can i afford a pp?

#1

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

can i afford a pp?

So I'm still coming back to looking at an rx7 for a powerful car to get. I am thinking I would like to go na pp. I'm wondering how much I should budget in for that to cost me? Also,if I maintain it with regular rebuilds,what should I expect in terms of reliability? And lastly,I live in Minnesota, so most rx7's available are using the 12a,is it safe to pp a 12a? Or should I just find a 13b?

Thanks in advance

Thanks in advance

#3

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

i dont know why you'd think a 12A PP was unsafe, its not going to burgle your house...

cost to build the engine really depends on what kind of deal you get on the housings/seals etc. my friend is about 2/3rd of the way through putting one together, and he found a set of PP rotor housings for $300, bought seals for about $1000, carb was $500, and then we've got another couple hundred in making the intake, and devcon and stuff. around 2k.

if you had to buy everything brand new retail, you'd be spending more than $5k.

reliability depends on the apex seal choice, and how hard you drive it. for instance if you used the carbon apex seals, and just drove it on the freeway, you'd have a hard time going 50,000miles, but steel apex seals in that same situation would go 150,000miles.

cost to build the engine really depends on what kind of deal you get on the housings/seals etc. my friend is about 2/3rd of the way through putting one together, and he found a set of PP rotor housings for $300, bought seals for about $1000, carb was $500, and then we've got another couple hundred in making the intake, and devcon and stuff. around 2k.

if you had to buy everything brand new retail, you'd be spending more than $5k.

reliability depends on the apex seal choice, and how hard you drive it. for instance if you used the carbon apex seals, and just drove it on the freeway, you'd have a hard time going 50,000miles, but steel apex seals in that same situation would go 150,000miles.

#4

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

I plan on steel seals, and I would be doing the machining on my own,I'm thinking about trying to just use the housings on the car I get if they're in good shape. Items such as manifold will also be made by me. And I'm not sure if it matters,but I plan on going efi.

#5

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

if you had access to a good machine shop, you could basically PP for a couple hundred on top of the rebuild... efi can be really simple too, 2 injectors, practically any ecu...

#7

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

we built a PP intake manifold yesterday, its about the easiest manifold to make for anything ever.... 3 flanges, 2 pipes, and some measuring

Trending Topics

#8

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Ok thanks for the info! this is actually pretty promising. Anything I should look for on determining if the housings I get are good enough to be ported? Also,do I need sleeves put in if I'm doing a rectangular port? And where would my money be going in this port if I did the work myself? what kind of a shopping list am I looking at?

#9

i dont know why you'd think a 12A PP was unsafe, its not going to burgle your house...

cost to build the engine really depends on what kind of deal you get on the housings/seals etc. my friend is about 2/3rd of the way through putting one together, and he found a set of PP rotor housings for $300, bought seals for about $1000, carb was $500, and then we've got another couple hundred in making the intake, and devcon and stuff. around 2k.

if you had to buy everything brand new retail, you'd be spending more than $5k.

reliability depends on the apex seal choice, and how hard you drive it. for instance if you used the carbon apex seals, and just drove it on the freeway, you'd have a hard time going 50,000miles, but steel apex seals in that same situation would go 150,000miles.

cost to build the engine really depends on what kind of deal you get on the housings/seals etc. my friend is about 2/3rd of the way through putting one together, and he found a set of PP rotor housings for $300, bought seals for about $1000, carb was $500, and then we've got another couple hundred in making the intake, and devcon and stuff. around 2k.

if you had to buy everything brand new retail, you'd be spending more than $5k.

reliability depends on the apex seal choice, and how hard you drive it. for instance if you used the carbon apex seals, and just drove it on the freeway, you'd have a hard time going 50,000miles, but steel apex seals in that same situation would go 150,000miles.

Can it be built for 2k including $500 carb? sure, but you will be disappointed in the long run, Find yourself a descent carb 58mm minimum, research racers with results and find out what they charge for a good set of pp rotor housings or at least the machining part.

I seen street ports take out pp engines way too many times, You don't want to be that dude making brap brap noise and no go. good luck on the build

#10

Exhaust Manifold Leak

for the street I would say a 48 or 51mm ida is more than enough. it wil make around 270-280hp at the flywheel with good torque from close to idle. only thing a PP does not like a part load driving.

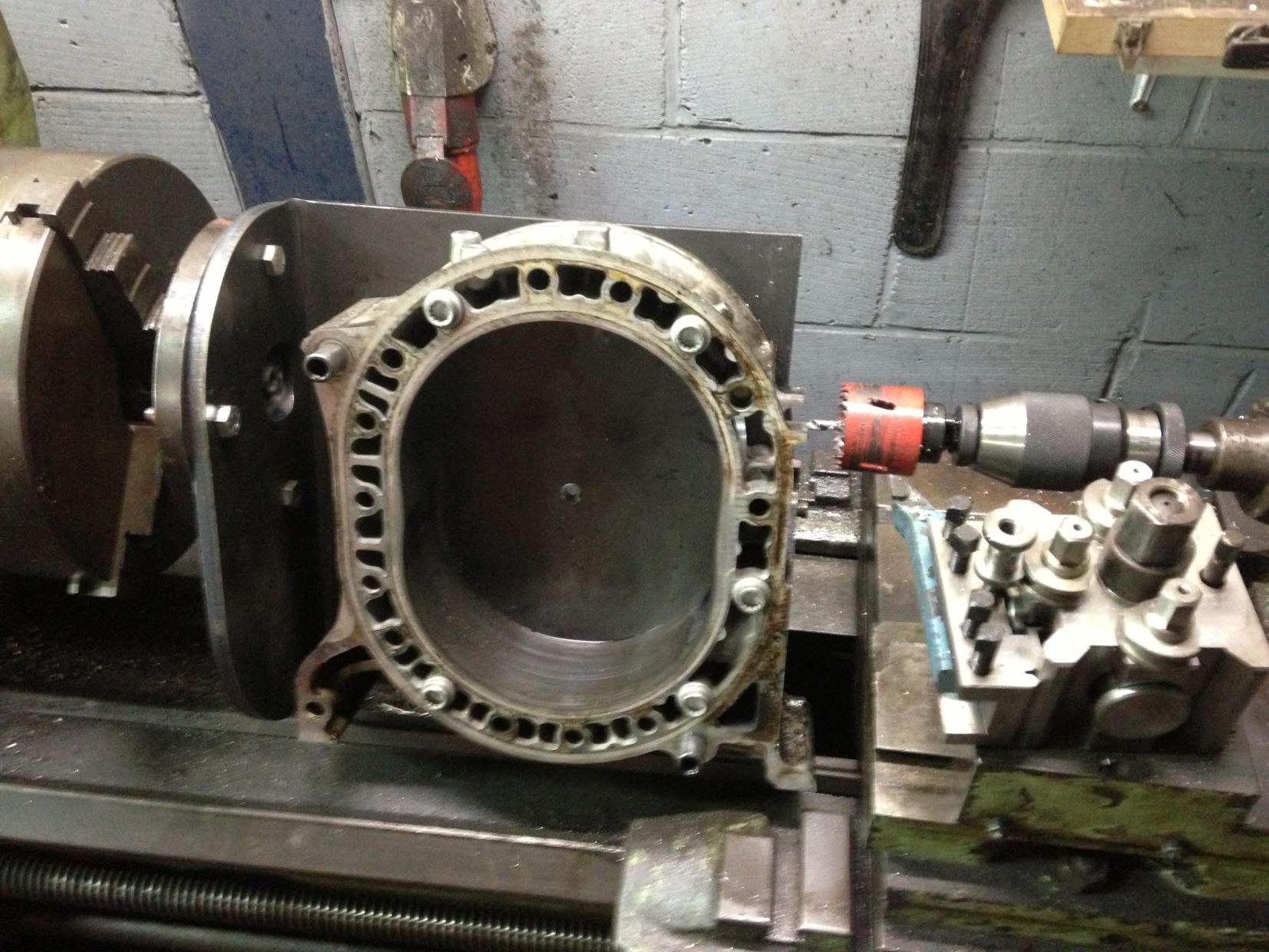

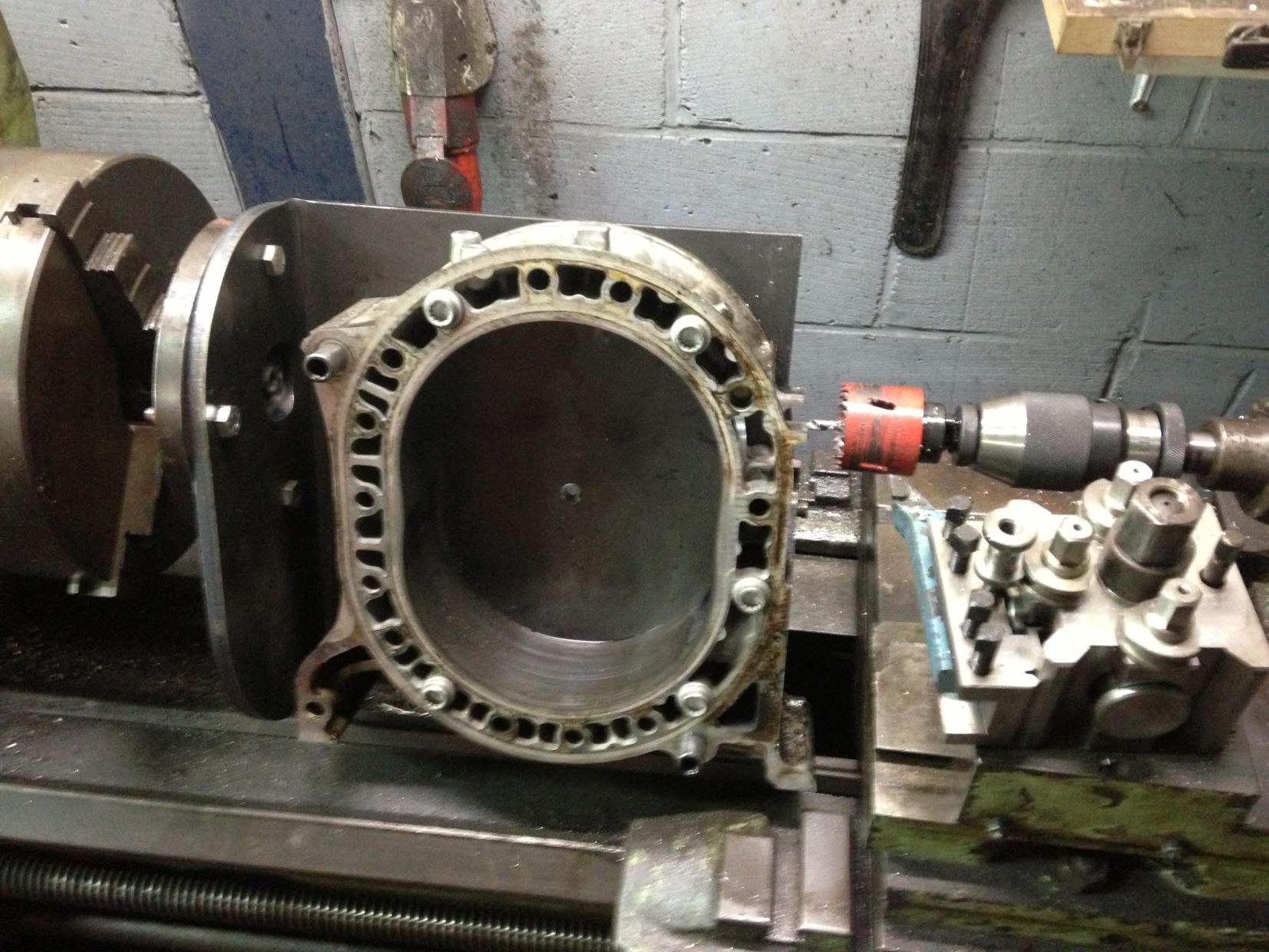

Here is my DIY way of making housings. Still perfect after a season of racing.

Here is my DIY way of making housings. Still perfect after a season of racing.

#11

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

$300 PP housings? and 2k total build? What about race bearings, clearancing the rotors. bearings and balancing? A pp is not for the street, they run like pigs below 5,000 rpms and need a very loud free flow exhaust to make descent power.

Can it be built for 2k including $500 carb? sure, but you will be disappointed in the long run, Find yourself a descent carb 58mm minimum, research racers with results and find out what they charge for a good set of pp rotor housings or at least the machining part.

I seen street ports take out pp engines way too many times, You don't want to be that dude making brap brap noise and no go. good luck on the build

Can it be built for 2k including $500 carb? sure, but you will be disappointed in the long run, Find yourself a descent carb 58mm minimum, research racers with results and find out what they charge for a good set of pp rotor housings or at least the machining part.

I seen street ports take out pp engines way too many times, You don't want to be that dude making brap brap noise and no go. good luck on the build

i actually own a PP, and maybe yours runs like a pig under 5,000rpm, but mine doesn't. you would be surprised how tame a PP can be when you spend your time tuning part throttle. i have a friend with a you tube channel, and most of his videos are just him driving his PP 1st gen in traffic...

i am wrong about the carb though, a 48 IDA is $500 new, but you need to change all the jets, so realistically its more like $1000

#13

Exhaust Manifold Leak

yes but losses at whees are measured during coastdown and added to measured wheelpower, so the power/torque you see is estimated at the flywheel. losses are quite low on this dyno as it uses 48"rolls. still a long way to go as most users here with a serious PP make around 300 so called whp. thus close to 320 at the eshaft on gasolone and at least 10% more on methanol. will try bigger exhaust ports this season. intake is already much bigger as what most run, still midrange torque is really good.

#15

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

#16

Old [Sch|F]ool

A pp is not for the street, they run like pigs below 5,000 rpms and need a very loud free flow exhaust to make descent power.

Then it started leaking coolant again, so I yanked it out and started playing with 13Bs because 12As got impossible to find. I do bridge ports now, because a Holley manifold and carb-as-throttle-body is simple and effective.

#17

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

we should tell this guy too! he's got a whole channel of his PP SA22 sitting in traffic

#18

the $300 PPP housings were just an amazing deal. if you would have seen the auction, you would have bought em too. we used stock apex seals, which caps the redline at about 8,500, so no need for fancy bearings, although its a good place to spend extra money.

i actually own a PP, and maybe yours runs like a pig under 5,000rpm, but mine doesn't. you would be surprised how tame a PP can be when you spend your time tuning part throttle. i have a friend with a you tube channel, and most of his videos are just him driving his PP 1st gen in traffic...

i am wrong about the carb though, a 48 IDA is $500 new, but you need to change all the jets, so realistically its more like $1000

i actually own a PP, and maybe yours runs like a pig under 5,000rpm, but mine doesn't. you would be surprised how tame a PP can be when you spend your time tuning part throttle. i have a friend with a you tube channel, and most of his videos are just him driving his PP 1st gen in traffic...

i am wrong about the carb though, a 48 IDA is $500 new, but you need to change all the jets, so realistically its more like $1000

It should be told like it is and not mislead the guys asking for advise, I guess the OP has to ask himself, What is my goal? and decide from there. good luck to all

#19

Old [Sch|F]ool

I winged an unclearanced 13B to 9k on a regular basis and 10k once on accident. When I had the engine apart over the winter, I noted where the rotors had shiny spots, and hit them with an angle grinder (sanding disks, not 24 grit stuff  ). The next set of rotors that I used, i just sanded the sides of the tips ~.003 or so on each face.

). The next set of rotors that I used, i just sanded the sides of the tips ~.003 or so on each face.

That was quite a long time ago, odometer was at 205k when I put it in, it's at either 237 or 242k (it's been so long since I sat in the car, i've forgotten!) and that also includes quite a while of driving with a broken speedometer drive. Engine sees up to 10k regularly. No race clearanced bearings, but I did port the heck out of the oil pump feed passages, teardropped the eccentric shaft, bumped oil pressure up to 80psi, and I am using a 12A oil pump because they cavitate less at high RPM.

I'm not saying some people can't break a crowbar in a sand box. What I am saying is a lot of the "common knowledge" only makes sense for the OLD engines where the rotors were heavy, the rotor gears had only 9 pins and not 12 (12-pin setup greatly reduces stress on the stat gears and reduces/eliminates rotor gear walkout), things like that.

Which brings me to my next point: Bite the bullet, suck it up, start with an '86-up engine. Waaay worth it on many levels, and you're also not effectively destroying what are now increasingly rare and valuable 12A parts.

). The next set of rotors that I used, i just sanded the sides of the tips ~.003 or so on each face.

). The next set of rotors that I used, i just sanded the sides of the tips ~.003 or so on each face.That was quite a long time ago, odometer was at 205k when I put it in, it's at either 237 or 242k (it's been so long since I sat in the car, i've forgotten!) and that also includes quite a while of driving with a broken speedometer drive. Engine sees up to 10k regularly. No race clearanced bearings, but I did port the heck out of the oil pump feed passages, teardropped the eccentric shaft, bumped oil pressure up to 80psi, and I am using a 12A oil pump because they cavitate less at high RPM.

I'm not saying some people can't break a crowbar in a sand box. What I am saying is a lot of the "common knowledge" only makes sense for the OLD engines where the rotors were heavy, the rotor gears had only 9 pins and not 12 (12-pin setup greatly reduces stress on the stat gears and reduces/eliminates rotor gear walkout), things like that.

Which brings me to my next point: Bite the bullet, suck it up, start with an '86-up engine. Waaay worth it on many levels, and you're also not effectively destroying what are now increasingly rare and valuable 12A parts.

#20

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

I will agree with your pricing but what's the ultimate goal? to just build a pp for cheap with a 48 ida carb? will it run brap brap around town under 8500 rpms? YES! Can it compete in a race environment (even in a 1/8 mile drag race) with the guy that clearanced his engine for higher rpms running a 58carb? HELL NO!

It should be told like it is and not mislead the guys asking for advise, I guess the OP has to ask himself, What is my goal? and decide from there. good luck to all

It should be told like it is and not mislead the guys asking for advise, I guess the OP has to ask himself, What is my goal? and decide from there. good luck to all

we also ran a stock unclearanced, unbalanced S5 engine to 9400rpms for a season of road racing, which is close to 30 hours. we parted out the car, but the engine is still sitting, tired, but unblown up.

so yes goal is important.

#21

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Well people talking bout carb size is somewhat irrelevant because I plan on doing efi,and my goal is most peak power I can afford. I will be doing autocross and low speed,tight course drifting,and most often drag racing. While on the strip I don't expect to be competitive,but I would like to fearlessly take on the diesel trucks rolling around Minnesota here on the highway.

most of all though,this car is supposed to be fun car on a budget.

most of all though,this car is supposed to be fun car on a budget.

#22

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

Well people talking bout carb size is somewhat irrelevant because I plan on doing efi,and my goal is most peak power I can afford. I will be doing autocross and low speed,tight course drifting,and most often drag racing. While on the strip I don't expect to be competitive,but I would like to fearlessly take on the diesel trucks rolling around Minnesota here on the highway.

most of all though,this car is supposed to be fun car on a budget.

most of all though,this car is supposed to be fun car on a budget.

so the more friendly more midrange power band engine, is going to have smaller ports than the drag racing grenade, so basically the difference is the whole saw bit you need to buy, which costs the same for either size

#23

it is actually the crux of the whole deal. if you're willing to live within the margins of the stock parts, a PP can be quite simple and cheap. if you decide you need to try and make more power than anyone has ever made before, you had better be prepared to buy a lot of parts and rebuild the engine a few times. so the more friendly more midrange power band engine, is going to have smaller ports than the drag racing grenade, so basically the difference is the whole saw bit you need to buy, which costs the same for either size

#24

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

Mazda used a 46mm port and 48mm throttle on a 13B/20B. Mazda's port is always straight in from the side. the aftermarket Japanese housings use a threaded sleeve, that also goes straight in from the side, and it uses the housing casting to make the difference, or in other words the port is a smaller size than the hole for the sleeve, they have a seam like Rub's housings.

the Japanese leave a flange on the outside of the tube, to hold the intake manifold flange on, which is free to float.

the Japanese leave a flange on the outside of the tube, to hold the intake manifold flange on, which is free to float.

#25

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

So you're saying that I should be around 46mm ports? And why wouldn't I want to use rectangular ports? seems to me that would leave more area for air to flow through,while having less overlap?

And when you say I should stick within stock components ability,about what rwhp would that be? And what parts would I be having to replace/upgrade?

And when you say I should stick within stock components ability,about what rwhp would that be? And what parts would I be having to replace/upgrade?