Initial EFR 7670 dyno results

#1

Initial EFR 7670 dyno results

After 13 years with a BNR Stage IV stock hybrid turbo the EFR series turbos finally interested me enough to give something new a try.

I fabbed up a manifold using an old HKS T04Z manifold as the base. I added two Tial MVR 44mm wastegates since I wanted to be able to run low boost on pump gas.

I went with an EFR 7670 as I wasn't really looking for more power, but rather even better power delivery.

As you can see, the 7670 fit the FC well.

Looks like there is room for the larger EFR turbos using this manifold as the exhaust side and center housing is the same, the EFR 8374 and 9180 just have the next size up compressor cover.

I fabbed up a manifold using an old HKS T04Z manifold as the base. I added two Tial MVR 44mm wastegates since I wanted to be able to run low boost on pump gas.

I went with an EFR 7670 as I wasn't really looking for more power, but rather even better power delivery.

As you can see, the 7670 fit the FC well.

Looks like there is room for the larger EFR turbos using this manifold as the exhaust side and center housing is the same, the EFR 8374 and 9180 just have the next size up compressor cover.

#2

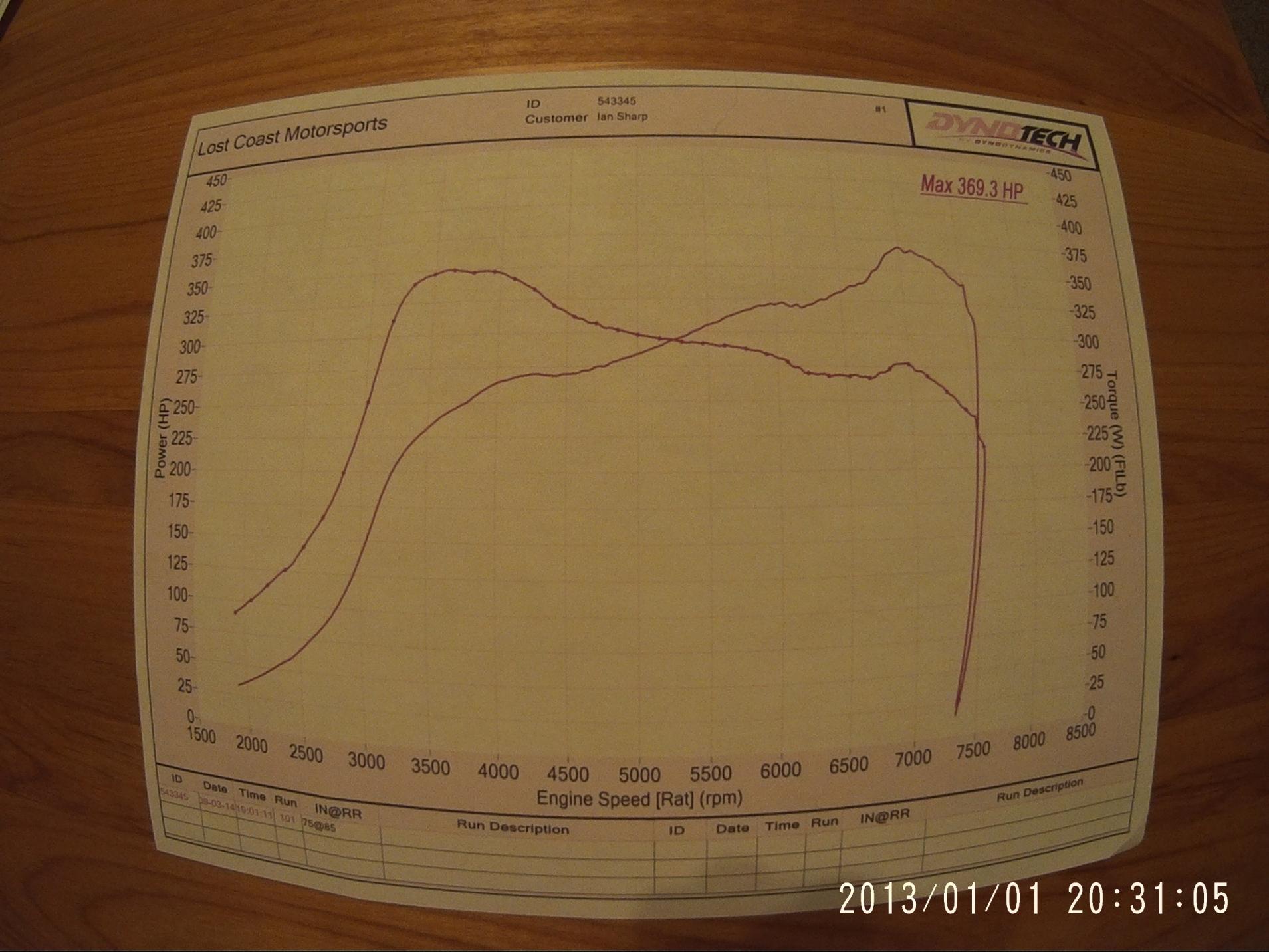

Here is the initial dyno at 26psi boost.

I have the 13psi springs in the wastegate because I want to be able to run low boost on pump gas and then turn up the boost on race gas.

The low boost wastegate springs are probably a contributing factor on the boost fade this set up has. It hits peak boost fast, but then fades down. We turned up the manual boost controller and both peak boost and faded boost rose about the same so we went ahead with the tuning session.

Final dyno (shown) is 26psi peak boost and fading to ~20psi from memory.

The AFRs are still richer than 10:1 from about 4,500 to 7,000rpm- that "sag" in the power could probably be fixed leaning it out, but we ran out of time and tolerance to the noise this evening.

I wasn't able to do a full pull at 28psi as it hit 100% duty cycle around 4,000rpm.

I have the 13psi springs in the wastegate because I want to be able to run low boost on pump gas and then turn up the boost on race gas.

The low boost wastegate springs are probably a contributing factor on the boost fade this set up has. It hits peak boost fast, but then fades down. We turned up the manual boost controller and both peak boost and faded boost rose about the same so we went ahead with the tuning session.

Final dyno (shown) is 26psi peak boost and fading to ~20psi from memory.

The AFRs are still richer than 10:1 from about 4,500 to 7,000rpm- that "sag" in the power could probably be fixed leaning it out, but we ran out of time and tolerance to the noise this evening.

I wasn't able to do a full pull at 28psi as it hit 100% duty cycle around 4,000rpm.

#5

*Probably* just over 400rwhp on a dynojet. I am hoping to find out this Sunday.

Also I noticed the Dynojet loads the engine correctly for the same spool as on the street. Even playing with Dyno Dynamics ramp rates it doesn't load the engine enough at low rpms. Maybe I need to pay for some training/read up on DD to figure it out.

My old hybrid turbo-

Dynojet = 340rwhp @ 12psi.

Dynapack= 340 @ 12psi, 380 @ 14psi.

DynoDynamics= 295rwhp @ 10psi, 320rwhp @ 16psi, 325rwhp @ 18psi.

Also I noticed the Dynojet loads the engine correctly for the same spool as on the street. Even playing with Dyno Dynamics ramp rates it doesn't load the engine enough at low rpms. Maybe I need to pay for some training/read up on DD to figure it out.

My old hybrid turbo-

Dynojet = 340rwhp @ 12psi.

Dynapack= 340 @ 12psi, 380 @ 14psi.

DynoDynamics= 295rwhp @ 10psi, 320rwhp @ 16psi, 325rwhp @ 18psi.

#6

Here are my results from the 8374 I did today. This was in shootout mod( so they are dynojet figures)

Ran out of time to try a new set of plugs with a smaller gap, and continue trouble shooting..

Will retry again and fit new boost control actuator( medium canister was past its limits)

Boost response is identical on a dynojet with this car, actually slightly higher HP figures on a dynojet...

Ran out of time to try a new set of plugs with a smaller gap, and continue trouble shooting..

Will retry again and fit new boost control actuator( medium canister was past its limits)

Boost response is identical on a dynojet with this car, actually slightly higher HP figures on a dynojet...

#7

I did a 4th gear log last night and the DD settings we have are actually spooling it exactly the same as when driving.

We set it off when we reached full boost on my old turbo. I think it is 85 which is 8.5km/sec?

10psi @ 2,500rpm

19psi @ 3,000rpm

26psi @ 3,300rpm

Luckily, I found when driving it holds 26psi until 6,000rpm and then slowly and evenly fades down to 20psi at redline. So, possibly the Dyno Dynamics is not loading enough at high rpm?

We set it off when we reached full boost on my old turbo. I think it is 85 which is 8.5km/sec?

10psi @ 2,500rpm

19psi @ 3,000rpm

26psi @ 3,300rpm

Luckily, I found when driving it holds 26psi until 6,000rpm and then slowly and evenly fades down to 20psi at redline. So, possibly the Dyno Dynamics is not loading enough at high rpm?

Trending Topics

#8

Racing Rotary Since 1983

iTrader: (6)

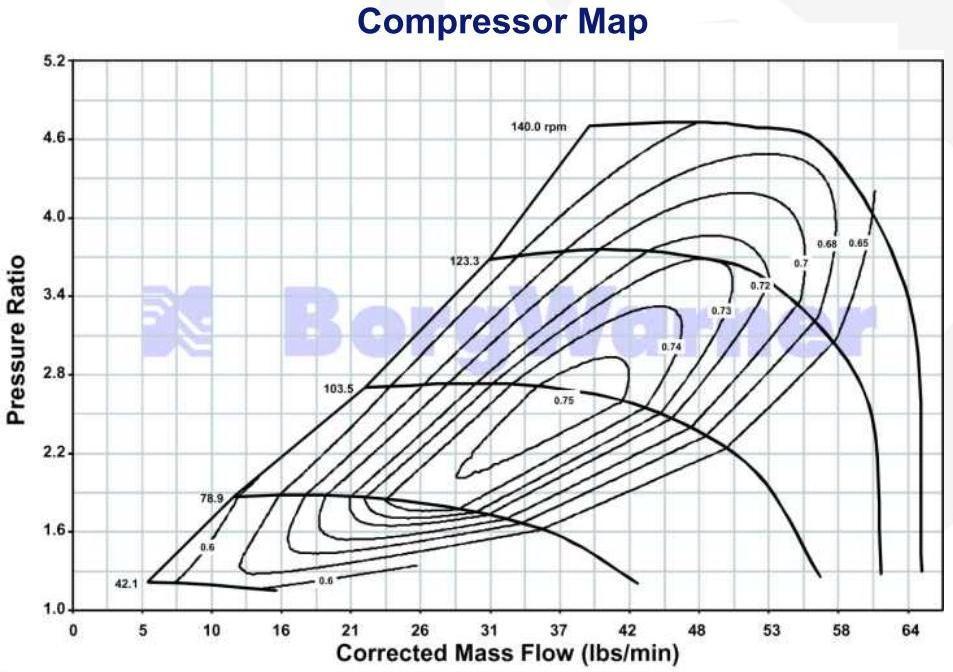

while the EFR line of turbos are a clean sheet of paper design purpose built for our interests instead of hauling trucks down the road it still comes down to pressure and flow to determine power.

as in a compressor map. note that BW did not plot the 60% efficiency line further than 26 pounds so let's just draw in a line in order to speak apples/apples language. do note, however, flow ends when the RPM line goes vertical. just before that the efficiency goes away as too much heat enters the picture.

the 7670 has a very small compressor wheel.

BW EFR 7670 comp wheel is 5.524 average square inches

Garrett GT3582r is 6.386!

while smaller, the wheel is of a stronger material than the cast aluminum GT35. stronger is very important at higher boost where temps can reach 400 F and pressures are extreme. cast aluminum probably gives up a bit of form and flow V billet.

BW shows the backbone in the billet wheel by running the compressor to 44 PSI or 4 Pressure Ratios absolute where it produces max output.

since it is stronger, a billet wheel needs less center mass so it has delivers longer vanes per diameter, and vanes, not the nose, do the heavy lifting.

the 7670 needs all these advantages as the compressor wheel is only 86.5% the size of the GT35.

while there isn't a single component on the EFR line of turbos that isn't superior to other turbos the weight/design of the turbine wheel probably takes center stage.

if you have ever held a turbine wheel in your hand you know they are very heavy. as in boat anchor. take a look at the RPM plot on the compressor map. the 123.3 number is RPM as in 123,000 RPM! now think about early boost as in spool, as in accelerating a heavy turbine wheel.

the EFR line of turbines are around 50% lighter! while i grant you that the primary opposing force to the turbo is moving the air thru the compressor, rotating mass has to be also important.

BW must have agreed as they no doubt invested a lot of effort in the Titanium Alumide material.

all the design features aside, power still gets back to airflow and the compressor map.

maximum rotary rwhp SAE from the 7670:

at 1.68 pressure ratio (Absolute) or 10 PSI 37 pounds/min or 278 hp

at 2.36 PR/20 PSI 54 pounds 407 hp

at 2.77 PR/26 PSI 58 pounds 437

at 4 PR/44 PSI 64 pounds 482

all derived using an estimated 60% efficiency line.

of course these numbers are maximum and your engine/setup may or may not be able to power the turbo to that particular spot on the map.

it is relatively easy to get early boost. a few years ago my maiden voyage on my GT4094r resulted in 30 PSI before 3000 RPM. i had hooked up the wastegate incorrectly and the valve was closed. generally you get higher EGTs. i see high EGTs from improperly designed turbo manifolds which restrict airflow similar to a small hotside.

the downside to a restricted hotside in addition to higher EGTs is lower flow/boost pressure at higher RPMs.

i grant that most of the early power/boost/flow from the EFR line is due to the more efficient design since the 8374 also produces better midrange and it has a 6.23 turbine area. my 9180 is 7.19 hotside area.

i do believe the BW EFR line remains the only 21st century turbo and expect to see others eventually release similar designs down the road.

howard

#9

I am starting to wonder if we will continue to even sell the 7670. The 8374 delivers amazing response with much better midrange and topend compared to the 7670. I do not see a reason to have any better response by moving down to the 7670. Also lower egts and backpressure of bigger turbine section on 8374 is a big plus as mentioned.

#10

I am starting to wonder if we will continue to even sell the 7670. The 8374 delivers amazing response with much better midrange and topend compared to the 7670.

Well, as you said the shootout mode #s you posted for the EFR 8374 are much more like dynojet #s.

If you pm me the settings you entered for shootout mode we might dyno the EFR 7670 that way sometime for a direct comparison- otherwise the chart you posted in shootout mode is no where near to the chart I posted with correction.

Also lower egts and backpressure of bigger turbine section on 8374 is a big plus as mentioned.

Since the 8374 exhaust housing is the same and just the exhaust wheel is 4mm larger lower EMAP/EGT from larger hotside is likely offset by the 7mm larger compressor wheel the exhaust has to power. More work = higher EMAP/EGT.

On my 7670 set-up, because of the shallow merge angle and how close my wastegate runners are to the motor the EMAP pushes the 13psi WG springs open fairly easy compared to the IWG EFR exhaust housing with medium boost cannister.

I think this has a lot to do with my boost fade. Dual 44mm WGs pushed open wide with exhaust flow/pressure don't maintain the compressor RPM and boost drops.

I did the high priority WG though to prevent boost creep on my 13psi low boost pump gas setting and promote WG flow as WG is open at ~2,700rpm (90hp) on 13psi low boost and then has to flow enough exhaust to maintain just 13psi at 7,000rpm (310hp).

I am trying to balance a 13psi low boost setting for pump gas and a 26psi high boost setting for race gas on the same setup (just change boost controller setting) which is a tough job for any turbo!

Also, I don't think I am anywhere near surge line at low rpm, so the EFR 7670 could use much smaller volume exhaust manifold/housing on the low end to improve spool.

Imagine a stock 3rd gen sequential manifold under a divided manifold/housing so that all exhaust gas enters the turbo wheel through one of the T4 divided exhaust housings at low rpm for faster spool.

The 7670 could do this for more power 1,000rpm to 3,000rpm whereas the 8374 is already near surge at low rpm.

So... in judging the EFR 7670 by my results remember the impediments I have shackled the turbo with to meet the criteria of my set-up.

Well, as you said the shootout mode #s you posted for the EFR 8374 are much more like dynojet #s.

If you pm me the settings you entered for shootout mode we might dyno the EFR 7670 that way sometime for a direct comparison- otherwise the chart you posted in shootout mode is no where near to the chart I posted with correction.

Also lower egts and backpressure of bigger turbine section on 8374 is a big plus as mentioned.

Since the 8374 exhaust housing is the same and just the exhaust wheel is 4mm larger lower EMAP/EGT from larger hotside is likely offset by the 7mm larger compressor wheel the exhaust has to power. More work = higher EMAP/EGT.

On my 7670 set-up, because of the shallow merge angle and how close my wastegate runners are to the motor the EMAP pushes the 13psi WG springs open fairly easy compared to the IWG EFR exhaust housing with medium boost cannister.

I think this has a lot to do with my boost fade. Dual 44mm WGs pushed open wide with exhaust flow/pressure don't maintain the compressor RPM and boost drops.

I did the high priority WG though to prevent boost creep on my 13psi low boost pump gas setting and promote WG flow as WG is open at ~2,700rpm (90hp) on 13psi low boost and then has to flow enough exhaust to maintain just 13psi at 7,000rpm (310hp).

I am trying to balance a 13psi low boost setting for pump gas and a 26psi high boost setting for race gas on the same setup (just change boost controller setting) which is a tough job for any turbo!

Also, I don't think I am anywhere near surge line at low rpm, so the EFR 7670 could use much smaller volume exhaust manifold/housing on the low end to improve spool.

Imagine a stock 3rd gen sequential manifold under a divided manifold/housing so that all exhaust gas enters the turbo wheel through one of the T4 divided exhaust housings at low rpm for faster spool.

The 7670 could do this for more power 1,000rpm to 3,000rpm whereas the 8374 is already near surge at low rpm.

So... in judging the EFR 7670 by my results remember the impediments I have shackled the turbo with to meet the criteria of my set-up.

#11

For comparisons sake

I will add 10% to your torque figures

RPM Yours( +10%) VS 8374 (

2000 105 125

2500 150 170

3000 260 250

4000 375 405

5000 330 425

Obviously there is a big difference in boost pressure, but if one had to choose between the two plots, I would pick the 8374. Again I do want to see apples to apples comparison( no boost fade on your setup).

Keep in mind the medium canister( on the 8374) with a lot of preload is not working correctly at all. I wasn't able to verify visually( at what RPM it started cracking). I was able to go from 3 to 5 turns of preload and gain a good 500rpms worth of boost response too.

We will try again with the turbosmart actuator with a 30psi spring. I bet boost response will be even better.

I do want to see your car on a dynojet, with bigger base springs, and more time spent on the tuning. I have two 7670s that I will be tuning shortly too..

Do you have a dynosheet of torque vs boost pressure like the one I posted?

Also when you checked on the street was it 4th gear?

My offer via PM still stands too, at this point I will also get some WG springs to your door for free if you are going back to the dyno anytime soon.

I will add 10% to your torque figures

RPM Yours( +10%) VS 8374 (

2000 105 125

2500 150 170

3000 260 250

4000 375 405

5000 330 425

Obviously there is a big difference in boost pressure, but if one had to choose between the two plots, I would pick the 8374. Again I do want to see apples to apples comparison( no boost fade on your setup).

Keep in mind the medium canister( on the 8374) with a lot of preload is not working correctly at all. I wasn't able to verify visually( at what RPM it started cracking). I was able to go from 3 to 5 turns of preload and gain a good 500rpms worth of boost response too.

We will try again with the turbosmart actuator with a 30psi spring. I bet boost response will be even better.

I do want to see your car on a dynojet, with bigger base springs, and more time spent on the tuning. I have two 7670s that I will be tuning shortly too..

Do you have a dynosheet of torque vs boost pressure like the one I posted?

Also when you checked on the street was it 4th gear?

My offer via PM still stands too, at this point I will also get some WG springs to your door for free if you are going back to the dyno anytime soon.

#13

This is making me worry I went the wrong route with my 7670.... still brand new in the box....

How is the curve at 15-18psi all the way?

On 15psi my set up would spike 18psi and settle to 15psi. I always had this kind of problem on my old set up as well running the stiffer spring in the Hallman MBC- probably need to change the size of the bleed hole.

I didn't try it with the soft spring in the MBC that always worked well for me because of the 13psi pump, 26psi race plan.

How is the curve at 15-18psi all the way?

On 15psi my set up would spike 18psi and settle to 15psi. I always had this kind of problem on my old set up as well running the stiffer spring in the Hallman MBC- probably need to change the size of the bleed hole.

I didn't try it with the soft spring in the MBC that always worked well for me because of the 13psi pump, 26psi race plan.

#14

Obviously there is a big difference in boost pressure, but if one had to choose between the two plots, I would pick the 8374. Again I do want to see apples to apples comparison( no boost fade on your setup).

Well, we don't race dynos and the racing I do is mainly in parking lots, so response is the most important thing for me.

I do want to see your car on a dynojet, with bigger base springs, and more time spent on the tuning. I have two 7670s that I will be tuning shortly too..

I hope to clean up the tune for sure, but a Dynojet isn't available to me on a regular basis.

I might try the stiffer springs (they all come with Tial WGs), but honestly it is a lot of work to switch them out and its not the set up I will running anyways.

I will never be over 6,000rpm in 3rd or full throttle in 2nd over 6,000rpm racing anyways as the traction and space to do it isn't there.

Do you have a dynosheet of torque vs boost pressure like the one I posted?

No, I could get torque & boost printed out from my earlier session, but it won't read as high as your shootout #s. PM me the settings you used and I might do that at a later date or you could just run your #s in regular Dyno Dynamics #s corrected.

Also when you checked on the street was it 4th gear?

Yes.

Well, we don't race dynos and the racing I do is mainly in parking lots, so response is the most important thing for me.

I do want to see your car on a dynojet, with bigger base springs, and more time spent on the tuning. I have two 7670s that I will be tuning shortly too..

I hope to clean up the tune for sure, but a Dynojet isn't available to me on a regular basis.

I might try the stiffer springs (they all come with Tial WGs), but honestly it is a lot of work to switch them out and its not the set up I will running anyways.

I will never be over 6,000rpm in 3rd or full throttle in 2nd over 6,000rpm racing anyways as the traction and space to do it isn't there.

Do you have a dynosheet of torque vs boost pressure like the one I posted?

No, I could get torque & boost printed out from my earlier session, but it won't read as high as your shootout #s. PM me the settings you used and I might do that at a later date or you could just run your #s in regular Dyno Dynamics #s corrected.

Also when you checked on the street was it 4th gear?

Yes.

#16

This vid shows response in 5th, 4th, 3rd and back to 5th.

I don't know how it compares to 8374, but it is better than my 60-1 was.

https://www.youtube.com/watch?v=XpkJ...ature=youtu.be

I don't know how it compares to 8374, but it is better than my 60-1 was.

https://www.youtube.com/watch?v=XpkJ...ature=youtu.be

#18

Racing Rotary Since 1983

iTrader: (6)

i suggest you contact whoever did your dyno session and ask them to send you something of actual value to you and the club.

1. change the X line to Engine Speed

2. click on "Correction Factor" and choose SAE. almost no one would offer a dyno sheet uncorrected. further while i am on the subject any time you see STD as a correction selection you should know that someone is simply wanting bigger numbers. the difference between SAE, which is the OE standard, versus STD is 2.55%. at 500 hp that inflates output by 13 hp merely by using different temp/hum and pressure. so if you want more hp use STD but know that your number is inflated.

3. given you paid for the dyno time you should also ask for a boost plot (v rpm). the best way to portray boost is devoid of other data so it is not minimized. a boost and torque would also be helpful.

just as a note to others, if you download the Winpep7 software you can then ask for the entire dyno FILE. you then can examine every data point, you can compare different runs on your computer etc. if you used the software you could set up your own page, w whatever factors you wished and then post it as a jpg/clean screen save...

you are to be commended for purposely sizing your turbo for your specific objectives. it is now possible to fit a turbo as perfectly as a custom made suit. once you get it tuned out i will be interested in your lower RPM traction. i do think this will be a factor w the EFR turbo line going forward. (maybe not a bad problem)

i did look at your video and if i was reading your AFR correctly it seems like you are quite rich in boost so there is probably a bit more power available.

i have a dyno file of 72 plots all corrected to SAE that posts power at 500 RPM intervals from 5000 thru 7500. (power under the curve wins races.) i will be very interested to see where the EFR line apportions power thru the rpm band.

hc

1. change the X line to Engine Speed

2. click on "Correction Factor" and choose SAE. almost no one would offer a dyno sheet uncorrected. further while i am on the subject any time you see STD as a correction selection you should know that someone is simply wanting bigger numbers. the difference between SAE, which is the OE standard, versus STD is 2.55%. at 500 hp that inflates output by 13 hp merely by using different temp/hum and pressure. so if you want more hp use STD but know that your number is inflated.

3. given you paid for the dyno time you should also ask for a boost plot (v rpm). the best way to portray boost is devoid of other data so it is not minimized. a boost and torque would also be helpful.

just as a note to others, if you download the Winpep7 software you can then ask for the entire dyno FILE. you then can examine every data point, you can compare different runs on your computer etc. if you used the software you could set up your own page, w whatever factors you wished and then post it as a jpg/clean screen save...

you are to be commended for purposely sizing your turbo for your specific objectives. it is now possible to fit a turbo as perfectly as a custom made suit. once you get it tuned out i will be interested in your lower RPM traction. i do think this will be a factor w the EFR turbo line going forward. (maybe not a bad problem)

i did look at your video and if i was reading your AFR correctly it seems like you are quite rich in boost so there is probably a bit more power available.

i have a dyno file of 72 plots all corrected to SAE that posts power at 500 RPM intervals from 5000 thru 7500. (power under the curve wins races.) i will be very interested to see where the EFR line apportions power thru the rpm band.

hc

#20

Good stuff, keep it coming. In comparison to my 6266 on my FC with my very conservative timing you definitely have more response below 4k, but after that it looks to be about the same. I have some videos floating around that show the response. I will say that the precision turbos seem to make more power per psi than the EFRs but the response of them haven't been jaw dropping like I've seen on some of the EFR results.

#21

Good stuff, keep it coming. In comparison to my 6266 on my FC with my very conservative timing you definitely have more response below 4k, but after that it looks to be about the same. I have some videos floating around that show the response. I will say that the precision turbos seem to make more power per psi than the EFRs but the response of them haven't been jaw dropping like I've seen on some of the EFR results.

#22

Well Howard, I have to crash a diesel day dyno contest where they truck a Dynojet 150 miles once a year to get Dynojet figures.

I wait from 9am to 4:30pm watching diesels dyno and MAYBE get a chance to dyno if the operators are feeling up to it when the last diesel has run.

They run an optical pickup (diesel) and my crank pulley is too hidden by the fan shroud and undertray to get a reading.

So, I had them switch to the inductive pickup which I put on the plug end of the leading plug wire and asked them to set the pickup to 720 degrees. After his blank look I told him to set it up as 6 cylinder. He said he wasn't getting a clean enough signal and ran it in road speed.

The weather station stats are right there on the bottom of the sheet if you want to calculate it as corrected.

I will have to calculate the torque line by gearing and tire height.

I wait from 9am to 4:30pm watching diesels dyno and MAYBE get a chance to dyno if the operators are feeling up to it when the last diesel has run.

They run an optical pickup (diesel) and my crank pulley is too hidden by the fan shroud and undertray to get a reading.

So, I had them switch to the inductive pickup which I put on the plug end of the leading plug wire and asked them to set the pickup to 720 degrees. After his blank look I told him to set it up as 6 cylinder. He said he wasn't getting a clean enough signal and ran it in road speed.

The weather station stats are right there on the bottom of the sheet if you want to calculate it as corrected.

I will have to calculate the torque line by gearing and tire height.

#23

Thank you for sharing. Did you make any adjustments on the tune for the dynojet or just another pull( zero changes vs the DD).

There was no adjustments between runs.

They didn't even have a fan in front of the dyno; the lowest run was actually the second pull.

After that 2nd run I asked my friend to spray my oil cooler and IC with my water sprayer. As you can see from the time stamps, just 30 seconds of that (roller decel took 30 seconds) and the HP recovered quite well.

There was no adjustments between runs.

They didn't even have a fan in front of the dyno; the lowest run was actually the second pull.

After that 2nd run I asked my friend to spray my oil cooler and IC with my water sprayer. As you can see from the time stamps, just 30 seconds of that (roller decel took 30 seconds) and the HP recovered quite well.

#24

once you get it tuned out i will be interested in your lower RPM traction. i do think this will be a factor w the EFR turbo line going forward. (maybe not a bad problem)

This is an interesting topic on the EFRs.

I actually find that it is much easier to maintain traction.

The old turbo went from having no power to full power over a shorter rpm span and so spun the tires up easily. The EFR starts right out with great power, so you don't have that sudden increase shocking the contact patch.

In addition, with the EFR and its BOV integrated into the anti-surge slot you can get any boost you want by varying the throttle position. It doesn't drop boost when you let off the throttle like my old turbo.

This means you can precisely backpedal to maintain traction.

This is an interesting topic on the EFRs.

I actually find that it is much easier to maintain traction.

The old turbo went from having no power to full power over a shorter rpm span and so spun the tires up easily. The EFR starts right out with great power, so you don't have that sudden increase shocking the contact patch.

In addition, with the EFR and its BOV integrated into the anti-surge slot you can get any boost you want by varying the throttle position. It doesn't drop boost when you let off the throttle like my old turbo.

This means you can precisely backpedal to maintain traction.

#25

For example of 6766 numbers, post #43 & 48

https://www.rx7club.com/single-turbo...1023860/page2/