Comparison of older style Bosch EV1 vs newer Bosch EV14 injectors

#1

Comparison of older style Bosch EV1 vs newer Bosch EV14 injectors

(Bosch L-Jetronic Injection Manual)

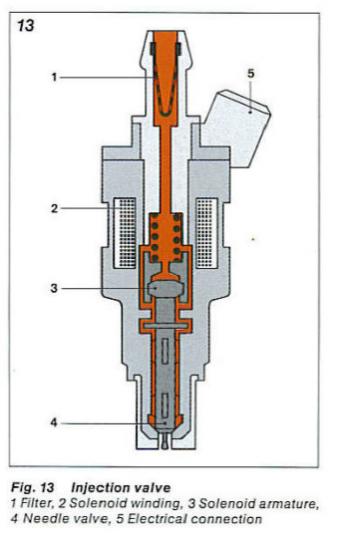

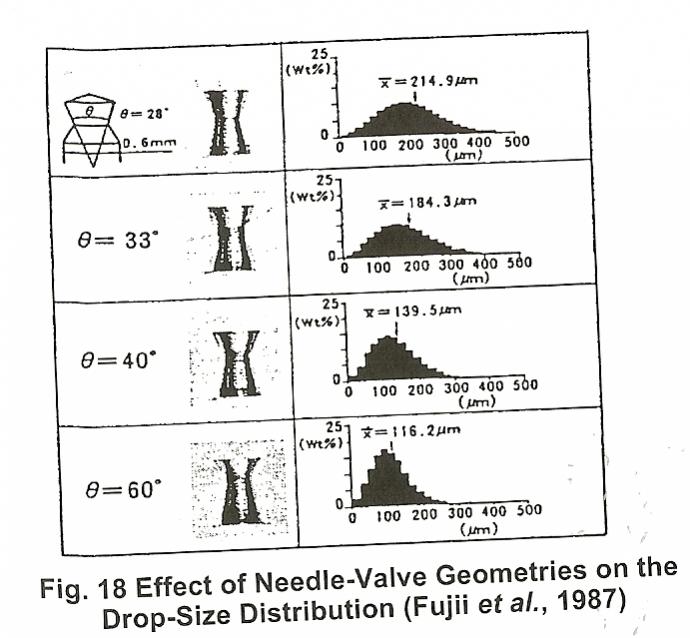

Above is a diagram of an EV1 style top feed injector (old 80s Japanese injectors, like on the 2nd gen Rx-7, are similar). The valve is at the bottom. The geometry of the valve and the single orifice below it determines the spray pattern and the distribution of the droplet size.

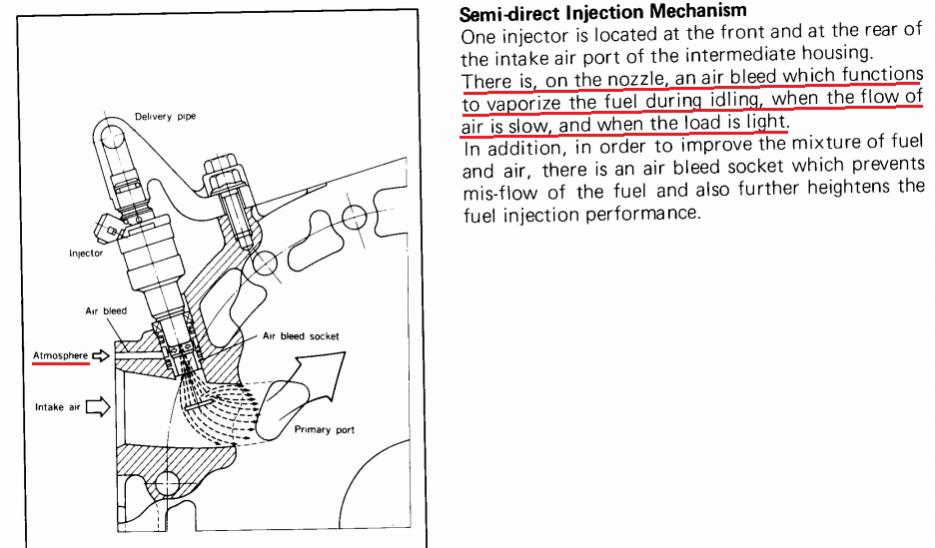

Air assistance and injector diffuser plates can be used with this style injector to improve atomization. Mazda used both:

(1984 Rx-7 GSL-SE training manual)

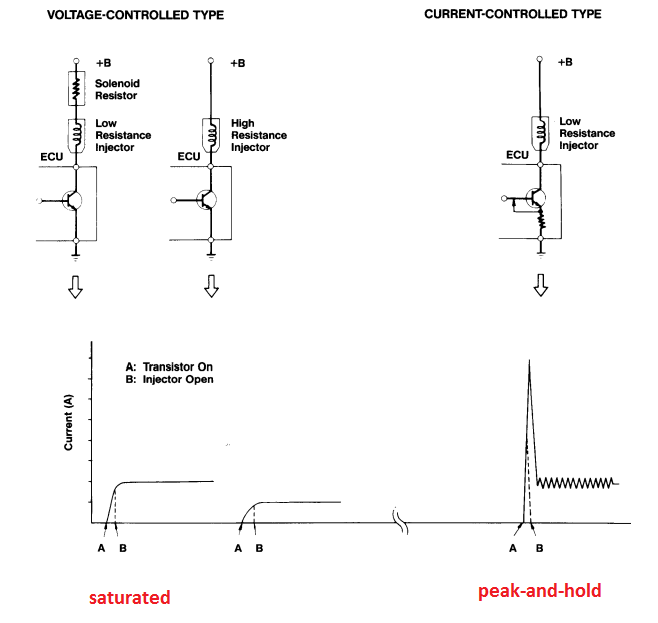

These injectors come in high and low impedence forms. The low impedence forms have a faster response time. A high impedence injector is driven by a voltage-controlled or "saturated" driver. A low impedence injector can be driven by a saturated driver as long as a resistor is used to prevent the solenoid and/or driver from burning up. A peak-and-hold current-controlled driver can also be used to improve response times, but with greater expense and additional complexity.

(Toyota technician fuel injection training manual)

One of the biggest issues with this style of injector is that the valve is directly exposed to the operating environment. Operating temperatures and heatsoak conditions tend to cause buildup. This is a very old style of injector, but there were a lot of variations to it over the years--some were connected to engine-driven air pumps to improve atomization, some had some interesting nozzle designs ("impingement" injector), some used special plates to induce a swirl motion on the droplets. The pintle-type design fell out of favor back in the 90s as manufacturers moved to the multi-hole design, which the Bosch EV14 and the Rx-8 injectors use.

#2

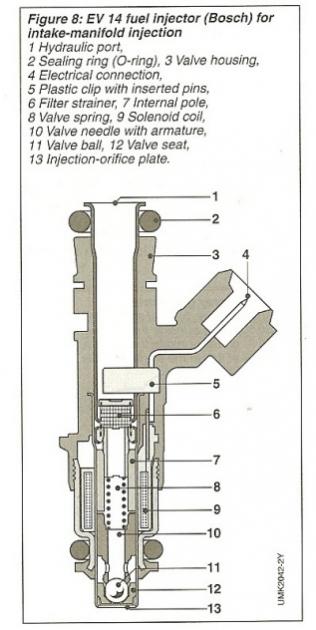

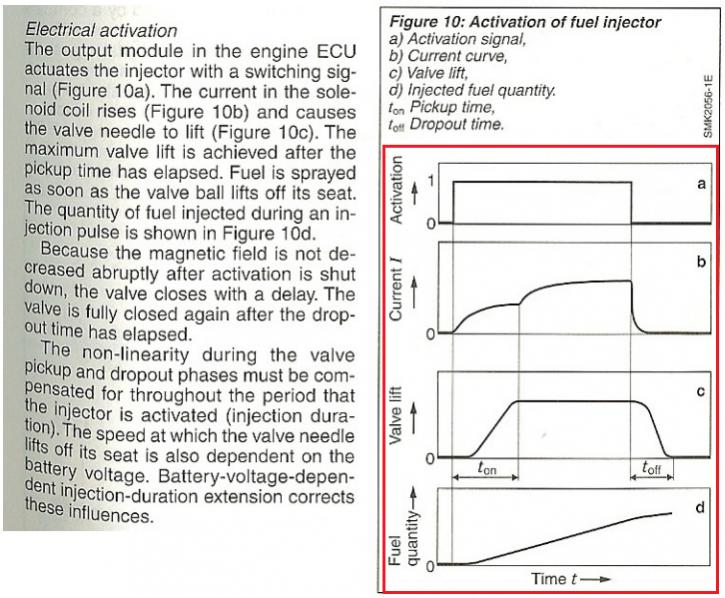

(Bosch Automotive Handbook 8th Edition, 2011)

The EV14 style has a ball valve and an orifice plate below it. The ball valve is more responsive than the older pintle valves. The orifice plate consists of a series of small holes--the number and arrangement can vary. The orifice plate design keeps the ball valve from being directly exposed to the operating environment, reducing the tendency towards deposits which can affect the flow rate and spray pattern.

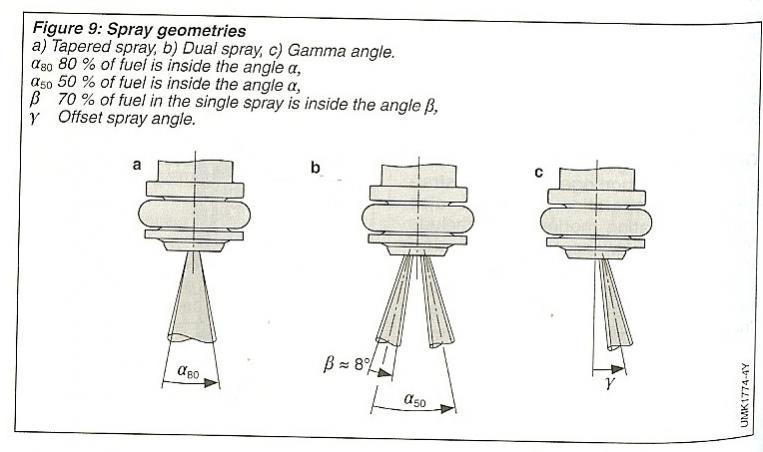

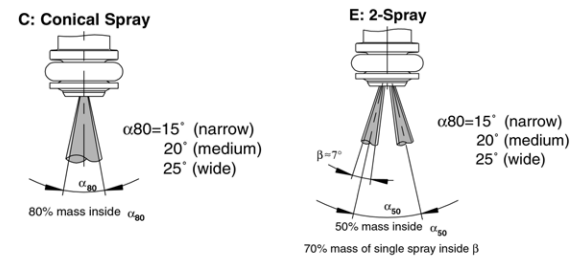

(Bosch Automotive Handbook 8th Edition, 2011)

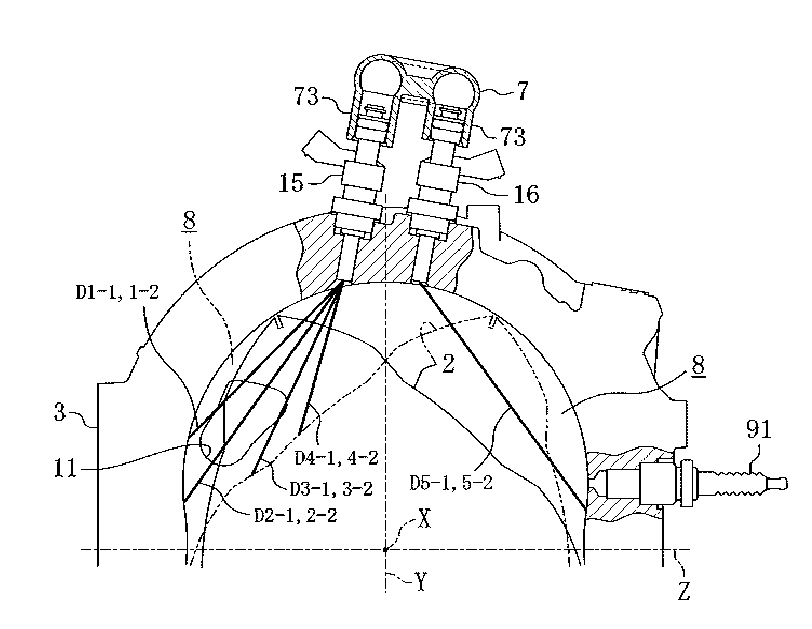

The spray patterns come in different arrangements. The two main categories are the single cone-type and the offset multi-spray type. To my knowledge the various EV14 vendors for the aftermarket are selling the single-cone style spray pattern. As you can see above, there are a number of parameters which determine the spray angle.

The single-cone type should be fine for a rotary application. One interesting question to me is, "What is the effect of Mazda's spray diffuser plates and air assist system on the droplets when using an EV14 injector?" A 4 valve piston engine is often better served by the offset type with dual sprays so that separate jets hit the back of the valves.

(Bosch Automotive Handbook 8th Edition, 2011)

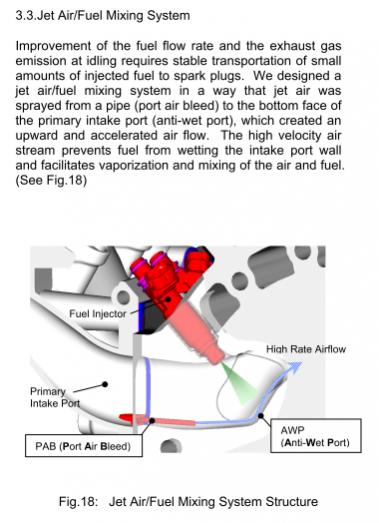

You can see above that there are a couple areas of non-linearity in the injector flow, due to the valve lift profile of the injector. Mazda is already using multi-hole injectors on rotaries with a revised air assist system:

(Ohkubo, "Developed Technologies of the New Rotary Engine (Renesis)," 2004)

The EV14 style is designed for a saturated (voltage controlled) type of driver only. Peak-and-hold drivers have fallen out of favor on port-injection fuel systems, but they are now being used on gasoline direct injection applications. Typically an injection control module outputs about 60V to open solenoid-style multi hole injectors, then tapers off the voltage to keep them open. This style of driver allows multiple injection events per combustion cycle, and helps the valve overcome the much higher fuel pressures used in direct injection.

#3

Not Track Ready

iTrader: (6)

Join Date: Jul 2005

Location: Arcadia, CA

Posts: 291

Likes: 0

Received 0 Likes

on

0 Posts

Great, tons of good info here. The engineer in me loves to dig through data.

The area gain on a ball valve tends to be much greater with a smaller risk of flow force stability issues equaling greater more consistent flow delivery and volume in a smaller package/weight. However one of the big issues with ball poppet valves is the seating and guiding during initial lift off and reseat the seat can be excessively worn by the lack of a guide and line to line contact.

As for the plate with holes, it's a good idea for pre-atomizing the fuel. However I think using a flow votex design offers greater gains in this department:

Spin Jets utilize unique vortices and flow passages to provide a finely atomized hollow cone spray pattern. When used with most normal fuels, Spin Jets produce a 70° cone angle spray with differential pressure in the 50-200 psi range.

If you couple this with a piezoelectric solenoid (twin stage) you get a very fast acting, highly atomized spray.

http://www.youtube.com/watch?v=utnC8...eature=related

The area gain on a ball valve tends to be much greater with a smaller risk of flow force stability issues equaling greater more consistent flow delivery and volume in a smaller package/weight. However one of the big issues with ball poppet valves is the seating and guiding during initial lift off and reseat the seat can be excessively worn by the lack of a guide and line to line contact.

As for the plate with holes, it's a good idea for pre-atomizing the fuel. However I think using a flow votex design offers greater gains in this department:

Spin Jets utilize unique vortices and flow passages to provide a finely atomized hollow cone spray pattern. When used with most normal fuels, Spin Jets produce a 70° cone angle spray with differential pressure in the 50-200 psi range.

If you couple this with a piezoelectric solenoid (twin stage) you get a very fast acting, highly atomized spray.

http://www.youtube.com/watch?v=utnC8...eature=related

#4

Great, tons of good info here. The engineer in me loves to dig through data.

The area gain on a ball valve tends to be much greater with a smaller risk of flow force stability issues equaling greater more consistent flow delivery and volume in a smaller package/weight. However one of the big issues with ball poppet valves is the seating and guiding during initial lift off and reseat the seat can be excessively worn by the lack of a guide and line to line contact.

The area gain on a ball valve tends to be much greater with a smaller risk of flow force stability issues equaling greater more consistent flow delivery and volume in a smaller package/weight. However one of the big issues with ball poppet valves is the seating and guiding during initial lift off and reseat the seat can be excessively worn by the lack of a guide and line to line contact.

As for the plate with holes, it's a good idea for pre-atomizing the fuel. However I think using a flow votex design offers greater gains in this department:

Spin Jets utilize unique vortices and flow passages to provide a finely atomized hollow cone spray pattern. When used with most normal fuels, Spin Jets produce a 70° cone angle spray with differential pressure in the 50-200 psi range.

Spin Jets utilize unique vortices and flow passages to provide a finely atomized hollow cone spray pattern. When used with most normal fuels, Spin Jets produce a 70° cone angle spray with differential pressure in the 50-200 psi range.

If you couple this with a piezoelectric solenoid (twin stage) you get a very fast acting, highly atomized spray.

The nice things about the Multi-hole type of port injector is that they are basically "drop in" and don't require any real hardware changes.

#5

Not Track Ready

iTrader: (6)

Join Date: Jul 2005

Location: Arcadia, CA

Posts: 291

Likes: 0

Received 0 Likes

on

0 Posts

This sounds like an issue related to the manufacturing process more than anything else.

These are referred to as "swirl" or "swirl plate" injectors. I'm not aware of any production applications using this design that are port injection. Very early production gasoline direct injected engines (Mitsubishi & Toyota GDI engines from the 90s) used this design. It is my understanding that the swirl plates are prone to issues with buildup of deposits. Most of the swirl plate injectors are used in air-assisted applications where the air pump is driven by the engine. One application has an air solenoid to accompany each fuel injector, so that air injection and fuel are both pulsewidth modulated. This is a lot more precise (and more complex/expensive) than the simple low pressure air assistance Mazda and other manufacturers have used in production applications.

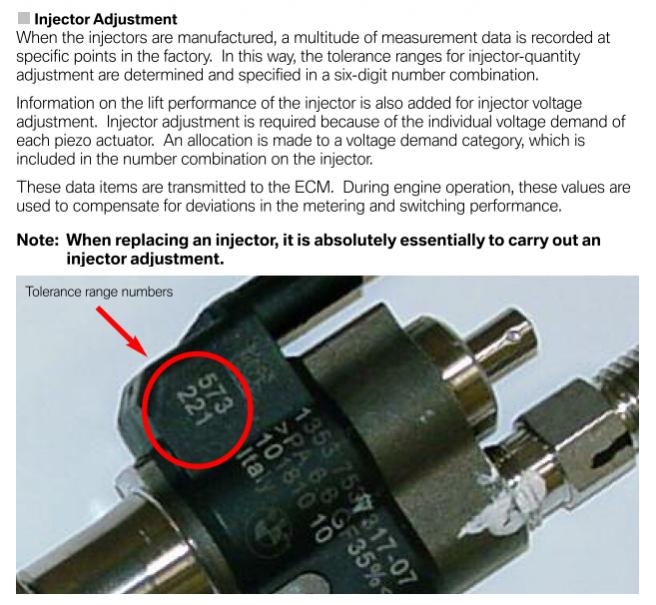

Piezoelectric injectors to my knowledge have never been used in a port injected production application. BMW is the only one using them in gasoline direct injection, for a spray-guided homogenous charge (not stratified) engine concept with the injector located next to the spark plug. All the new BMW direct injection engines are set up like this. Piezoelectric injectors have been used in diesels for a long time now. They are a lot faster responding and can handle higher fuel pressures, delivering finer atomization. However they are more expensive to manufacture and control.

The nice things about the Multi-hole type of port injector is that they are basically "drop in" and don't require any real hardware changes.

These are referred to as "swirl" or "swirl plate" injectors. I'm not aware of any production applications using this design that are port injection. Very early production gasoline direct injected engines (Mitsubishi & Toyota GDI engines from the 90s) used this design. It is my understanding that the swirl plates are prone to issues with buildup of deposits. Most of the swirl plate injectors are used in air-assisted applications where the air pump is driven by the engine. One application has an air solenoid to accompany each fuel injector, so that air injection and fuel are both pulsewidth modulated. This is a lot more precise (and more complex/expensive) than the simple low pressure air assistance Mazda and other manufacturers have used in production applications.

Piezoelectric injectors to my knowledge have never been used in a port injected production application. BMW is the only one using them in gasoline direct injection, for a spray-guided homogenous charge (not stratified) engine concept with the injector located next to the spark plug. All the new BMW direct injection engines are set up like this. Piezoelectric injectors have been used in diesels for a long time now. They are a lot faster responding and can handle higher fuel pressures, delivering finer atomization. However they are more expensive to manufacture and control.

The nice things about the Multi-hole type of port injector is that they are basically "drop in" and don't require any real hardware changes.

As with any small orifice below .070", blockage is always an issue. With the design shown above, the part utilizes a micro screen prior to the jet allow for protection of the jet orifice. This design is common in Aerospace turbine designs for it's greater efficiencies at atomizing fuel. Of course these are also expensive to manufacture.

You are right about the piezoelectric injectors being expensive. These would see the greatest advantage in direct injection applications where you don't have large air flow rates to help distrubtion of the fuel so more precision is needed. In our cars this doesn't really offer greater performance aside from tighter timing control, lower required voltage/current (one or the other), and a more even distribution of fuel allowing more precision fuel delivery (though the gains may be marginal).

#7

Not Track Ready

iTrader: (6)

Join Date: Jul 2005

Location: Arcadia, CA

Posts: 291

Likes: 0

Received 0 Likes

on

0 Posts

Perhaps on Mazda's next generation 'Skyactive' rotary this piezo might make a good fit.

Trending Topics

#8

I agree. Due to the nature of the piezo driver, it must be calibrated each time it's rebuilt or swaped. This probably isn't for people just looking to put down more power. I'd suspect for our cars there are alot of other areas which could use more attention and R&D. This might be more applicable to the Renesis as that motor is direct injection if I'm not mistaken.

Perhaps on Mazda's next generation 'Skyactive' rotary this piezo might make a good fit.

Perhaps on Mazda's next generation 'Skyactive' rotary this piezo might make a good fit.

Just from looking at the sketches the injectors appear to be the multi-hole solenoid type that you would find in a Ford Ecoboost engine for example.

The Renesis uses multi-hole injectors of the same concept as the EV14 Bosch injector, with 3 per rotor on series 1 and 2 per rotor on series 2. The staging is pretty complicated.

#9

Original Gangster/Rotary!

iTrader: (213)

Bumping this great thread up to the top for more 2015 discussion

I know on my BB '95 FD moving to the Bosch 715/2200 combo has proven to make for a very smooth running car, and my tuner loves the newer EV14 style injectors.

Far cry from the days of running 850cc stock secondary injectors in the primary slots, that's for damn sure

Bump for the comments and observations of the rest of you guys

I know on my BB '95 FD moving to the Bosch 715/2200 combo has proven to make for a very smooth running car, and my tuner loves the newer EV14 style injectors.

Far cry from the days of running 850cc stock secondary injectors in the primary slots, that's for damn sure

Bump for the comments and observations of the rest of you guys

#10

On a stock engine, I switched from the stock LIM and injectors to an Xcessive LIM with 4x ID1000 injectors - and Racing Beat blocking plugs in place of the OEM primary injectors. This was in 2008 or 2009, before the ID725 or ID2000 was available. No other changes were made to the car aside from the fuel system and LIM, and after some adjustments to the standalone the car idled and drove about as well as it had with the stock injectors.

About a year ago, I had spent some time daily-driving a Honda and wanted to see if I could improve the RX-7's manners at idle. The little gutless 1.6L Civic with a similar standalone ECU was better behaved idling at lean AFRs and when the A/C compressor kicked in. It was non-turbo so using injectors much smaller than our stock primaries. I got a good price on a Full Function Engineering primary fuel rail, and added some spare ~250cc/min injectors (from an E46 BMW M3)... still keeping the ID1000's in all 4 ports of the Xcessive LIM.

On the stock primaries or ID1000's, the engine was happy idling around 12-13 AFR and would misfire if trying to idle at 14 or 15 AFR. With the tiny 250cc/min primaries the car is happy idling at 15 AFR, even when not fully warmed up. It is also better behaved when the AC compressor activates. The little primary injectors aren't useful for much more than idle or cruising, however, they hit 90% duty cycle before the primary turbo even hits full boost. I'm happy with how the car runs for now, but I'm interested to eventually try some ID750's or modern OEM injectors that flow 400-500cc/min.

About a year ago, I had spent some time daily-driving a Honda and wanted to see if I could improve the RX-7's manners at idle. The little gutless 1.6L Civic with a similar standalone ECU was better behaved idling at lean AFRs and when the A/C compressor kicked in. It was non-turbo so using injectors much smaller than our stock primaries. I got a good price on a Full Function Engineering primary fuel rail, and added some spare ~250cc/min injectors (from an E46 BMW M3)... still keeping the ID1000's in all 4 ports of the Xcessive LIM.

On the stock primaries or ID1000's, the engine was happy idling around 12-13 AFR and would misfire if trying to idle at 14 or 15 AFR. With the tiny 250cc/min primaries the car is happy idling at 15 AFR, even when not fully warmed up. It is also better behaved when the AC compressor activates. The little primary injectors aren't useful for much more than idle or cruising, however, they hit 90% duty cycle before the primary turbo even hits full boost. I'm happy with how the car runs for now, but I'm interested to eventually try some ID750's or modern OEM injectors that flow 400-500cc/min.

Last edited by scotty305; 12-06-15 at 01:07 AM.

Thread

Thread Starter

Forum

Replies

Last Post