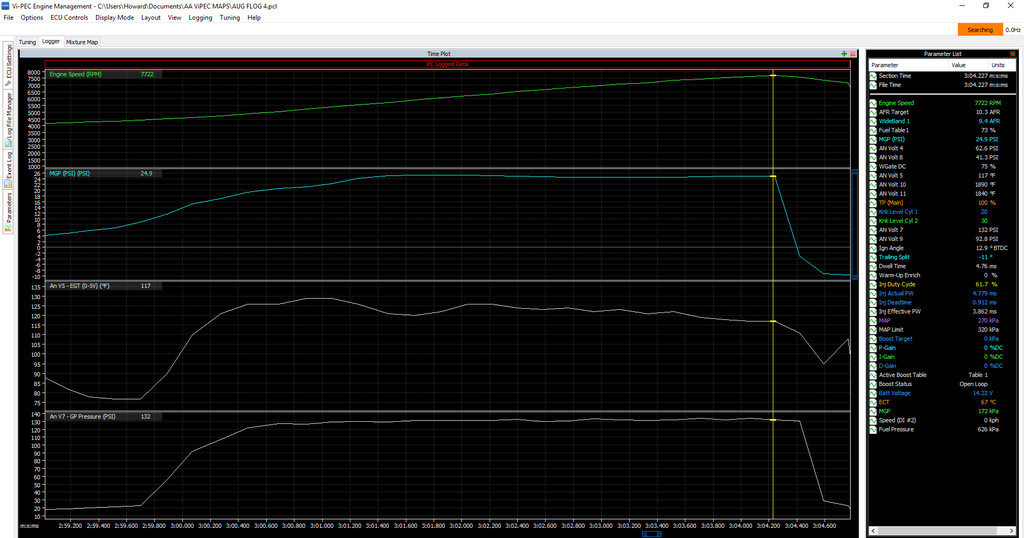

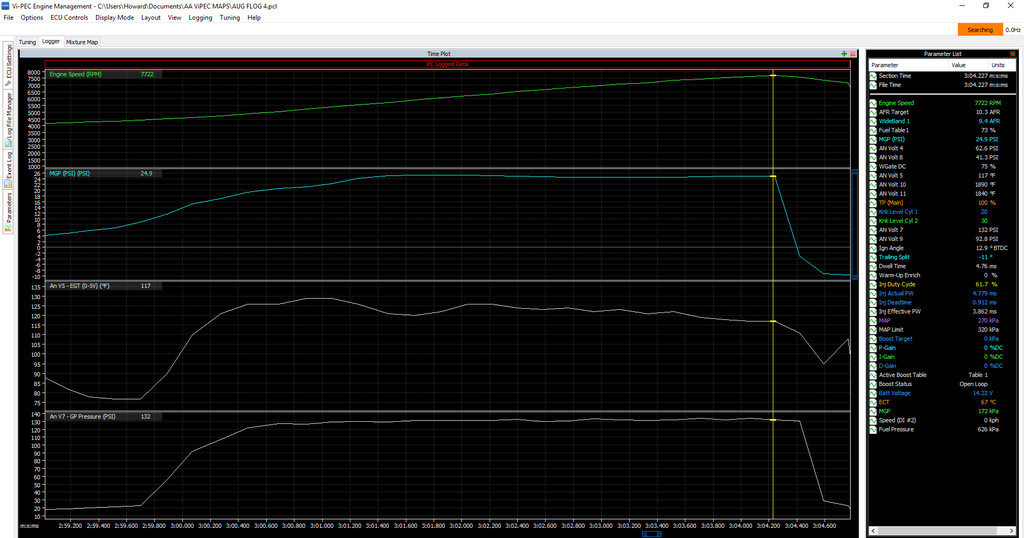

thanks to the magic of methanol my IAT trends downward to 117 F at 7722 rpm 24.9 psi boost and approx 585 hp.

my IAT data is generated by a specially engineered "air" thermocouple from The Sensor Connection. the sensor is made by them in the USA and is a product of more than 20 years of engineering to get the right balance between fast and durable. it generates four readings a second and is accurate to around one per cent.

for the record i have no idea as to the speed of other thermister type sensors.

i will be adding a thermistor to my UIM shortly and we will have comparison data.

i have a suspicion that if we knew our actual IATs there would be a lot more re-thinking of system design.

SYSTEM DESIGN

here's a recent log proving the point.

boost went from 8.9 psi at 2:59.790 to 19.4 at 3.00.374

just over a half second!

IAT went from 77 F to 126 F according to my thermocouple.

here's 8.9 psi:

here's the log at 3 minutes and .374 seconds:

IAT rose from 77 F to 126 F in less than three quarters of a second. note the bottom section of the log... that's my 100% methanol pressure log. AI pressure rose from 23.2 psi to 121.6 psi. i can't imagine where my IAT would be without it. i do plan to add a bit more meth to drop my IAT below ambient.

thanks to the magic of methanol my IAT trends downward to 117 F at 7722 rpm 24.9 psi boost and approx 585 hp.

my IAT data is generated by a specially engineered "air" thermocouple from The Sensor Connection. the sensor is made by them in the USA and is a product of more than 20 years of engineering to get the right balance between fast and durable. it generates four readings a second and is accurate to around one per cent.

for the record i have no idea as to the speed of other thermister type sensors.

i will be adding a thermistor to my UIM shortly and we will have comparison data.

i have a suspicion that if we knew our actual IATs there would be a lot more re-thinking of system design.

SYSTEM DESIGN