Haltech Spark and LS2 coil issues

#1

Full Member

Thread Starter

Spark and LS2 coil issues

Hi. After installing my haltech e6x on a REW engine I got it started but it ran very rough. When i checked the spark today it showed that it had no spark on T2 and L2. When checking the L2 spark it did work for a second but I never got it back.

I tried switching the connectors from the L1 and T1 to the L2/T2 coils, but dit not get any spark. Guess the coils are bad.

Is there any way to measure if a coil is broken? And how do I measure if I get the right voltage/signal to the coils?

The coils is brand new, I´ve had the car running for about 5 minutes total. Any ideas on how the coils got bad? Can they be damaged by having the sparkplug wires hanging around (plugs in but not connected to the engine) and possibly touch each other?

The power source for the coils is from the ignition switch which always have power. And they are grounded in the chassis beam which are also connected to the engine block.

I also tried using the two working coils for L1 and L2 so I could get it running but It ran very bad and I couldnt get it over 1000rpm no mather how I did.

I tried switching the connectors from the L1 and T1 to the L2/T2 coils, but dit not get any spark. Guess the coils are bad.

Is there any way to measure if a coil is broken? And how do I measure if I get the right voltage/signal to the coils?

The coils is brand new, I´ve had the car running for about 5 minutes total. Any ideas on how the coils got bad? Can they be damaged by having the sparkplug wires hanging around (plugs in but not connected to the engine) and possibly touch each other?

The power source for the coils is from the ignition switch which always have power. And they are grounded in the chassis beam which are also connected to the engine block.

I also tried using the two working coils for L1 and L2 so I could get it running but It ran very bad and I couldnt get it over 1000rpm no mather how I did.

#2

Ignition Autosport

Join Date: Apr 2010

Location: New Zealand

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

If the spark has nowhere to go, ie you have the HT leads disconnected but still trying to fire into nothing, then it encourages the spark to arc out inside the coil and you will never get a good spark after that has happened as it leaves a carbon track inside for it to follow.

Not revving over 1000rpm sounds like fueling issue assuming your timing has been set correctly, but need a wideband O2 setup to confirm.

Not revving over 1000rpm sounds like fueling issue assuming your timing has been set correctly, but need a wideband O2 setup to confirm.

#3

Full Member

Thread Starter

If the spark has nowhere to go, ie you have the HT leads disconnected but still trying to fire into nothing, then it encourages the spark to arc out inside the coil and you will never get a good spark after that has happened as it leaves a carbon track inside for it to follow.

Not revving over 1000rpm sounds like fueling issue assuming your timing has been set correctly, but need a wideband O2 setup to confirm.

Not revving over 1000rpm sounds like fueling issue assuming your timing has been set correctly, but need a wideband O2 setup to confirm.

I have a wideband O2 setup and its around 12-13 when on 1000rpm. Before it started to run this bad I was able to rev the engine more like 2-3000 rpm and then O2 was around 17.

#5

Full Member

Thread Starter

Thanks Nige

This is how the car runs now.

http://s34.photobucket.com/albums/d1...nt=rx7film.mp4

Doesnt sound quite right to my ears?

I´m going to order two new coils. But any ideas of how my coils have went bad is much appreciated. I dont want to put 2 new coils on and have them burnt too.

This is how the car runs now.

http://s34.photobucket.com/albums/d1...nt=rx7film.mp4

Doesnt sound quite right to my ears?

I´m going to order two new coils. But any ideas of how my coils have went bad is much appreciated. I dont want to put 2 new coils on and have them burnt too.

#6

Movie Star

iTrader: (11)

Join Date: Dec 2003

Location: Fort Wayne, Indiana

Posts: 982

Likes: 0

Received 0 Likes

on

0 Posts

Are you using new spark plugs?

I've fouled out a few sets of brand new plugs when I first got my haltech.

It took like 4-5 sets before I found out that I one of my fuel correction maps was dumping a ton of fuel.

Dumb question but, have you tried pulling the fuse to the injectors while testing for spark so they don't foul out?

I've fouled out a few sets of brand new plugs when I first got my haltech.

It took like 4-5 sets before I found out that I one of my fuel correction maps was dumping a ton of fuel.

Dumb question but, have you tried pulling the fuse to the injectors while testing for spark so they don't foul out?

Trending Topics

#8

Ignition Autosport

Join Date: Apr 2010

Location: New Zealand

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

That vid is of fouled plugs.

You can flood the engine from being too lean, which is what it sounds like when cranking. Eventually it builds up enough fuel int he engine to fire up, but int he mean time it has wet all your plugs.

I use some cheap plugs to startup, then once cranking and startup is fine, I put in a good set for tuning.

You can flood the engine from being too lean, which is what it sounds like when cranking. Eventually it builds up enough fuel int he engine to fire up, but int he mean time it has wet all your plugs.

I use some cheap plugs to startup, then once cranking and startup is fine, I put in a good set for tuning.

#9

Full Member

Thread Starter

That vid is of fouled plugs.

You can flood the engine from being too lean, which is what it sounds like when cranking. Eventually it builds up enough fuel int he engine to fire up, but int he mean time it has wet all your plugs.

I use some cheap plugs to startup, then once cranking and startup is fine, I put in a good set for tuning.

You can flood the engine from being too lean, which is what it sounds like when cranking. Eventually it builds up enough fuel int he engine to fire up, but int he mean time it has wet all your plugs.

I use some cheap plugs to startup, then once cranking and startup is fine, I put in a good set for tuning.

Can the coils be damaged when runned with fouled plugs?

Should I use plugs with a lower number, maybe 7´s instead of my current 9´s ?

#10

Ignition Autosport

Join Date: Apr 2010

Location: New Zealand

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

still should be difficult to damage them, I'd try some new 7's, or some cheap BKR6's till its running right (check electrode/earth length in housing first, I can't remember exactly what plug I used).

#11

Full Member

Thread Starter

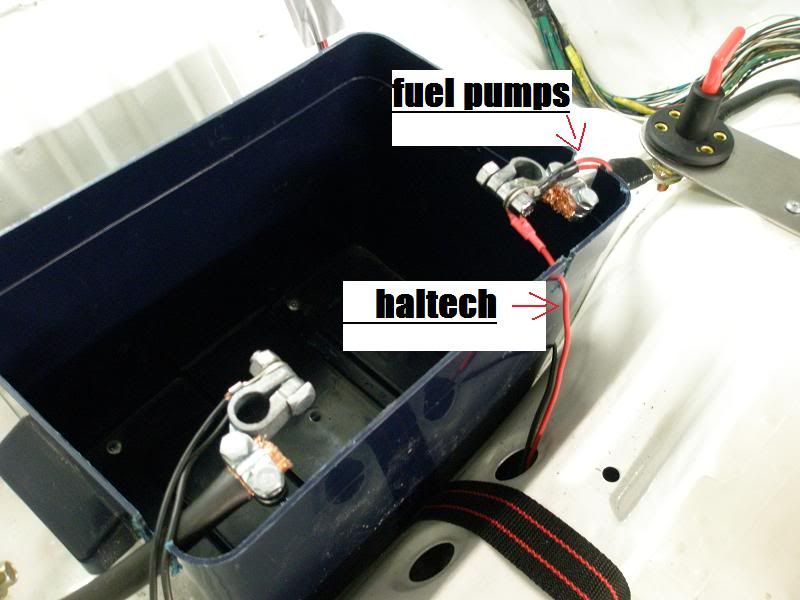

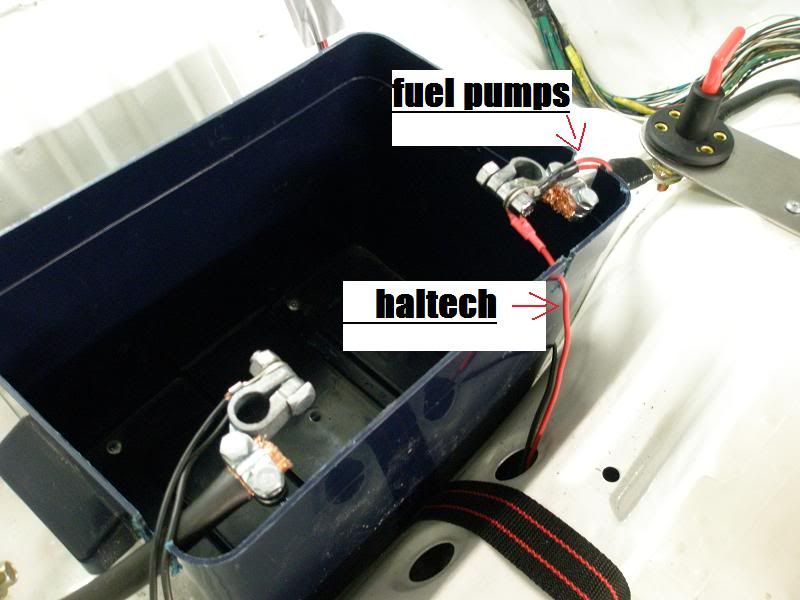

Ok I´ve installed 2 new coils and now I have spark again, but seems to be a little weaker on the T2 coil. Well now I have another problem. Cant really tell if it runs any better cause I keep losing connection to the ecu as soon as it starts or even when cranking.

When cranking the injector duty jumps around from 1% and sometimes up to 100%

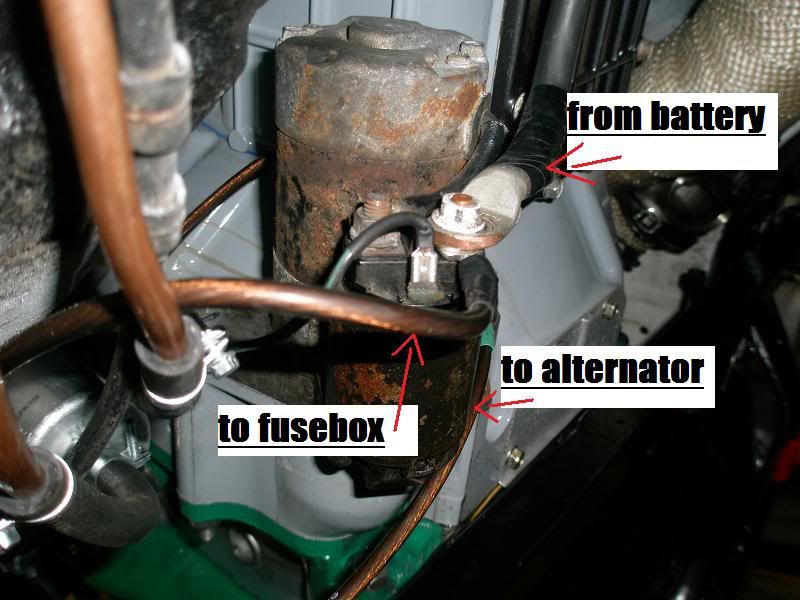

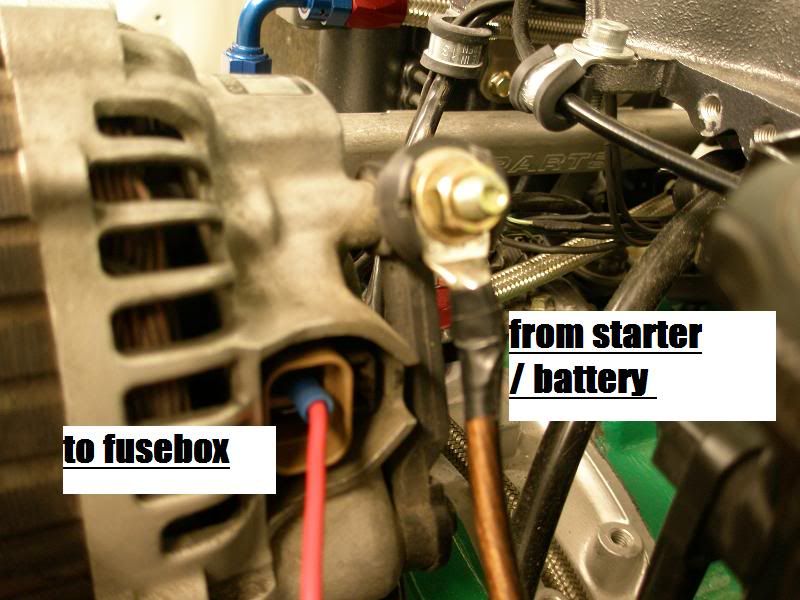

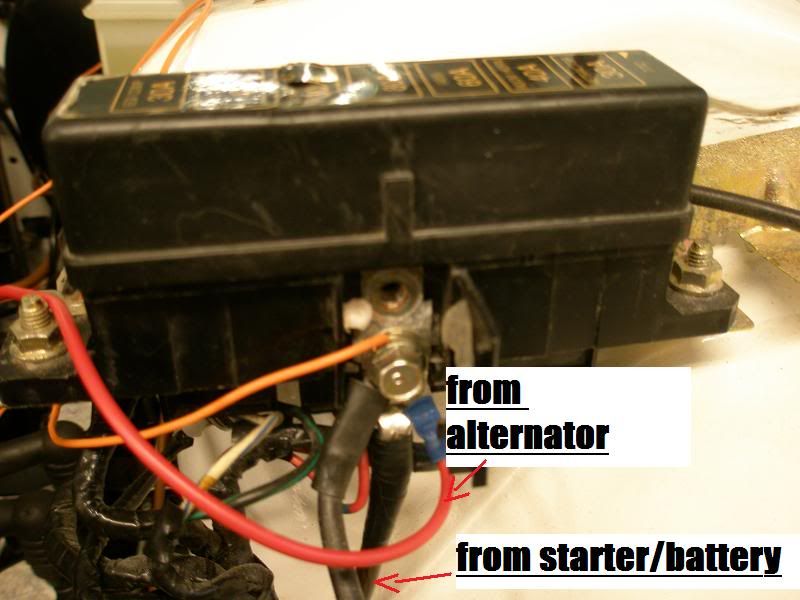

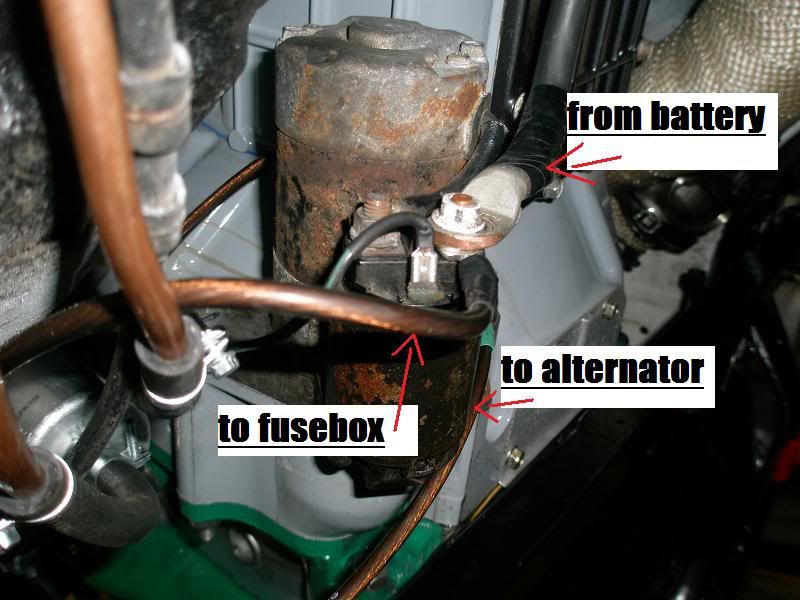

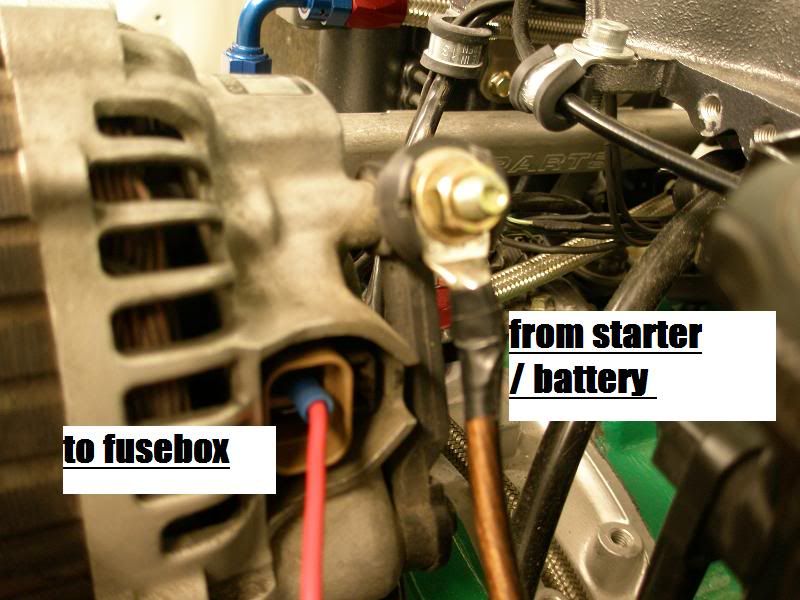

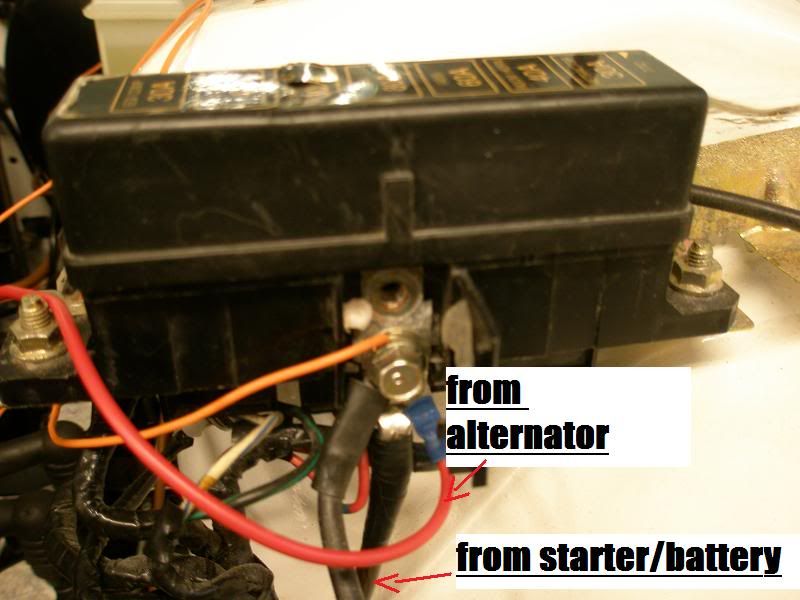

I think my alternator might be connected wrong cause the battery seems to drain very quick. I have all new wiring to the alternator since I run a REW engine in the FC and have moved the battery to behind the passenger seat. The cable goes from : Battery - Starter motor- Alternator and Fuse box. Also have a smaller wire from the top pin of the alternator which goes to the fuse box.

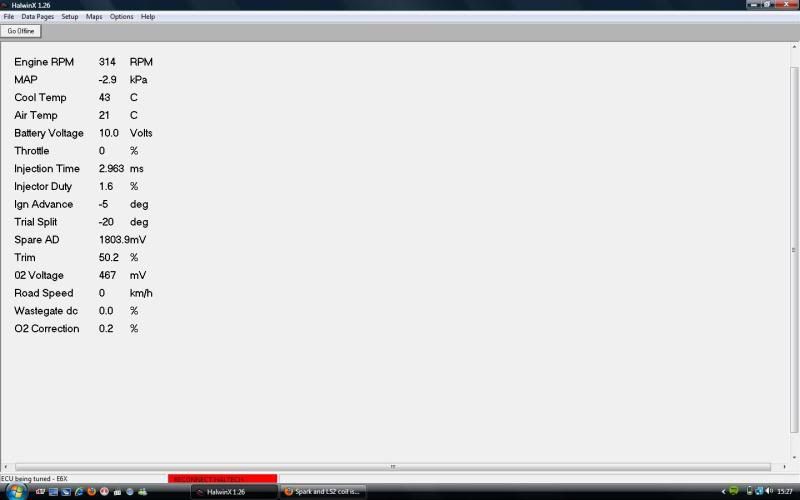

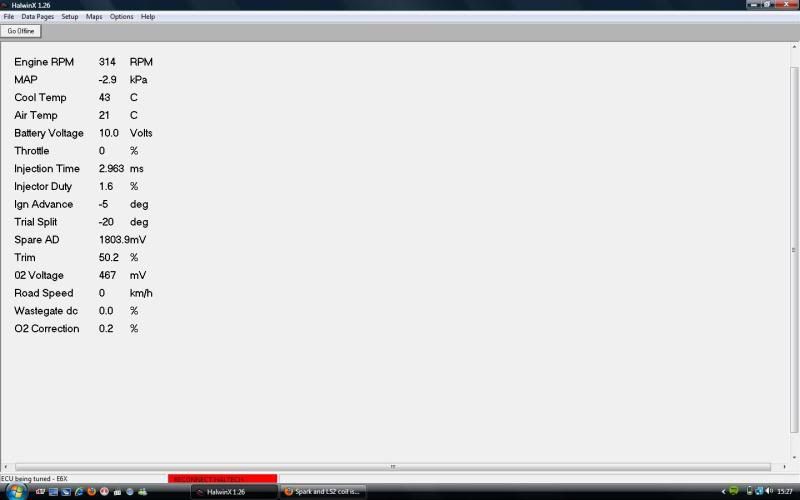

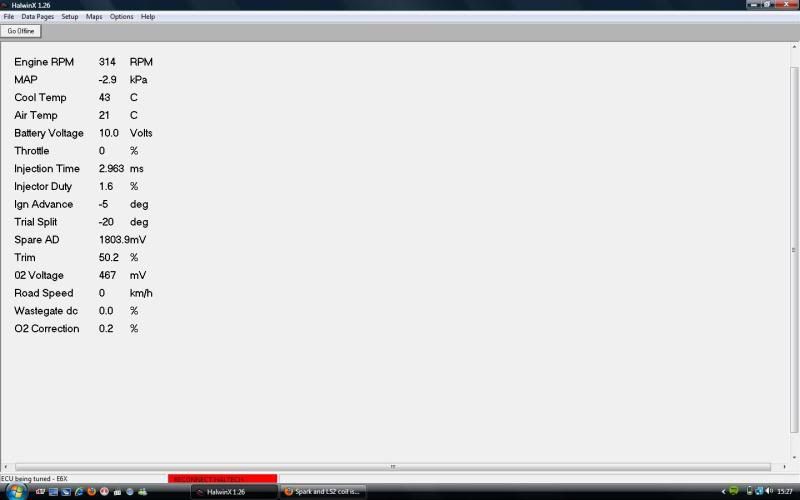

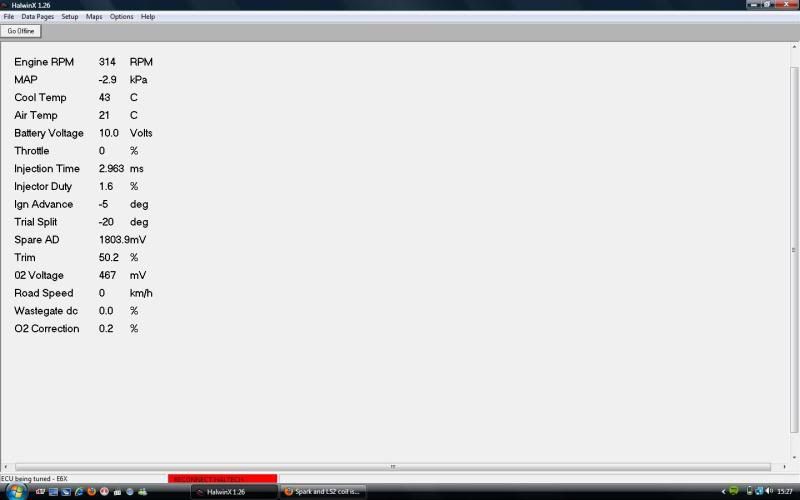

This is a screenshot from my last start attempt. Never got it running at this time it just fired randomly.

And video of when it ran.

http://s34.photobucket.com/albums/d1...t=P6300086.mp4

When cranking the injector duty jumps around from 1% and sometimes up to 100%

I think my alternator might be connected wrong cause the battery seems to drain very quick. I have all new wiring to the alternator since I run a REW engine in the FC and have moved the battery to behind the passenger seat. The cable goes from : Battery - Starter motor- Alternator and Fuse box. Also have a smaller wire from the top pin of the alternator which goes to the fuse box.

This is a screenshot from my last start attempt. Never got it running at this time it just fired randomly.

And video of when it ran.

http://s34.photobucket.com/albums/d1...t=P6300086.mp4

#13

Canned. I got CORNED!

iTrader: (5)

Join Date: Mar 2007

Location: Appleton, WI

Posts: 1,029

Likes: 0

Received 0 Likes

on

0 Posts

First of all, that's during cranking I would hope? Battery voltage might be a little low.

Second, your trim **** should probably be unplugged until you're actually using it.

You may have hosed something up during battery relocation. How are your grounds?

Second, your trim **** should probably be unplugged until you're actually using it.

You may have hosed something up during battery relocation. How are your grounds?

#15

Tenseiga

iTrader: (1)

Join Date: Apr 2003

Location: Iowa

Posts: 2,252

Likes: 0

Received 0 Likes

on

0 Posts

Ok I´ve installed 2 new coils and now I have spark again, but seems to be a little weaker on the T2 coil. Well now I have another problem. Cant really tell if it runs any better cause I keep losing connection to the ecu as soon as it starts or even when cranking.

When cranking the injector duty jumps around from 1% and sometimes up to 100%

I think my alternator might be connected wrong cause the battery seems to drain very quick. I have all new wiring to the alternator since I run a REW engine in the FC and have moved the battery to behind the passenger seat. The cable goes from : Battery - Starter motor- Alternator and Fuse box. Also have a smaller wire from the top pin of the alternator which goes to the fuse box.

This is a screenshot from my last start attempt. Never got it running at this time it just fired randomly.

And video of when it ran.

http://s34.photobucket.com/albums/d1...t=P6300086.mp4

When cranking the injector duty jumps around from 1% and sometimes up to 100%

I think my alternator might be connected wrong cause the battery seems to drain very quick. I have all new wiring to the alternator since I run a REW engine in the FC and have moved the battery to behind the passenger seat. The cable goes from : Battery - Starter motor- Alternator and Fuse box. Also have a smaller wire from the top pin of the alternator which goes to the fuse box.

This is a screenshot from my last start attempt. Never got it running at this time it just fired randomly.

And video of when it ran.

http://s34.photobucket.com/albums/d1...t=P6300086.mp4

You should have a 12v switched/fused power on one and a batter light on the other.

the 12V switch is to power the internal rectifier and the light actually draws current to start the rectifier for the stator.

If the battery light is out your rectifier will not power on and you won't make power.

easiest way is just to look at the voltage when the car is running to tell if your alternator is working.

If it is you most likely have something wired on all the time (such as your haltech) - you can take a multimeter and run it in series with the + cable lead and measure the current draw when your car is off.

Then you can remove fuses until you narrow it down.

#16

Full Member

Thread Starter

My english is not great so I´ll try to show how the alternator is connected with some pictures. However, I had it started again today. Before I started the battery was 12.6 V, when it was running it was at 12,2 V so I guess its not charging. I didnt got a printscreen on the log though, engine flooded and I couldnt get it started again.

Also noticed my haltech would go offline like every 30 seconds. I connected an extra ground cable from the battery and it seemed to work, time will tell.

Also noticed my haltech would go offline like every 30 seconds. I connected an extra ground cable from the battery and it seemed to work, time will tell.

#17

Tenseiga

iTrader: (1)

Join Date: Apr 2003

Location: Iowa

Posts: 2,252

Likes: 0

Received 0 Likes

on

0 Posts

your internal rectifier is not wired correctly (the two spades on the alternator).

You need two wires in order for it to work (not just the one spade you have connected).

Look at page Z-24 of the FSM for a better understanding of how the internal rectifier is to be wired.

It does need the charging check light for the rectifier to work - I believe it's the signal to start the stator power (1.4w light page Z-44).

The way you have the wire going directly to the rectifier is not preferred and I would use the stock method and use the 30amp EGI fused connection.

On a side note -

The haltech/fuel pump power wires are too small imo and should be protected against that metal with a rubber groument.

-just realized you have FC.... those page references was for a FD manual - your upgrade was not done properly so I would search for install guides and follow those.

You need two wires in order for it to work (not just the one spade you have connected).

Look at page Z-24 of the FSM for a better understanding of how the internal rectifier is to be wired.

It does need the charging check light for the rectifier to work - I believe it's the signal to start the stator power (1.4w light page Z-44).

The way you have the wire going directly to the rectifier is not preferred and I would use the stock method and use the 30amp EGI fused connection.

On a side note -

The haltech/fuel pump power wires are too small imo and should be protected against that metal with a rubber groument.

-just realized you have FC.... those page references was for a FD manual - your upgrade was not done properly so I would search for install guides and follow those.

#18

Canned. I got CORNED!

iTrader: (5)

Join Date: Mar 2007

Location: Appleton, WI

Posts: 1,029

Likes: 0

Received 0 Likes

on

0 Posts

Fairly certain you only need one wire off the alternator...at least, that's what I decided after searching the bejesus out of the forums here. Are you certain you have the right terminal? Should definitely see around 14V+ with the car running.

#19

Tenseiga

iTrader: (1)

Join Date: Apr 2003

Location: Iowa

Posts: 2,252

Likes: 0

Received 0 Likes

on

0 Posts

- You also need a source for the field current which is then used for the rotor current based off the above connection (this is from the battery and from the alternator output). Once the car is running the alternator output can drive it's own field current and inturn excite itself.

This is the type of alternator the FD is.

I'm not sure how you achive a correct working alternator with one wire.

The above picture is providing the sensing voltage for the alternator.

He needs the other connection for the field current so that he can generate rotor current.

If he doesn't get any current in the rotor he's not going to make any current and the alternator wont' start because it can't generate it's own field current and sustain itself.

You can see that two inputs are required for the regulator.

#20

Ignition Autosport

Join Date: Apr 2010

Location: New Zealand

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

Most modern alternators will also internally regulate with only the warning light wire connected. The external voltage sensing wire is a correction over the internal voltage, to allow for voltage drop in the electrical system. It is a good idea to connect it to correct for aged wiring causing voltage drop.

#21

Full Member

Thread Starter

Thank you for all replys. I´ve looked at the wiring diagrams, but I dont get much wiser.

Can I connect the small power wire, to the wire which goes to any 30amp EGI fuse in the fusebox? And since I dont have any stock alternator harness installed, can I "cheat" and make it work without the cluster light?

Thanks

Can I connect the small power wire, to the wire which goes to any 30amp EGI fuse in the fusebox? And since I dont have any stock alternator harness installed, can I "cheat" and make it work without the cluster light?

Thanks

#23

Full Member

Thread Starter

#24

Canned. I got CORNED!

iTrader: (5)

Join Date: Mar 2007

Location: Appleton, WI

Posts: 1,029

Likes: 0

Received 0 Likes

on

0 Posts

This is for an FC alternator, so it might be different.

But from what I read, the warning light terminal was optional, and the other terminal made the alternator work all the time....apparently, if you just hook up the main connector, the alternator will not work until you rev it above 2000 RPM, as was mentioned above.

My battery is in a rear bin as well. 0/2 gauge wire going from battery>circuit breaker>starter>fuse box>alternator. There is a smaller wire running from the fuse box to the spade connector on the alternator as well, but the warning light spade is open.

But from what I read, the warning light terminal was optional, and the other terminal made the alternator work all the time....apparently, if you just hook up the main connector, the alternator will not work until you rev it above 2000 RPM, as was mentioned above.

My battery is in a rear bin as well. 0/2 gauge wire going from battery>circuit breaker>starter>fuse box>alternator. There is a smaller wire running from the fuse box to the spade connector on the alternator as well, but the warning light spade is open.

#25

Full Member

Thread Starter

This is for an FC alternator, so it might be different.

But from what I read, the warning light terminal was optional, and the other terminal made the alternator work all the time....apparently, if you just hook up the main connector, the alternator will not work until you rev it above 2000 RPM, as was mentioned above.

My battery is in a rear bin as well. 0/2 gauge wire going from battery>circuit breaker>starter>fuse box>alternator. There is a smaller wire running from the fuse box to the spade connector on the alternator as well, but the warning light spade is open.

But from what I read, the warning light terminal was optional, and the other terminal made the alternator work all the time....apparently, if you just hook up the main connector, the alternator will not work until you rev it above 2000 RPM, as was mentioned above.

My battery is in a rear bin as well. 0/2 gauge wire going from battery>circuit breaker>starter>fuse box>alternator. There is a smaller wire running from the fuse box to the spade connector on the alternator as well, but the warning light spade is open.

Thank you