Trimming side seals?

#26

Retired Moderator, RIP

iTrader: (142)

Join Date: Sep 2005

Location: Smiths Falls.(near Ottawa!.Mapquest IT!)

Posts: 25,581

Likes: 0

Received 131 Likes

on

114 Posts

Would .0015 side seal clearance be the bare minimum clearance for side seals?? I ask because I remember seeing Aaron Cake grind his side seals until they barely fit in one of his youtube videos.... please let me know because I'm currently redoing my side seals for my rebuild. Thank in advanced.

God..old thread..

#27

"Elusive, not deceptive!”

#28

F'n Newbie...

iTrader: (6)

Would .0015 side seal clearance be the bare minimum clearance for side seals?? I ask because I remember seeing Aaron Cake grind his side seals until they barely fit in one of his youtube videos.... please let me know because I'm currently redoing my side seals for my rebuild. Thank in advanced.

It's doable, you'd just need to be very disciplined during your break-in. Obviously binding/breaking would be counter-productive..

#29

2SoonJr

iTrader: (8)

Join Date: Mar 2008

Location: OrangeCounty-Santa Ana

Posts: 525

Likes: 0

Received 5 Likes

on

4 Posts

I was just under the impression that a tighter clearance yields the best compression and in this case N/A .0015 is what you want to obtain; while turbo .002 is the best choice due to thermal expansion. Please correct me if im wrong.

thank you again.

Last edited by FD7KiD; 09-07-16 at 10:57 AM.

#30

F'n Newbie...

iTrader: (6)

The seals are going to seat and wear down slightly, losing clearance, regardless. If you start at .0025 and settle at .005 after a few thousand miles than you'll be driving around with .005 as your clearance number. If you start with .0015 and they settle at .003 after a few thousand miles than you'll be driving with that as the clearance.

My last engine shat the bed at 3,000 miles due to a freak (catastrophic) oil leak. I spun some bearings and "lost" one rotor due to the tips contacting the irons, despite having the rotor clearanced. I chucked all the seals from that rotor, but when I stacked the motor back up I def noticed that the side seals from the "good" rotor had lost/eased clearance during the break in.

*IF* you run very tight clearances you must adhere to a disciplined break in, no boost, no burn outs, no impulsive moments of joy. I'm no forum guru though, so take my experience with a grain of salt, it won't hurt my feelings.

My last engine shat the bed at 3,000 miles due to a freak (catastrophic) oil leak. I spun some bearings and "lost" one rotor due to the tips contacting the irons, despite having the rotor clearanced. I chucked all the seals from that rotor, but when I stacked the motor back up I def noticed that the side seals from the "good" rotor had lost/eased clearance during the break in.

*IF* you run very tight clearances you must adhere to a disciplined break in, no boost, no burn outs, no impulsive moments of joy. I'm no forum guru though, so take my experience with a grain of salt, it won't hurt my feelings.

#31

2SoonJr

iTrader: (8)

Join Date: Mar 2008

Location: OrangeCounty-Santa Ana

Posts: 525

Likes: 0

Received 5 Likes

on

4 Posts

The seals are going to seat and wear down slightly, losing clearance, regardless. If you start at .0025 and settle at .005 after a few thousand miles than you'll be driving around with .005 as your clearance number. If you start with .0015 and they settle at .003 after a few thousand miles than you'll be driving with that as the clearance.

My last engine shat the bed at 3,000 miles due to a freak (catastrophic) oil leak. I spun some bearings and "lost" one rotor due to the tips contacting the irons, despite having the rotor clearanced. I chucked all the seals from that rotor, but when I stacked the motor back up I def noticed that the side seals from the "good" rotor had lost/eased clearance during the break in.

*IF* you run very tight clearances you must adhere to a disciplined break in, no boost, no burn outs, no impulsive moments of joy. I'm no forum guru though, so take my experience with a grain of salt, it won't hurt my feelings.

My last engine shat the bed at 3,000 miles due to a freak (catastrophic) oil leak. I spun some bearings and "lost" one rotor due to the tips contacting the irons, despite having the rotor clearanced. I chucked all the seals from that rotor, but when I stacked the motor back up I def noticed that the side seals from the "good" rotor had lost/eased clearance during the break in.

*IF* you run very tight clearances you must adhere to a disciplined break in, no boost, no burn outs, no impulsive moments of joy. I'm no forum guru though, so take my experience with a grain of salt, it won't hurt my feelings.

most likely if the feeler gauge can slide in freely @ .0015 and persuade a .002 to fit in and slide off with some drag.

just an I dea

#32

F'n Newbie...

iTrader: (6)

wow that's news to me, I always thought the side seals only wore down from the contact of the irons. but given the new piece of information, im going to try and clearance the side seals somewhere in between .0015 and .002

most likely if the feeler gauge can slide in freely @ .0015 and persuade a .002 to fit in and slide off with some drag.

just an I dea

most likely if the feeler gauge can slide in freely @ .0015 and persuade a .002 to fit in and slide off with some drag.

just an I dea

The rear rotor remained the same (same rotor, same apex/side/corner seals, new springs all across and new oil control ring bits) and was all reinstalled in the same orientation. The front rotor was replaced completely (looking at the "ruined" rotor right now, it's sitting on my desk at work

) and a "new" S4 NA rotor was sent of for lightening/balancing/clearancing. I reused the apex seals on that front rotor, but everything else was replaced with new parts from Malloy.

) and a "new" S4 NA rotor was sent of for lightening/balancing/clearancing. I reused the apex seals on that front rotor, but everything else was replaced with new parts from Malloy.Hind sight, I probably should have replaced the side seals in the rear rotor as well so I could get them all clearanced exactly the same.. But since they were still well within FSM specs I just said "**** it" and left them

I may have some slight blow-by on the rear rotor as a result, but that's not the end of the world..

I may have some slight blow-by on the rear rotor as a result, but that's not the end of the world..

#33

"Elusive, not deceptive!”

If you use a magnifying glass to examine the end of the side seal you see how hard it is to get it to fit perfectly to the corner seal. An imperfect cut will allow a wear rate inversely proportion to its contact area (less contact faster wear).

Full contact will not wear at all!

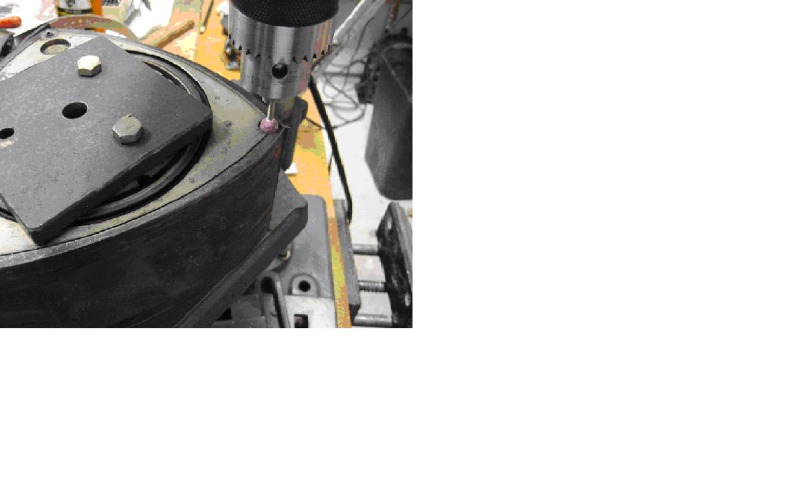

That is why a Dremel grinding stone is used in the drill press with the rotor as a fixture to get the correct fit.

Full contact will not wear at all!

That is why a Dremel grinding stone is used in the drill press with the rotor as a fixture to get the correct fit.

#34

F'n Newbie...

iTrader: (6)

^ Too many complications imo. If I'm clearancing a side seal to the THOUSANDTH of an inch, I'm not trying to use a dremel to get there. It just seems way to easy to push it a fraction further than it needs to go, and then you're way off the mark. At that point you're stuck with sloppy clearances or throwing out a seal that would have otherwise been perfectly good.

Just take your time and sand it down by hand with a self adhesive pad of sand paper, a coffee table, a favorite program on tv and your rotor, corner seal, and feeler gauges. It's not THAT difficult to maintain the proper angle if you take your time and are careful. NOBODY will ever put as much care and attention to detail into building your engine as you yourself will. I learned that the hard way...

Not sure why you'd want/need to use a magnifying glass, but then again I've got 20/15 vision so I can see what's in front of me.

Just take your time and sand it down by hand with a self adhesive pad of sand paper, a coffee table, a favorite program on tv and your rotor, corner seal, and feeler gauges. It's not THAT difficult to maintain the proper angle if you take your time and are careful. NOBODY will ever put as much care and attention to detail into building your engine as you yourself will. I learned that the hard way...

Not sure why you'd want/need to use a magnifying glass, but then again I've got 20/15 vision so I can see what's in front of me.

#35

"Elusive, not deceptive!”

The problem is- In order for the end surface to be hollow ground how else could you make this cut?

And if it is not cut like this with 100% contact it will leak badly and wear quickly.

This is what is know as a "Best Practice".

Barry

And if it is not cut like this with 100% contact it will leak badly and wear quickly.

This is what is know as a "Best Practice".

Barry

#37

Red Pill Dealer

iTrader: (10)

It gets better, It's not hard to shape the mounted point. The exact dia is nice but, the error from a smaller ratios is minimal when it is figured for contact radius.

It does effect it though.

It does effect it though.

#39

Old [Sch|F]ool

Personally I just clearance them to the very tight side and make the edge a flat bevel, making extra careful that it's square. I've always done them (laboriously...) by hand but I bought a diamond-wheel ring filer a while back, looks extremely easy to add more rollpins to the base so I can use it as a side seal filer and apex seal filer. It removes metal VERY quickly as I discovered the first time I used it... good thing I had to have two four-cylinder sets to put rings in a five cylinder engine

My opinion is that as long as the cut is perpendicular to the sealing surface and beveled so it meets the corner seal on the face instead of on an edge, you're already doing pretty well. The corner seals will get worn in regardless of how well you match the seal face to the corner seal, but at least if you don't have point contact or edge contact, it won't actively be hurting things.

#40

F'n Newbie...

iTrader: (6)

My opinion is that as long as the cut is perpendicular to the sealing surface and beveled so it meets the corner seal on the face instead of on an edge, you're already doing pretty well. The corner seals will get worn in regardless of how well you match the seal face to the corner seal, but at least if you don't have point contact or edge contact, it won't actively be hurting things.

It makes me think of those stupid/crazy snake dancing christian types

#41

"Elusive, not deceptive!”

Just remember you are dealing with 12 potential compression leaks.

You know how some engines seem to be slow starting? This is common with poor compression.

Set the side seals poorly and you get poor compression.... set them too tight and you will score the side plates and crack the corner seals.

Actually I don't use the method that I depicted in the photo above.

fendamonky, you already know what I use... Zero clearance.

You know how some engines seem to be slow starting? This is common with poor compression.

Set the side seals poorly and you get poor compression.... set them too tight and you will score the side plates and crack the corner seals.

Actually I don't use the method that I depicted in the photo above.

fendamonky, you already know what I use... Zero clearance.

#42

F'n Newbie...

iTrader: (6)

Really?

Really?Also, correlation does NOT imply causation... Sorry, but I see your stuff and I think of your buddy that tried to use pseudo-science to convince people that wind speed lowers ambient temperatures.

#43

"Elusive, not deceptive!”

And remember you are not required to use any of my ideas.... they are only for people who think they have merit.

let me add something so this thread can still be an intellectual exchange ... my engine is able to operate without an blow-by oil catch-can because of it's better sealing.

Barry Bordes

#44

F'n Newbie...

iTrader: (6)

Barry I don't have a problem with you (though your blue text gets pretty old). What I have a problem with is your statements of absolutes like "And if it is not cut like this with 100% contact it will leak badly and wear quickly" which are based on your assumptions only without factual support.

Um, bragging that tight clearances leads to little or no blow-by doesn't equate to "an intellectual exchange" You will NOT hear me arguing against the fact that minimizing clearances on the side to corner seal areas will reduce blow by. I completely agree there and have seen the results in my own engines!!

You will NOT hear me arguing against the fact that minimizing clearances on the side to corner seal areas will reduce blow by. I completely agree there and have seen the results in my own engines!!

I do, however, take issue with your preaching snake-oil assumptions that one MUST do things exactly as you dictate (even though you don't follow your own advice, as you've suggested above) at the peril of assumed catastrophic side effects.

Um, bragging that tight clearances leads to little or no blow-by doesn't equate to "an intellectual exchange"

You will NOT hear me arguing against the fact that minimizing clearances on the side to corner seal areas will reduce blow by. I completely agree there and have seen the results in my own engines!!

You will NOT hear me arguing against the fact that minimizing clearances on the side to corner seal areas will reduce blow by. I completely agree there and have seen the results in my own engines!!I do, however, take issue with your preaching snake-oil assumptions that one MUST do things exactly as you dictate (even though you don't follow your own advice, as you've suggested above) at the peril of assumed catastrophic side effects.

#45

"Elusive, not deceptive!”

fenda, perhaps an example of wear rate might help.

When lapping carbon seals for turbine engines to within a few helium light bands... the initial high spots wear quickly but as it gets flatter it will practically stop cutting. This because the force is being distributed over more surface area to the point of not allowing wear.

Likewise when the end of the side seal has high spots it will wear quickly and open clearance for a leak on the leading end.

Barry

And who is my friend that you don't like?

When lapping carbon seals for turbine engines to within a few helium light bands... the initial high spots wear quickly but as it gets flatter it will practically stop cutting. This because the force is being distributed over more surface area to the point of not allowing wear.

Likewise when the end of the side seal has high spots it will wear quickly and open clearance for a leak on the leading end.

Barry

And who is my friend that you don't like?

#46

Old [Sch|F]ool

For what it's worth, wouldn't there be only six gaps of compression loss? Rotation and friction should be shoving the trailing edge of the side seals hard into the corner seals.

You can see this on used corner seals, there will be a significant wear mark on only one side and a much, much smaller one on the other side, if present at all.

You can see this on used corner seals, there will be a significant wear mark on only one side and a much, much smaller one on the other side, if present at all.

#47

"Elusive, not deceptive!”

peejay,

Yes if we follow the normal procedure of using the factory cut on the pushing side we shouldn't have a leak on that end.

But there are still 12 trimming cuts that need to be made.

Six per rotor but 12 for our 2 rotors ( and 18 for a 3 rotor, etc.)

That is why I went to Zero.

I was the worried about cutting the zero clearance for people without physically having the rotors.

But a couple of guys convinced me to send them out for them to check fit and it worked.

Here is an all new setup that I did for a friend in Dallas.

Yes if we follow the normal procedure of using the factory cut on the pushing side we shouldn't have a leak on that end.

But there are still 12 trimming cuts that need to be made.

Six per rotor but 12 for our 2 rotors ( and 18 for a 3 rotor, etc.)

That is why I went to Zero.

I was the worried about cutting the zero clearance for people without physically having the rotors.

But a couple of guys convinced me to send them out for them to check fit and it worked.

Here is an all new setup that I did for a friend in Dallas.

#48

Old [Sch|F]ool

It's still a fascinating concept and I'd like to try it someday. How does it tolerate the corner seal moving around? Note, I am a firm non-believer in solid corner seals, so I'd be doing it with the more flexible Mazda seals.

I suppose I should try to find the thread you did on it...

https://www.rx7club.com/rotary-car-p...-seals-750374/.

I suppose I should try to find the thread you did on it...

https://www.rx7club.com/rotary-car-p...-seals-750374/.

Last edited by peejay; 12-18-16 at 09:01 AM.

#49

"Elusive, not deceptive!”

peejay,

I did a set for a big NA drag racer who thought they may be an advantage. He also was under the opinion that the solid seals caused problems with wearing side plates.

I cannot say for sure because I have not examined enough failure samples but I suspect that setting the side seal to corner seal clearance too tight is the culprit. I say this because I once assembled one of my engine and had to pull one rotor back out during assemble..... and all the seals stuck to the oiled plate. You have probably been there. Trying beat the drying time of the sealant and getting everything assembled correctly. Well I thought I clocked the seals back correctly but I should have remeasured. One displaced seal was to tight (less than .002") and scored the side plate as examined after about 10k miles.

That is when I decided to go to a seal interface that was more tolerant to clearances but sealed effectively.

The factory corner seals do allow a little more flex for an ill-fitting side seal but large port engines eat the rubber insert and cause a leak path. So you must pick your poison.

I did a set for a big NA drag racer who thought they may be an advantage. He also was under the opinion that the solid seals caused problems with wearing side plates.

I cannot say for sure because I have not examined enough failure samples but I suspect that setting the side seal to corner seal clearance too tight is the culprit. I say this because I once assembled one of my engine and had to pull one rotor back out during assemble..... and all the seals stuck to the oiled plate. You have probably been there. Trying beat the drying time of the sealant and getting everything assembled correctly. Well I thought I clocked the seals back correctly but I should have remeasured. One displaced seal was to tight (less than .002") and scored the side plate as examined after about 10k miles.

That is when I decided to go to a seal interface that was more tolerant to clearances but sealed effectively.

The factory corner seals do allow a little more flex for an ill-fitting side seal but large port engines eat the rubber insert and cause a leak path. So you must pick your poison.

#50

F'n Newbie...

iTrader: (6)

the initial high spots wear quickly but as it gets flatter it will practically stop cutting. This because the force is being distributed over more surface area to the point of not allowing wear.

Likewise when the end of the side seal has high spots it will wear quickly and open clearance for a leak on the leading end.

Likewise when the end of the side seal has high spots it will wear quickly and open clearance for a leak on the leading end.

Besides, if you're so adamant that one MUST use a rounded cutting surface in order to achieve a concave mating surface at the expense of "if it is not cut like this with 100% contact it will leak badly and wear quickly" then why would you post picture of a setup you did for a friend that clearly displays a flat (even potentially convex) end of a side seal where it mates to the corner seal?

Last edited by fendamonky; 12-19-16 at 08:48 AM.