Bought a semi p-port, bridgeport. Have questions.

#1

Full Member

Thread Starter

Bought a semi p-port, bridgeport. Have questions.

Hey Guys,

Picked up a Kp61 Starlet with semi peripheral port bridgeport. 12a.

First thing. It takes a long time to start. Lots of cranking, lots of fuel/pumping of the pedal. In comparison, my full bridgeport engine takes 2 pumps and starts instantly.

Do p-ports need more cranking?

Next, and is probably my answer to the first question, both rotors are at 55-60psi cold cranking compression.

The only thing is, the starter is not for a rotary, and is only spinning at maybe 500 rpm's. It is mated to the stock starlet transmission, and probably its starter. Its also only getting 10 volts at the starter, so thats not helping any either. (12v off, 13.8 running). Wire going to starter is laughably puny.

I will address those issues next weekend.

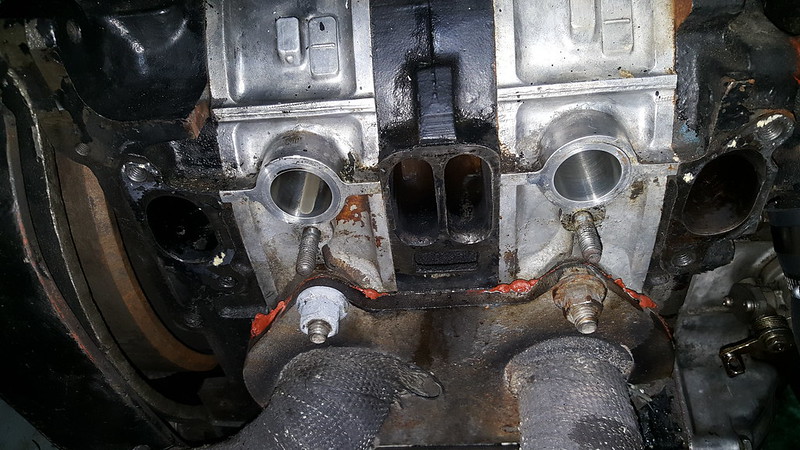

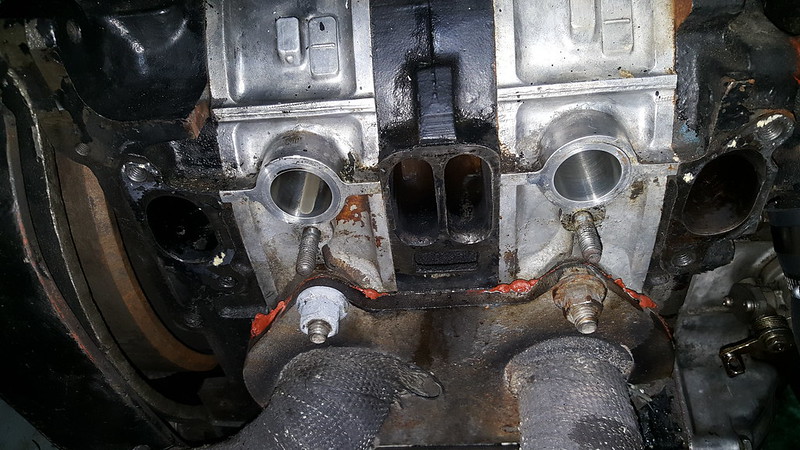

Another odd thing is when I pulled the intake manifold to confirm it was a p-port, It was puddled up with a white/grey milky liquid. See picture.

It could not have been sitting in there, as I was driving/launching hard, and it would had to have been sucked in. Which means it happened while parked.

Does it look like coolant? It does not smell or taste like it, but it is slippery.

Fuel is premixed, and premixed heavy.

Starts hot with out a problem. A little bit of cranking & fuel, like 5 seconds worth, but nothing like the cold start.

When running, runs extremely well. Idles fine. Lumpy and high, but fine. No smoke at all, when driving or idling. A small expected amount at start up.

Carb needs tuning, as it has a terrible lean stumble, but it is a straight line track car, so the gas pedal is for on and off only!

Just looking for your professional opinions.

Thanks,

Picked up a Kp61 Starlet with semi peripheral port bridgeport. 12a.

First thing. It takes a long time to start. Lots of cranking, lots of fuel/pumping of the pedal. In comparison, my full bridgeport engine takes 2 pumps and starts instantly.

Do p-ports need more cranking?

Next, and is probably my answer to the first question, both rotors are at 55-60psi cold cranking compression.

The only thing is, the starter is not for a rotary, and is only spinning at maybe 500 rpm's. It is mated to the stock starlet transmission, and probably its starter. Its also only getting 10 volts at the starter, so thats not helping any either. (12v off, 13.8 running). Wire going to starter is laughably puny.

I will address those issues next weekend.

Another odd thing is when I pulled the intake manifold to confirm it was a p-port, It was puddled up with a white/grey milky liquid. See picture.

It could not have been sitting in there, as I was driving/launching hard, and it would had to have been sucked in. Which means it happened while parked.

Does it look like coolant? It does not smell or taste like it, but it is slippery.

Fuel is premixed, and premixed heavy.

Starts hot with out a problem. A little bit of cranking & fuel, like 5 seconds worth, but nothing like the cold start.

When running, runs extremely well. Idles fine. Lumpy and high, but fine. No smoke at all, when driving or idling. A small expected amount at start up.

Carb needs tuning, as it has a terrible lean stumble, but it is a straight line track car, so the gas pedal is for on and off only!

Just looking for your professional opinions.

Thanks,

Last edited by heywier427; 01-23-17 at 08:42 PM.

#2

Full Member

Thread Starter

And dont pay any attention to the grime. This thing has not been cleaned in a long time. I dont think its been apart in any way, since it was built.

I have no info on the builder, other than it was a guy from PR, who lived in NJ. Car has been on the east coast for a while now.

Extremely loud, extremely brappy, extremely fun!

I have no info on the builder, other than it was a guy from PR, who lived in NJ. Car has been on the east coast for a while now.

Extremely loud, extremely brappy, extremely fun!

Last edited by heywier427; 01-23-17 at 07:47 PM.

#4

Full Member

Thread Starter

So things are looking better after a few changes.

Hot compression is 70-75 on both. Not great, but hey.

The carb that was on there (Holley 600) had no choke the air horn was cut off, and a 1" open spacer.

I installed a 750 double pumper and things are much better.

The 600 had a wicked lean stumble when stabbing the gas.

Ive gradually upped both pump shots and cams, and almost have it totally gone. Its very driveable now.

I started on the 750 with a 4 hole spacer, as thats what my full bridge likes, but after tuning, the 600 still pulled harder up top. I added the open 1" spacer, and a large improvement was had. The driveability went down a bit, but I know I can fine tune it to be better.

The hard starting I think is just getting used to this engine/setup. The guy I bought it from would pump it 10-15 times, then crank it while pumping 10-20 times. I figured it would get flooded, but it always started.

Now that I have a choke added, I dont need to pump the gas at all, but press it a 1/4 or less of the way down (to keep the secondary's closed) and it fires up no problem. Same starting procedure hot.

It wants more fuel!

Setting it up on my brothers dyno this weekend to fine tune.

Things are looking up!

Edit: Timing is locked, and was locked at 26ish with a Rb pulley. Ive backed it off and advanced it from there with little change. I will probably unlock it, and let the advance do its thing. Theres not enough to be gained with it locked. Have to snag another distributor, as somebody altered this one beyond repair.

Edit: The previous owner says the stuff in the intake track was CRC intake cleaner/defogger. He had blown the upper rad. hose, and sucked down alot of coolant. Its hard to believe it was still in there after driving it so hard, but there is no evidence of coolant seepage into the rotors, so fingers crossed!

Hot compression is 70-75 on both. Not great, but hey.

The carb that was on there (Holley 600) had no choke the air horn was cut off, and a 1" open spacer.

I installed a 750 double pumper and things are much better.

The 600 had a wicked lean stumble when stabbing the gas.

Ive gradually upped both pump shots and cams, and almost have it totally gone. Its very driveable now.

I started on the 750 with a 4 hole spacer, as thats what my full bridge likes, but after tuning, the 600 still pulled harder up top. I added the open 1" spacer, and a large improvement was had. The driveability went down a bit, but I know I can fine tune it to be better.

The hard starting I think is just getting used to this engine/setup. The guy I bought it from would pump it 10-15 times, then crank it while pumping 10-20 times. I figured it would get flooded, but it always started.

Now that I have a choke added, I dont need to pump the gas at all, but press it a 1/4 or less of the way down (to keep the secondary's closed) and it fires up no problem. Same starting procedure hot.

It wants more fuel!

Setting it up on my brothers dyno this weekend to fine tune.

Things are looking up!

Edit: Timing is locked, and was locked at 26ish with a Rb pulley. Ive backed it off and advanced it from there with little change. I will probably unlock it, and let the advance do its thing. Theres not enough to be gained with it locked. Have to snag another distributor, as somebody altered this one beyond repair.

Edit: The previous owner says the stuff in the intake track was CRC intake cleaner/defogger. He had blown the upper rad. hose, and sucked down alot of coolant. Its hard to believe it was still in there after driving it so hard, but there is no evidence of coolant seepage into the rotors, so fingers crossed!

Last edited by heywier427; 01-27-17 at 11:10 AM.

#5

Full Member

Thread Starter

Didnt make it on the dyno!

Who says rotaries make no torque?

20170127_204947[1] by thomas telesco, on Flickr

20170127_204947[1] by thomas telesco, on Flickr

Wasn't even a launch! Hard 3rd gear pull! Another push car in the fleet!

Who says rotaries make no torque?

20170127_204947[1] by thomas telesco, on Flickr

20170127_204947[1] by thomas telesco, on FlickrWasn't even a launch! Hard 3rd gear pull! Another push car in the fleet!

Last edited by heywier427; 01-28-17 at 11:03 AM.

#6

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,796

Received 2,574 Likes

on

1,830 Posts

on the starting thing, i've got a full P port with a 48ida (no choke), and from dead cold it needs some pumping of gas, and cranking to get fuel in there. it depends on how cold it is outside, on a warm summer day, it needs like 1 pump, on a 32f morning, probably 6-8.

once it starts though, and its run for more than 10 seconds, i can turn it off and it'll restart like any stock engine.

it will idle on its own after about 30 seconds of running, although its low and a bit lumpy, ~600rpm, idle comes up to about 950-1000 as it warms up.

i notice if i over premix it, the premix stays a liquid, and it'll pool and leak out of strange places.

once it starts though, and its run for more than 10 seconds, i can turn it off and it'll restart like any stock engine.

it will idle on its own after about 30 seconds of running, although its low and a bit lumpy, ~600rpm, idle comes up to about 950-1000 as it warms up.

i notice if i over premix it, the premix stays a liquid, and it'll pool and leak out of strange places.

#7

Old [Sch|F]ool

Cold starts were always funny for me too, I think the problem is it's easier for the rotor to pull from the exhaust port than through the intake manifold most of the time. On a hot engine you probably have a burnable mix in the exhaust port so it starts okay

I remembered what one guy said a looong time about about starting his IDA-fed peripheral port cold - pump the throttle three or four times then hold it WOT when cranking. Makes sense if my gut feeling is right.

I remembered what one guy said a looong time about about starting his IDA-fed peripheral port cold - pump the throttle three or four times then hold it WOT when cranking. Makes sense if my gut feeling is right.

Trending Topics

#9

Old [Sch|F]ool

85psi on what gauge? On a Mazda tester with a 1' long hose or a generic tester with a 4' long one? It makes a huge difference.

I've had engines start and run just fine with 50psi compression, hot and cold. My peripheral port had 100+psi compression when it was a stockport, when I built it as a peripheral port it had 60psi compression using all of the same rotors and seals and engine housings.

Ignore compression numbers...

I've had engines start and run just fine with 50psi compression, hot and cold. My peripheral port had 100+psi compression when it was a stockport, when I built it as a peripheral port it had 60psi compression using all of the same rotors and seals and engine housings.

Ignore compression numbers...

#10

Full Member

Thread Starter

Compression tester is a standard one, with about a 12-14" hose. Valve removed of course.

My thinking on the starting procedure, is what the function of the choke is. It chokes air, so the mixture is richer, as well as creating a suction/vacuum to pull the fuel in.

While keeping the butterflys open when flooded always gets things going, it seems when cold, keeping all the blades closed works for me.

It always starts, and runs really really well. I know its cold out, but it brakes the tires loose in 4th if Im really honking on it. 11" Drag radials It does help that the rear is welded, and this thing is a tin can!

It does help that the rear is welded, and this thing is a tin can!

Rear is said to be coming in today via ups. Hurry up!

My thinking on the starting procedure, is what the function of the choke is. It chokes air, so the mixture is richer, as well as creating a suction/vacuum to pull the fuel in.

While keeping the butterflys open when flooded always gets things going, it seems when cold, keeping all the blades closed works for me.

It always starts, and runs really really well. I know its cold out, but it brakes the tires loose in 4th if Im really honking on it. 11" Drag radials

It does help that the rear is welded, and this thing is a tin can!

It does help that the rear is welded, and this thing is a tin can! Rear is said to be coming in today via ups. Hurry up!

#11

Old [Sch|F]ool

If you remove the valve your numbers will be incredibly low. For reference, with the valve in I will get 80-90psi compression, with no valve so I can watch the bounces it will read about 25psi.

#12

Full Member

Thread Starter

Interesting. I always thought you removed the valve.

Not to pester a veteran, but what is your procedure with a generic tester.

Im kinda excited to hear your thoughts, as 70-75psi with no valve, should yield higher numbers.

But how do those numbers compare to a mazda tester?

Has anyone done back to back comparisons?

Again, it drives like a bat out of hell, so im going to drive it such!

The rear came in! But unfortunately Ive eaten a larger order of chicken n broccoli, and im not doing **** tonight!

Not to pester a veteran, but what is your procedure with a generic tester.

Im kinda excited to hear your thoughts, as 70-75psi with no valve, should yield higher numbers.

But how do those numbers compare to a mazda tester?

Has anyone done back to back comparisons?

Again, it drives like a bat out of hell, so im going to drive it such!

The rear came in! But unfortunately Ive eaten a larger order of chicken n broccoli, and im not doing **** tonight!

#13

Old [Sch|F]ool

I crank it with the gauge "normal" until the number stabilizes. You can usually see a weak pulse as the needle will pause for a cycle before it kicks again.

To check evenness I hold the valve open and just watch to see if the bounces are even.

If we ever get a proper scope at work with a pressure transducer, I want to compare my methods to what the pressure transducer reads.

There are so many flaws with checking rotaries with a non-rotary tester, all you can really do is test the engine when new, when broken in, and monitor it periodically. From there you can watch trends as they occur. But I wouldn't condemn an engine just because of number taken out of context. If it's testing at 70, what does that mean? If the engine tested at 80 when it was new and it was at 80 when broken in and it was 80 after 20,000 mi and now it's at 70, okay, now we can plot the engine degrading gracefully. If it tested at 130 when it was new and you got it too hot and now it's testing at 70, okay, we have a problem.

To check evenness I hold the valve open and just watch to see if the bounces are even.

If we ever get a proper scope at work with a pressure transducer, I want to compare my methods to what the pressure transducer reads.

There are so many flaws with checking rotaries with a non-rotary tester, all you can really do is test the engine when new, when broken in, and monitor it periodically. From there you can watch trends as they occur. But I wouldn't condemn an engine just because of number taken out of context. If it's testing at 70, what does that mean? If the engine tested at 80 when it was new and it was at 80 when broken in and it was 80 after 20,000 mi and now it's at 70, okay, now we can plot the engine degrading gracefully. If it tested at 130 when it was new and you got it too hot and now it's testing at 70, okay, we have a problem.

Last edited by peejay; 02-06-17 at 10:41 PM.

#14

Full Member

Thread Starter

Boy, some funky stuff going on with this rear!

Maybe it is all old news for older quarter mile guys, but it slowed my *** right down...

So the rear end and diff are Datsun 521 truck. The datsun spider gears have been removed and ford 9" spider gears welded in. Welded with the teeth to the outside of the spider gear cage.

This is because the ford 9" drive shafts are much longer than the datsun stuff. They flipped the spider gears so the teeth extend further into the center of the diff, then cut down the splined ends of the ford shafts.

Pretty creative, parts are super cheap, and it was probably what they had on hand. But holy hell, figuring that mess out was a few days of internetting!

How the f did they weld those spider gears in straight! They must have used a long splined axle (or 2 splined ends cut and welded together) to lock it all in place for welding.

Theres snow on the ground, so Im not going anywhere anyway!

Maybe it is all old news for older quarter mile guys, but it slowed my *** right down...

So the rear end and diff are Datsun 521 truck. The datsun spider gears have been removed and ford 9" spider gears welded in. Welded with the teeth to the outside of the spider gear cage.

This is because the ford 9" drive shafts are much longer than the datsun stuff. They flipped the spider gears so the teeth extend further into the center of the diff, then cut down the splined ends of the ford shafts.

Pretty creative, parts are super cheap, and it was probably what they had on hand. But holy hell, figuring that mess out was a few days of internetting!

How the f did they weld those spider gears in straight! They must have used a long splined axle (or 2 splined ends cut and welded together) to lock it all in place for welding.

Theres snow on the ground, so Im not going anywhere anyway!