Fuel Pumps 2014

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Fuel Pumps 2014: update June 2017 re Walbro

i continue to get a significant amount of PMs re Fuel Pump options. i did a "Fuel Pumps 2013" a year ago and it has become buried in this section so i thought it would be worthwhile to update and sticky this important subject....

the 13B rotary needs 30% more air than a piston engine to make equivalent power.

that means it needs 30% (+-) more fuel.

in order to make 600 rotary rwhp we need as much fuel as a 780 rwhp piston motor.

500 rotary requires similar air and fuel as a 650 piston setup.

in addition, we make our hp using forced induction, so the fuel pump must overcome the boost pressure working against it.

43.5 static rail pressure plus 20 psi boost means the fuel pump needs to work at 63.5 pressure.

flow drops as pressure increases.

let's take a look at fuel requirements. i am going to use 600 rotary rwhp. most of us probably won't be running that number but it is sort of a top number for dual purpose FDs and feel free to multiply it by .83 for 500 etc.

fuel certainly should be an overkill calculation.

let's assume:

we want to run 43.5 psi rail pressure at zero boost.

we want to run no more than 85% duty cycle.

we lose 13% deliverability to lag.

we want to run 30 psi max boost.

we want to make 600 SAE rwhp.

we want to be able to run down to 10.0 AFR

we want the numbers for gasoline & E85

600 rotary rwhp requires 1152 CFM

1152 CFM is 80 pounds per minute of air

at 10 AFR that is 8 pounds per minute of gasoline

8 pounds of gasoline is 1.26 gallons per minute. (GPM)

now let's figure how much E85 is needed:

1.26 GPM is 146,273 BTUs per minute to make 600 rotary rwhp at 10 AFR

E85 has 82,293 per gallon V gas at 116,090 so multiply gas times 1.41 for E85

1.26 GPM X 1.41 = 1.77 GPM for 600 hp w E85 at 10 AFR

measured in other increments...

NET GAS FOR 600 ROTARY RWHP AT 30 PSI

1.26 GPM

4770 CC/Minute

276 Liters per Hour

NET E85 FOR 600 ROTARY RWHP AT 30 PSI

1.77 GPM

6726 CC/Minute

389 Liters per Hour

do keep in mind w regard to fuel injector sizing these are NET of lag and 85% duty cycle.

in order to size injectors (GROSS) you need to multiply the above numbers by 1.35

for gas and 600 you need

4770 X 1.35 = 6440 CC/Min of (GROSS) stated injector capacity

for E85 and 600 you need

6726 X 1.35 = 9080 CC/Min of (GROSS) stated injector capacity

back to fuel pumps............

most are listed here but i am going to cut to the chase...

let's start with the highest flowing gasoline (only) drop in pump.

Walbro 9000262

notice the statement... "outperforms all current market in-tank fuel pumps" as well as "OE technology" OE as in failures are too expensive to tolerate. ask GM what failure is going to cost.

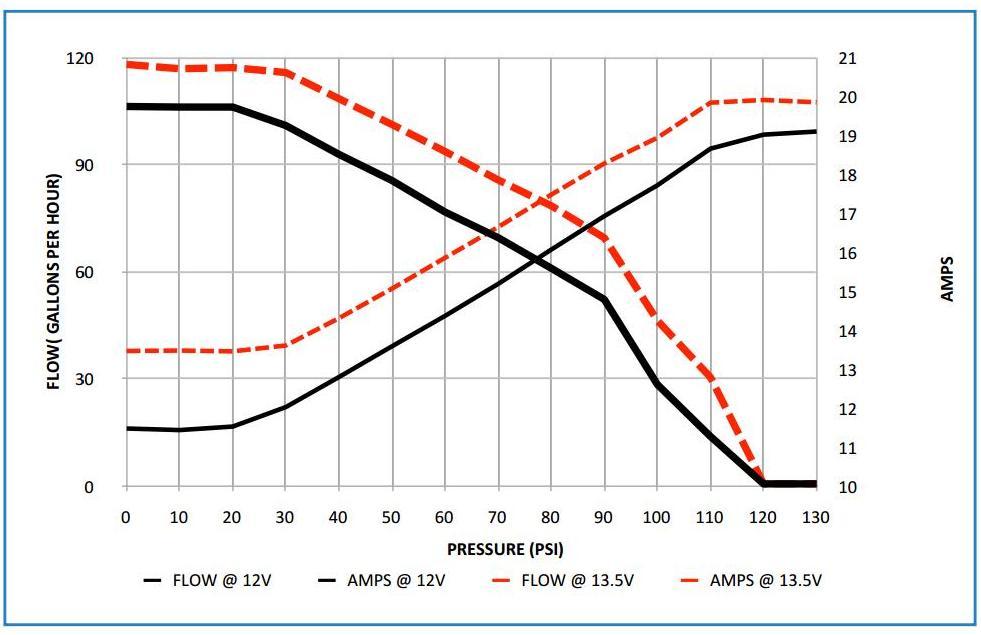

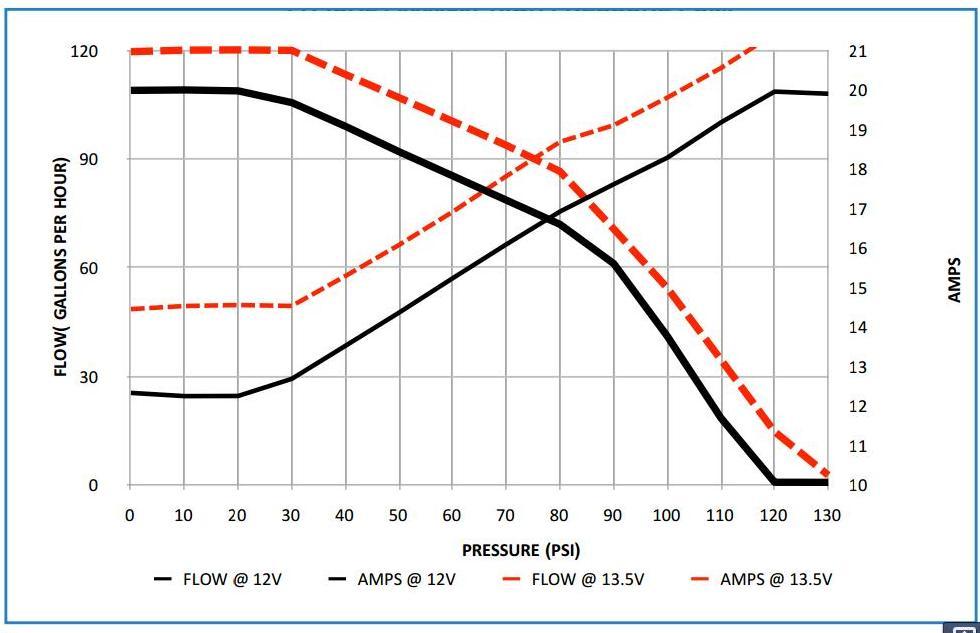

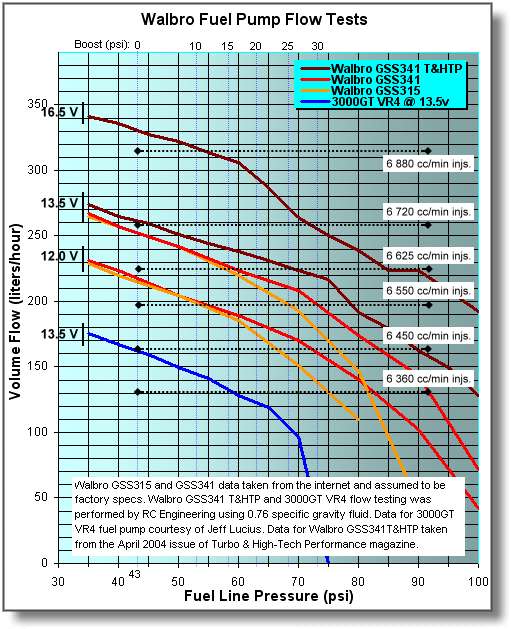

here's the "outperforms" picture...

80 gallons per hour/303 liters per hour/5050 cc per minute at 30 psi boost at 13.5 V

650 hp, a drop in at a friendly price.

E85 converts are even more interested in fuel pump delivery as approx 41% more volume is needed and the pump must stand up to alcohol...

here, again Walbro heads the list as to drop in big time delivery for E85...

drop in, OE build quality, purpose built for E85 and bargain priced.

did i mention killer delivery?

90 gallons per hour/341 liters per hour/5683 cc per minute at 30 psi boost and 13.5 V

you need 6511 of Net E85 for 600 so the pump alone will not get you there...

it will do 523 rw rotary hp. pls keep in mind i am at 10.0 AFR so if you want to not have the amount of reserve fuel i am comfortable w you can probably get it (600) done.

both Walbro pumps require an (additional) installation kit that includes the filter sock, about $30.

UPDATE June 2017

the E85 pump works fine for E85 AND gasoline. since it is a higher output pump it should be the choice. pump P/Ns listed above are for just the pump.

P/N for the pump and install kit:

the E85 pump and install kit is:

90000274

from the current Walbro site:

"Outperforms all current market in-tank fuel pumps

Designed for engines with more than 750 HP

Award-winning OE technology

High-pressure, high-flow performance OEM technology designed and developed for E85 Ethanol

Dual channel turbine design for maximum efficiency under high-pressure and high-temperature applications

Made in USA by TI Automotive (parent company of Walbro)

Outperforms all current market in-tank fuel pumps

Designed for engines with more than 750 HP

Award-winning OE technology

High-pressure, high-flow performance

OEM technology designed and developed for E85

Dual channel turbine design for maximum efficiency under high pressure and high temperature applications

Made in USA by TI Automotive (parent company of Walbro)

All pumping components have been validated to OEM specifications for approved use in E85/flex fuel applications

100% Authentic & Genuine Walbro/ TI Automotive E85 Racing In tank 450 LPH high pressure fuel pump with installation kit

TI Automotive Walbro TIA450-2 / F90000274 internal E85 HP RACING fuel pump plus Install kit

Installation kit ( fuel strainer, fuel hose, harness pigtail, 2 clamps, 2 wire connectors

The F90000274 requires modifications to system wiring, fuel lines and the fuel module, and should be professionally installed.

The innovative design of the DCSS 39/50 features a single impeller with two parallel rows of turbine blades.

Designed for high performance engines exceeding 750hp.

Designed for E85 or Gasoline applications.

The blades feed two high-pressure pumping channels, as opposed to a conventional single-stage pump that uses an impeller with a single row of blades at its outer edge.

This innovative design results in improved hot fuel flow, as well as minimal noise and current use, resulting in efficiency thatís 20 percent higher than conventional pumps. SPECIFICATIONS 465 lph @ 40 psi and 13.5V (14.1 amps) in gasoline Outlet diameter: 10mm (3/8") Diameter (upper body) 39mm Diameter (lower body) 50mm"

ENTER VOLTAGE...

first off, if you haven't hardwired your pump you are looking at 11. something volts and none of the above applies. you must hardwire your pump, larger wires, a 30 amp fuse (essential) and really good 30/40 amp relays complete the picture.

that all gets you to the above flow.

if you need more i suggest a Kenne Bell Boost A Pump (BAP).

here's a link to BAP Tech:

http://www.kennebell.net/KBWebsite/C...elpumptech.pdf

this simple $270 system allows you to add voltage to your fuel pump ONLY when you need it, in boost.

the flow difference between 13.5 V and 17 is FORTY PERCENT!

i ran a BAP on my Supra pump from 2004 to 2013. i currently run it on my Walbro E85 pump.

the next pump you may consider is the Aeromotive Stealth pump. it is a drop in gas pump and is a few clicks down from the Walbros mentioned above. i believe the pump is rebadged for AEM and FIC.

the Stealth flows 244 liters per hour or 4066 cc per minute at 30 psi boost and 13.5 V.

good for 523 rw rotary hp w my conservative assumptions.

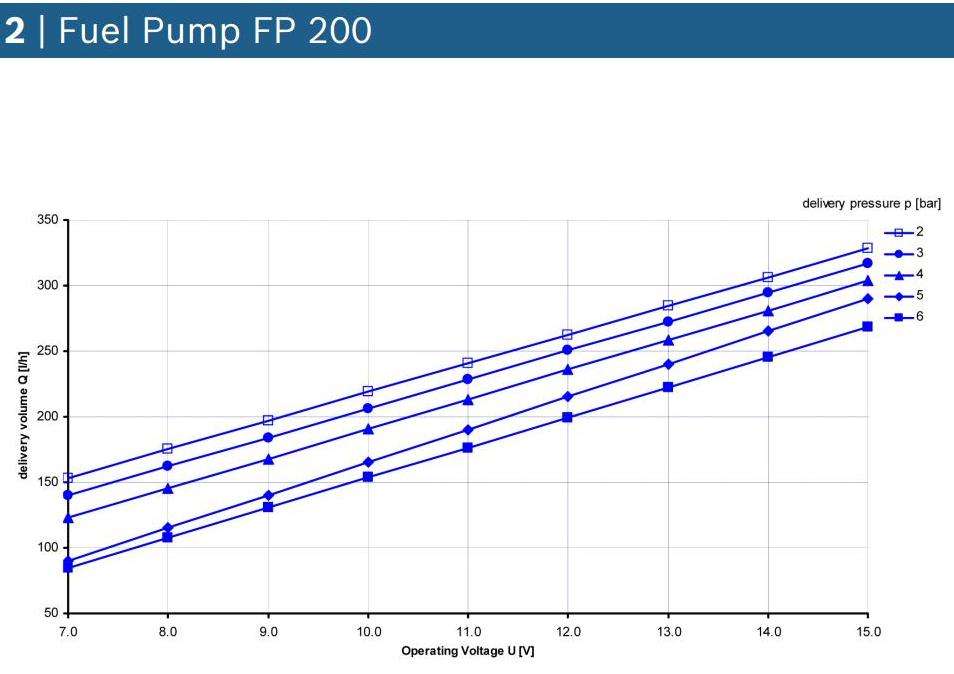

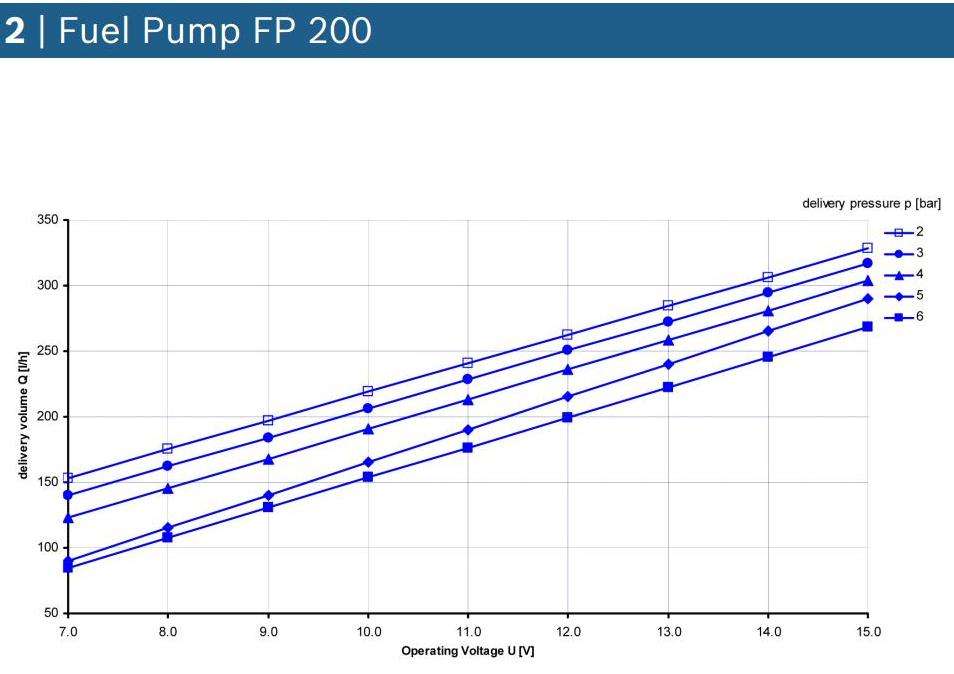

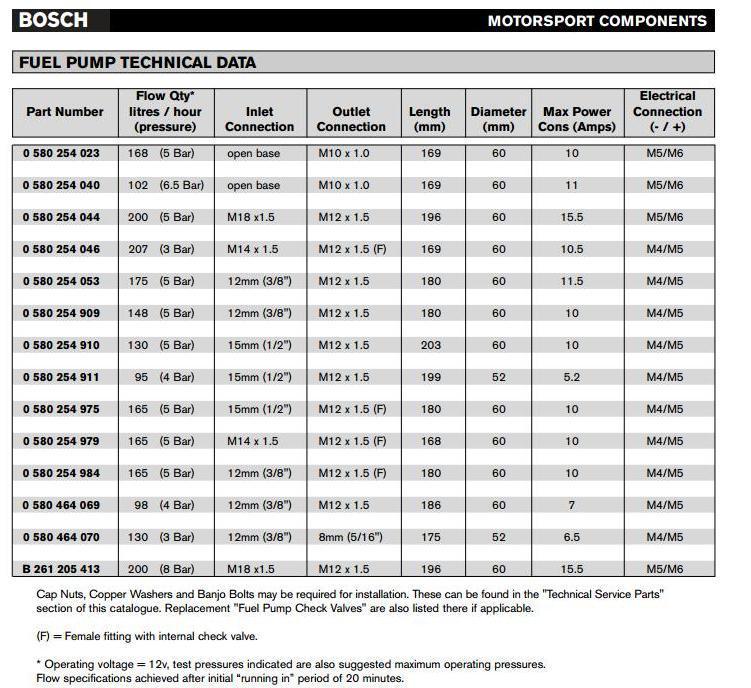

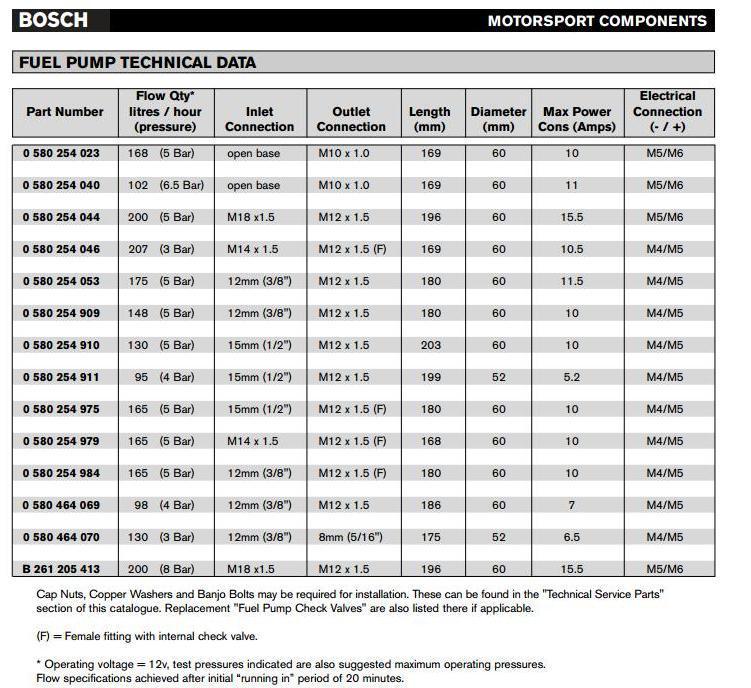

here is the Bosch 044.

at 13 V and 5 bar 72.5 psi (the second line from the bottom) the pump flows around 240 liters per hour. the chart is from the Bosch website. if you look around the net you will find other charts, some w unrecognizable outputs. it is easy to play w the outputs, lower viscosities, higher temps etc. i will buy Bosch numbers anytime.

using my subjective requirements (able to do 10 AFR, 85% duty cycle, 13% lag, 13 V) the 044 is good for 522 rw rotary hp.

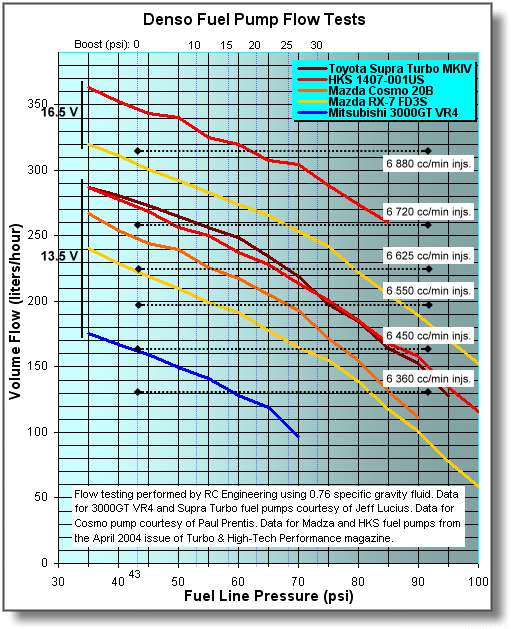

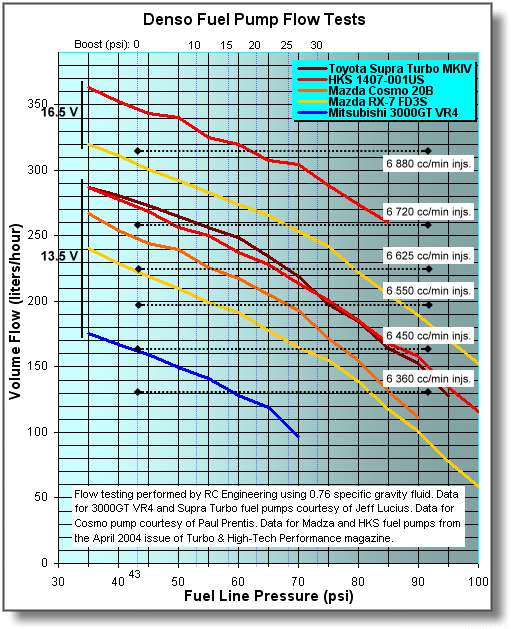

a couple of Denso pumps....

thanks Stealth316 for the chart.

as you can see there is quite a difference between the Cosmo and Supra pumps.

the Cosmo flows 170 Liters per Hour at 73

the Supra flows 205 Liters per hour at 73.

Cosmo P/N 195130-0771

Supra P/N 195130-1020

Cosmo good for 370 rotary rwhp w my assumptions

Supra good for 446 "

i made 514 w the Supra pump and a BAP and was in my car from 99 til 2013.

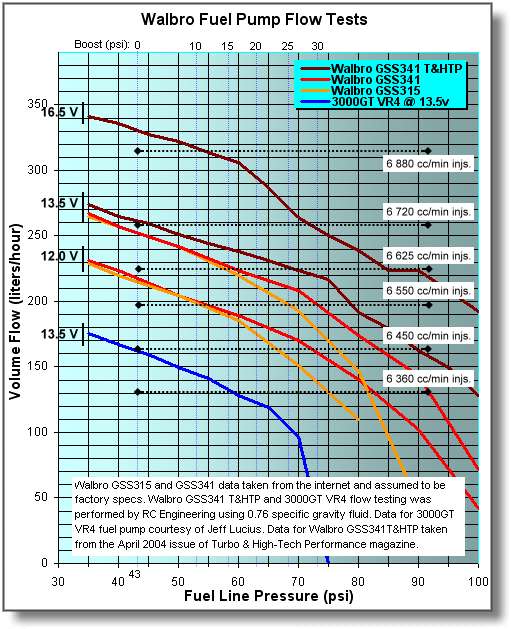

here's a spread of Walbro pumps

the often used GSS340/1 HP flows 220 at 13.5 V

VOLTS ARE THE ELEPHANT IN THE ROOM

consider:

Walbro GSS340 at 60 psi output pressure:

12 V 206 L/H

13.5 V 257 L/H 12.5% INCREASE N VOLTS = 24.7% INCREASE IN FLOW

17 V 351 L/H......... 41.6% INCREASE IN VOLTS = 70% INCREASE IN FLOW

21 V 440 L/H..........75% INCREASE IN VOLTS = 114% INCREASE IN FLOW

being able to set the volts in boost w the BAP certainly is a game changer.

I datalog fuel pressure so i KNOW what my pressure is at 8000. do you? i consider a digital logged fuel pressure essential. if you have the numbers you know your pump is performing, your filter isn't clogged and your lines are o k..

my 600 hp on E85 is solved w a BAP at 16 V and the Walbro E85 pump..

how well does this simple setup work?

between 7200 and 8900 the maximum difference between my boost and fuel pressure was seven tenths of one PSI.

until the emergence of the two higher flow drop in pumps double pumps have been the most popular answer as to fuel delivery. done properly they work fine. i prefer the BAP option as it eliminates excess cycling of fuel and the attendant heating that is created. the BAP works just like the turbo, only when needed.

i do get asked about some of the more race oriented options...

most trade higher delivery for lots of noise and excess re-cycling of fuel and are expensive.

the Weldon 2035 ($829 plus a really neat controller/option for $360) does 180 gallons per hour/

680 liters per hour/11,333 CC per minute... off the charts build quality and a great option if you are looking to make more than 1000 rwhp.

another option is the Fuelab series. around $540 and between 85 and 150 gallons per minute. they have a slick electrical fuel pressure regulator ($350) that controls pump output.

lots of good options to consider in 2014 and that's good as we do have thirsty motors.

any additional comments welcomed

Howard

the 13B rotary needs 30% more air than a piston engine to make equivalent power.

that means it needs 30% (+-) more fuel.

in order to make 600 rotary rwhp we need as much fuel as a 780 rwhp piston motor.

500 rotary requires similar air and fuel as a 650 piston setup.

in addition, we make our hp using forced induction, so the fuel pump must overcome the boost pressure working against it.

43.5 static rail pressure plus 20 psi boost means the fuel pump needs to work at 63.5 pressure.

flow drops as pressure increases.

let's take a look at fuel requirements. i am going to use 600 rotary rwhp. most of us probably won't be running that number but it is sort of a top number for dual purpose FDs and feel free to multiply it by .83 for 500 etc.

fuel certainly should be an overkill calculation.

let's assume:

we want to run 43.5 psi rail pressure at zero boost.

we want to run no more than 85% duty cycle.

we lose 13% deliverability to lag.

we want to run 30 psi max boost.

we want to make 600 SAE rwhp.

we want to be able to run down to 10.0 AFR

we want the numbers for gasoline & E85

600 rotary rwhp requires 1152 CFM

1152 CFM is 80 pounds per minute of air

at 10 AFR that is 8 pounds per minute of gasoline

8 pounds of gasoline is 1.26 gallons per minute. (GPM)

now let's figure how much E85 is needed:

1.26 GPM is 146,273 BTUs per minute to make 600 rotary rwhp at 10 AFR

E85 has 82,293 per gallon V gas at 116,090 so multiply gas times 1.41 for E85

1.26 GPM X 1.41 = 1.77 GPM for 600 hp w E85 at 10 AFR

measured in other increments...

NET GAS FOR 600 ROTARY RWHP AT 30 PSI

1.26 GPM

4770 CC/Minute

276 Liters per Hour

NET E85 FOR 600 ROTARY RWHP AT 30 PSI

1.77 GPM

6726 CC/Minute

389 Liters per Hour

do keep in mind w regard to fuel injector sizing these are NET of lag and 85% duty cycle.

in order to size injectors (GROSS) you need to multiply the above numbers by 1.35

for gas and 600 you need

4770 X 1.35 = 6440 CC/Min of (GROSS) stated injector capacity

for E85 and 600 you need

6726 X 1.35 = 9080 CC/Min of (GROSS) stated injector capacity

back to fuel pumps............

most are listed here but i am going to cut to the chase...

let's start with the highest flowing gasoline (only) drop in pump.

Walbro 9000262

notice the statement... "outperforms all current market in-tank fuel pumps" as well as "OE technology" OE as in failures are too expensive to tolerate. ask GM what failure is going to cost.

here's the "outperforms" picture...

80 gallons per hour/303 liters per hour/5050 cc per minute at 30 psi boost at 13.5 V

650 hp, a drop in at a friendly price.

E85 converts are even more interested in fuel pump delivery as approx 41% more volume is needed and the pump must stand up to alcohol...

here, again Walbro heads the list as to drop in big time delivery for E85...

drop in, OE build quality, purpose built for E85 and bargain priced.

did i mention killer delivery?

90 gallons per hour/341 liters per hour/5683 cc per minute at 30 psi boost and 13.5 V

you need 6511 of Net E85 for 600 so the pump alone will not get you there...

it will do 523 rw rotary hp. pls keep in mind i am at 10.0 AFR so if you want to not have the amount of reserve fuel i am comfortable w you can probably get it (600) done.

both Walbro pumps require an (additional) installation kit that includes the filter sock, about $30.

UPDATE June 2017

the E85 pump works fine for E85 AND gasoline. since it is a higher output pump it should be the choice. pump P/Ns listed above are for just the pump.

P/N for the pump and install kit:

the E85 pump and install kit is:

90000274

from the current Walbro site:

"Outperforms all current market in-tank fuel pumps

Designed for engines with more than 750 HP

Award-winning OE technology

High-pressure, high-flow performance OEM technology designed and developed for E85 Ethanol

Dual channel turbine design for maximum efficiency under high-pressure and high-temperature applications

Made in USA by TI Automotive (parent company of Walbro)

Outperforms all current market in-tank fuel pumps

Designed for engines with more than 750 HP

Award-winning OE technology

High-pressure, high-flow performance

OEM technology designed and developed for E85

Dual channel turbine design for maximum efficiency under high pressure and high temperature applications

Made in USA by TI Automotive (parent company of Walbro)

All pumping components have been validated to OEM specifications for approved use in E85/flex fuel applications

100% Authentic & Genuine Walbro/ TI Automotive E85 Racing In tank 450 LPH high pressure fuel pump with installation kit

TI Automotive Walbro TIA450-2 / F90000274 internal E85 HP RACING fuel pump plus Install kit

Installation kit ( fuel strainer, fuel hose, harness pigtail, 2 clamps, 2 wire connectors

The F90000274 requires modifications to system wiring, fuel lines and the fuel module, and should be professionally installed.

The innovative design of the DCSS 39/50 features a single impeller with two parallel rows of turbine blades.

Designed for high performance engines exceeding 750hp.

Designed for E85 or Gasoline applications.

The blades feed two high-pressure pumping channels, as opposed to a conventional single-stage pump that uses an impeller with a single row of blades at its outer edge.

This innovative design results in improved hot fuel flow, as well as minimal noise and current use, resulting in efficiency thatís 20 percent higher than conventional pumps. SPECIFICATIONS 465 lph @ 40 psi and 13.5V (14.1 amps) in gasoline Outlet diameter: 10mm (3/8") Diameter (upper body) 39mm Diameter (lower body) 50mm"

ENTER VOLTAGE...

first off, if you haven't hardwired your pump you are looking at 11. something volts and none of the above applies. you must hardwire your pump, larger wires, a 30 amp fuse (essential) and really good 30/40 amp relays complete the picture.

that all gets you to the above flow.

if you need more i suggest a Kenne Bell Boost A Pump (BAP).

here's a link to BAP Tech:

http://www.kennebell.net/KBWebsite/C...elpumptech.pdf

this simple $270 system allows you to add voltage to your fuel pump ONLY when you need it, in boost.

the flow difference between 13.5 V and 17 is FORTY PERCENT!

i ran a BAP on my Supra pump from 2004 to 2013. i currently run it on my Walbro E85 pump.

the next pump you may consider is the Aeromotive Stealth pump. it is a drop in gas pump and is a few clicks down from the Walbros mentioned above. i believe the pump is rebadged for AEM and FIC.

the Stealth flows 244 liters per hour or 4066 cc per minute at 30 psi boost and 13.5 V.

good for 523 rw rotary hp w my conservative assumptions.

here is the Bosch 044.

at 13 V and 5 bar 72.5 psi (the second line from the bottom) the pump flows around 240 liters per hour. the chart is from the Bosch website. if you look around the net you will find other charts, some w unrecognizable outputs. it is easy to play w the outputs, lower viscosities, higher temps etc. i will buy Bosch numbers anytime.

using my subjective requirements (able to do 10 AFR, 85% duty cycle, 13% lag, 13 V) the 044 is good for 522 rw rotary hp.

a couple of Denso pumps....

thanks Stealth316 for the chart.

as you can see there is quite a difference between the Cosmo and Supra pumps.

the Cosmo flows 170 Liters per Hour at 73

the Supra flows 205 Liters per hour at 73.

Cosmo P/N 195130-0771

Supra P/N 195130-1020

Cosmo good for 370 rotary rwhp w my assumptions

Supra good for 446 "

i made 514 w the Supra pump and a BAP and was in my car from 99 til 2013.

here's a spread of Walbro pumps

the often used GSS340/1 HP flows 220 at 13.5 V

VOLTS ARE THE ELEPHANT IN THE ROOM

consider:

Walbro GSS340 at 60 psi output pressure:

12 V 206 L/H

13.5 V 257 L/H 12.5% INCREASE N VOLTS = 24.7% INCREASE IN FLOW

17 V 351 L/H......... 41.6% INCREASE IN VOLTS = 70% INCREASE IN FLOW

21 V 440 L/H..........75% INCREASE IN VOLTS = 114% INCREASE IN FLOW

being able to set the volts in boost w the BAP certainly is a game changer.

I datalog fuel pressure so i KNOW what my pressure is at 8000. do you? i consider a digital logged fuel pressure essential. if you have the numbers you know your pump is performing, your filter isn't clogged and your lines are o k..

my 600 hp on E85 is solved w a BAP at 16 V and the Walbro E85 pump..

how well does this simple setup work?

between 7200 and 8900 the maximum difference between my boost and fuel pressure was seven tenths of one PSI.

until the emergence of the two higher flow drop in pumps double pumps have been the most popular answer as to fuel delivery. done properly they work fine. i prefer the BAP option as it eliminates excess cycling of fuel and the attendant heating that is created. the BAP works just like the turbo, only when needed.

i do get asked about some of the more race oriented options...

most trade higher delivery for lots of noise and excess re-cycling of fuel and are expensive.

the Weldon 2035 ($829 plus a really neat controller/option for $360) does 180 gallons per hour/

680 liters per hour/11,333 CC per minute... off the charts build quality and a great option if you are looking to make more than 1000 rwhp.

another option is the Fuelab series. around $540 and between 85 and 150 gallons per minute. they have a slick electrical fuel pressure regulator ($350) that controls pump output.

lots of good options to consider in 2014 and that's good as we do have thirsty motors.

any additional comments welcomed

Howard

Last edited by Howard Coleman; 06-13-17 at 09:36 AM.

The following users liked this post:

Namxi (01-28-22)

#3

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

I think that the readers of this article would be best served if you add a disclaimer that you are making up most of these numbers, and that they should consult a professional before selecting a fuel pump for their particular application.

#4

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

here's a chart on my Walbro E85 pump running at 16 volts powered by my Kenne Bell Boost A Pump setup from last Oct...

GT4094r, boost around 25.5 to 26 at 575 SAE, 588 STD rwhp

from 7239 to 8911, the greatest difference between rail pressure and boost was...

seven tenths of one psi.

i will be further testing the fuel delivery of this setup shortly w my BW EFR9180.

fuel pressure is absolute on this chart so rail pressure was approx 39.

howard

GT4094r, boost around 25.5 to 26 at 575 SAE, 588 STD rwhp

from 7239 to 8911, the greatest difference between rail pressure and boost was...

seven tenths of one psi.

i will be further testing the fuel delivery of this setup shortly w my BW EFR9180.

fuel pressure is absolute on this chart so rail pressure was approx 39.

howard

Last edited by Howard Coleman; 06-26-15 at 03:32 PM.

#6

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"Fuel Lab is the ticket"

I agree, Fuelab could be the ticket... as they offer a number of innovative fuel system components.

for instance they now offer their high flowing Prodigy line of pumps as an intank option.

the intank pumps use the familiar Prodigy power/pump modules which feature two pump speeds.

additional output control can be provided by using a PWM signal from an ECU or from Fuelabs innovative electrical output 529 Fuel Pressure Regulator. a PWM signal is provided off the fuel return line providing truly variable output control.

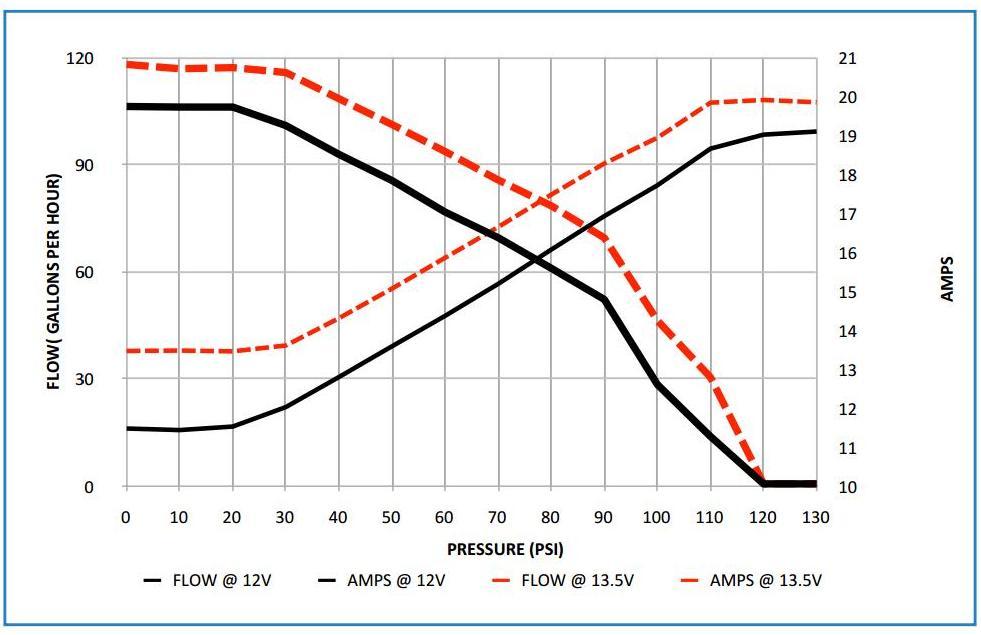

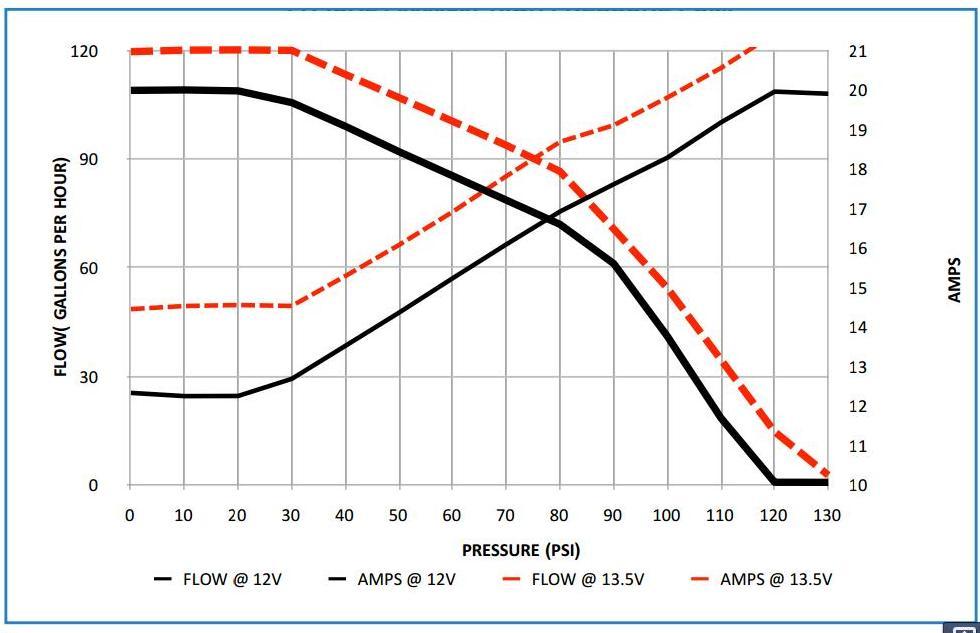

here's the flow chart for the two pumps...

all pumps are happy w gas, E85 or meth.

at 30 psi and 13.5 V

Walbro E85 intank 5683 CC per minute

Fuelab 40401 external 5425 CC per minute

Fuelab 41401 external 7444 CC per minute

output numbers above are NET to the motor, since lag and 85% suggested max duty cycle decrease flow the Grossed up number which represents Nominal Injector Capacity that the pumps will run is up 35%.

meaning

Walbro E85 pump will service 7672 CC of injectors at 13.5 V and 74 psi

Fuelab 40401 pump 7323 CC

Fuelab 41401 pump 10,050 CC

Fuelab states that their pumps will run fine at 16 V which could add an additional output of around 30%. (Kenne Bell BAP at plus 20%)

howard

I agree, Fuelab could be the ticket... as they offer a number of innovative fuel system components.

for instance they now offer their high flowing Prodigy line of pumps as an intank option.

the intank pumps use the familiar Prodigy power/pump modules which feature two pump speeds.

additional output control can be provided by using a PWM signal from an ECU or from Fuelabs innovative electrical output 529 Fuel Pressure Regulator. a PWM signal is provided off the fuel return line providing truly variable output control.

here's the flow chart for the two pumps...

all pumps are happy w gas, E85 or meth.

at 30 psi and 13.5 V

Walbro E85 intank 5683 CC per minute

Fuelab 40401 external 5425 CC per minute

Fuelab 41401 external 7444 CC per minute

output numbers above are NET to the motor, since lag and 85% suggested max duty cycle decrease flow the Grossed up number which represents Nominal Injector Capacity that the pumps will run is up 35%.

meaning

Walbro E85 pump will service 7672 CC of injectors at 13.5 V and 74 psi

Fuelab 40401 pump 7323 CC

Fuelab 41401 pump 10,050 CC

Fuelab states that their pumps will run fine at 16 V which could add an additional output of around 30%. (Kenne Bell BAP at plus 20%)

howard

Last edited by Howard Coleman; 06-26-15 at 03:33 PM.

#7

MagnaFuel MP 4303

Hi Howard,

Another Great post. Some help if you would.....

We are getting closer to completion with our circuit/track FD.

13B REW Bridgeport, BW 364 (.91), 6x 1680cc Inj (indy Blue), Xcessive LIM, E85.

AEM smart coils, AR3932 plugs, have NGK R6725-11 also.

3.5'' s/steel side exit exhaust, 6 speed sequential on 280x650x18 Hankooks.

Car weight 1050kg. + driver

We have installed 2x Carter Black 100GPH (16psi) lift pumps feeding the 3L surge tank, All lines are teflon braided, dash 10 feed to -8 split at rails, -6 rtn.

Main pump is the Magnafuel MP 4303 (2000hp) suitable for E85, we have struggled to find accurate data on these pumps (GPH or LPM).

We have read the pump is good for 1200rwhp on E85???

We are aiming for 550RW/Hp @ 20/25psi +/- boost.

Is it possible for you to run the numbers for us to confirm the setup is adequate, especially the main pump.

Many Many Thanks in advance.

Another Great post. Some help if you would.....

We are getting closer to completion with our circuit/track FD.

13B REW Bridgeport, BW 364 (.91), 6x 1680cc Inj (indy Blue), Xcessive LIM, E85.

AEM smart coils, AR3932 plugs, have NGK R6725-11 also.

3.5'' s/steel side exit exhaust, 6 speed sequential on 280x650x18 Hankooks.

Car weight 1050kg. + driver

We have installed 2x Carter Black 100GPH (16psi) lift pumps feeding the 3L surge tank, All lines are teflon braided, dash 10 feed to -8 split at rails, -6 rtn.

Main pump is the Magnafuel MP 4303 (2000hp) suitable for E85, we have struggled to find accurate data on these pumps (GPH or LPM).

We have read the pump is good for 1200rwhp on E85???

We are aiming for 550RW/Hp @ 20/25psi +/- boost.

Is it possible for you to run the numbers for us to confirm the setup is adequate, especially the main pump.

Many Many Thanks in advance.

Trending Topics

#8

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"Is it possible for you to run the numbers for us to confirm the setup is adequate, especially the main pump."

given that your main pump is a Magnafuel... not really.

the reason that Magnafuel is not in the thread is they don't provide a flow chart. they may make the best pumps available, and i am sure you could reverse calculate from their posted hp a crude flow chart, but i am not interested in doing their job.

as far as your needs...

550 is 1056 CFM or 72.9 pounds of air. 7.29 pounds of gas is 1.15 GPM

1.15 GPM is 4353 CC/Min X 1.41 for E85 = 6138 CC/Min

6138 CC/Min

368 liters per hour at 25 psi (really 25 plus your static rail pressure... for example:

43.5 + 25 or 68.5 psi.

so, 368 at 68.5

Hi to all at ViPEC/Link and the Green Bros in beautiful New Zealand and your car sounds like it is going to fly. nice choices on the components. i would try to stay w the copper/nickel plugs and am somewhat concerned w the platinum content w alcohol.

loving my V88,

Howard

given that your main pump is a Magnafuel... not really.

the reason that Magnafuel is not in the thread is they don't provide a flow chart. they may make the best pumps available, and i am sure you could reverse calculate from their posted hp a crude flow chart, but i am not interested in doing their job.

as far as your needs...

550 is 1056 CFM or 72.9 pounds of air. 7.29 pounds of gas is 1.15 GPM

1.15 GPM is 4353 CC/Min X 1.41 for E85 = 6138 CC/Min

6138 CC/Min

368 liters per hour at 25 psi (really 25 plus your static rail pressure... for example:

43.5 + 25 or 68.5 psi.

so, 368 at 68.5

Hi to all at ViPEC/Link and the Green Bros in beautiful New Zealand and your car sounds like it is going to fly. nice choices on the components. i would try to stay w the copper/nickel plugs and am somewhat concerned w the platinum content w alcohol.

loving my V88,

Howard

Last edited by Howard Coleman; 06-26-15 at 03:34 PM.

#9

Much appreciated Howard,

As far as Injectors go - we have 6x1600cc (1680cc rated) + 9600cc min @ 100%.

8160cc @ 85% so we have plenty of reserve.

As you calculated we need 6100cc approx, so we are good here.

We will do some digging with Magnafuel on flow ratings, they suggest a test of flow after the reg once installed, @ 25psi I dont think so...

Is there a safe way we could test the flow rating. Info on these pumps is pour considering the cost, although very well built & fully rebuildable.

Just spoke with Magnafuel USA, MP4303 will flow the following:

12V @ 70psi = 2.1 GPM

16V @ 70psi = 2.85 GPM

Therefore we should have sufficient supply..

Yes we are looking forward to setting some fast lap times after a long build.

Thanks again,

Mark

As far as Injectors go - we have 6x1600cc (1680cc rated) + 9600cc min @ 100%.

8160cc @ 85% so we have plenty of reserve.

As you calculated we need 6100cc approx, so we are good here.

We will do some digging with Magnafuel on flow ratings, they suggest a test of flow after the reg once installed, @ 25psi I dont think so...

Is there a safe way we could test the flow rating. Info on these pumps is pour considering the cost, although very well built & fully rebuildable.

Just spoke with Magnafuel USA, MP4303 will flow the following:

12V @ 70psi = 2.1 GPM

16V @ 70psi = 2.85 GPM

Therefore we should have sufficient supply..

Yes we are looking forward to setting some fast lap times after a long build.

Thanks again,

Mark

Last edited by BatmanNZ3; 05-15-14 at 04:08 PM. Reason: Additional Info added

#11

Just curious what a dual Bosch 040 setup would be good for on e85. In Radium's test Radium Engineering - Tech Articles it showed that it flowed well less than all other pumps, but it also used less amperage that the others. I think a single 044 flows a lot, but two seem like a lot of overkill for my goals.

S363 <30psi e85.

Maybe the lower flow would result in cooler gas than dual 044s at 30psi would be at about 30 amps, whereas a pair of 040s would be at 16, and the dual Walbro e85 pump would be at 34 amps. Does amperage have any indication to how much it heat the fuel?

040 Flow suggests ~180 lph between 4.5 (21.75 lbs) and 5 bar (29 lbs) totaling ~360 lph.

I'm on a Borg Warner S363 so I'm guessing ~ 500hp. I've heard 550 thrown around so I'm wanting to make sure I have the fuel for that just in case I run into that. Is 360 lph (~15 lph more than the Walbro e85) about sufficient and preferable to dual 044s for this setup? Realistically I'm expecting to be around the 25 psi mark +/- a couple pounds.

Thanks for any feedback.

S363 <30psi e85.

Maybe the lower flow would result in cooler gas than dual 044s at 30psi would be at about 30 amps, whereas a pair of 040s would be at 16, and the dual Walbro e85 pump would be at 34 amps. Does amperage have any indication to how much it heat the fuel?

040 Flow suggests ~180 lph between 4.5 (21.75 lbs) and 5 bar (29 lbs) totaling ~360 lph.

I'm on a Borg Warner S363 so I'm guessing ~ 500hp. I've heard 550 thrown around so I'm wanting to make sure I have the fuel for that just in case I run into that. Is 360 lph (~15 lph more than the Walbro e85) about sufficient and preferable to dual 044s for this setup? Realistically I'm expecting to be around the 25 psi mark +/- a couple pounds.

Thanks for any feedback.

#12

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Borg Warner S363

Max is approx 75 pounds of air at 29 psi.

the pump will have to work against the 29, call it 30, and 43.5 of static rail pressure so let's use 73 or 5 bar which is (14.5 X 5 = 72.5) as Max.

using my conservative 10 AFR suggestion

73 pounds of air per minute

7.3 pounds of fuel per minute

7.3/ 6.35 (weight of gas per gallon) = 1.149 gallons per minute

or after Googling: "1.149 gallons per minute to cc per minute"

4349 CC per minute of gasoline NET into the motor for your turbo's max output. we use the Net number for fuel pumps and the Gross number for fuel injectors... (see Fuel Injector sticky thread)

4349 CC per minute is 261 Liters per hour (again, thanks Google convertor function)

looking at fuel pump flow charts at 5 Bar...

Walbro 262 Gas 303 Liters per hour

Walbro 267 E85 341 Liters per hour

Stealth 244

Bosch 044 240

Walbro 255 220

Supra 205

Bosch 040 180

FWIW, i used a Bosch external 044 derivative to run my 100% methanol AI system for 3 years and it stood up to the methanol which is more corrosive than ethanol/E85. Bosch suggests that the internals aren't designed for alcohol but...

courtesy of Bosch Motorsports here are the details re their spread of pumps. pls note that flow numbers are at 12 Volts, not the 13.5 number generally used in this thread.

at 12 V the 044 makes 12.9 liters per hour per amp

at 12 V the 040 makes 9.27 liters per hour per amp

note according to Bosch's own data (chart in post one)

the 044 makes 240 L/hour at 13 V!

8.3% increase in volts produces 20% more flow!

i spoke w the Jim at Kenne Bell friday....

according to their very well executed flow bench the Walbro E85 pump makes:

389 Liters per hour at 60 psi on 13.5 volts and...............

568 liters per hour at 16 volts.

an 18.5% increase in volts produces 46% more flow

please do understand that if you haven't uprated the connections, fuses, relays etc you are probably running at 11 point something, not the 13.5 that produces the flow in most of the foregoing charts.

Jim spoke quite a bit about fuel heating and the consequences. various key parts of gasoline vaporize around 90 degrees F. if you are constantly running an overkill flow system you are heating the gas which ends up as vapor above the liquid in your tank. the best setup is to have the flow only when needed.

the vaporisation issue is why Ford has gone to a non-return fuel system according to Jim.

Kenne Bell has changed their Boost A Pump recently and eliminated the "Cockpit Controller" which allows the owner to set Volt gain. the system is set for 17 Volts and that setting is too much for the Walbro 262 and 267.

i have always run my BAP at +20% gain or just under 16 V. i have had no pump problems though i did blow a 20 A fuse which should never have been in my system.

i am working w Jim to get the controller back as just running 16 V makes a huge flow difference and will not hurt the pump.

one important and, IMO, currently unsettled factor is the relationship between power and fuel volume between E85 and gasoline.

gasoline is pretty much settled and we know that gasoline, all gasoline including race gas has 116,090 BTUs per gallon.

we also know that ethanol has 76,330. adjusting for 83% Ethanol, 15% gas and 2% poison E85 works out to be approx 82,300 BTUs.

116,090/82,300 = 1.41

on a BTU Basis we need 41% volume of E85 than gasoline.

i believe, according to my limited experience that there are other factors that effect the relationship. simply put, alcohol and gasoline translate somewhat differently into power than strictly on a BTU basis.

i find my E85 fuel consumption is much less than the 41% BTU relationship. while there is plenty of data re E85/Power relationships there is modest data available when it comes to a turbo rotary. there are a number of people on our board that have been running E85 very successfully and probably have the data.

it would be very helpful if you would post your HP, fuel injector sizing, max fuel injector duty cycle, static fuel pressure and boost.

one of my objectives in 2014 is to come up w a answer to this relationship. doing a fuel system at present i would use the 1.41 relationship as it is better to be on the safe side.

howard

Max is approx 75 pounds of air at 29 psi.

the pump will have to work against the 29, call it 30, and 43.5 of static rail pressure so let's use 73 or 5 bar which is (14.5 X 5 = 72.5) as Max.

using my conservative 10 AFR suggestion

73 pounds of air per minute

7.3 pounds of fuel per minute

7.3/ 6.35 (weight of gas per gallon) = 1.149 gallons per minute

or after Googling: "1.149 gallons per minute to cc per minute"

4349 CC per minute of gasoline NET into the motor for your turbo's max output. we use the Net number for fuel pumps and the Gross number for fuel injectors... (see Fuel Injector sticky thread)

4349 CC per minute is 261 Liters per hour (again, thanks Google convertor function)

looking at fuel pump flow charts at 5 Bar...

Walbro 262 Gas 303 Liters per hour

Walbro 267 E85 341 Liters per hour

Stealth 244

Bosch 044 240

Walbro 255 220

Supra 205

Bosch 040 180

FWIW, i used a Bosch external 044 derivative to run my 100% methanol AI system for 3 years and it stood up to the methanol which is more corrosive than ethanol/E85. Bosch suggests that the internals aren't designed for alcohol but...

courtesy of Bosch Motorsports here are the details re their spread of pumps. pls note that flow numbers are at 12 Volts, not the 13.5 number generally used in this thread.

at 12 V the 044 makes 12.9 liters per hour per amp

at 12 V the 040 makes 9.27 liters per hour per amp

note according to Bosch's own data (chart in post one)

the 044 makes 240 L/hour at 13 V!

8.3% increase in volts produces 20% more flow!

i spoke w the Jim at Kenne Bell friday....

according to their very well executed flow bench the Walbro E85 pump makes:

389 Liters per hour at 60 psi on 13.5 volts and...............

568 liters per hour at 16 volts.

an 18.5% increase in volts produces 46% more flow

please do understand that if you haven't uprated the connections, fuses, relays etc you are probably running at 11 point something, not the 13.5 that produces the flow in most of the foregoing charts.

Jim spoke quite a bit about fuel heating and the consequences. various key parts of gasoline vaporize around 90 degrees F. if you are constantly running an overkill flow system you are heating the gas which ends up as vapor above the liquid in your tank. the best setup is to have the flow only when needed.

the vaporisation issue is why Ford has gone to a non-return fuel system according to Jim.

Kenne Bell has changed their Boost A Pump recently and eliminated the "Cockpit Controller" which allows the owner to set Volt gain. the system is set for 17 Volts and that setting is too much for the Walbro 262 and 267.

i have always run my BAP at +20% gain or just under 16 V. i have had no pump problems though i did blow a 20 A fuse which should never have been in my system.

i am working w Jim to get the controller back as just running 16 V makes a huge flow difference and will not hurt the pump.

one important and, IMO, currently unsettled factor is the relationship between power and fuel volume between E85 and gasoline.

gasoline is pretty much settled and we know that gasoline, all gasoline including race gas has 116,090 BTUs per gallon.

we also know that ethanol has 76,330. adjusting for 83% Ethanol, 15% gas and 2% poison E85 works out to be approx 82,300 BTUs.

116,090/82,300 = 1.41

on a BTU Basis we need 41% volume of E85 than gasoline.

i believe, according to my limited experience that there are other factors that effect the relationship. simply put, alcohol and gasoline translate somewhat differently into power than strictly on a BTU basis.

i find my E85 fuel consumption is much less than the 41% BTU relationship. while there is plenty of data re E85/Power relationships there is modest data available when it comes to a turbo rotary. there are a number of people on our board that have been running E85 very successfully and probably have the data.

it would be very helpful if you would post your HP, fuel injector sizing, max fuel injector duty cycle, static fuel pressure and boost.

one of my objectives in 2014 is to come up w a answer to this relationship. doing a fuel system at present i would use the 1.41 relationship as it is better to be on the safe side.

howard

Last edited by Howard Coleman; 06-26-15 at 03:35 PM.

#13

Here's something I hadn't quite thought of, but if I were to a mix a gallon or two of 93 octane gasoline with e85 might that make the Walbro e85 a viable pump for me with no pump booster. Looks like trips to the gas station may seem a bit silly hitting up two pumps and having measuring cups in hand. All the things that make e85 desirable are available down to e50 levels aren't they?

#14

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"All the things that make e85 desirable are available down to e50 levels aren't they?"

i have heard lots of comments that most of the detonation prevention/cooling do work very well with as low as 50% ethanol. i note that my FFS was showing 75% ethanol on most of my runs that showed no knock.

howard

i have heard lots of comments that most of the detonation prevention/cooling do work very well with as low as 50% ethanol. i note that my FFS was showing 75% ethanol on most of my runs that showed no knock.

howard

Last edited by Howard Coleman; 06-26-15 at 03:36 PM.

#16

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

VOLTAGE to the pump, your fuel flow turbocharger

Walbro E85 pump 900267

13.5 V 389 Liters per hour

16 V 568 Liters per Hour

an 18% increase in volts =s 46% increase in fuel flow at 60 PIS.

as per Jim Bell/Kenne Bell/ fuel flow bench.

since both the Kenne Bell and the MSD unit (thanks gxl90rx7) work only in boost you don't get the over recycling of fuel which does tend to add heat.

combine either product w the newer Walbro intank pump and most have fuel needs covered.

i looked at both the Kenne Bell Boost A Pump (BAP) and the MSD product in 2004 and decided in favor the the BAP. unlike the MSD unit, the BAP has a separate boost solenoid that situates in the engine compartment. you will see it in the plastic bag. since it is very small it is a non factor spacewise in a typically cluttered engine compartment. since it sends a signal (boost) to the module via two small wires it allows the command module to situate where it belongs, near the battery (pass side rear compartment) and near the fuel pump.

the MSD unit has the boost solenoid within the module so it must be in the engine compartment. that means if your battery is in the rear you will need to run significant sized wires up to the engine compartment and then all the way back to the pump.

the current drawback is the BAP now has a 17 volt floor which doesn't work w the new Walbro pumps according to KB.

the fix is to use a resistor to step down the output or go w the MSD setup.

the MSD unit was recently upgraded and is now Windows based and apparently offers pretty much any Voltage so you don't have to do the resisitor to show the pump 16.0 V.

both units are priced close... BAP is generally available direct from KB at $280 and the MSD unit is $309 on AMZ.

properly fixtured, they take fuel out of the picture.

BTW, i also run KB's Boost A Spark.... adj V to the coil only in boost.

howard

Walbro E85 pump 900267

13.5 V 389 Liters per hour

16 V 568 Liters per Hour

an 18% increase in volts =s 46% increase in fuel flow at 60 PIS.

as per Jim Bell/Kenne Bell/ fuel flow bench.

since both the Kenne Bell and the MSD unit (thanks gxl90rx7) work only in boost you don't get the over recycling of fuel which does tend to add heat.

combine either product w the newer Walbro intank pump and most have fuel needs covered.

i looked at both the Kenne Bell Boost A Pump (BAP) and the MSD product in 2004 and decided in favor the the BAP. unlike the MSD unit, the BAP has a separate boost solenoid that situates in the engine compartment. you will see it in the plastic bag. since it is very small it is a non factor spacewise in a typically cluttered engine compartment. since it sends a signal (boost) to the module via two small wires it allows the command module to situate where it belongs, near the battery (pass side rear compartment) and near the fuel pump.

the MSD unit has the boost solenoid within the module so it must be in the engine compartment. that means if your battery is in the rear you will need to run significant sized wires up to the engine compartment and then all the way back to the pump.

the current drawback is the BAP now has a 17 volt floor which doesn't work w the new Walbro pumps according to KB.

the fix is to use a resistor to step down the output or go w the MSD setup.

the MSD unit was recently upgraded and is now Windows based and apparently offers pretty much any Voltage so you don't have to do the resisitor to show the pump 16.0 V.

both units are priced close... BAP is generally available direct from KB at $280 and the MSD unit is $309 on AMZ.

properly fixtured, they take fuel out of the picture.

BTW, i also run KB's Boost A Spark.... adj V to the coil only in boost.

howard

Last edited by Howard Coleman; 06-26-15 at 03:37 PM.

#18

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"Boost A Spark system"

i do run the Kenne Bell Boost A Spark (BAS). i like it because, similar to the BAP, it works only in boost and it is adjustable as to output. the IGN-1A coils have a built in volt limiter at either 17 or 18 volts, i forget which, but do respond to additional input voltage. i am running them at 15V in boost.

my BAS control module is near my battery in the pass side compartment behind the seat.

there are some who believe that the turbo rotary is happiest at high power levels at a rich AFR and the only limiting factor is ignition capability.

given we have 80 cubic inch (1.3L) motors capable of making 500 rwhp or more the combustion pressure and heat has to be crazy.... it takes a lot of ignition power to light such a mixture.

no matter which way you go, ignition is extremely important in our motors.

hc

i do run the Kenne Bell Boost A Spark (BAS). i like it because, similar to the BAP, it works only in boost and it is adjustable as to output. the IGN-1A coils have a built in volt limiter at either 17 or 18 volts, i forget which, but do respond to additional input voltage. i am running them at 15V in boost.

my BAS control module is near my battery in the pass side compartment behind the seat.

there are some who believe that the turbo rotary is happiest at high power levels at a rich AFR and the only limiting factor is ignition capability.

given we have 80 cubic inch (1.3L) motors capable of making 500 rwhp or more the combustion pressure and heat has to be crazy.... it takes a lot of ignition power to light such a mixture.

no matter which way you go, ignition is extremely important in our motors.

hc

Last edited by Howard Coleman; 06-26-15 at 03:38 PM.

#20

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Supra at 13.5 v and 17 psi boost w 5 psi line loss:

delivery is 3958 CC/Minute

fuel injectors at 85% max IDC and 13% lag:

3919 CC/Minute

using the above assumptions you are O K.

there is one elephant in the room... or shall i say turbo.

17 psi boost is 2.16 on the boost Y scale. if you look eastward on the flow scale you will see that 62 pounds per minute is max flow .

62 pounds per minute at 60% efficiency is 467 (max) rotary rwhp. since you have fuel for 500 you are O K.

there are two howevers.

1. while BW did not post past 65% there is additional flow at lower efficiencies. more flow and you are lean. additional flow is available eastward until the RPM line goes vertical.

2. boost spike.

if you look upward on the map you will see at higher boost (upward) higher flow is delivered up to 73 pounds (550 hp at 60% 594 at 65%)

if you get a boost spike you will run out of fuel. if you have the newer generation of apex seals you will probably only collapse your corner seal springs, but you will end up pulling your motor.

a Kenne Bell Boost A Pump will totally fix your fuel pump deliverability but w the BW 8374 you really should consider larger injectors.

you can raise the static pressure setting to gain deliverability but you will go richer at idle if you are running a Power FC. your secondary injectors can be run at as much as 8 BAR or 116 psi but your primary injectors will not work at these pressure levels. deliverability goes up w the square root of the pressure change, i e a 10% pressure increase adds 4.8% flow.

the 8374 is a lot more turbo, flow wise, and that flow level needs to be respected.

i always recommend that a system be fuel for max turbo output to guard against broken motors.

howard

delivery is 3958 CC/Minute

fuel injectors at 85% max IDC and 13% lag:

3919 CC/Minute

using the above assumptions you are O K.

there is one elephant in the room... or shall i say turbo.

17 psi boost is 2.16 on the boost Y scale. if you look eastward on the flow scale you will see that 62 pounds per minute is max flow .

62 pounds per minute at 60% efficiency is 467 (max) rotary rwhp. since you have fuel for 500 you are O K.

there are two howevers.

1. while BW did not post past 65% there is additional flow at lower efficiencies. more flow and you are lean. additional flow is available eastward until the RPM line goes vertical.

2. boost spike.

if you look upward on the map you will see at higher boost (upward) higher flow is delivered up to 73 pounds (550 hp at 60% 594 at 65%)

if you get a boost spike you will run out of fuel. if you have the newer generation of apex seals you will probably only collapse your corner seal springs, but you will end up pulling your motor.

a Kenne Bell Boost A Pump will totally fix your fuel pump deliverability but w the BW 8374 you really should consider larger injectors.

you can raise the static pressure setting to gain deliverability but you will go richer at idle if you are running a Power FC. your secondary injectors can be run at as much as 8 BAR or 116 psi but your primary injectors will not work at these pressure levels. deliverability goes up w the square root of the pressure change, i e a 10% pressure increase adds 4.8% flow.

the 8374 is a lot more turbo, flow wise, and that flow level needs to be respected.

i always recommend that a system be fuel for max turbo output to guard against broken motors.

howard

Last edited by Howard Coleman; 06-26-15 at 03:39 PM.

#22

Thanks Howard,

So, I could either boost the pump (or run a higher flowing or dual supra pump), and you're saying I also need more injector than the 550/2000 combo?

I've also noticed that some people redo the lines underneath the car (remove the hardlines), but I'm not sure why really. Is this really necessary? I'm looking to do a very simple, OE-as-possible sort of set up.

P

So, I could either boost the pump (or run a higher flowing or dual supra pump), and you're saying I also need more injector than the 550/2000 combo?

I've also noticed that some people redo the lines underneath the car (remove the hardlines), but I'm not sure why really. Is this really necessary? I'm looking to do a very simple, OE-as-possible sort of set up.

P

#23

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Peter,

you have enough pump for 500 rwhp.

you have enough fuel injector (550 plus 2100) for 500 rwhp

the 8374 can make 600 rotary.. 72 pounds at 68% efficiency, yes it will do it according to the comp map.

wastegates can stick

600 takes 4766 CC per minute net of lag but at 100% duty cycle which is fine as you are just at that point for a moment before you lift.

your fuel injectors will do 4506 so close enough IMO.

that just leaves you w a pump issue since your pump will do 3958 at 17 psi and less at the higher spike boost assumption.

IMO the solution is simple. rather than going w 2 pumps and getting into the plumbing business along w having your fuel recycling at a high rate just add a Boost A Pump. it only works in boost and you will soon forget it is in your car. set it at plus 20% volt gain.

i highly recommend you read Kenne Bell's Tech Section:

http://www.kennebell.net/KBWebsite/C...elpumptech.pdf

if you go w the BAP, make sure you call Kenne Bell, ask for Mike and stipulate as per Jim Bell, you want the 13.5 V model.

howard

you have enough pump for 500 rwhp.

you have enough fuel injector (550 plus 2100) for 500 rwhp

the 8374 can make 600 rotary.. 72 pounds at 68% efficiency, yes it will do it according to the comp map.

wastegates can stick

600 takes 4766 CC per minute net of lag but at 100% duty cycle which is fine as you are just at that point for a moment before you lift.

your fuel injectors will do 4506 so close enough IMO.

that just leaves you w a pump issue since your pump will do 3958 at 17 psi and less at the higher spike boost assumption.

IMO the solution is simple. rather than going w 2 pumps and getting into the plumbing business along w having your fuel recycling at a high rate just add a Boost A Pump. it only works in boost and you will soon forget it is in your car. set it at plus 20% volt gain.

i highly recommend you read Kenne Bell's Tech Section:

http://www.kennebell.net/KBWebsite/C...elpumptech.pdf

if you go w the BAP, make sure you call Kenne Bell, ask for Mike and stipulate as per Jim Bell, you want the 13.5 V model.

howard

Last edited by Howard Coleman; 06-26-15 at 03:40 PM.