6 port na track day build, which Bridgeport?

#1

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

I am building my 87 rx7 with 6 Port NA motor into a trackday car with the below 2 goals.

1. The motor has to be reliable.

2. I want good power 4k rpm to redline. Good power as in 120, 130 ftlb torque at the wheels.

I will be using Holley carb, Jaytech manifold, Stock FC coils, dizzy, the 6 port motor, 9.3 compression rotors and DIY Exhaust manifold-merging before rear wheels. Might switch over to a Fitech or similar EFI. Stock clutch and fly wheel. I don't want to use any intake sleeves. Less parts, less issues!

The car will weight at about 2200-2300 lb. Gutted interior, no AC, Manual steering, gutted wiring etc.

I have 2 questions:

1. Which Porting? Bridge the Secondary and Aux ports or Bridge all 6 ports? I will be driving it to the local track and AutoX events which are about an hour which means cruising at 2500-3k rpm. As long as I can get there without bogging and sputtering I am fine.

2. Any other mods I should consider? Oiling mods and such. I am guessing the car will make 200 rwhp around 7000 rpm. Does this seem right? Any other suggestions?

This is a budget build so I am trying to avoid 4 port housings and 9.7 compression S5 rotors. Somebody's gotta use the 6 port stuff! I have 2 of these 6 port motors, so I am building one and using second one as a spare.

I have driven a gutted first gen with 12a motor, full bridge in 6 Lemons races and it drove great, slightly higher idle, loud as hell and took a bit to warm up. If I can replicate that I will be happy!

Thanks.

1. The motor has to be reliable.

2. I want good power 4k rpm to redline. Good power as in 120, 130 ftlb torque at the wheels.

I will be using Holley carb, Jaytech manifold, Stock FC coils, dizzy, the 6 port motor, 9.3 compression rotors and DIY Exhaust manifold-merging before rear wheels. Might switch over to a Fitech or similar EFI. Stock clutch and fly wheel. I don't want to use any intake sleeves. Less parts, less issues!

The car will weight at about 2200-2300 lb. Gutted interior, no AC, Manual steering, gutted wiring etc.

I have 2 questions:

1. Which Porting? Bridge the Secondary and Aux ports or Bridge all 6 ports? I will be driving it to the local track and AutoX events which are about an hour which means cruising at 2500-3k rpm. As long as I can get there without bogging and sputtering I am fine.

2. Any other mods I should consider? Oiling mods and such. I am guessing the car will make 200 rwhp around 7000 rpm. Does this seem right? Any other suggestions?

This is a budget build so I am trying to avoid 4 port housings and 9.7 compression S5 rotors. Somebody's gotta use the 6 port stuff! I have 2 of these 6 port motors, so I am building one and using second one as a spare.

I have driven a gutted first gen with 12a motor, full bridge in 6 Lemons races and it drove great, slightly higher idle, loud as hell and took a bit to warm up. If I can replicate that I will be happy!

Thanks.

#2

Old [Sch|F]ool

I've driven half bridge and full bridge engines almost exclusively since 2009, putting about 20k street miles per year on them, mostly driving 4-26 hours round trip to events.

Don't bother with a 6 port if at all possible. They close the ports way too late for good midrange torque no matter what you do.

I never saw more than 175hp at the wheels on a Dynojet from a half bridge 6 port. 135hp on a Mustang. It did shift the torque band down nicely compared to a stock/street port 6 port but it ends up asking more from the port geometry than it can deliver. The aux ports just close way too late for good chamber filling at low RPM, you end up blowing the charge right back up the intake manifold.

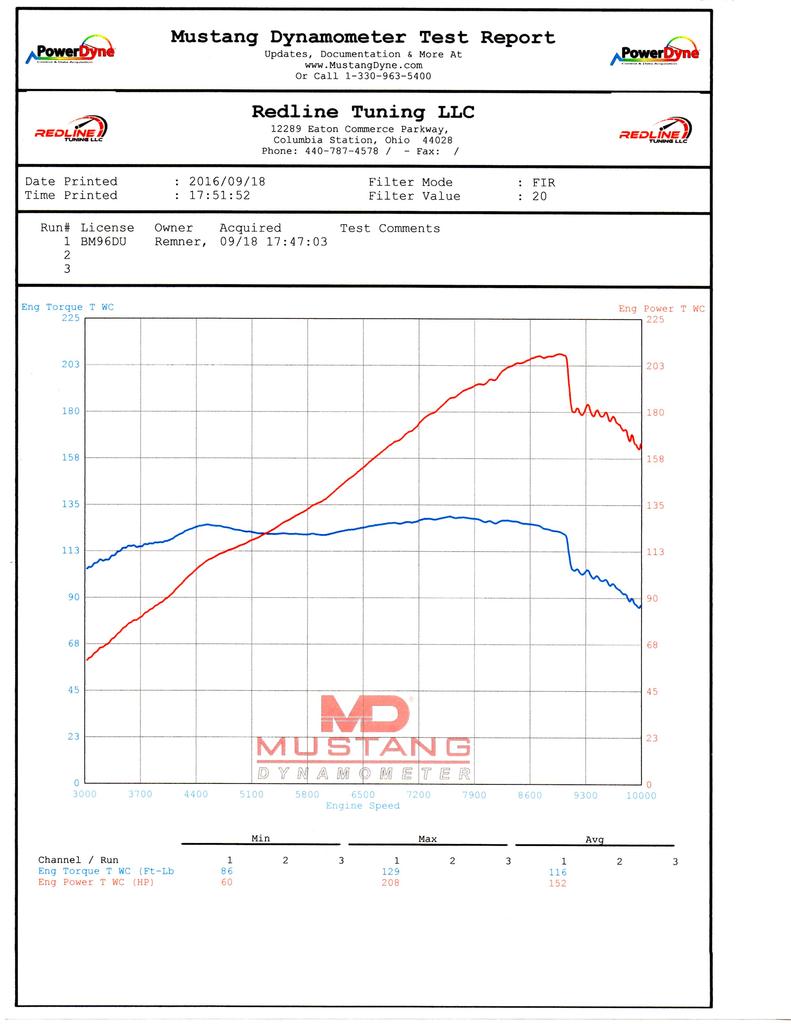

My current full bridge (4 port 13B, much smaller runners than Turbo II and later 4 ports) did 208whp on a Mustang, and while it was built for mid range torque, it sure as heck didn't make that power at 7000rpm. Intake ports close around 55ATDC.

With that in mind, I would NOT use a stock flywheel. That is a lot of iron spinning down there and all rotaries of any port type really benefit from an aluminum flywheel at the minimum. My class-limited stockport 12A is going to get a 5.5" or 7.5" clutch and non-flywheel as soon as the parts come up cheap on eBay.

Fuel injection is absolutely mandatory if you want drivability, IMO. My engines all drove like pussycats. You really want ITBs for street drivability but there are "tricks" you can do with the stock manifolding if you stick with a half bridge.

Don't bother with a 6 port if at all possible. They close the ports way too late for good midrange torque no matter what you do.

I never saw more than 175hp at the wheels on a Dynojet from a half bridge 6 port. 135hp on a Mustang. It did shift the torque band down nicely compared to a stock/street port 6 port but it ends up asking more from the port geometry than it can deliver. The aux ports just close way too late for good chamber filling at low RPM, you end up blowing the charge right back up the intake manifold.

My current full bridge (4 port 13B, much smaller runners than Turbo II and later 4 ports) did 208whp on a Mustang, and while it was built for mid range torque, it sure as heck didn't make that power at 7000rpm. Intake ports close around 55ATDC.

With that in mind, I would NOT use a stock flywheel. That is a lot of iron spinning down there and all rotaries of any port type really benefit from an aluminum flywheel at the minimum. My class-limited stockport 12A is going to get a 5.5" or 7.5" clutch and non-flywheel as soon as the parts come up cheap on eBay.

Fuel injection is absolutely mandatory if you want drivability, IMO. My engines all drove like pussycats. You really want ITBs for street drivability but there are "tricks" you can do with the stock manifolding if you stick with a half bridge.

Last edited by peejay; 01-12-17 at 12:25 PM.

#3

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,780

Received 2,565 Likes

on

1,824 Posts

we used to make 125ish lbs feet with a stock port 6 port and stock intakes...

https://www.rx7club.com/time-slips-d...-port-1006884/

https://www.rx7club.com/time-slips-d...-port-1006884/

#4

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Peejay, J9fd3s.

Thanks for the reply.

I really want to keep this on budget hence the 6 port motor. I have 2 complete 6 port motors so it doesn't make sense doing parts selling/buying to get 4 port housings. Once the motor is in the car if I am not happy, I will go buy 4 a port motor.

So far I do want the ability to drive to the track in NJ traffic. So I am opting for half bridge to be a little conservative.

I am going to buy a flywheel, thanks for that suggestion Peejay.

I would love ITB or webers. But I am not well versed with tuning a rotary so might skip the carb route and go FITECH! Its the cheapest stand alone ECU/THrottle body for fuel. Dizzy and stock coils for spark.

Here is the Plot twist. My builder and a close friend recommended Rx8 rotating assembly which gives me 10:1 compression, lower weight rotors and possibility to rev up to 9.5k. I am really thinking of going this route. Its a non turbo motor, so the depth of apex seals isn't an issue. Plus my motor came with 3 piece apex seals which proves the point that extra depth isn't really necessary for my build.

I will also be playing with throttle body spacers to move the power band down if needed. Its a lemons/roadkill inspired build so cutting a hole in the hood is almost necessary!

j9fd3s, that dyno plot looks great. The torque gets flat at 6100 rpm, will that be due to stock intake/fuel setup? My intake will be much better suited for higher flow and with higher rpm motor I am hoping the torque stays flat till 7000 or 8000 rpm. I know I am taking a huge penalty under 4k rpm, my intake velocities are going to be super slow.

My goal isn't peak hp numbers, but a flat torque curve starting the 4k and up range. From my lemons experience in the first gen rx7, I saw that the most benefit of the rotary is coming out of turns. With a linear curve, I can go WOT right at apex climb from 5000 to 8000-8500 rpm before I shift. Most piston and turbo engines have tons of torque and they may spin the tires if you stab the throttle. Part throttle takes finesse! The rotary loves to be in mid/high rpm range under full load and its a blast to come out of turns a few mph faster than everybody else!

Thanks for the reply.

I really want to keep this on budget hence the 6 port motor. I have 2 complete 6 port motors so it doesn't make sense doing parts selling/buying to get 4 port housings. Once the motor is in the car if I am not happy, I will go buy 4 a port motor.

So far I do want the ability to drive to the track in NJ traffic. So I am opting for half bridge to be a little conservative.

I am going to buy a flywheel, thanks for that suggestion Peejay.

I would love ITB or webers. But I am not well versed with tuning a rotary so might skip the carb route and go FITECH! Its the cheapest stand alone ECU/THrottle body for fuel. Dizzy and stock coils for spark.

Here is the Plot twist. My builder and a close friend recommended Rx8 rotating assembly which gives me 10:1 compression, lower weight rotors and possibility to rev up to 9.5k. I am really thinking of going this route. Its a non turbo motor, so the depth of apex seals isn't an issue. Plus my motor came with 3 piece apex seals which proves the point that extra depth isn't really necessary for my build.

I will also be playing with throttle body spacers to move the power band down if needed. Its a lemons/roadkill inspired build so cutting a hole in the hood is almost necessary!

j9fd3s, that dyno plot looks great. The torque gets flat at 6100 rpm, will that be due to stock intake/fuel setup? My intake will be much better suited for higher flow and with higher rpm motor I am hoping the torque stays flat till 7000 or 8000 rpm. I know I am taking a huge penalty under 4k rpm, my intake velocities are going to be super slow.

My goal isn't peak hp numbers, but a flat torque curve starting the 4k and up range. From my lemons experience in the first gen rx7, I saw that the most benefit of the rotary is coming out of turns. With a linear curve, I can go WOT right at apex climb from 5000 to 8000-8500 rpm before I shift. Most piston and turbo engines have tons of torque and they may spin the tires if you stab the throttle. Part throttle takes finesse! The rotary loves to be in mid/high rpm range under full load and its a blast to come out of turns a few mph faster than everybody else!

#5

Megasquirt and 2x ID1000 injectors would be cheaper than the FITECH! setup. The advice from others above is very very sound advice since they have years of experience under their belts. I still think you should look into ITBs for making flat predictable power. 23Racer has been running a set of Hyabusa ITBs on his 2nd gen half bridge race car and he always raves about how flat and tractable his power curve is (no dyno numbers for his setup though). The only downside is you would have to fab up a custom intake manifold but tuning would be a breeze if you went megasquirt and 2x ID1000s in the primary position only. Aaron Cake has a very in depth write up on his website about how to install a Megasquirt MS3X into an RX7.

Ultimately you should choose whichever route interests you the most. It sounds like this is a project of self discovery and fun as much as making the most power so you want to choose mods that you will enjoy and feel comfortable with because you don't want to get frustrated and burnt out on working on something you don't enjoy working on. Plus there is not much info on people running Holley style FI TBs like the one you mentioned. Peejay has taken an actual Holley carb and removed the fuel bits and used it just as a TB then used a Megasquirt and 2x ID1000s in the primary position but that's the only FI Holley setup I have seen. Just my 0.02

Ultimately you should choose whichever route interests you the most. It sounds like this is a project of self discovery and fun as much as making the most power so you want to choose mods that you will enjoy and feel comfortable with because you don't want to get frustrated and burnt out on working on something you don't enjoy working on. Plus there is not much info on people running Holley style FI TBs like the one you mentioned. Peejay has taken an actual Holley carb and removed the fuel bits and used it just as a TB then used a Megasquirt and 2x ID1000s in the primary position but that's the only FI Holley setup I have seen. Just my 0.02

Last edited by Lavitzlegend; 01-13-17 at 08:54 AM.

#6

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Lavitzlegend.

I definitely agree on advice above. Its just the time-money-skills equation that I have to balance.

I looked up the Aaron cake megasquirt writeup. It might be a good option down the road, but this is my first rotary build! I don't want to spend hours wiring stuff. Fitech is 4 bolts and 2 wires. Super easy setup. I also have to break in this motor and I don't want to risk running lean. The other thing is easy of debugging/parts removal at track/race. ITBs seem just a tad bit more complicated than Fitech or a holley carb.

It will take a couple of weeks to get my motor ported and couple of weeks to build and put the motor in the car. I also have to build the exhaust manifold! So the megasquirt with ITB seems like a bit of time-challenge for now, I have 4 weeks to decide. Hayabusa ITBs looks like a fun project too!

Definitely has a self discovery and fun perspective. I want to build something cool and fun but not an all out race car. Not yet!

I like you advice, I will keep it fun.

I definitely agree on advice above. Its just the time-money-skills equation that I have to balance.

I looked up the Aaron cake megasquirt writeup. It might be a good option down the road, but this is my first rotary build! I don't want to spend hours wiring stuff. Fitech is 4 bolts and 2 wires. Super easy setup. I also have to break in this motor and I don't want to risk running lean. The other thing is easy of debugging/parts removal at track/race. ITBs seem just a tad bit more complicated than Fitech or a holley carb.

It will take a couple of weeks to get my motor ported and couple of weeks to build and put the motor in the car. I also have to build the exhaust manifold! So the megasquirt with ITB seems like a bit of time-challenge for now, I have 4 weeks to decide. Hayabusa ITBs looks like a fun project too!

Definitely has a self discovery and fun perspective. I want to build something cool and fun but not an all out race car. Not yet!

I like you advice, I will keep it fun.

#7

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Here are some fun pictures of our car on small fire in September at Kershaw SC.

We had fuel starvation issues all day long. A backfire caught the carb on fire.

https://photos.google.com/share/AF1Q...V2Q1pCWmU5dEVB

I got the car in pits, jumped out, a nice fellow racer helped me pop the hood and I put the fire out. Went for a lap at 15 minutes later!

We had fuel starvation issues all day long. A backfire caught the carb on fire.

https://photos.google.com/share/AF1Q...V2Q1pCWmU5dEVB

I got the car in pits, jumped out, a nice fellow racer helped me pop the hood and I put the fire out. Went for a lap at 15 minutes later!

Trending Topics

#8

Senior Member

you shouldn't even need a bridge to make the power you want, my car has street ported 6 port GSL-SE housings ,with S4 rotors, S5 intake, MS3Pro with RX8 injectors. It made 205 on a Mustang dyno and ran great. This year I am building an S5 engine with half bridge and expect to make more like 240.

#9

Old [Sch|F]ool

Peejay, J9fd3s.

Thanks for the reply.

I really want to keep this on budget hence the 6 port motor. I have 2 complete 6 port motors so it doesn't make sense doing parts selling/buying to get 4 port housings. Once the motor is in the car if I am not happy, I will go buy 4 a port motor.

Thanks for the reply.

I really want to keep this on budget hence the 6 port motor. I have 2 complete 6 port motors so it doesn't make sense doing parts selling/buying to get 4 port housings. Once the motor is in the car if I am not happy, I will go buy 4 a port motor.

So far I do want the ability to drive to the track in NJ traffic. So I am opting for half bridge to be a little conservative.

I would love ITB or webers. But I am not well versed with tuning a rotary so might skip the carb route and go FITECH! Its the cheapest stand alone ECU/THrottle body for fuel. Dizzy and stock coils for spark.

Here is the Plot twist. My builder and a close friend recommended Rx8 rotating assembly which gives me 10:1 compression, lower weight rotors and possibility to rev up to 9.5k. I am really thinking of going this route. Its a non turbo motor, so the depth of apex seals isn't an issue. Plus my motor came with 3 piece apex seals which proves the point that extra depth isn't really necessary for my build.

I will also be playing with throttle body spacers to move the power band down if needed. Its a lemons/roadkill inspired build so cutting a hole in the hood is almost necessary!

j9fd3s, that dyno plot looks great. The torque gets flat at 6100 rpm, will that be due to stock intake/fuel setup? My intake will be much better suited for higher flow and with higher rpm motor I am hoping the torque stays flat till 7000 or 8000 rpm. I know I am taking a huge penalty under 4k rpm, my intake velocities are going to be super slow.

My goal isn't peak hp numbers, but a flat torque curve starting the 4k and up range. From my lemons experience in the first gen rx7, I saw that the most benefit of the rotary is coming out of turns. With a linear curve, I can go WOT right at apex climb from 5000 to 8000-8500 rpm before I shift. Most piston and turbo engines have tons of torque and they may spin the tires if you stab the throttle. Part throttle takes finesse! The rotary loves to be in mid/high rpm range under full load and its a blast to come out of turns a few mph faster than everybody else!

j9fd3s, that dyno plot looks great. The torque gets flat at 6100 rpm, will that be due to stock intake/fuel setup? My intake will be much better suited for higher flow and with higher rpm motor I am hoping the torque stays flat till 7000 or 8000 rpm. I know I am taking a huge penalty under 4k rpm, my intake velocities are going to be super slow.

My goal isn't peak hp numbers, but a flat torque curve starting the 4k and up range. From my lemons experience in the first gen rx7, I saw that the most benefit of the rotary is coming out of turns. With a linear curve, I can go WOT right at apex climb from 5000 to 8000-8500 rpm before I shift. Most piston and turbo engines have tons of torque and they may spin the tires if you stab the throttle. Part throttle takes finesse! The rotary loves to be in mid/high rpm range under full load and its a blast to come out of turns a few mph faster than everybody else!

This is my full bridge's torque curve. Holley 3310-based throttle body on an unported Racing Beat manifold.

#10

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Mhr650. I don't think I will be able to cross 200 without porting! Either ways, Jim at JPR imports is doing half bridge on mine in a week or so.

Peejay, Lots of good info.

I agree with No parts, no build!

I will call Fitech and make sure I can get my hands it. If not I might just go holley. Fitech is $ 800, not cheap but not super expensive either, but it will make my setup super easy. I already have the Jaytech 6 port intake.

The Rx8 stuff is bit of an experiment. Since I have the spare motor, I can afford to do this. I hope it works out and I don't blow the housings and the apex seals. That seems to be the largest risk I am taking with this motor build.

Sticking to half bridge for now. I can always port to full bridge. Taking motor in and out of the car is going to be super easy with the setup I am planning.

I saw this dyno chart on the forums. Its fantastic, flat torque and linear power delivery. If I can make this happen it will be awesome!

Peejay, Lots of good info.

I agree with No parts, no build!

I will call Fitech and make sure I can get my hands it. If not I might just go holley. Fitech is $ 800, not cheap but not super expensive either, but it will make my setup super easy. I already have the Jaytech 6 port intake.

The Rx8 stuff is bit of an experiment. Since I have the spare motor, I can afford to do this. I hope it works out and I don't blow the housings and the apex seals. That seems to be the largest risk I am taking with this motor build.

Sticking to half bridge for now. I can always port to full bridge. Taking motor in and out of the car is going to be super easy with the setup I am planning.

I saw this dyno chart on the forums. Its fantastic, flat torque and linear power delivery. If I can make this happen it will be awesome!

#11

Old [Sch|F]ool

If you use the FITech throttle body, either modify it so that the throttle blades open in unison. If that is not possible, rotate the throttle body on the manifold so that the engine idles and does part throttle on the bridged ports, and the secondaries are the non bridged ports. In this way will you get the best drivability.

The poor drivability comes from vacuum in the intake ports being exposed to the bridges, which pulls up a lot of exhaust gases during the overlap period. If you have primary/secondary style throttles, and you have the secondary throttles going to the bridged ports of a half bridge, the bridge ports will see high vacuum until you push the pedal down enough to open them. This is the exact opposite of what you want for good drivability!

When I had half bridge engines with stock manifolds, I modified the throttle bodies so that almost all idle air went through the secondary side instead of the primary. Had to relocate the MAP sensor and brake booster pickup to make this work, get their vacuum from the primary chamber of the plenum rather than the secondary runners. Worked extremely well. With ITBs the vacuum bleeds away rapidly so there isn't as much of an exhaust pullup problem but it was critical to convert my Holley to operate both throttle shafts in unison. This was achieved with a blob of weld in the right place, trivial to do really. Starting with a vacuum secondary carb instead of a mechanical secondary carb made it easier.

Here's one of my half bridge 6 port engines on the street...

The poor drivability comes from vacuum in the intake ports being exposed to the bridges, which pulls up a lot of exhaust gases during the overlap period. If you have primary/secondary style throttles, and you have the secondary throttles going to the bridged ports of a half bridge, the bridge ports will see high vacuum until you push the pedal down enough to open them. This is the exact opposite of what you want for good drivability!

When I had half bridge engines with stock manifolds, I modified the throttle bodies so that almost all idle air went through the secondary side instead of the primary. Had to relocate the MAP sensor and brake booster pickup to make this work, get their vacuum from the primary chamber of the plenum rather than the secondary runners. Worked extremely well. With ITBs the vacuum bleeds away rapidly so there isn't as much of an exhaust pullup problem but it was critical to convert my Holley to operate both throttle shafts in unison. This was achieved with a blob of weld in the right place, trivial to do really. Starting with a vacuum secondary carb instead of a mechanical secondary carb made it easier.

Here's one of my half bridge 6 port engines on the street...

Last edited by peejay; 01-13-17 at 10:19 PM.

#12

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

I am learning a lot.

I think the FITech throttle plates open in unison. I will be calling them anyways with some questions. I can also add a couple of large spacers to increase the plenum volume and make all ports as 1 giant port like they do with single plane intake in a V8.

I am under the impression that I want to keep the intake velocities high at lower rpm. To do so Mazda closes the aux port under 3 or 4 k rpm. In the ideal world I can setup the Fitech like a quadrajet. Just run 2 primary ports and keep the secondaries and aux completely closed They open when the rpm reaches 3 or 4k.

Also I am bridging the second and aux ports not the primary. At least that is what my builder and I had talked about.

How much does it cost to do the ITB megasquirt setup? Aaron Cake writeup seems like a ton of work!

I think the FITech throttle plates open in unison. I will be calling them anyways with some questions. I can also add a couple of large spacers to increase the plenum volume and make all ports as 1 giant port like they do with single plane intake in a V8.

I am under the impression that I want to keep the intake velocities high at lower rpm. To do so Mazda closes the aux port under 3 or 4 k rpm. In the ideal world I can setup the Fitech like a quadrajet. Just run 2 primary ports and keep the secondaries and aux completely closed They open when the rpm reaches 3 or 4k.

Also I am bridging the second and aux ports not the primary. At least that is what my builder and I had talked about.

How much does it cost to do the ITB megasquirt setup? Aaron Cake writeup seems like a ton of work!

#13

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,780

Received 2,565 Likes

on

1,824 Posts

I am learning a lot.

I think the FITech throttle plates open in unison. I will be calling them anyways with some questions. I can also add a couple of large spacers to increase the plenum volume and make all ports as 1 giant port like they do with single plane intake in a V8.

I think the FITech throttle plates open in unison. I will be calling them anyways with some questions. I can also add a couple of large spacers to increase the plenum volume and make all ports as 1 giant port like they do with single plane intake in a V8.

when you get down to it, the typical v8 is a really weird engine, and stuff works on those that doesn't work on normal engines.

am under the impression that I want to keep the intake velocities high at lower rpm. To do so Mazda closes the aux port under 3 or 4 k rpm. In the ideal world I can setup the Fitech like a quadrajet. Just run 2 primary ports and keep the secondaries and aux completely closed They open when the rpm reaches 3 or 4k.

generally higher port velocity = more power under the power peak. until port velocity gets too high, and then you will loose power at peak.

#14

Old [Sch|F]ool

You do NOT want any kind of plenum if you have short runners. I tried it on my peripheral port. It sucks! What ends up happening is the intake port on the intake cycle pulls exhaust gases through the intake port exposed to overlap instead of pulling air through the throttle plates.

With high overlap engines, you want an ITB style setup with a minimal amount of volume downstream of the throttle plates. Stock manifolds work okay with bridge ports because the runners are so long that inertia works to prevent backfilling, to some degree. But they are compromised in other ways as a result.

With high overlap engines, you want an ITB style setup with a minimal amount of volume downstream of the throttle plates. Stock manifolds work okay with bridge ports because the runners are so long that inertia works to prevent backfilling, to some degree. But they are compromised in other ways as a result.

#15

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Ok. I will try the open spacer out and the 4 hole spacer. I think I have those laying around somewhere. I understand that no spacer might be the best deal.

I did not realise the port timing differences between a 4 port and a 6 port was 30 degrees! No wonder everybody loves the 4 port motor! I gotta run what I got!

I will be picking up the motor by end of January. I might order all the rebuild parts and the FItech by then. Once the motor is in the car I can figure out headers and such.

Any idea what timing-advance I should be running? I want to be extremely cautious. I am ok loosing the 5 or 10 hp to keep the detonation away.

I did not realise the port timing differences between a 4 port and a 6 port was 30 degrees! No wonder everybody loves the 4 port motor! I gotta run what I got!

I will be picking up the motor by end of January. I might order all the rebuild parts and the FItech by then. Once the motor is in the car I can figure out headers and such.

Any idea what timing-advance I should be running? I want to be extremely cautious. I am ok loosing the 5 or 10 hp to keep the detonation away.

#16

Old [Sch|F]ool

Detonation is pretty much impossible, more timing just makes you lose power, really.

I think I have my engine at 18 or 22 degrees max advance, something like that. I'm also running vacuum advance. Basically I just sorta farted around with it until it got the drivability I wanted. Electronic timing control is in the cards but I want to run a crank trigger and not the FC crank angle sensor Fitting a crank trigger is hard if you want to keep the water pump.

With stockport 12As, i would run in the 25-27 degree region. The better the ports, the less timing you need. Either way, you're not going to detonate, there is way too much chamber motion and WAY too much heat loss for detonation to be possible.

I think I have my engine at 18 or 22 degrees max advance, something like that. I'm also running vacuum advance. Basically I just sorta farted around with it until it got the drivability I wanted. Electronic timing control is in the cards but I want to run a crank trigger and not the FC crank angle sensor Fitting a crank trigger is hard if you want to keep the water pump.

With stockport 12As, i would run in the 25-27 degree region. The better the ports, the less timing you need. Either way, you're not going to detonate, there is way too much chamber motion and WAY too much heat loss for detonation to be possible.

#17

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Peejay. Good to know.

So far here is whats going in.

13b 6 port motor with half bridge. Rx8 rotating assembly.

Rx8 counter weight and Rx7 aftermarket flywheel mating to stock trans.

Jaytech + Fitech for fuel!

Dizzy and stock FC coils for spark.

Time to order parts!

So far here is whats going in.

13b 6 port motor with half bridge. Rx8 rotating assembly.

Rx8 counter weight and Rx7 aftermarket flywheel mating to stock trans.

Jaytech + Fitech for fuel!

Dizzy and stock FC coils for spark.

Time to order parts!

#18

Here is the Plot twist. My builder and a close friend recommended Rx8 rotating assembly which gives me 10:1 compression, lower weight rotors and possibility to rev up to 9.5k. I am really thinking of going this route. Its a non turbo motor, so the depth of apex seals isn't an issue. Plus my motor came with 3 piece apex seals which proves the point that extra depth isn't really necessary for my build.

The Renesis apex seal is about as tall (actually 0.3mm shorter) than the top piece of a 3-piece seal, but even the last FD had a stock red line of 8k, so I would have stuck with that. I keep reading someone had done it, but no one seems to have posted first hand experience with it, so I'm interested in seeing how this goes.

I also thought the side seals of the Renesis rotor were pushed far back enough that a bridge port shouldn't be used, but you could push the opening back further than was possible with previous rotors.

#19

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

The apex grooves are not as deep, so the biggest worry is the flexing of the seal when it goes over the exhaust port. I will be calling Atkins and see if their Rx8 seals are up to the task. My exhaust port will be similar to T2 port, I am not going bigger / wider port.

The Side seals are about 2 mm further out, so that makes my bridge wider and the port thinner. I can live with that. Probably supports the side seal better than a wide port and thin bridge.

The benefits are, e shaft has a bit better clearance with bearings and its tad bit lighter. Rotors are lighter and balanced to 10k rpm, compression ratio is 10:1.

I think this combo should yield the most HP for the money as long as I stay NA. Not the most peak hp but the most torque under the curve starting at 4k rpm. Redline of 9k or 9.5k should be possible.

We will see what happens. I am not doing this because I can save money vs. S5 rotors. I am doing it as a fun different thing to try and get the rpm a bit higher which results in wider power band.

If money was no object I would love to build a nasty NA motor that goes to 12k or so rpm and puts down decent power all the way till the end.

The Side seals are about 2 mm further out, so that makes my bridge wider and the port thinner. I can live with that. Probably supports the side seal better than a wide port and thin bridge.

The benefits are, e shaft has a bit better clearance with bearings and its tad bit lighter. Rotors are lighter and balanced to 10k rpm, compression ratio is 10:1.

I think this combo should yield the most HP for the money as long as I stay NA. Not the most peak hp but the most torque under the curve starting at 4k rpm. Redline of 9k or 9.5k should be possible.

We will see what happens. I am not doing this because I can save money vs. S5 rotors. I am doing it as a fun different thing to try and get the rpm a bit higher which results in wider power band.

If money was no object I would love to build a nasty NA motor that goes to 12k or so rpm and puts down decent power all the way till the end.

#20

Old [Sch|F]ool

I can't find the thread. Mazdatrix tried using RX-8 rotors in 2002 or 2003 or something and posted the results here. Basically the apex seals wouldn't handle it.

Yes, I know, three piece seals. Something to bear in mind is that a lot of the force against the apex seal is gas pressure on the backside. With a three piece seal, the seal gets pushed against the rotor housing evenly by the second piece behind it. With a two piece, the seal is pushed directly by gas pressure. Food for thought.

Another thing is that other people then went to the trouble of EDMing the seal slots deeper so that "standard" apex seals could be used. They then found that they made no more power than 9.7 rotors and in some cases slightly less. There's an interesting effect in the engine where higher compression makes for higher pumping losses as the airflow gets moved through the engine.

One of the highest horsepower 2 rotor N/A engines I'm aware of (meaning had numbers published), had 8.5:1 rotors. When you're stretching the limits at high RPM, strange things come into play.

These ain't piston engines, that's for sure. Anyway, this is why I stick with the 9.4 rotors, they are common and don't really give anything up. Money is better spent elsewhere.

Yes, I know, three piece seals. Something to bear in mind is that a lot of the force against the apex seal is gas pressure on the backside. With a three piece seal, the seal gets pushed against the rotor housing evenly by the second piece behind it. With a two piece, the seal is pushed directly by gas pressure. Food for thought.

Another thing is that other people then went to the trouble of EDMing the seal slots deeper so that "standard" apex seals could be used. They then found that they made no more power than 9.7 rotors and in some cases slightly less. There's an interesting effect in the engine where higher compression makes for higher pumping losses as the airflow gets moved through the engine.

One of the highest horsepower 2 rotor N/A engines I'm aware of (meaning had numbers published), had 8.5:1 rotors. When you're stretching the limits at high RPM, strange things come into play.

These ain't piston engines, that's for sure. Anyway, this is why I stick with the 9.4 rotors, they are common and don't really give anything up. Money is better spent elsewhere.

#21

Information Regurgitator

Aren't three piece seals kind of a moot point now. I thought Mazda stopped selling them and OEM seals were two piece now. At least when I built mine back in 2013 mine were two piece. Have they started selling thee piece again?

#22

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,780

Received 2,565 Likes

on

1,824 Posts

Mazda went to 2 piece shortly after the Rx8 came out, and haven't switched back. there are a couple of JDM tuners that take the 2 piece and cut it into a 3 piece. they seal better. they also will DLC them.

#24

Funny enough JPR imports built my current engine. It's a full bridge na that started with t2 irons and housings with s5 na rotors. I bought it from Jorx7 on the forums here about 2 years ago and swapped it into my car.

ITBs are just like everything else. They can be as expensive or as cheap as you choose. Borla induction and Jenvey make some really nice kits but they are quite a bit of money. Then you have to buy an IDA style intake on top of that. I am planning before winter is over to make my own custom 4-runner intake and mate it up to some Hayabusa ITBs off ebay. I currently have an Apexi PowerFC in the car but I might switch over to Megasquirt MS3X (around 600-700 bucks) and sell off the PowerFC. I've been having some weird wiring issues lately since the PowerFC uses the stock wiring harness. Then on top of that I am going to pick up 2 ID1000s which is around 240 bucks. So all in all it will cost around a grand for me if I make the intake myself. But luckily I should be able to sell the PowerFC for around that much but we'll see.

ITBs are just like everything else. They can be as expensive or as cheap as you choose. Borla induction and Jenvey make some really nice kits but they are quite a bit of money. Then you have to buy an IDA style intake on top of that. I am planning before winter is over to make my own custom 4-runner intake and mate it up to some Hayabusa ITBs off ebay. I currently have an Apexi PowerFC in the car but I might switch over to Megasquirt MS3X (around 600-700 bucks) and sell off the PowerFC. I've been having some weird wiring issues lately since the PowerFC uses the stock wiring harness. Then on top of that I am going to pick up 2 ID1000s which is around 240 bucks. So all in all it will cost around a grand for me if I make the intake myself. But luckily I should be able to sell the PowerFC for around that much but we'll see.

#25

Junior Member

Thread Starter

Join Date: Dec 2015

Location: NJ

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Lavitzlegend you are from Iowa and Jim built your motor? Wow thats a long haul!

Itbs are out of question for now. They definitely seem cool but time is not my friend. I need to get the motor done by spring. I am hoping Fitech will work out, from a few phone calls it seems that it should work with 13b and they are in stock.

I read up some more on these 4 port vs. 6 port motors. Yup, PeeJay was right Dammit! I have 1 spare 6 port motor that is going for sale now. I will be buying a 4 port front and rear iron for future use, may be next winter build!

For now, I am sticking to 6 port motor with 9:7 rotors. I should be getting the ported plates back from Jim this weekend.

I do have to figure out exhaust. I wanted to make my own headers but it depends on time and what mother decides to do with the snow!

Itbs are out of question for now. They definitely seem cool but time is not my friend. I need to get the motor done by spring. I am hoping Fitech will work out, from a few phone calls it seems that it should work with 13b and they are in stock.

I read up some more on these 4 port vs. 6 port motors. Yup, PeeJay was right Dammit! I have 1 spare 6 port motor that is going for sale now. I will be buying a 4 port front and rear iron for future use, may be next winter build!

For now, I am sticking to 6 port motor with 9:7 rotors. I should be getting the ported plates back from Jim this weekend.

I do have to figure out exhaust. I wanted to make my own headers but it depends on time and what mother decides to do with the snow!