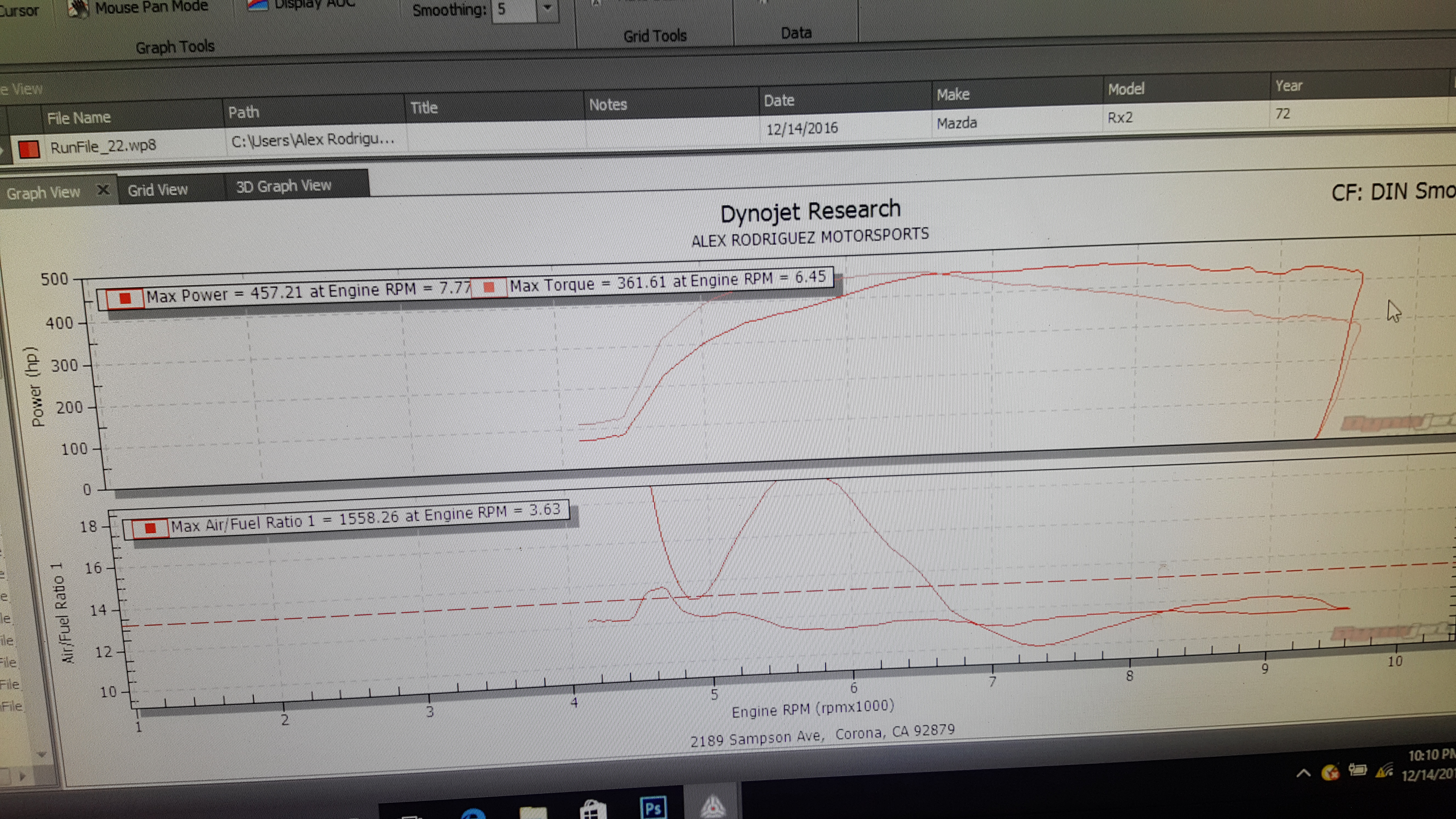

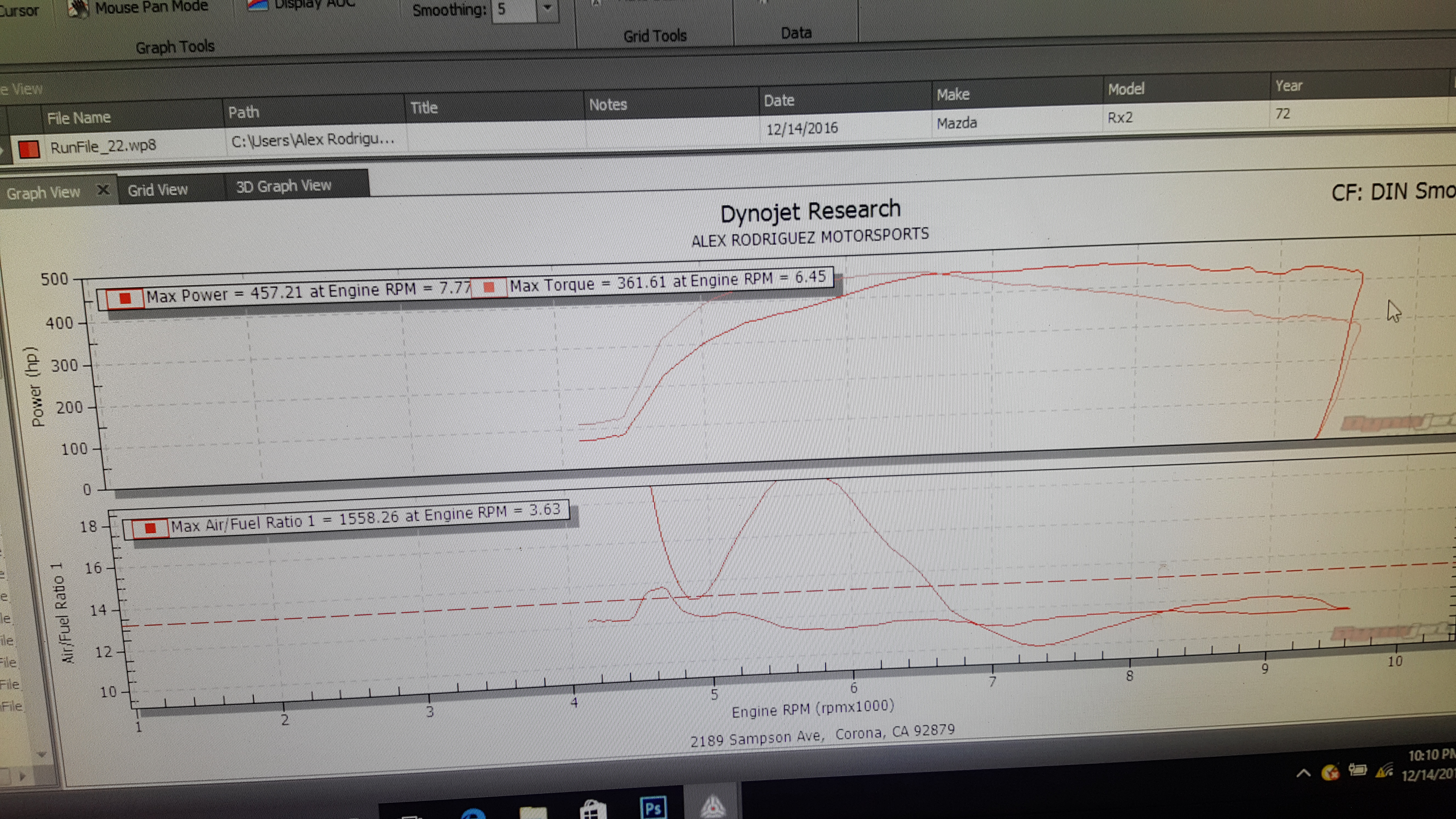

Semi Peripheral EFR9174 E85 @17psi Dyno #ThisistheWolf

#1

Semi Peripheral EFR9174 E85 @17psi Dyno #ThisistheWolf

Before people Blast me for not cranking up the boost. I'm done breaking transmissions....and so I've asked Abel to bring power and Tq down. This lets me drive the car harder and worry about the next clipping point or following a driver rather than worrying about slipping the clutch extra every time I shift.

Engine Specs:

FR Performance Built 13B REW

Semi Peripheral Port/Street Port

Non-Balanced but weight Matched

PTS 2mm 2 piece seals

Glease Man Billet Series Manifold

Dual EGT's (not running)

EMAP (Running) All the Above was at 8lbs of Back Pressure

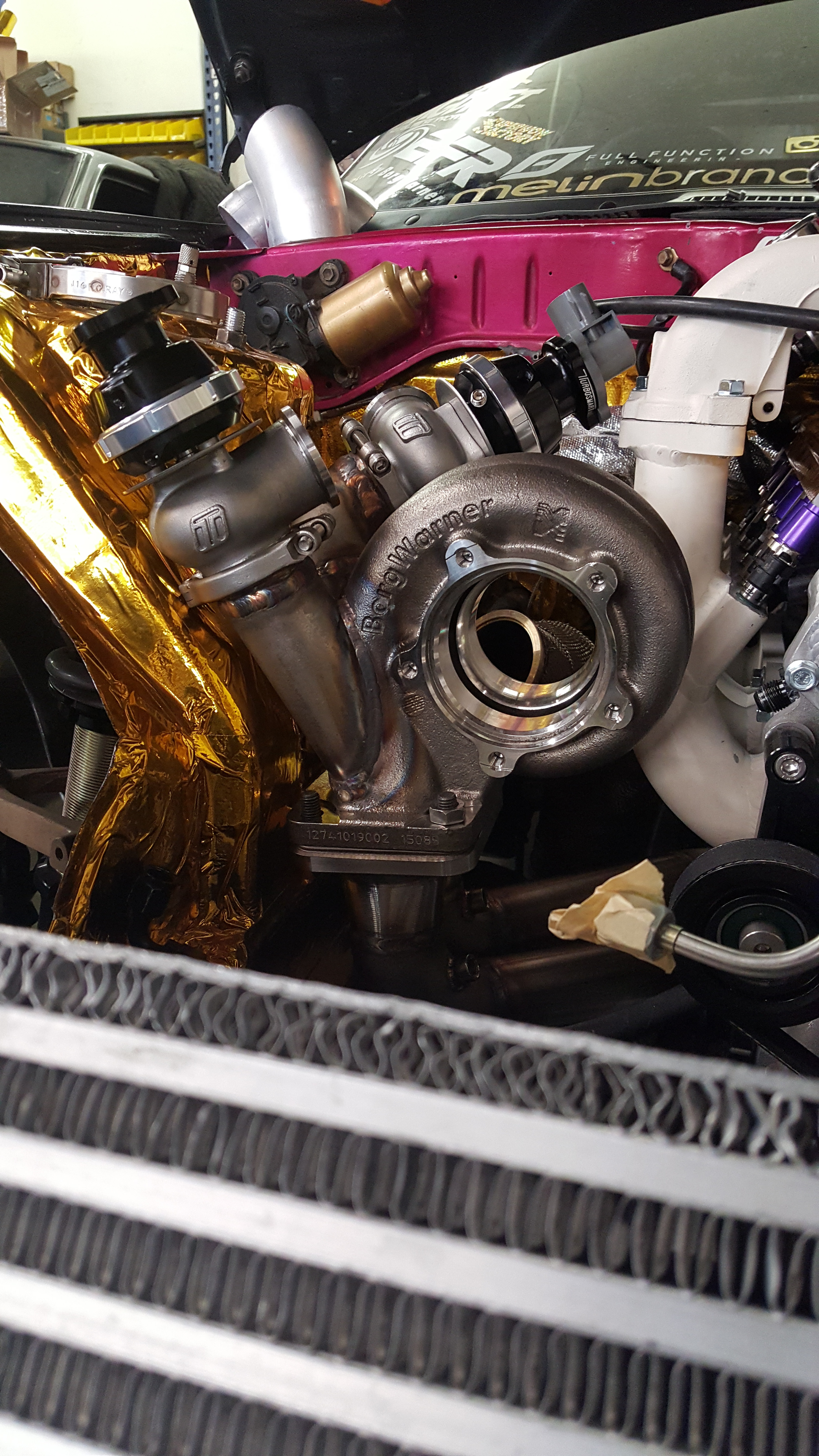

Dual Turbosmart Comp gate 40's off turbine Housing

17Lb Springs

Not running EBC Yet

ECU: Adaptronic Modular PnP

Fueling:

Custom Set up:

CJ-M Dual Pump Hanger with Walbro E85 Lift Pump

Radium Dual Bosch External Surge Set up W/2 Fuel Filters

All AN-8 Lines

(6) Injector Dynamics ID1700X

Full Function Engineering Primary Rail W/(4) Secondary Injectors

Running 3 stages of Injector

If anyone is interested in the Dyno Logs... I can send em no prob

Response is beautiful and easily the best I've ever felt on an FD. Andy Wyatt came and set up the new ECU himself. And Abel Ibarra took over the Full Boost Maps!!

car drives like a dream.. even at the slightest bit of throttle. No issues driving at 1400RPM..and I'll try and get some video of it asap.

I'll probably be going back to the 8374 to gain the bit of low end we had before.. Tune for what you need... not for all out power

Dyno Video

Track Testing

In Cabin

Engine Specs:

FR Performance Built 13B REW

Semi Peripheral Port/Street Port

Non-Balanced but weight Matched

PTS 2mm 2 piece seals

Glease Man Billet Series Manifold

Dual EGT's (not running)

EMAP (Running) All the Above was at 8lbs of Back Pressure

Dual Turbosmart Comp gate 40's off turbine Housing

17Lb Springs

Not running EBC Yet

ECU: Adaptronic Modular PnP

Fueling:

Custom Set up:

CJ-M Dual Pump Hanger with Walbro E85 Lift Pump

Radium Dual Bosch External Surge Set up W/2 Fuel Filters

All AN-8 Lines

(6) Injector Dynamics ID1700X

Full Function Engineering Primary Rail W/(4) Secondary Injectors

Running 3 stages of Injector

If anyone is interested in the Dyno Logs... I can send em no prob

Response is beautiful and easily the best I've ever felt on an FD. Andy Wyatt came and set up the new ECU himself. And Abel Ibarra took over the Full Boost Maps!!

car drives like a dream.. even at the slightest bit of throttle. No issues driving at 1400RPM..and I'll try and get some video of it asap.

I'll probably be going back to the 8374 to gain the bit of low end we had before.. Tune for what you need... not for all out power

Dyno Video

Track Testing

In Cabin

#5

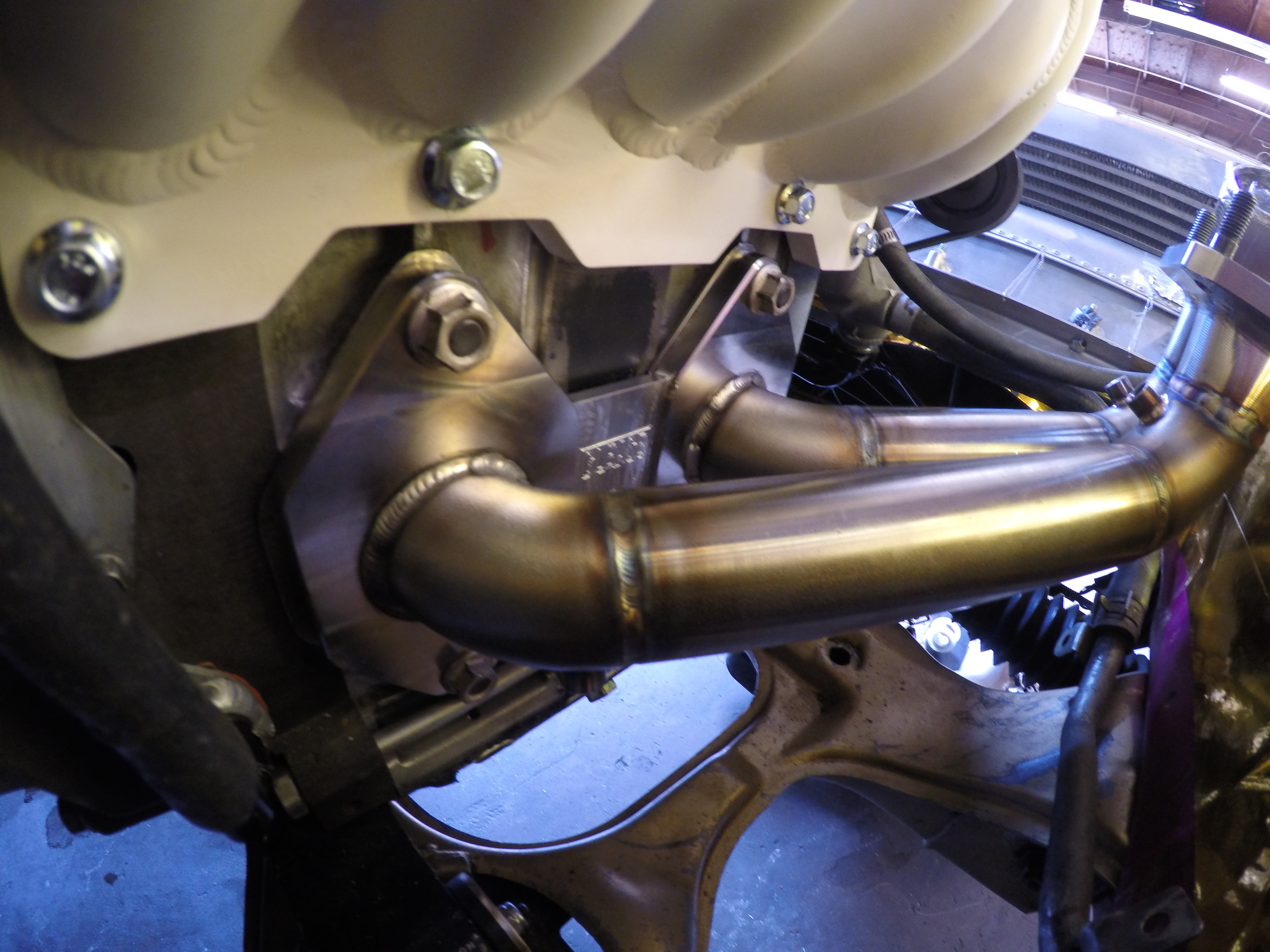

Yezzir!! I actually had answered this with pictures of my manifold..but I guess I forgot to hit post and then closed out of chrome before checking.

But here are some pics of the manifold's set up:

EGT's roughly 2.5" out of the housings. And EMAP bungs at the top there before gleasemans billet collector

better pic

Housing Set up:

But Yes! The values are in my log =-)

Trending Topics

#8

So although the I can carry 17lbs of boost all the way to 10K ..and although the 9174 would produce more power at 10k than the 8374.... Thats not where I "Need" the power. I need the power after I've slipped back into the power band from Lifting...and I need for the car to be as fast revving as possible... (Semi pp) and I need for response to be there when I'm following a V8 who has tq even at 2K rpm. So I look at things like this:

9174 comes on slightly later...slightly slower spooling due to larger inducer, I don't look at power up top because I don't and shouldn't drive on the limiter. Driveable powerband is from 4000 to 9600. giving me roughly 5K to work with or Operate within.

8374 comes on quicker....3500 rpm... rev's quicker due to smaller inducer, doesn't produce the flow up top...but I don't need it to.. I just need it to punch hard when it comes back online.. Driveable power band is from 3400 to 9600. Giving me 6200RPM to work with or operate within... Making the car car More driveable.

Hope that makes sense.

#9

Also..to answer your question.. It's the Shaft that our gears sit on that bend under load. Tq is what's doing it.. and out of the last few.... the transmissions all have let go at the same scenario.. 4k ish Rpm in 3rd gear... Lower Wheel speed.... meaning a very hefty load for 3rd gear.

Although I'm still trying to figure out one of the failures. It was before the semi Pp. I was at 7800ISH rpm in 2nd gear... Initiated... and hadn't even fully released the clutch..and BAM!!! It was the loudest noise to date. Chunks of metal filled the trans pan. 1st gear was the only thing that worked.. and it was impossible to get in and out of it after it went in. It was stuck.

Although I'm still trying to figure out one of the failures. It was before the semi Pp. I was at 7800ISH rpm in 2nd gear... Initiated... and hadn't even fully released the clutch..and BAM!!! It was the loudest noise to date. Chunks of metal filled the trans pan. 1st gear was the only thing that worked.. and it was impossible to get in and out of it after it went in. It was stuck.

#11

Also..to answer your question.. It's the Shaft that our gears sit on that bend under load. Tq is what's doing it.. and out of the last few.... the transmissions all have let go at the same scenario.. 4k ish Rpm in 3rd gear... Lower Wheel speed.... meaning a very hefty load for 3rd gear.

Although I'm still trying to figure out one of the failures. It was before the semi Pp. I was at 7800ISH rpm in 2nd gear... Initiated... and hadn't even fully released the clutch..and BAM!!! It was the loudest noise to date. Chunks of metal filled the trans pan. 1st gear was the only thing that worked.. and it was impossible to get in and out of it after it went in. It was stuck.

Although I'm still trying to figure out one of the failures. It was before the semi Pp. I was at 7800ISH rpm in 2nd gear... Initiated... and hadn't even fully released the clutch..and BAM!!! It was the loudest noise to date. Chunks of metal filled the trans pan. 1st gear was the only thing that worked.. and it was impossible to get in and out of it after it went in. It was stuck.

Last edited by lastphaseofthis; 12-28-16 at 06:39 PM.

#12

#14

#15

But it's all based off of theory in the whole exhaust gas Expansion debate. I believe in long runners. I think it allows for more efficient Burning of fuel...and exhaust gas expansion before it hits the turbo.

The other theory is to have the turbo as close to the exhaust ports out of the housings as possible to take advantage of the Heat/Energy.

But going along with what I believe...if you gate your exhaust pressure right out of the rotor housings... your dumping un-burned fuel and wasting energy. If you put the gates at the furthest along option (in my set up....it's the turbine housing) you vent that same exhaust gas pressure after it's had time to expand. And I've had first hand experience with both set up's. I still think the expansion theory is better.

But anyways... Hope that sheds a little light as to why I did it. Plus...gates out of the hood are always cool! This is the first set up welding gates to the turbine housing... but the third set up with gates out of the hood!!

#16

I wouldn't necessarily call it popular. Done before..absolutely. There are tricks. There's a reason I did it where I did on the housing. There's ton's of debate about priority etc.. but at the same time.. Everything in moderation. Too little..and you over boost..too much and you're losing spool and compressing springs and compromising diaphragms. People may argue against me...but I wouldn't ever put the gate where the above video did on the housing. i'm also not a fan of sharing a single gate per divided runners. Will it work? yes..but it's not better. To me...and from what i've learned....you really don't want to create more turbulence than you have to.

#19

I don't want to detract from all the cool and useful info in this thread but nice job! Very cool build, please keep the rotary drifting scene alive! Keep up the good work!

#21

So the plan is to try a different transmission. 90% of the guys I'm competing with have Dog Box's. The Dream is a sequential Trans. But that's out of my budget. I still haven't cut out the Nissan CD009 H-Pattern box either..and it's honestly the smartest choice budget, and reliability wise. So we shall see what I can work out

I thought about Liberty..but I'd still question the box's other components. Although its' a shaft upgrade...from memory thats just the input shaft correct? So I always weigh the price of the service...vs a whole new purpose built box ya know? or a box that is capable of the purpose

Any experience with the Liberty upgrades?

Any experience with the Liberty upgrades?Thanks much!! Appreciate the encouragement!!

#24

Yezzir there is!!

But it's all based off of theory in the whole exhaust gas Expansion debate. I believe in long runners. I think it allows for more efficient Burning of fuel...and exhaust gas expansion before it hits the turbo.

The other theory is to have the turbo as close to the exhaust ports out of the housings as possible to take advantage of the Heat/Energy.

But going along with what I believe...if you gate your exhaust pressure right out of the rotor housings... your dumping un-burned fuel and wasting energy. If you put the gates at the furthest along option (in my set up....it's the turbine housing) you vent that same exhaust gas pressure after it's had time to expand. And I've had first hand experience with both set up's. I still think the expansion theory is better.

But anyways... Hope that sheds a little light as to why I did it. Plus...gates out of the hood are always cool! This is the first set up welding gates to the turbine housing... but the third set up with gates out of the hood!!

But it's all based off of theory in the whole exhaust gas Expansion debate. I believe in long runners. I think it allows for more efficient Burning of fuel...and exhaust gas expansion before it hits the turbo.

The other theory is to have the turbo as close to the exhaust ports out of the housings as possible to take advantage of the Heat/Energy.

But going along with what I believe...if you gate your exhaust pressure right out of the rotor housings... your dumping un-burned fuel and wasting energy. If you put the gates at the furthest along option (in my set up....it's the turbine housing) you vent that same exhaust gas pressure after it's had time to expand. And I've had first hand experience with both set up's. I still think the expansion theory is better.

But anyways... Hope that sheds a little light as to why I did it. Plus...gates out of the hood are always cool! This is the first set up welding gates to the turbine housing... but the third set up with gates out of the hood!!