Big injectors and fuel pulsations

#1

Big injectors and fuel pulsations

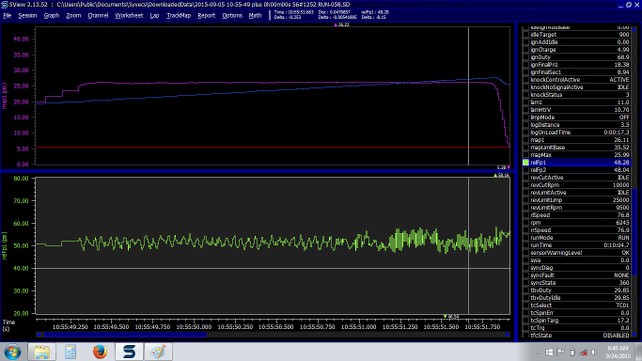

Recently finished up a car that is running a flex fuel setup and some decent sized injectors. The assembly of parts I would consider pretty common and would not have expected the issues we saw and never would have known we were having issues without some good instrumentation and datalogging. The car runs 2 x ID1300 primary and 4 x ID1700 secondary injectors. And 2 x Ti/Walbro 450lph pumps mounted in-tank. The issue was fuel pressure pulsations. At idle we'd see +/- 2-3 psi and that would continue as long as it was running on the primaries only. Once the secondaries came on line the pulsations went to as much as +10 psi and -30 psi! The scary part, in retrospect, was that you never felt the issue. I had the car on the dyno and it ran fine. We cut that first dyno session short because we had some boost control issues we wanted to address. It was only after we got the car off the dyno and spent some time diving into the datalogs that the issue showed up. A screehsot of a log of that first session is shown below.

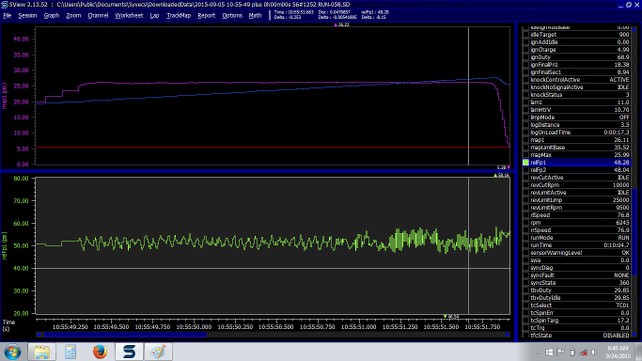

First thing we did was replace the fuel pressure regulator. It was running an Aeromotive A1000 regulator and we swapped that for a Turbosmart unit. No change. We then looked at fuel pump pickup to make sure we didn't have any restrictions. We looked at a bunch of other common issues and nothing touched the issue. In the end we picked up a pulsation damper from Radium and added it to the secondary rail. The results were pressure fluctuation at idle was now +/- a couple tenths of a psi. Under load we now saw a max fluctuation of -10 psi with very little positive spikes. Screen shot below.

In the end, the information was eye opening to me. The assembly of parts is pretty common and anyone in this community would probably say that it's a proven setup and should work with no issues. In retrospect, there was some slight oddities in the fuel mapping created by the fluctuations but, other than that, you would never feel the issue when driving. I can see anyone bolting these parts together and saying they had a good fuel system and never suspecting an issue like this. In the end, an inexpensive part allow everything to work much, much better. I'll never overlook a pulsation damper again and would now consider it a part of any complete fuel system; specifically a system with four relatively large injectors on the one secondary rail. The rotary creates a unique problem here relative to a 4-cylinder or V8 with four injectors on each rail as the rotary will pulse two of those injectors at the same time and all four injectors every 360* of crank rotation v. the sequential firing of the piston engine and only firing all four injector once per 720* of rotation. Pulsation damper, think about it!

First thing we did was replace the fuel pressure regulator. It was running an Aeromotive A1000 regulator and we swapped that for a Turbosmart unit. No change. We then looked at fuel pump pickup to make sure we didn't have any restrictions. We looked at a bunch of other common issues and nothing touched the issue. In the end we picked up a pulsation damper from Radium and added it to the secondary rail. The results were pressure fluctuation at idle was now +/- a couple tenths of a psi. Under load we now saw a max fluctuation of -10 psi with very little positive spikes. Screen shot below.

In the end, the information was eye opening to me. The assembly of parts is pretty common and anyone in this community would probably say that it's a proven setup and should work with no issues. In retrospect, there was some slight oddities in the fuel mapping created by the fluctuations but, other than that, you would never feel the issue when driving. I can see anyone bolting these parts together and saying they had a good fuel system and never suspecting an issue like this. In the end, an inexpensive part allow everything to work much, much better. I'll never overlook a pulsation damper again and would now consider it a part of any complete fuel system; specifically a system with four relatively large injectors on the one secondary rail. The rotary creates a unique problem here relative to a 4-cylinder or V8 with four injectors on each rail as the rotary will pulse two of those injectors at the same time and all four injectors every 360* of crank rotation v. the sequential firing of the piston engine and only firing all four injector once per 720* of rotation. Pulsation damper, think about it!

#3

Here you can see my creative mounting of the FPD I purchased from Radium. Mounted to the end of the primary rail using a combination of fittings and also I had to tap out the center of the bore of the FPD instead of using the external threads. This allowed me to mount it to the end of a "T".

FYI, the damper sold by Radium appears to be a oem part for a Kia, maybe a Sportage.

Also I saw during my research that CJM is now incorporating a FPD into their fuel rail kit. Looks like they use an oem part from Nissan R35 skyline.

FYI, the damper sold by Radium appears to be a oem part for a Kia, maybe a Sportage.

Also I saw during my research that CJM is now incorporating a FPD into their fuel rail kit. Looks like they use an oem part from Nissan R35 skyline.

#5

From my understanding, you want it as close to the injectors as possible so it can react more quickly. I decided that with my fuel rails in series, having it between the rails would be pretty good.

Would like to hear some more opinions though.

On the CJM setup, it is built into the secondary rail, between the injectors.

Would like to hear some more opinions though.

On the CJM setup, it is built into the secondary rail, between the injectors.

Last edited by Andre The Giant; 10-02-15 at 11:03 AM.

#6

Rotary Porn Addict

iTrader: (2)

Join Date: Jul 2014

Location: Charleston SC

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

I agree it should be mounted as close to the injectors as possible(on a return style fuel system), IMO if running in series it should be before the fuel rails if running parallel one could be applied to each fuel rail prior to the injectors

Trending Topics

#8

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,770

Received 2,562 Likes

on

1,822 Posts

to those worried about leaky dampers/fires etc, Mazda quite often mounts the damper on the frame rail. it can basically go anywhere on the pressure side of the fuel system.

the 1991 MPV has a pulsation damper with hose barbs on it, and a mounting hole, on that car its mounted on the valve cover or something, it would be very easy to put it anywhere, oe # is JF01-20-180D

the 99+ miata has one mounted on the frame rail, BP4X-20-180, it is setup to take the clip on quick disconnect fuel lines, so it might be good for the Rx8/REW people

the 1991 MPV has a pulsation damper with hose barbs on it, and a mounting hole, on that car its mounted on the valve cover or something, it would be very easy to put it anywhere, oe # is JF01-20-180D

the 99+ miata has one mounted on the frame rail, BP4X-20-180, it is setup to take the clip on quick disconnect fuel lines, so it might be good for the Rx8/REW people

#12

I'm of the mind, and its something we discussed with this car, that we need to look at larger diameter fuel rails, at least for the secondary rail on these 4 injector setups. It's certainly not going to hurt anything to step up to a 5/8" or 3/4" ID rail, if space permits.

#13

I'm of the mind, and its something we discussed with this car, that we need to look at larger diameter fuel rails, at least for the secondary rail on these 4 injector setups. It's certainly not going to hurt anything to step up to a 5/8" or 3/4" ID rail, if space permits.

#14

Old [Sch|F]ool

Nice to see data confirming what I've been thinking. I'm a huge fan of pulsation dampers, to the point where I hunted down some inline hose-barb dampers from Subarus for my car.

GM mounted a damper right on the fuel pump outlet on Grand Nationals. Most Euro makes with external pumps put the damper right by the pump, as well.

GM mounted a damper right on the fuel pump outlet on Grand Nationals. Most Euro makes with external pumps put the damper right by the pump, as well.

Last edited by peejay; 10-03-15 at 10:50 AM.

#16

I pretty much had the exact same issue.

I am running 2 ID 1000 primaries and 4 ID 2000 secondaries. I never knew how bad the issue was until I switched to a modern EMS and tuned off of fuel pressure. It was so bad that we were only able to get a rough tune at low boost levels until the issue was corrected. I have previously ran a Power FC and a AEM series 1. Just as the OP said it was completely undetectable while tuning or driving.

To start I did my own research and bough 2 billet big marren FPD's. They are pretty large and I was having a hard time getting them integrated into my setup. My tuner knows the owner of ID and told me to hold off on the FPD's as he wanted to get his opinion first. After sending him my full fuel mod list he said the main reason I was having this issue was the PTFE fuel lines I was running off each rail to the regulator. These lines are notorious for causing this problem. He recommended that I replace them with E85 companionable rubber SS line. He also recommended that I move the fuel pressure sensor further away from the regulator.

I followed his recommendations and replaced the lines from the rails to the regulator and ran a line off the fuel pressure port on the regulator and mounted the pressure sensor on the back fire wall.

Issue solved and no FPD's needed! Next tuning session we were able to max out my current turbo at 32psi and fuel pressure is pretty much perfect.

I am running 2 ID 1000 primaries and 4 ID 2000 secondaries. I never knew how bad the issue was until I switched to a modern EMS and tuned off of fuel pressure. It was so bad that we were only able to get a rough tune at low boost levels until the issue was corrected. I have previously ran a Power FC and a AEM series 1. Just as the OP said it was completely undetectable while tuning or driving.

To start I did my own research and bough 2 billet big marren FPD's. They are pretty large and I was having a hard time getting them integrated into my setup. My tuner knows the owner of ID and told me to hold off on the FPD's as he wanted to get his opinion first. After sending him my full fuel mod list he said the main reason I was having this issue was the PTFE fuel lines I was running off each rail to the regulator. These lines are notorious for causing this problem. He recommended that I replace them with E85 companionable rubber SS line. He also recommended that I move the fuel pressure sensor further away from the regulator.

I followed his recommendations and replaced the lines from the rails to the regulator and ran a line off the fuel pressure port on the regulator and mounted the pressure sensor on the back fire wall.

Issue solved and no FPD's needed! Next tuning session we were able to max out my current turbo at 32psi and fuel pressure is pretty much perfect.

#17

^

So is the take-away that the more flexible rubber hose tends to absorb more of the spikes and dips of the pressure fluctuation? And I suppose it would also decrease the tendency of a pressure change resonance to form?

I wonder if this also would indicate that using mainly bent hardline for the majority of the system would make the fluctuation even worse?

So is the take-away that the more flexible rubber hose tends to absorb more of the spikes and dips of the pressure fluctuation? And I suppose it would also decrease the tendency of a pressure change resonance to form?

I wonder if this also would indicate that using mainly bent hardline for the majority of the system would make the fluctuation even worse?

#18

Old [Sch|F]ool

Yep. And this is why, when I couldn't find any Subaru pulsation dampers, I made do with having several feet of high pressure rubber hose in the fuel system... Not perfect but it's better than nothing.

#19

https://www.radiumauto.com/Fuel-Puls...Kits-P751.aspx

Hey the guys above have some info on these damper, some of u already know most of this stuff but it's always good to learn more.

Hey the guys above have some info on these damper, some of u already know most of this stuff but it's always good to learn more.

#20

^

So is the take-away that the more flexible rubber hose tends to absorb more of the spikes and dips of the pressure fluctuation? And I suppose it would also decrease the tendency of a pressure change resonance to form?

I wonder if this also would indicate that using mainly bent hardline for the majority of the system would make the fluctuation even worse?

So is the take-away that the more flexible rubber hose tends to absorb more of the spikes and dips of the pressure fluctuation? And I suppose it would also decrease the tendency of a pressure change resonance to form?

I wonder if this also would indicate that using mainly bent hardline for the majority of the system would make the fluctuation even worse?

#21

Freedoms worth a buck o'5

Join Date: May 2001

Location: Calgary Alberta Canada

Posts: 2,544

Likes: 0

Received 1 Like

on

1 Post

What's old is new again...lol..

I guess now people have better equipment to confirm what was happening..pulsation dampers are necessary.. The mazda race 13G's had one on each rail..

Years ago my car pounded out a 1600cc injector and it locked the pintle solid from the pulsations, I did get a piece of hose to work but it was a huge chunk, 5/8 ID x 40" or something like that and it was fairly soft hose rated for 100 psi. It did work, it stopped eating fuel pressure gauges and I never lost an injector after that.

The Apex fuel pump has one built one into it, for an in tank solution.

I guess now people have better equipment to confirm what was happening..pulsation dampers are necessary.. The mazda race 13G's had one on each rail..

Years ago my car pounded out a 1600cc injector and it locked the pintle solid from the pulsations, I did get a piece of hose to work but it was a huge chunk, 5/8 ID x 40" or something like that and it was fairly soft hose rated for 100 psi. It did work, it stopped eating fuel pressure gauges and I never lost an injector after that.

The Apex fuel pump has one built one into it, for an in tank solution.

#23

I had assumed that a typical aftermarket FPR acted as damper since they have a rubber diaphragm inside. Not sure why this didn't work, but vibration can be tricky. FPR mounted insufficiently close to fuel rail?

Interesting post Chris, thanx.

Interesting post Chris, thanx.

Last edited by cone_crushr; 10-13-15 at 12:25 PM.

#25

Modern PTFE and Nylon hoses do contribute to the fuel pressure pulsations, and this is most likely why modern vehicles that are plumbing entirely with hardline or Nylon or PTFE feature more dampers than vehicles of the past. Interesting to note, the R35 even has a damper in the return after the regulator, and one per rail on the pressure side.

Last edited by phunk; 10-26-15 at 03:36 PM.