FB Rear Suspension Geometry Problems/Options/Solutions

#252

since the upper trailing arms are at an angle in the car they have to twist, AND pivot left to right as well as pivot up and down.

so the bushings used in them need to be really flexible. the racing parts were just stock with an adjuster for length.

so anything you can do to make it more flexible is good, the tri link simply gets rid of these links

so the bushings used in them need to be really flexible. the racing parts were just stock with an adjuster for length.

so anything you can do to make it more flexible is good, the tri link simply gets rid of these links

#253

Lives on the Forum

since the upper trailing arms are at an angle in the car they have to twist, AND pivot left to right as well as pivot up and down.

so the bushings used in them need to be really flexible. the racing parts were just stock with an adjuster for length.

so anything you can do to make it more flexible is good, the tri link simply gets rid of these links

so the bushings used in them need to be really flexible. the racing parts were just stock with an adjuster for length.

so anything you can do to make it more flexible is good, the tri link simply gets rid of these links

.

#254

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,802

Received 2,577 Likes

on

1,831 Posts

#255

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,802

Received 2,577 Likes

on

1,831 Posts

the factory fix was to change the mounting point to the axle, and run longer links.

the toyota people do this with the traction brackets https://technotoytuning.com/toyota/a...s-ae86-corolla

a friend of mine has a fully built hatchi, which is almost the same as a 1st gen, and they lowered the lower link on the axle, so they could lower the car, and then they just run a set of lower links as upper links, and made the panhard adjustable.

#256

What are people using to replace the suspension with a subframe/IRS when not restricted by rules that mandate the solid axle?

I seem to remember a few that had custom or aftermarket IRS and possibly Jaguar rears? What about an FD rear end? Any recommendations?

I seem to remember a few that had custom or aftermarket IRS and possibly Jaguar rears? What about an FD rear end? Any recommendations?

#257

Senior Member

Join Date: Apr 2004

Location: South Jordan UT

Posts: 453

Likes: 0

Received 0 Likes

on

0 Posts

To the issue of rear suspension mods for 300+H.p., You may want to read the toyota 8" swap thread because these axles are known to go bad at a lower HP than 300. Just saying the 'yota or ford 8.8 may be in your near future.

#258

^^Yeah, the standard 26 spline diff (with torsen) has stood up surprisingly well when ive gone thru a couple of s5 g'boxes and three button clutches, although thats probly just bad driving - no more burnouts for me lol, so im guessing im on a good thing with the relatively light weight std diff, and reluctant to go tri-link on it if it makes it more vulnerable to twisting forces, but i'll definately be looking into it.

- no more burnouts for me lol, so im guessing im on a good thing with the relatively light weight std diff, and reluctant to go tri-link on it if it makes it more vulnerable to twisting forces, but i'll definately be looking into it.

^^ this is pretty much exactly what im toying with the idea of;

extend the lower link mount on the axle, and raise the upper link mount on the chassis, thereby compensating for lowered ride height, and hopefully reducing the amount the pinion wants to hit the floor becuase of the extra leverage of the longer lower mounts.

The other hare-brain idea im playing with is moving the watts mount lower on the diff, and lengthening the short side of the pivot piece( excuse the incorrect terminology) so that the pivot piece is actually symetrical (will keep the standard enequal length arms tho).

I'll probably end up just using a panhard bar tho, too much stuffing about trying to polish a turd.

Ok sorry guys for polluting such a great thread with so much jibberish.

Mods, feel free to clean up after me. next time i should be able to put up some pics of what ive been up to.

i was thinking that last night, but i think you'd really have to get up in there and make sure. the binding comes from the upper links not being parallel, and kind of short.

the factory fix was to change the mounting point to the axle, and run longer links.

the toyota people do this with the traction brackets https://technotoytuning.com/toyota/a...s-ae86-corolla

a friend of mine has a fully built hatchi, which is almost the same as a 1st gen, and they lowered the lower link on the axle, so they could lower the car, and then they just run a set of lower links as upper links, and made the panhard adjustable.

the factory fix was to change the mounting point to the axle, and run longer links.

the toyota people do this with the traction brackets https://technotoytuning.com/toyota/a...s-ae86-corolla

a friend of mine has a fully built hatchi, which is almost the same as a 1st gen, and they lowered the lower link on the axle, so they could lower the car, and then they just run a set of lower links as upper links, and made the panhard adjustable.

extend the lower link mount on the axle, and raise the upper link mount on the chassis, thereby compensating for lowered ride height, and hopefully reducing the amount the pinion wants to hit the floor becuase of the extra leverage of the longer lower mounts.

The other hare-brain idea im playing with is moving the watts mount lower on the diff, and lengthening the short side of the pivot piece( excuse the incorrect terminology) so that the pivot piece is actually symetrical (will keep the standard enequal length arms tho).

I'll probably end up just using a panhard bar tho, too much stuffing about trying to polish a turd.

Ok sorry guys for polluting such a great thread with so much jibberish.

Mods, feel free to clean up after me. next time i should be able to put up some pics of what ive been up to.

Last edited by WANKfactor; 10-10-12 at 11:24 PM.

#259

Old [Sch|F]ool

I'm toying with the idea of moving to an E30 BMW, but part of the plan is replacing the IRS with a stick axle because they just work better.

#260

Old [Sch|F]ool

3-linking solves that issue, but then you get into the issue of the axle housing developing more and more toe-in, which eats axle bearings, and then the middle splits open like an egg and you eat the front pinion bearing after you drive 150 miles with no fluid in the diff...

#261

I'm not sure what you mean with that kind of general statement. I'm not a big fan of the E30 trailing links either but they still do pretty well and there are other options like a Ford 8.8 IRS or multilink IRS. I think someone has swapped in an E90 rear. (referring to BMW's not Mazda's)

I'm not sure what you mean with that kind of general statement. I'm not a big fan of the E30 trailing links either but they still do pretty well and there are other options like a Ford 8.8 IRS or multilink IRS. I think someone has swapped in an E90 rear. (referring to BMW's not Mazda's)Solid axles have some advantages including cost and less complexity, and can be a good choice for certain very specific applications, like drag racing. However that technology was passed by 50+ years ago. When you get your E30 converted let me know and we can meet for a few laps at the Glen or mid Ohio.

#262

The old IRS vs. Live Axle debate has raged for decades. After some research on this while designing my Toyota 8 setup (https://www.rx7club.com/build-thread...a-8-fb-992844/), most designers agree that live axle geometry benefits from long control arms -- whether it's a tri-link setup like mine or a torque arm arrangement. Packaging that stuff in a production vehicle is difficult.

That said, the current Mustang rear end seems to work fairly well. It uses a tri-link/Panhard with a very short upper link (generally undesirable for performance, but necessary for rear occcupant room). In recent road race comparisons with current generation Camaros and Challengers that both have IRS, the Mustang fairs very well.

I think my car would corner slightly better with a little negative camber in the rear. While this can be done with a live axle, I'm told it's best done with full floater hubs and crowned axle shafts, which aren't a production solution and aren't in my budget either.

That said, the current Mustang rear end seems to work fairly well. It uses a tri-link/Panhard with a very short upper link (generally undesirable for performance, but necessary for rear occcupant room). In recent road race comparisons with current generation Camaros and Challengers that both have IRS, the Mustang fairs very well.

I think my car would corner slightly better with a little negative camber in the rear. While this can be done with a live axle, I'm told it's best done with full floater hubs and crowned axle shafts, which aren't a production solution and aren't in my budget either.

#263

I don't think there's any inherent issue with a tri link and high horsepower. Trans-Am cars ran them for years with good success. I was personally concerned with the bent upper arm used in setups that don't alter the tunnel area, so I modified the tunnel in my car so I could use a straight one.

#264

Old [Sch|F]ool

The old IRS vs. Live Axle debate has raged for decades. After some research on this while designing my Toyota 8 setup (https://www.rx7club.com/build-thread...a-8-fb-992844/), most designers agree that live axle geometry benefits from long control arms -- whether it's a tri-link setup like mine or a torque arm arrangement. Packaging that stuff in a production vehicle is difficult.

Mind you, I'm competing on "unimproved surfaces". (Most will admit that on smooth tracks, there's no real difference between IRS and solid) At Nationals, my cars was quicker than all of the Miatas, all of the BMWs, most of the front-drives, AND most of the all wheel drives. Sadly it wasn't with ME actually driving

but solid axle is just plain superior as a performance item. There are huge benefits you can get with respect to planting the rear tires that are not available to you if you decouple axle torque from suspension motion.

but solid axle is just plain superior as a performance item. There are huge benefits you can get with respect to planting the rear tires that are not available to you if you decouple axle torque from suspension motion.

#265

Full Member

iTrader: (2)

Join Date: Aug 2010

Location: Dayton, Ohio

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

And that's the only reason for IRS - it requires less interior volume for the same amount of suspension travel, and it's easier to isolate NVH.

Mind you, I'm competing on "unimproved surfaces". (Most will admit that on smooth tracks, there's no real difference between IRS and solid) At Nationals, my cars was quicker than all of the Miatas, all of the BMWs, most of the front-drives, AND most of the all wheel drives. Sadly it wasn't with ME actually driving but solid axle is just plain superior as a performance item. There are huge benefits you can get with respect to planting the rear tires that are not available to you if you decouple axle torque from suspension motion.

but solid axle is just plain superior as a performance item. There are huge benefits you can get with respect to planting the rear tires that are not available to you if you decouple axle torque from suspension motion.

Mind you, I'm competing on "unimproved surfaces". (Most will admit that on smooth tracks, there's no real difference between IRS and solid) At Nationals, my cars was quicker than all of the Miatas, all of the BMWs, most of the front-drives, AND most of the all wheel drives. Sadly it wasn't with ME actually driving

but solid axle is just plain superior as a performance item. There are huge benefits you can get with respect to planting the rear tires that are not available to you if you decouple axle torque from suspension motion.

but solid axle is just plain superior as a performance item. There are huge benefits you can get with respect to planting the rear tires that are not available to you if you decouple axle torque from suspension motion.

#266

Rotary Enthusiast

Not that this could be done to this extent on a street car, but I am sure with some careful design, it could be done on a street car!

Inverted triangulated 4-link:

Inverted triangulated 4-link:

#267

Old [Sch|F]ool

As a rule, FWD is much quicker than RWD and often quicker than AWD, at rallycross.

Some of the fastest times posted at Nationals, IIRC, were in a bone stock Mazda2.

FWD is much more fragile, much more prone to debeading tires and breaking CVs, so I stopped running them.

Some of the fastest times posted at Nationals, IIRC, were in a bone stock Mazda2.

FWD is much more fragile, much more prone to debeading tires and breaking CVs, so I stopped running them.

#269

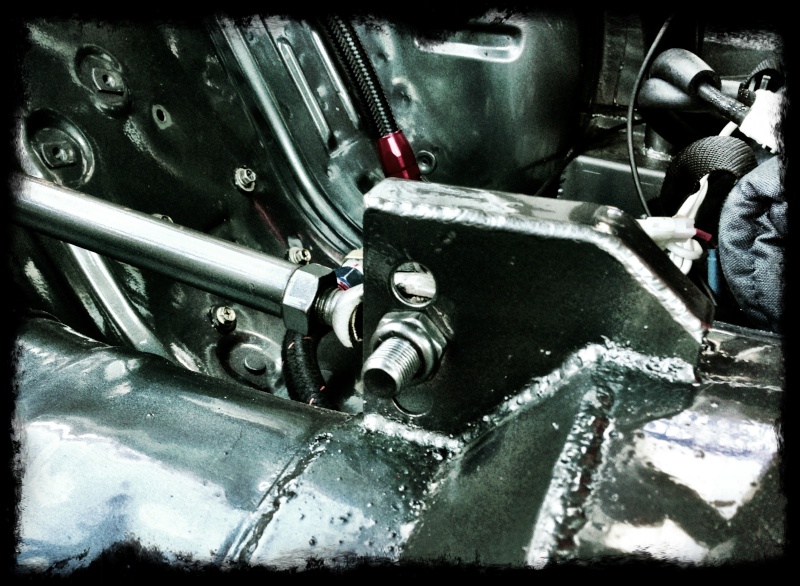

http://www.flickr.com/photos/rk970/8080617330/http://www.flickr.com/photos/rk970/8080617330/ by http://www.flickr.com/people/rk970/, on Flickr

http://www.flickr.com/photos/rk970/8080617406/http://www.flickr.com/photos/rk970/8080617406/ by http://www.flickr.com/people/rk970/, on Flickr

Anti squat is at about 55%. Upper third link is off set the to the right 4.5" (helps to stop lifting the right rear under acceleration) Panhard is close to the bottom of the diff housing..

I have a question.. Since I have converted/built a three link rear suspension.. is it really necessary to run the huge 1 1/8" front sway bar..? 225 in/lbs in the front and 175 in/lbs in the rear.. 3/4" suspension drop from stock height with 5/8" spacer between the steering arm and strut..

This is for a street car not a track weapon..

Rk

http://www.flickr.com/photos/rk970/8080617406/http://www.flickr.com/photos/rk970/8080617406/ by http://www.flickr.com/people/rk970/, on Flickr

Anti squat is at about 55%. Upper third link is off set the to the right 4.5" (helps to stop lifting the right rear under acceleration) Panhard is close to the bottom of the diff housing..

I have a question.. Since I have converted/built a three link rear suspension.. is it really necessary to run the huge 1 1/8" front sway bar..? 225 in/lbs in the front and 175 in/lbs in the rear.. 3/4" suspension drop from stock height with 5/8" spacer between the steering arm and strut..

This is for a street car not a track weapon..

Rk

#270

Rotary Enthusiast

I will have to do some calcs to see if your spring rates are good with those numbers!

However, I would highly recommend adding some gussets or something similar around where the bottom bars connect to the center of the diff. The bar welded alone will most likely fail as some point! If you can send me a picture looking at the diff from the back, I can put some gussets on there that will work!

However, I would highly recommend adding some gussets or something similar around where the bottom bars connect to the center of the diff. The bar welded alone will most likely fail as some point! If you can send me a picture looking at the diff from the back, I can put some gussets on there that will work!

#271

Old [Sch|F]ool

For what it's worth:

The problem I had:

Note that I'd already welded one crack shut. A new cracked opened up right by it, signifying that there's got to be a strong stretching force right there.

Solution:

Simple, effective.

The problem I had:

Note that I'd already welded one crack shut. A new cracked opened up right by it, signifying that there's got to be a strong stretching force right there.

Solution:

Simple, effective.

#273

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,802

Received 2,577 Likes

on

1,831 Posts

the E30 just looks like it has IRS, it doesn't actually WORK like it has IRS, if there is a swaybar on it, its just a solid axle with lots of negative camber.

#274