Link Ci-PEC ViPEC V88

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

ViPEC V88

i think this is my last "finally" post... after more than 2 months of waiting my ViPEC V88 actually has a tracking number and is due to take off from Auckland via DHL within a few hours.

i let Link make the call as to whether it would be the Xtreme of V88 and they decided V88. i do like that as the V88 is Peak and Hold.

our chief admin guy (Mar3) is still battling the clock and thinks he will be able to enable our section in the engine management forum this weekend.. it will be entitled "Link-ViPEC."

since the two brands are very similar the setup and tuning will be close to the same.

Finally...

howard

i let Link make the call as to whether it would be the Xtreme of V88 and they decided V88. i do like that as the V88 is Peak and Hold.

our chief admin guy (Mar3) is still battling the clock and thinks he will be able to enable our section in the engine management forum this weekend.. it will be entitled "Link-ViPEC."

since the two brands are very similar the setup and tuning will be close to the same.

Finally...

howard

#2

Awesome Howard. I'm kind of glad that they are sending you the ViPEC instead. Now you won't have to mess around injector drivers. Plus the ViPEC is supposedly going to support real, honest to goodness traction control at some point. I'm just waiting of my ProEFI to come in to get started on my project.

#4

I imagine the support for peak and hold (low impedance) injectors out of the box probably had something to do with it. For whatever reason that option was removed from the Link during a firmware update. Also according the people I spoke with full on traction control is only going to be released on the ViPEC. I guess they are trying to differentiate the product lines from each other. My guess is you will be seeing more premium features added to the ViPEC first, with them eventually making their way to the Link line.

#6

The feature set on the Pro EFI is pretty amazing though. However the Link and ViPECs also offer a comparable solution at an amazing price. I went with the Pro EFI mainly because I think its flex fuel integration is the best, bar none. However both the Links and ViPEC's support this feature. Also if I have any questions I can call Jason up or send him an e-mail and he'll get right back to me. Having a US based company and support is important to me. Plus I can also call Ray at PFS if I have questions since he know's these ECUs and rotaries like the back of his hand. Not that Link or ViPEC or lacking in this regard either. They'll answer questions right away and even Skype with you if you want to talk with one of their technicians or engineers.

Bottom line either way, I think it's an exciting time for the rotary community to finally be getting aftermarket ECU's worthy of our rather fickle engines. With people like Howard willing to pioneer and share his experiences, both good and bad, we all benefit.

#7

Anyone interested in ViPec in the US should talk to Apex Speed www.apexspeedtech.com Neel and the gang have the experience of Daytona 24 wins and AMA championships all the while providing peerless customer support to mere hobbyists. They may not be the least expensive option, but when you need an expert to talk you through a tough spot, no one is better.

Trending Topics

#8

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

update:

i am happy to report that my V88 fits comfortably in the stock FD ECU position. i might, w some luck, be able to finish the wiring part of the install tomorrow.

i received a PM indicating our chances are pretty good for having our own Link ViPEC Section this weekend.

hc

i am happy to report that my V88 fits comfortably in the stock FD ECU position. i might, w some luck, be able to finish the wiring part of the install tomorrow.

i received a PM indicating our chances are pretty good for having our own Link ViPEC Section this weekend.

hc

#9

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

after making a lot of work for myself wiring the V88 into my OE wire bridge i decided that wasn't the way to go...

i removed the engine harness from my car.

i tagged each (46) wire i will be using and ID'd (for future reference) the other (21). i ran the two (A & B) headers thru the rubber deal that goes thru the firewall and plugged them in to the V88 which situates perfectly in the stock ECU location.

i then ran the wires to the general area within the engine compartment. a few of the wires will actually be turned around and go back thru the firewall to the rear of the car. ( to the battery which is located behind the pass seat etc)

tomorrow almost all the wires will be mated to the appropriate sensor/fuel injector/coil.

the sticky part would seem to be the additional headers for the dash and the other various subsystems X the engine.

it is really nice to have the better part of the ECU/wiring in the car.

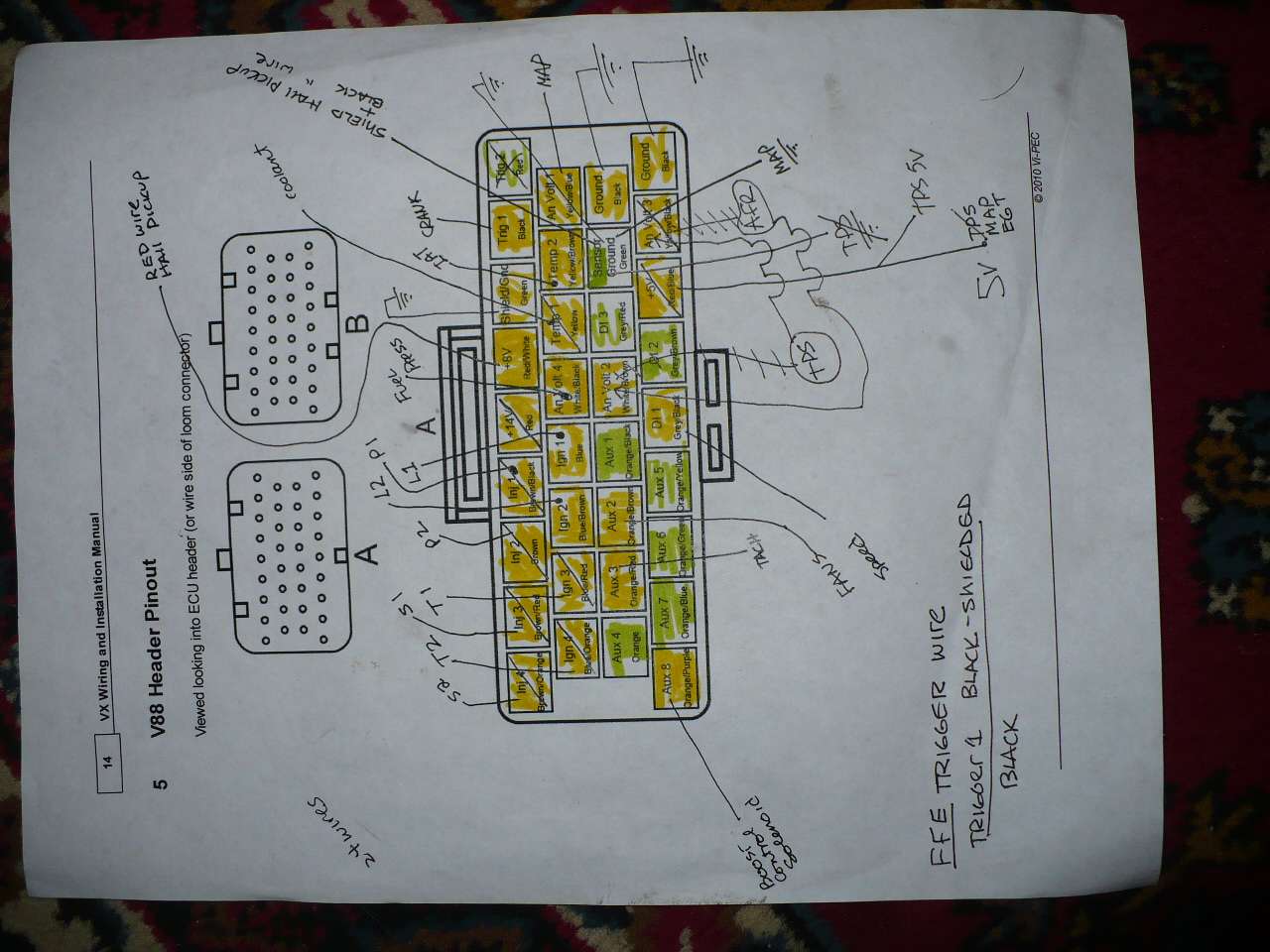

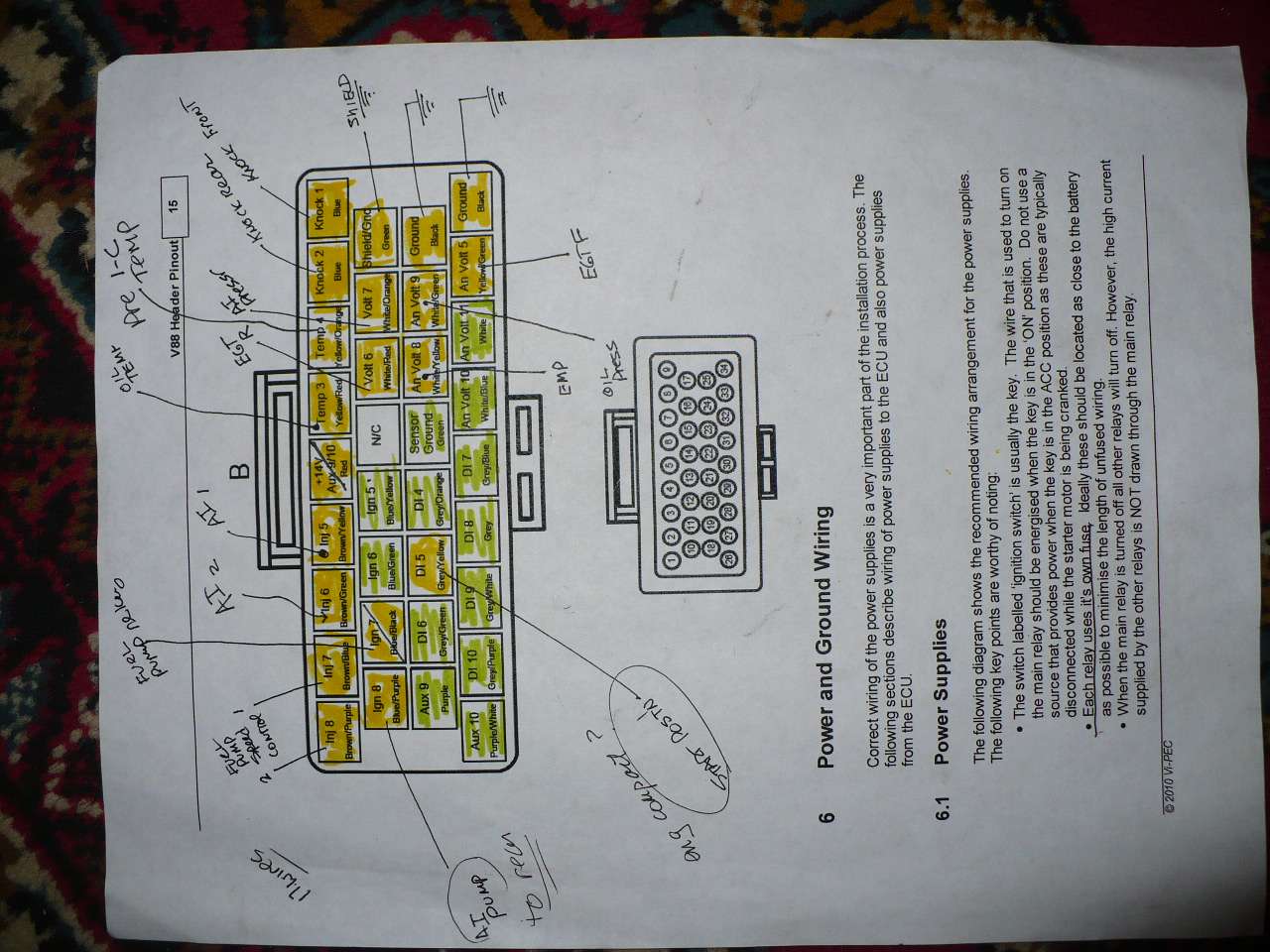

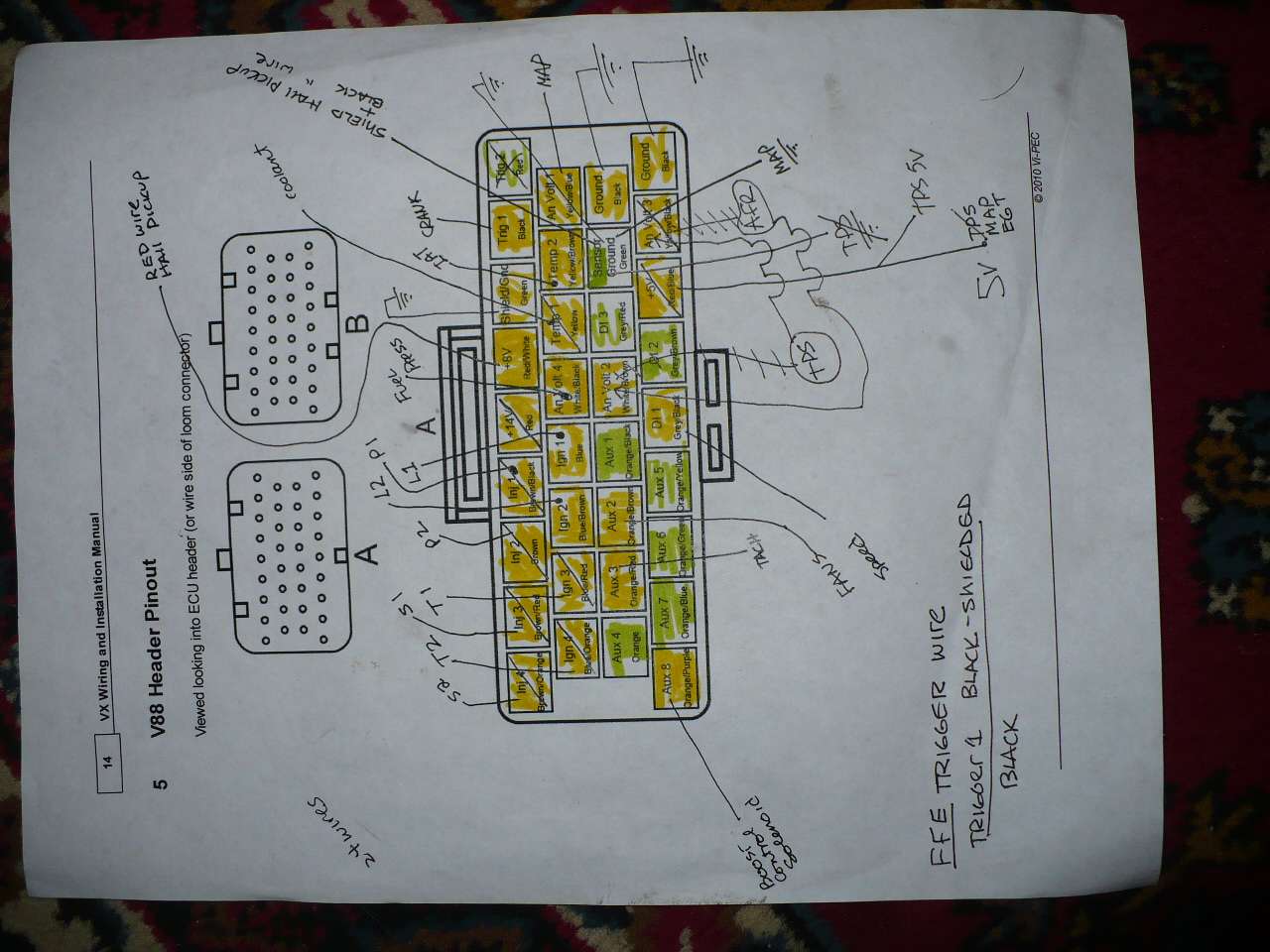

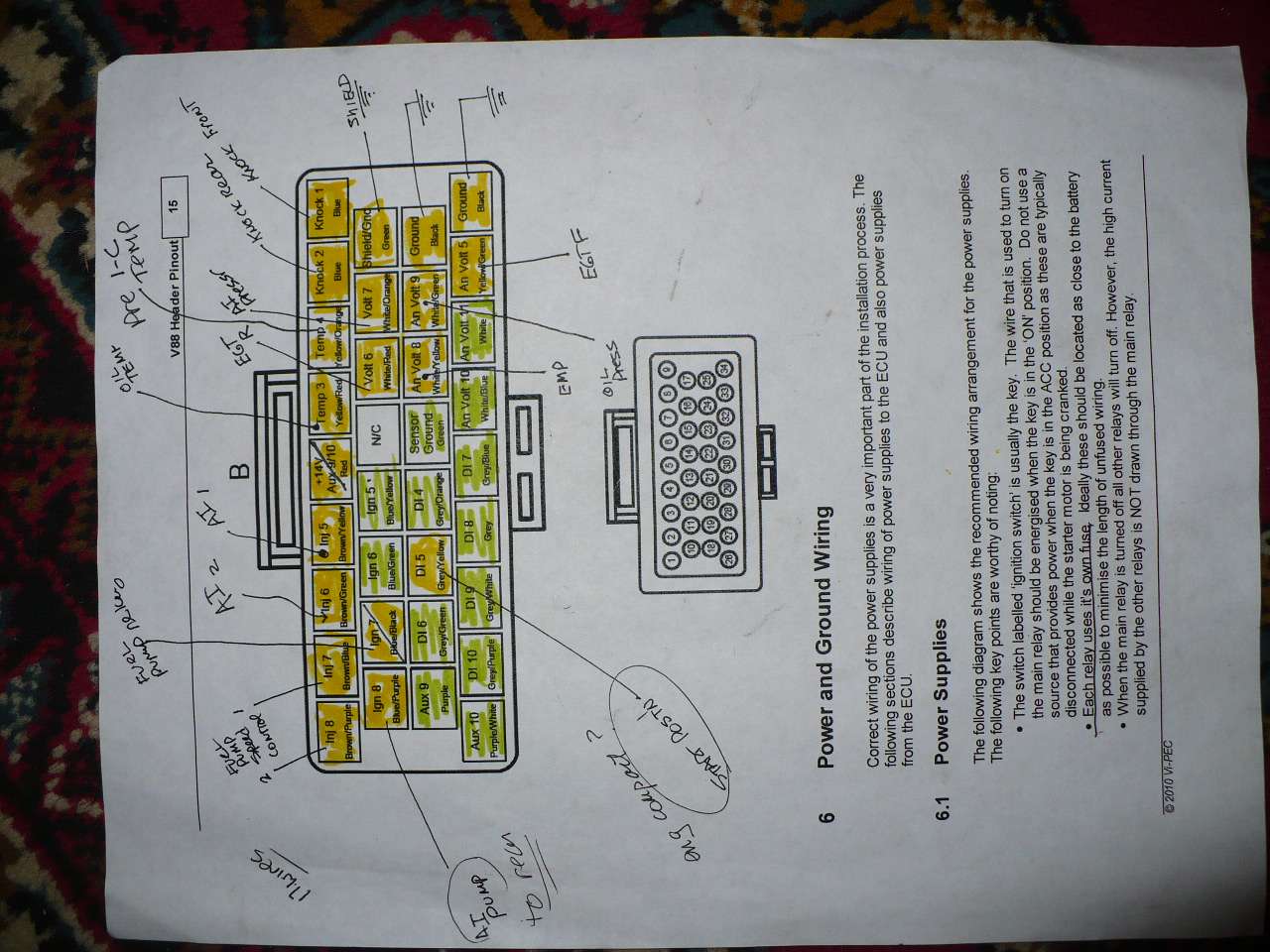

here are my two worksheets... yellow pins are used and light green are not used presently.

howard

i removed the engine harness from my car.

i tagged each (46) wire i will be using and ID'd (for future reference) the other (21). i ran the two (A & B) headers thru the rubber deal that goes thru the firewall and plugged them in to the V88 which situates perfectly in the stock ECU location.

i then ran the wires to the general area within the engine compartment. a few of the wires will actually be turned around and go back thru the firewall to the rear of the car. ( to the battery which is located behind the pass seat etc)

tomorrow almost all the wires will be mated to the appropriate sensor/fuel injector/coil.

the sticky part would seem to be the additional headers for the dash and the other various subsystems X the engine.

it is really nice to have the better part of the ECU/wiring in the car.

here are my two worksheets... yellow pins are used and light green are not used presently.

howard

Last edited by Howard Coleman; 07-05-12 at 08:57 PM.

#10

Senior Member

#12

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

i am enjoying the wire in process. lots of it is straight forward but there will be challenges as i marry the ECU to the other harnesses.

an item:

i elected to upgrade my knock sensors. the FD has an earlier one wire sensor that i thought worked pretty well. i ran a J&S ignition retard on knock module and it employed a newer style Bosch knock sensor. i did some digging and found that the RX8 runs the new Bosch 2 wire sensor. since knock sensors are tuned to a frequency for each app, i figured the Renesis would have the same frequency so i made the switch.

as i started the wire-in i found theat the two knock sensor wires were one wire/shielded. i contacted Link/V and they directed me to run the second wire to the ECU sensor ground. the second wire should be shielded. i just wrapped it in alum foil and spliced the first knock wire's ground to the second wire. L?V indicated they will be switching their harnesses to two wire going forward. no biggie.

lots more to come.

howard

an item:

i elected to upgrade my knock sensors. the FD has an earlier one wire sensor that i thought worked pretty well. i ran a J&S ignition retard on knock module and it employed a newer style Bosch knock sensor. i did some digging and found that the RX8 runs the new Bosch 2 wire sensor. since knock sensors are tuned to a frequency for each app, i figured the Renesis would have the same frequency so i made the switch.

as i started the wire-in i found theat the two knock sensor wires were one wire/shielded. i contacted Link/V and they directed me to run the second wire to the ECU sensor ground. the second wire should be shielded. i just wrapped it in alum foil and spliced the first knock wire's ground to the second wire. L?V indicated they will be switching their harnesses to two wire going forward. no biggie.

lots more to come.

howard

#13

since knock sensors are tuned to a frequency for each app, i figured the Renesis would have the same frequency so i made the switch.

#14

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

lots of people consider the knock sensor on the FD useless...

IMO those people are wrong. it works very well. since it is passive, it isn't going to step up and save your engine if you encounter high knock in boost. (of course some of the newer systems do just that)... knock readings under boost will give you an advance warning if you are taking baby steps up the power ladder.

i don't know what the RX8 system does. i do greatly respect Bosch engineering and apparently so does Mazda as they picked the Bosch 2 wire unit. what Mazda chose to do w it is another issue.

i had 5 years experience w the later generation Bosch knock sensor that was part of my J&S system. it could reduce timing... it was an active system. it worked.

the ViPEC V88 has two on board knock systems.

i have one connected to each rotor housing. the V88 has an extremely capable, active, user definable system. it will also be nice to be logging at 50 HZ rather than 11.

the knock capabilities of the V88 were one of the reasons i decided on it.

my absolute go to engine guy (he makes better than 1000 rwhp w his 13 brew so what does he know) said forget knock. by the time you get it you are toast.

yes, if you are making 1000 hp. if, however, you are tuning your way up the hp ladder it would be very valuable to keep your eye on knock as it progresses. it has been helpful to me.

if you are looking to active knock as a safeguard forget the wastegate. as John Pizzuto said to me, you need help on the NEXT ROTOR FACE! ignition retard is the answer. John is the J in J&S and is one smart guy.

howard

IMO those people are wrong. it works very well. since it is passive, it isn't going to step up and save your engine if you encounter high knock in boost. (of course some of the newer systems do just that)... knock readings under boost will give you an advance warning if you are taking baby steps up the power ladder.

i don't know what the RX8 system does. i do greatly respect Bosch engineering and apparently so does Mazda as they picked the Bosch 2 wire unit. what Mazda chose to do w it is another issue.

i had 5 years experience w the later generation Bosch knock sensor that was part of my J&S system. it could reduce timing... it was an active system. it worked.

the ViPEC V88 has two on board knock systems.

i have one connected to each rotor housing. the V88 has an extremely capable, active, user definable system. it will also be nice to be logging at 50 HZ rather than 11.

the knock capabilities of the V88 were one of the reasons i decided on it.

my absolute go to engine guy (he makes better than 1000 rwhp w his 13 brew so what does he know) said forget knock. by the time you get it you are toast.

yes, if you are making 1000 hp. if, however, you are tuning your way up the hp ladder it would be very valuable to keep your eye on knock as it progresses. it has been helpful to me.

if you are looking to active knock as a safeguard forget the wastegate. as John Pizzuto said to me, you need help on the NEXT ROTOR FACE! ignition retard is the answer. John is the J in J&S and is one smart guy.

howard

Last edited by Howard Coleman; 07-14-12 at 09:33 PM.

#15

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

as i started the wire-in i found theat the two knock sensor wires were one wire/shielded. i contacted Link/V and they directed me to run the second wire to the ECU sensor ground. the second wire should be shielded. i just wrapped it in alum foil and spliced the first knock wire's ground to the second wire. L?V indicated they will be switching their harnesses to two wire going forward. no biggie.

lots more to come.

howard

You talk about how important good and reliable data is and spend thousands of dollars on a new ECU and wiring harness trying to elminate problems and then you cheap out and wrap wire to shield it with aluminum foil

. Rather than spending a few extra dollars for the correct wire

. Rather than spending a few extra dollars for the correct wireDoesnt make sense to me

.

.

#16

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

RenesisFD, i agree with you re the shield wire but didn't happen to have any on hand.

from purely an efficacy aspect aluminum foil works just as well as long as it it properly fixtured. aluminum is an adequate conductor of electricity and as long as it is properly grounded, and in this case it must be common w the knock sensor's shield, it will work perfectly.

plan B would have been to park the particular part of the wiring and hunt down some shield wire but since i have had 5 years of good results w some other custom shield wires using heavy duty aluminum foil i decided to just get it done.

from purely an efficacy aspect aluminum foil works just as well as long as it it properly fixtured. aluminum is an adequate conductor of electricity and as long as it is properly grounded, and in this case it must be common w the knock sensor's shield, it will work perfectly.

plan B would have been to park the particular part of the wiring and hunt down some shield wire but since i have had 5 years of good results w some other custom shield wires using heavy duty aluminum foil i decided to just get it done.

Last edited by Howard Coleman; 07-16-12 at 09:16 AM.

#17

Although aluminum-wrapped wire may have been 'good enough' in the past, it would be a wise idea to implement a better solution while you already have the engine harness out of the car.

I would suggest using "twisted shielded pair" because it will do a better job of preventing noise from interfering with the knock signal (or crank signal, or other important signals you want to be free of noise). This is especially important if you are installing a more powerful ignition system: the higher ignition energy is more likely to be picked up as interference on the wires near the ignition coils, spark plugs, rotor housings, etc...

This page doesn't specify in writing that the pairs are twisted, but I have bought some and it was in fact twisted. The 2-conductor wire could be used for knock sensors or the OEM 2-wire cam/crank sensors, and the 3-conductor wire could be used for hall-effect cam/crank sensors, MAP sensors, etc...

SHIELDED TEFZEL WIRE from Aircraft Spruce

Aircraft Spruce is a good supplier for high-quality wire, although you may be able to find similar materials for less if you spend a lot of time learning about wiring materials and shopping around. Tefzel-insulated wire is sometimes tougher to work with, especially if your wire strippers are worn. Pilot Supplies, Avionics, and Homebuilt Aircraft Parts from Aircraft Spruce and Specialty Co.

Out of curiosity, which signals have you shielded with aluminum foil in the past?

-s-

I would suggest using "twisted shielded pair" because it will do a better job of preventing noise from interfering with the knock signal (or crank signal, or other important signals you want to be free of noise). This is especially important if you are installing a more powerful ignition system: the higher ignition energy is more likely to be picked up as interference on the wires near the ignition coils, spark plugs, rotor housings, etc...

This page doesn't specify in writing that the pairs are twisted, but I have bought some and it was in fact twisted. The 2-conductor wire could be used for knock sensors or the OEM 2-wire cam/crank sensors, and the 3-conductor wire could be used for hall-effect cam/crank sensors, MAP sensors, etc...

SHIELDED TEFZEL WIRE from Aircraft Spruce

Aircraft Spruce is a good supplier for high-quality wire, although you may be able to find similar materials for less if you spend a lot of time learning about wiring materials and shopping around. Tefzel-insulated wire is sometimes tougher to work with, especially if your wire strippers are worn. Pilot Supplies, Avionics, and Homebuilt Aircraft Parts from Aircraft Spruce and Specialty Co.

Out of curiosity, which signals have you shielded with aluminum foil in the past?

-s-

#18

Senior Member

howard,

i just connected the knock signal cables to one side of the sensors, and the other side to sensor ground; this is how scott from link technical support told me to wire them. i assume the shielded cable is grounded to sensor ground at the ecu end?

Brad.

i just connected the knock signal cables to one side of the sensors, and the other side to sensor ground; this is how scott from link technical support told me to wire them. i assume the shielded cable is grounded to sensor ground at the ecu end?

Brad.

#19

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

thanks all for the input... having seriously raced for alot of seasons i am well aware of doing things right. while i do feel my second wire is good to go i am going to switch it out for a proper setup.

Aircraft Spruce is a great source. you can't get much better than aircraft tech. most of the more successful racers/racecar mechs came from WW2 aircraft engineering. living 60 miles from Oshkosh, Wi.... home of the annual EAA AirVenture, which is the ultimate Global aircraft candyland i am well aware of Aircraft Spruce. BTW, the EAA starts next monday and i will be there for a couple of days. 'way too much good stuff to miss, especially the workshops.

i have used aluminum foil in numerous apps. on my FD i used it to shield all the to and from signal/output wires from my two Jacobs FC3000 amps.

Brad, the second wire shielding (the foil) is common to the shield that is part of the one wire knock sensor wire which is grounded thru the ECU i assume.

howard

Aircraft Spruce is a great source. you can't get much better than aircraft tech. most of the more successful racers/racecar mechs came from WW2 aircraft engineering. living 60 miles from Oshkosh, Wi.... home of the annual EAA AirVenture, which is the ultimate Global aircraft candyland i am well aware of Aircraft Spruce. BTW, the EAA starts next monday and i will be there for a couple of days. 'way too much good stuff to miss, especially the workshops.

i have used aluminum foil in numerous apps. on my FD i used it to shield all the to and from signal/output wires from my two Jacobs FC3000 amps.

Brad, the second wire shielding (the foil) is common to the shield that is part of the one wire knock sensor wire which is grounded thru the ECU i assume.

howard

#20

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

just a brief update:

i am close to being finished w the wire-in. i am enjoying the work. it does take time but the ViPEC manual is very well executed and combined w the Mazda Wiring Shop Manual, a few emails to ViPEC which were answered the same day, searches thru the ECU Section, and help from fellow board member, the amazing, Chris Ludwig i am comfortable as to quality of execution to date.

there are lots of unique items.

four type K thermocouples (two EGTs, one intake air temp and one turbo output temp sensor)

two Bosch Mazda RX8 knock sensors

new type engine coolant and oil temperature sensors

new Link ViPEC four bar MAP sensor

four IGN-1A ignition coils (each w 5 wires that had to be soldered into their fittings)

four new custom Primary spark leads

two additional Bosch EV14 fuel injectors, one pre turbo, one in the elbow

two new EV14 1000 for my primaries

a new wide band featuring the uprated LSU 4.9 sensor and Bosch chip

three digital/logging pressure sensors, oil, fuel and AI system

new Full Function Eng primary and secondary fuel rails

new Full Function Eng Hall crank pickup system

new turbo manifold, new CHRA for the BW turbo, new engine

i am sure i am missing a few items but trail's end is in sight.

today i should finish the engine compartment and monday i will move to the cockpit... mainly connecting a number of relays... fuel pump, ignition coils & AI pump. then there's dealing w the dash items... tach speedo etc

it sure isn't over but it has been fun and will be exciting to experience initial blastoff.

there are a few issues i need to solve, mainly the fan hookup and dash items.

when finished i will post everything needed to do the wire in as i have been carefully making notes.

i can't wait to get to the point where i can install my transposed maps from my Power FC and turn the key.

howard

i am close to being finished w the wire-in. i am enjoying the work. it does take time but the ViPEC manual is very well executed and combined w the Mazda Wiring Shop Manual, a few emails to ViPEC which were answered the same day, searches thru the ECU Section, and help from fellow board member, the amazing, Chris Ludwig i am comfortable as to quality of execution to date.

there are lots of unique items.

four type K thermocouples (two EGTs, one intake air temp and one turbo output temp sensor)

two Bosch Mazda RX8 knock sensors

new type engine coolant and oil temperature sensors

new Link ViPEC four bar MAP sensor

four IGN-1A ignition coils (each w 5 wires that had to be soldered into their fittings)

four new custom Primary spark leads

two additional Bosch EV14 fuel injectors, one pre turbo, one in the elbow

two new EV14 1000 for my primaries

a new wide band featuring the uprated LSU 4.9 sensor and Bosch chip

three digital/logging pressure sensors, oil, fuel and AI system

new Full Function Eng primary and secondary fuel rails

new Full Function Eng Hall crank pickup system

new turbo manifold, new CHRA for the BW turbo, new engine

i am sure i am missing a few items but trail's end is in sight.

today i should finish the engine compartment and monday i will move to the cockpit... mainly connecting a number of relays... fuel pump, ignition coils & AI pump. then there's dealing w the dash items... tach speedo etc

it sure isn't over but it has been fun and will be exciting to experience initial blastoff.

there are a few issues i need to solve, mainly the fan hookup and dash items.

when finished i will post everything needed to do the wire in as i have been carefully making notes.

i can't wait to get to the point where i can install my transposed maps from my Power FC and turn the key.

howard

Last edited by Howard Coleman; 08-12-12 at 12:17 PM.

#22

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

i am finished w the wire in of my V88.. (of course i won't be sure i am "finished" until it actually runs which is a few days off)...

i will be posting a complete schematic which might be of help to others contemplating the project.

stay tuned,

hc

i will be posting a complete schematic which might be of help to others contemplating the project.

stay tuned,

hc

#24

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

i am pleased to report that my engine is up and running. Brad Hansen (brad89au) was a huge help in that he sent me his map. ViPEC was also of great help. they generally responded to my questions immediately.

there are a number of ways to do the stand alone V88 install in an FD. it is possible to graft into the OE harness. or not.

initially, since i had a new harness i thought i would do the graft but after spending some time working it i decided to start w an all ViPEC wire job.

the ViPEC harness is really really excellent. plenty of wire length and all color coded. i am happy i deep sixed my OE setup.

i will say that there are a whole lot of new things on my setup and they did take a bit more time. i wanted my FD my way. i really was tired of using the same old stuff that i had been using. i want to test new things.

overall, after over 175 splices etc it actually worked! started. well yes and no.

it wanted to run wonderfully for 23 seconds. and then it would turn off. it did that for a few days and during that time i had a chance to check all the nooks and cranies on the install and the ViPEC program. riding the learning curve makes us all better.

it turned out to be a setting issue. i am now dealing w my AFR system and should get it straight tomorrow. today was putting all the plastic back in the car, the seats, the wheelwells, tires.

i am blown away by all the metrics available w the ECU. i will be posting lots of screensaves as soon as i am on the road. the Auto-Tune AFR feature should make short work of the fuel map.

it has been almost a year since i sucked an injector diffuser on the dyno... probably 3 months getting the ECU, maybe 3 months building my new manifold, etc but it was necessary for what i want to do and i can't wait to see what is really going on.

water meth fuel injector in the air filter run by the ViPEC, water meth injector in the elbow... we will see just which location is optimum.

i also have already logged IAT data between the turbo and the intercooler and at the stock location w my EGT type thermocouples.

this is finally going to get interesting.

again, thanks Brad and thanks ViPEC

howard

there are a number of ways to do the stand alone V88 install in an FD. it is possible to graft into the OE harness. or not.

initially, since i had a new harness i thought i would do the graft but after spending some time working it i decided to start w an all ViPEC wire job.

the ViPEC harness is really really excellent. plenty of wire length and all color coded. i am happy i deep sixed my OE setup.

i will say that there are a whole lot of new things on my setup and they did take a bit more time. i wanted my FD my way. i really was tired of using the same old stuff that i had been using. i want to test new things.

overall, after over 175 splices etc it actually worked! started. well yes and no.

it wanted to run wonderfully for 23 seconds. and then it would turn off. it did that for a few days and during that time i had a chance to check all the nooks and cranies on the install and the ViPEC program. riding the learning curve makes us all better.

it turned out to be a setting issue. i am now dealing w my AFR system and should get it straight tomorrow. today was putting all the plastic back in the car, the seats, the wheelwells, tires.

i am blown away by all the metrics available w the ECU. i will be posting lots of screensaves as soon as i am on the road. the Auto-Tune AFR feature should make short work of the fuel map.

it has been almost a year since i sucked an injector diffuser on the dyno... probably 3 months getting the ECU, maybe 3 months building my new manifold, etc but it was necessary for what i want to do and i can't wait to see what is really going on.

water meth fuel injector in the air filter run by the ViPEC, water meth injector in the elbow... we will see just which location is optimum.

i also have already logged IAT data between the turbo and the intercooler and at the stock location w my EGT type thermocouples.

this is finally going to get interesting.

again, thanks Brad and thanks ViPEC

howard

#25

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

fortunately the winter is playing nice which has allowed me to log (literally) 150 miles on my V88. i resolved a few items today and it is starting to behave. i am also starting to get some interesting data.

this wednesday i make the 100 mile trip north to Green Bay and Beyond Redline where ace tuner Luke Stubbs will do his stuff and immediately thereafter we will finish wringing out the first of a series of turbos.

i really can't express how excited i am w my new setup. hopefully we will learn alot more about what can be done w the beloved 13 BREW.

and the V88 is just the tool to do it.

one of the items unresolved as of this morning were the two EGTs that measure incoming air temps. as you probably know i have one positioned between the turbo and intercooler and another in the stock UIM position. (since i have a water meth fuel injector in front of my turbo and another in my elbow we are going to evaluate both positions w re to AI. knowing the actual turbo output temperatures within a millisecond is part of the process)

anyway, i was getting higher temp readings from the thermocouple in the UIM which shouldn't be the case. i thought perhaps i had mixed up the leads.

so, finally, this morning i got to it. i figured i would find continuity on one of the wires and solve the problem. not exactly. i was unable to get a reading on my multimeter and did not want to chop into the tiny wires. after 40 minutes with no readings i decided to go to plan B.

plan B was a hairdryer.

i removed the thermocouple from the intercooler, started logging both thermocouples and hit one w the hairdryer... both were reading ambient and all of a sudden, zoom up went the temperature to 100. it did end up that i had reversed them and now all is well.

i was able to get some data and found at 2 psi boost the air from the turbo is very close to 200 degrees and the air into the motor at the UIM is less than 90. this was not unexpected of course but it will get more interesting at much higher boost and also when we hit the turbo w water meth.

here's a quick look at the log:

should you be interested in the details, maybe all the items i am logging, just blow it up 75%.

getting back to the bigger picture, i am still riding a learning curve but do feel i have a pretty good handle on the V88's abilities and they are immense. i also feel it is quite user friendly. it is evident that a lot of thought went into making the user's task less burdensome.

i especially like the "what's this?" function, the wonderful easy to navigate "Help" resource, the way that all the panels can be manipulated with one easy to learn system.

of course the real payoff is the ability to tune pretty much every aspect...

i do have a MAP and would be happy to share it so just PM me. of course fuel and to a much lesser extent ignition might be a bit different but quite a bit of settings are available.

i expect to get into more boost tomorrow .

the V88 makes shorter work of fuel map tuning. just go for a drive while logging and you can enable "Quick Tune" which will automatically adjust your fuel map... or you can enable the "Mixture Map." which, after logging, will display your AFR target, the actual average of your log, number of samples, show you the net AFR difference and then you may click on the cells and it will make the adjustment.

i used the Mixture Map to get close which didn't take much time... i was remembering the process w my Power FC... the Excel spread sheet, cutting and pasting... cutting and pasting and

i could have tuned a bit closer to my targets but my fuel correction was on as coolant was below 70 C so i was getting 13% additional fuel. i will wait til we get on the dyno and generate sufficient coolant temp to take enrichment out of the picture.

so many many toys to play with... an X Y chart sets coil dwell to your pleasure versus load and RPM. very welcome when you are running 30+$ plugs.

low boost, low dwell, low plug expense.

the alternative, if you are making big hp, is running big ignition all the time and big ignition eats, repeat eats, sparkplugs.

w the V88 you can have your ignition when you want it just like the magic a turbo provides.

the V88 can direct 8 fuel injectors all peak and hold. so, first off, say good by to waste spark on the leads... vs OE, lead plugs and coils and plug wires fire 50% less.

another plus V the Power FC, which i still greatly respect, is being able to idle lean. the Power FC has a floor as to injector ontime and when we add larger injectors it becomes quite difficult to not be rich at idle. i am running 1000 CC in the primaries and i am able to idle at any AFR i wish.

one of the key features of the V88 is that, being able to direct 8 injectors i will be able to exactly blend base fuel w my AI. the V88 provides 220 cells for all the injectors so we will be able to deliver just the right amount of WM.

i have yet to enable my internal knock package. i have posted the settings so probably tomorrow wil start to see some data.

barring some sort of mishap i do hope to be on the dyno within the week... maybe this week.

howard

this wednesday i make the 100 mile trip north to Green Bay and Beyond Redline where ace tuner Luke Stubbs will do his stuff and immediately thereafter we will finish wringing out the first of a series of turbos.

i really can't express how excited i am w my new setup. hopefully we will learn alot more about what can be done w the beloved 13 BREW.

and the V88 is just the tool to do it.

one of the items unresolved as of this morning were the two EGTs that measure incoming air temps. as you probably know i have one positioned between the turbo and intercooler and another in the stock UIM position. (since i have a water meth fuel injector in front of my turbo and another in my elbow we are going to evaluate both positions w re to AI. knowing the actual turbo output temperatures within a millisecond is part of the process)

anyway, i was getting higher temp readings from the thermocouple in the UIM which shouldn't be the case. i thought perhaps i had mixed up the leads.

so, finally, this morning i got to it. i figured i would find continuity on one of the wires and solve the problem. not exactly. i was unable to get a reading on my multimeter and did not want to chop into the tiny wires. after 40 minutes with no readings i decided to go to plan B.

plan B was a hairdryer.

i removed the thermocouple from the intercooler, started logging both thermocouples and hit one w the hairdryer... both were reading ambient and all of a sudden, zoom up went the temperature to 100. it did end up that i had reversed them and now all is well.

i was able to get some data and found at 2 psi boost the air from the turbo is very close to 200 degrees and the air into the motor at the UIM is less than 90. this was not unexpected of course but it will get more interesting at much higher boost and also when we hit the turbo w water meth.

here's a quick look at the log:

should you be interested in the details, maybe all the items i am logging, just blow it up 75%.

getting back to the bigger picture, i am still riding a learning curve but do feel i have a pretty good handle on the V88's abilities and they are immense. i also feel it is quite user friendly. it is evident that a lot of thought went into making the user's task less burdensome.

i especially like the "what's this?" function, the wonderful easy to navigate "Help" resource, the way that all the panels can be manipulated with one easy to learn system.

of course the real payoff is the ability to tune pretty much every aspect...

i do have a MAP and would be happy to share it so just PM me. of course fuel and to a much lesser extent ignition might be a bit different but quite a bit of settings are available.

i expect to get into more boost tomorrow .

the V88 makes shorter work of fuel map tuning. just go for a drive while logging and you can enable "Quick Tune" which will automatically adjust your fuel map... or you can enable the "Mixture Map." which, after logging, will display your AFR target, the actual average of your log, number of samples, show you the net AFR difference and then you may click on the cells and it will make the adjustment.

i used the Mixture Map to get close which didn't take much time... i was remembering the process w my Power FC... the Excel spread sheet, cutting and pasting... cutting and pasting and

i could have tuned a bit closer to my targets but my fuel correction was on as coolant was below 70 C so i was getting 13% additional fuel. i will wait til we get on the dyno and generate sufficient coolant temp to take enrichment out of the picture.

so many many toys to play with... an X Y chart sets coil dwell to your pleasure versus load and RPM. very welcome when you are running 30+$ plugs.

low boost, low dwell, low plug expense.

the alternative, if you are making big hp, is running big ignition all the time and big ignition eats, repeat eats, sparkplugs.

w the V88 you can have your ignition when you want it just like the magic a turbo provides.

the V88 can direct 8 fuel injectors all peak and hold. so, first off, say good by to waste spark on the leads... vs OE, lead plugs and coils and plug wires fire 50% less.

another plus V the Power FC, which i still greatly respect, is being able to idle lean. the Power FC has a floor as to injector ontime and when we add larger injectors it becomes quite difficult to not be rich at idle. i am running 1000 CC in the primaries and i am able to idle at any AFR i wish.

one of the key features of the V88 is that, being able to direct 8 injectors i will be able to exactly blend base fuel w my AI. the V88 provides 220 cells for all the injectors so we will be able to deliver just the right amount of WM.

i have yet to enable my internal knock package. i have posted the settings so probably tomorrow wil start to see some data.

barring some sort of mishap i do hope to be on the dyno within the week... maybe this week.

howard