Tension Rod Nut Torque Question - FB

#1

Tension Rod Nut Torque Question - FB

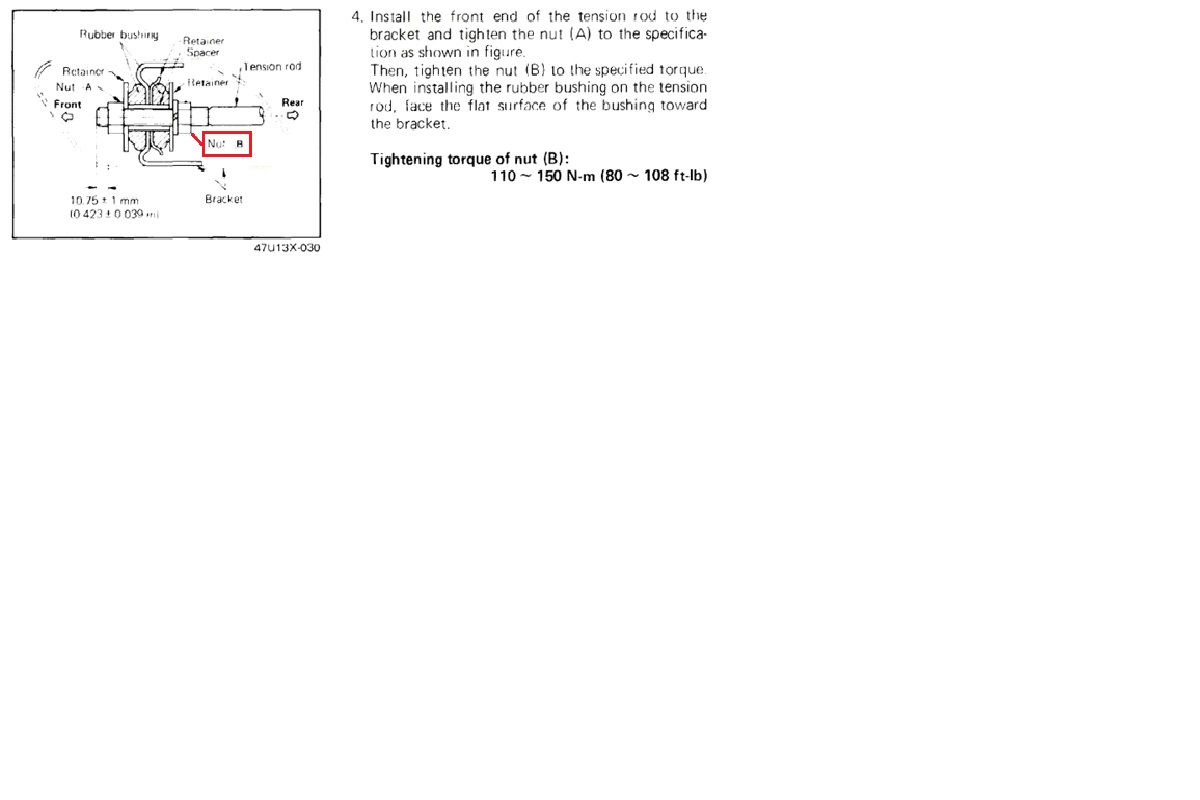

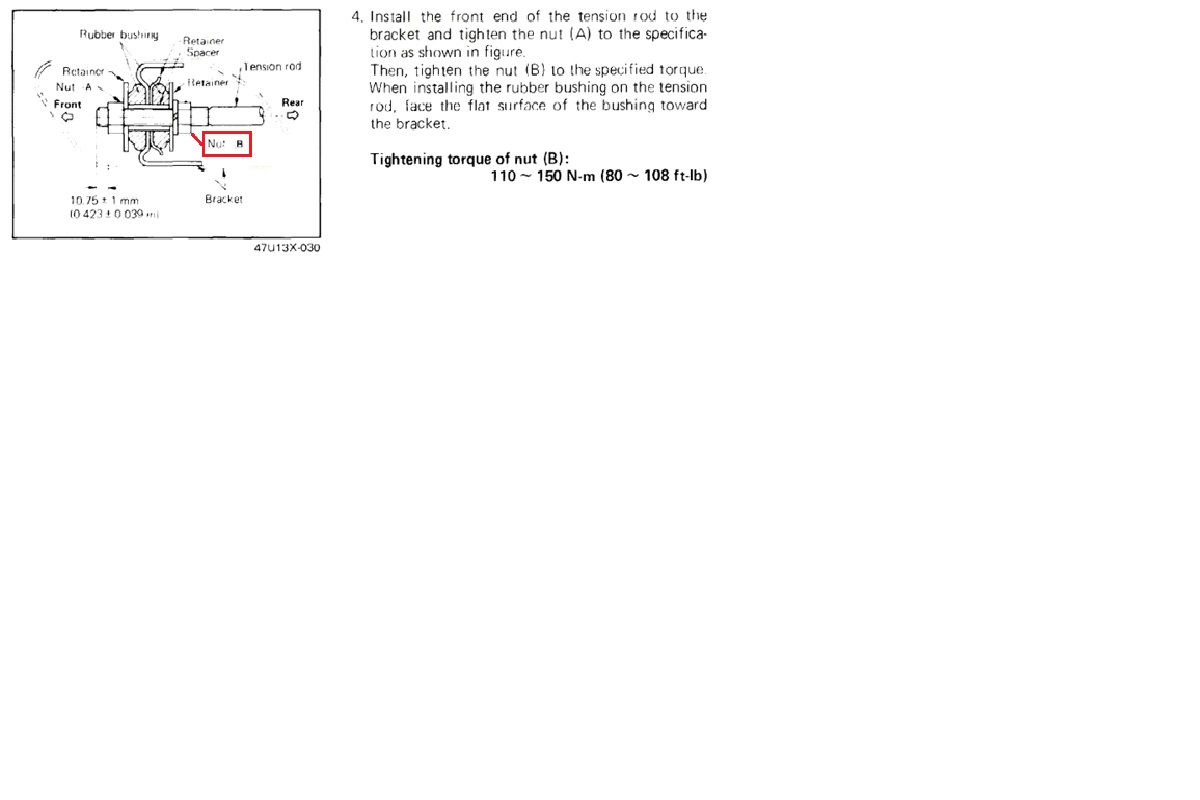

Can any of you guys that have replaced your tension rod bushings tell me how you torqued “nut B” in the diagram below?

Is there a way to do this without having to invest in a 26mm crow’s foot that I’ll use twice every decade?

Is there a way to do this without having to invest in a 26mm crow’s foot that I’ll use twice every decade?

#2

The plan

Okay, well what I think I'm gonna try then is a spin on the FSM procedure. It'll take some fiddling to get it proper, but if I use a deep socket 26mm and wrench on nut A instead of nut B it should have the same net effect as if I torque down nut B, thus eliminating the need for the crow's foot.

The poly bushings will compress less than the OEM rubber, so I gotta keep an eye on my control arm caster while torquing nut A to spec. and adjust nut B "in" or "out" accordingly. Considering this, it's likely the distance from rod end to nut A of 10.75mm will be less then FSM spec. which nullifies the FSM tension rod procedure.. i.e. if I set caster the FSM way and set nut A at the FSM 10.75mm using stiffer bushings I'd likely end up with more negative caster as less bushing compression would push the control arm back, which I don't want for street use.

Since I'm installing Ground Control camber/caster plates I'm not worried about dialing more caster in using the tension rod, I'll use the GC plate for that. My goal is to "zero" the tension rod so the control arm is perfectly aligned/parallel with the crossmember preventing uneven bushing wear or worse, binding.

I typically neglect threads for long periods of time , but if I get a chance and remember I'll post my results.

, but if I get a chance and remember I'll post my results.

The poly bushings will compress less than the OEM rubber, so I gotta keep an eye on my control arm caster while torquing nut A to spec. and adjust nut B "in" or "out" accordingly. Considering this, it's likely the distance from rod end to nut A of 10.75mm will be less then FSM spec. which nullifies the FSM tension rod procedure.. i.e. if I set caster the FSM way and set nut A at the FSM 10.75mm using stiffer bushings I'd likely end up with more negative caster as less bushing compression would push the control arm back, which I don't want for street use.

Since I'm installing Ground Control camber/caster plates I'm not worried about dialing more caster in using the tension rod, I'll use the GC plate for that. My goal is to "zero" the tension rod so the control arm is perfectly aligned/parallel with the crossmember preventing uneven bushing wear or worse, binding.

I typically neglect threads for long periods of time

, but if I get a chance and remember I'll post my results.

, but if I get a chance and remember I'll post my results.

#3

Plan B

Okay, so I tried that but it didn't quite work.. The FSM calls for 80-108ft-lb of torque which just seemed to be WAY too much. The bushings were deforming and looking "wrong" so I stopped tightening them down before they split and I changed the plan again.

What I finally did, was jack up and brace each control arm (2x4s) close to ride height. This got my control arms up "in" the crossmember instead of pivoted below making measuring easier and having a better idea where things would be on the ground.

I then took measurements using my Vernier calipers to keep the control arms somewhat centered in the crossmember as I tightened down the tension rod nuts. I had to jockey nut A and B to keep the control arm centered. Once I was satisfied the nuts felt fairly tight I torqued nuts A to an identical 18ft-lb and nuts B to where they felt tight enough and the control arm was returned to center (tighten nut A, control arm moves fwd. Tighten nut B, control arm moves backward).

I also checked geometry by using a piece of string precisely looped around the control arm and running it to the lateral ridge of the tension rod mounting plate. I marked where it intersected and checked it against the other side. I then repeated this procedure using the frontmost tension rod bolt instead of looping around the control arm. ...I did this because setting identical offsets on the end of the tension rods as outlined in the FSM (nut A vs end of rod) resulted in unequal control arm geometry between each side. The passenger side control arm had much less positive caster when set identical to the driver's side, and it was visually obvious the control arm was not parallel to the crossmember. By measuring the control arm using the string I was at least somewhat convinced that the control arms were even, even though the tension rod end offsets were not.

So to summarize that a little more clearly: the arms are centered in the crossmember ends, and they match when measured using the string at 2 different places. The "nut A to front end of rod" offsets DO NOT match each other, nor do they come close to matching the 10.75+/-mm bolt offset in the FSM.

Everything is tight without being deformed and the control arms look pretty even vs the crossmember. Only concerns are it's not FSM spec and the end offsets don't match each other. If they at least matched each other I'd be a whole lot less stressed about this. In retrospect I should've measured things before disassembly to see where they were initially.

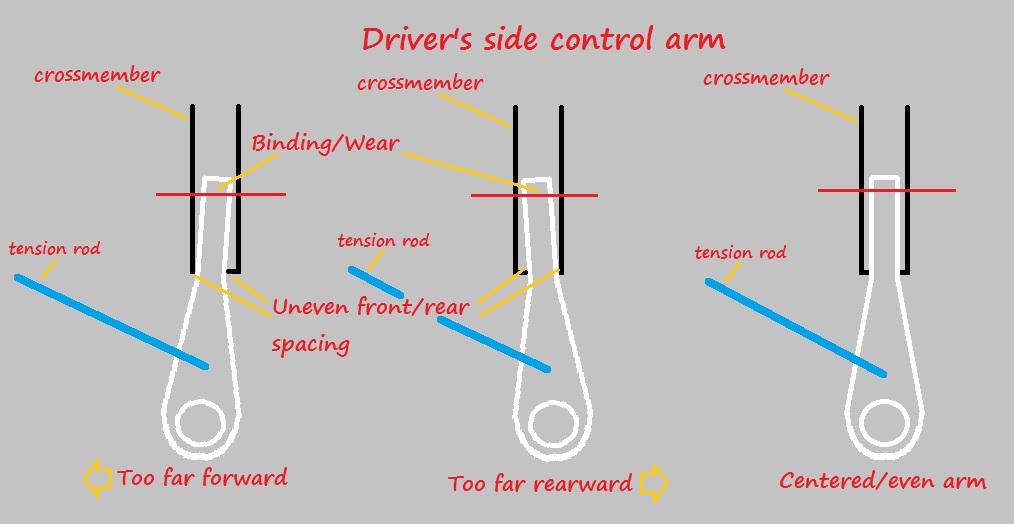

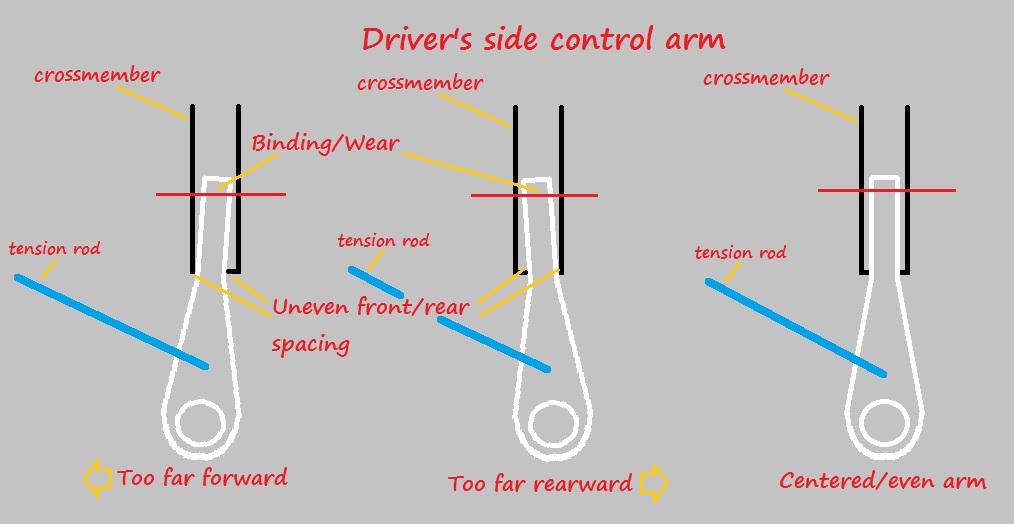

When I tried setting tension the FSM way, the control arms were being "pushed" too far back. Likely because the urethane is compressing less than the OEM rubber. This resulted in less positive caster and uneven pressure on the control arm bushing. The sketch below makes this easy to understand:

Well I'm done beating this horse for now... Now I need to get the car down so it can be driven while my wife's car is in the shop getting massive hail damage fixed. I think I'll just order the 27mm crowsfoot so I can be sure each side is evenly tensioned (nut B) and then see if I can get them close to matching.

Will update thread if progress is made. I can't be the only guy ever to scratch his head over this...

What I finally did, was jack up and brace each control arm (2x4s) close to ride height. This got my control arms up "in" the crossmember instead of pivoted below making measuring easier and having a better idea where things would be on the ground.

I then took measurements using my Vernier calipers to keep the control arms somewhat centered in the crossmember as I tightened down the tension rod nuts. I had to jockey nut A and B to keep the control arm centered. Once I was satisfied the nuts felt fairly tight I torqued nuts A to an identical 18ft-lb and nuts B to where they felt tight enough and the control arm was returned to center (tighten nut A, control arm moves fwd. Tighten nut B, control arm moves backward).

I also checked geometry by using a piece of string precisely looped around the control arm and running it to the lateral ridge of the tension rod mounting plate. I marked where it intersected and checked it against the other side. I then repeated this procedure using the frontmost tension rod bolt instead of looping around the control arm. ...I did this because setting identical offsets on the end of the tension rods as outlined in the FSM (nut A vs end of rod) resulted in unequal control arm geometry between each side. The passenger side control arm had much less positive caster when set identical to the driver's side, and it was visually obvious the control arm was not parallel to the crossmember. By measuring the control arm using the string I was at least somewhat convinced that the control arms were even, even though the tension rod end offsets were not.

So to summarize that a little more clearly: the arms are centered in the crossmember ends, and they match when measured using the string at 2 different places. The "nut A to front end of rod" offsets DO NOT match each other, nor do they come close to matching the 10.75+/-mm bolt offset in the FSM.

Everything is tight without being deformed and the control arms look pretty even vs the crossmember. Only concerns are it's not FSM spec and the end offsets don't match each other. If they at least matched each other I'd be a whole lot less stressed about this. In retrospect I should've measured things before disassembly to see where they were initially.

When I tried setting tension the FSM way, the control arms were being "pushed" too far back. Likely because the urethane is compressing less than the OEM rubber. This resulted in less positive caster and uneven pressure on the control arm bushing. The sketch below makes this easy to understand:

Well I'm done beating this horse for now... Now I need to get the car down so it can be driven while my wife's car is in the shop getting massive hail damage fixed. I think I'll just order the 27mm crowsfoot so I can be sure each side is evenly tensioned (nut B) and then see if I can get them close to matching.

Will update thread if progress is made. I can't be the only guy ever to scratch his head over this...

#4

Well the car passed inspection and I'm pleased with how the steering feels. Much more smooth and less wonder steer. I have yet to adjust the sector shaft so I'm glad the suspension upgrades paid off.

No issues with the tension rods, but will be paying attention to see how things look after I get more miles on it.

No issues with the tension rods, but will be paying attention to see how things look after I get more miles on it.

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM

Nosferatu

2nd Generation Specific (1986-1992)

7

09-05-15 02:13 PM