The Elusive Pre-Control Restrictor

#1

Magnet Boy

Thread Starter

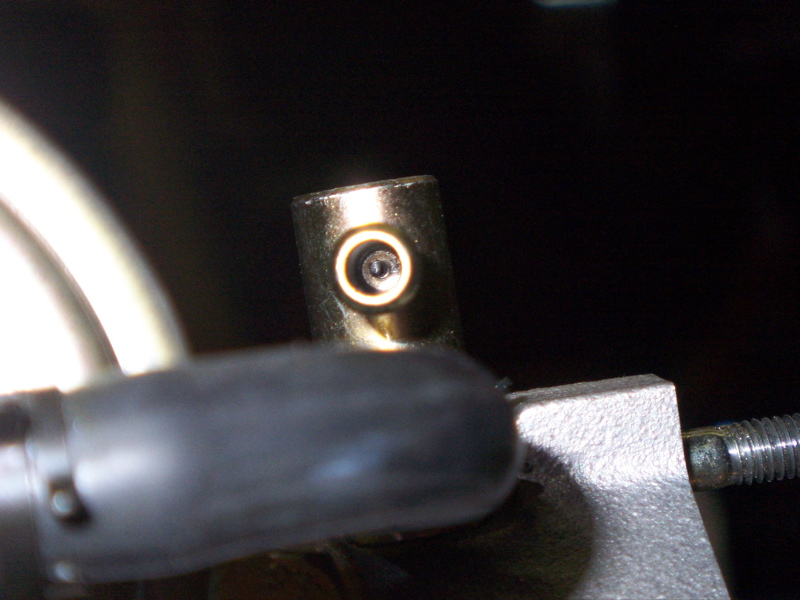

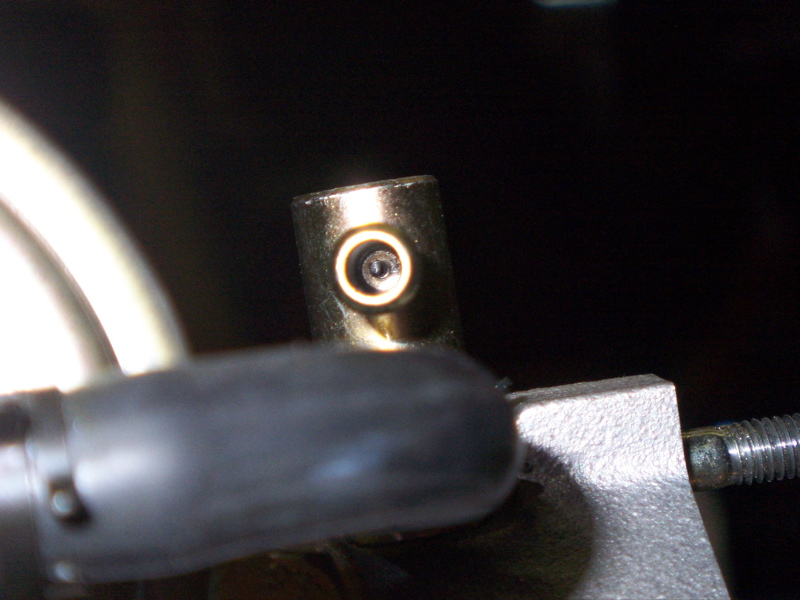

Heard stories about it, but never actually saw one. I'm in the middle of rebuilding my motor. I decided to upgrade my original 1994 twin turbos to Efinis. So I have the chance to see the original (in the hose) pre-contol actuator restrictor as well as the newer style built-in (in the nipple) restrictor. This little hole changes the rate at which the secondary turbo prespool kicks in as boost builds in the primary turbo. See attached photos.

My original 1994 pill was buried about an inch down the hose which connects from a nipple built-in to the output of the primary turbo, to one of the nipples on the pre-control actuator diaphragm. I noticed that with the old loose hose and oil film accumulated from years of use, it was easy to accidentaly twist the pill inside the hose so it would not work properly - probably why Mazda changed to the built-in restrictor. The effini restrictor is built-in to the primary turbo output nipple with an unrestricted hose connected to the pre-control actuator. I am drilling out the built-in restrictor and hooking up an adjustable needle valve so that I can dial in the pre-control transition for my modified engine.

Enjoy!!

My original 1994 pill was buried about an inch down the hose which connects from a nipple built-in to the output of the primary turbo, to one of the nipples on the pre-control actuator diaphragm. I noticed that with the old loose hose and oil film accumulated from years of use, it was easy to accidentaly twist the pill inside the hose so it would not work properly - probably why Mazda changed to the built-in restrictor. The effini restrictor is built-in to the primary turbo output nipple with an unrestricted hose connected to the pre-control actuator. I am drilling out the built-in restrictor and hooking up an adjustable needle valve so that I can dial in the pre-control transition for my modified engine.

Enjoy!!

#2

A needle valve type of boost controller won't work very well on the prespool line. I installed one, and removed it after about 6 weeks of trying to get it adjusted properly .... without success. I have heard that others have had better luck with a ball and spring controller on the pre spool control. I wound up placing my wastegate pill in the prespool line. This increased my transition from 8 psi to 9 psi. A bit smoother, but not as high as I would like, as I am boosting to 13 psi.

My needle valve controller works great on the wastegate line. No problems at all.

My needle valve controller works great on the wastegate line. No problems at all.

#3

Magnet Boy

Thread Starter

Hmm, thanks for the comment Adam. I am using a small brass plumbing valve I got at the hardware store. I rigged up a flow test apparatus using water and found a setting point for my valve which matches the oem pill, as a starting position. But since I used water, there's no telling how close I will be to start with. It seems like the valve is very sensitive, about 5/8 turn open gets me to the matched position. I'm pretty sure I can adjust it to some point in between (fully open and fully closed) which is correct, but I won't know how much of a PITA until I try it. I might just make my own pills eventually - drill out a piece of nylon with different sized holes until I get it right.

Originally Posted by adam c

A needle valve type of boost controller won't work very well on the prespool line. I installed one, and removed it after about 6 weeks of trying to get it adjusted properly .... without success. I have heard that others have had better luck with a ball and spring controller on the pre spool control. I wound up placing my wastegate pill in the prespool line. This increased my transition from 8 psi to 9 psi. A bit smoother, but not as high as I would like, as I am boosting to 13 psi.

My needle valve controller works great on the wastegate line. No problems at all.

My needle valve controller works great on the wastegate line. No problems at all.

#4

I have dual Hallman ball and spring controllers with remote adjustment ***** and, like Adam, had a bear of a time trying to control transition with precontrol adjustment.

I have very fine, very accurate control of boost via wastegate adjustment but precontrol was elusive. I think I have finally figured it out but now have creep problems because of the addition of a SMB cat so am not 100% sure that I have.

Previously I tried adjusting precontrol via Holley jets with inconsistent results.

I would just leave the stock precontrol pill in there and see what happens.

I have very fine, very accurate control of boost via wastegate adjustment but precontrol was elusive. I think I have finally figured it out but now have creep problems because of the addition of a SMB cat so am not 100% sure that I have.

Previously I tried adjusting precontrol via Holley jets with inconsistent results.

I would just leave the stock precontrol pill in there and see what happens.

Last edited by moconnor; 03-29-07 at 02:50 PM.

#5

Magnet Boy

Thread Starter

Originally Posted by moconnor

I would just leave the stock precontrol pill in there and see what happens.

#6

Originally Posted by rxcited2

But in theory, I don't see why it shouldn't work.

And increasing primary boost via the wastegate will also increase secondary boost - so you can't just keep increasing it because your secondary boost may get too high.

I had trouble getting this right via in-cabin control of the dual MBCs and did somewhere between 50-100 adjustments (and may still have not got it quite right).

Good luck getting this right by manually swapping pills.

#7

Magnet Boy

Thread Starter

I see what you are getting at moconnor. But I am not using a boost controller. I am using the duty cycle settings on the Apexi PFC to control boost. I know this is open loop and so is not as ideal (from a safety and stability standpoint), but my plan for adjustment is pretty simple:

1. Set primary boost duty cycle until I get the desired boost at rpm up to 3k.

2. Set secondary boost duty cycle until I get the desired (same) boost at rpm over 4.5k.

3. Adjust brass pre-control valve until I get the smoothest transition possible.

I can see how if you are relying on spring pressures and orifices (orifi?) to control boost and transition, that it would be tricky. Since I am relying on only one orifice to control transition only, I assumed this wouldn't be too hard. Am I high? What if you use an electronic boost controller? Presumably this would be closed loop so it would control both primary and secondary boost properly and again you would just use the valve to get a smooth transition.

What if you use an electronic boost controller? Presumably this would be closed loop so it would control both primary and secondary boost properly and again you would just use the valve to get a smooth transition.

The PFC allows two sets of primary/secondary boost duty cycles. I guess the idea is driver selectable mild and wild settings. As soon as mods started going on my car, the transition got whacked. But I was hoping that once I dial in the transition again, it will work for both mild and wild PFC boost settings. So I might be able to select 10-8-10 for mild and 15-13-15 for wild, without needing to re-tweek my brass valve for the two cases.

I'll let you know how it goes in a few weeks after I break my engine in!

1. Set primary boost duty cycle until I get the desired boost at rpm up to 3k.

2. Set secondary boost duty cycle until I get the desired (same) boost at rpm over 4.5k.

3. Adjust brass pre-control valve until I get the smoothest transition possible.

I can see how if you are relying on spring pressures and orifices (orifi?) to control boost and transition, that it would be tricky. Since I am relying on only one orifice to control transition only, I assumed this wouldn't be too hard. Am I high?

What if you use an electronic boost controller? Presumably this would be closed loop so it would control both primary and secondary boost properly and again you would just use the valve to get a smooth transition.

What if you use an electronic boost controller? Presumably this would be closed loop so it would control both primary and secondary boost properly and again you would just use the valve to get a smooth transition.The PFC allows two sets of primary/secondary boost duty cycles. I guess the idea is driver selectable mild and wild settings. As soon as mods started going on my car, the transition got whacked. But I was hoping that once I dial in the transition again, it will work for both mild and wild PFC boost settings. So I might be able to select 10-8-10 for mild and 15-13-15 for wild, without needing to re-tweek my brass valve for the two cases.

I'll let you know how it goes in a few weeks after I break my engine in!

Originally Posted by moconnor

Remember that the precontrol pill does not just affect transition - it can also influence primary boost. If you reduce the restriction, you will get earlier prespool and thus a smoother transition - however, if you reduce it too much you will bleed off some primary boost; which you can compensate for by using a large orifice wastegate pill to increase primary boost - but that will also affect transition , so you may have to adjust the precontrol pill again, which may affect primary boost - and so on.

And increasing primary boost via the wastegate will also increase secondary boost - so you can't just keep increasing it because your secondary boost may get too high.

I had trouble getting this right via in-cabin control of the dual MBCs and did somewhere between 50-100 adjustments (and may still have not got it quite right).

Good luck getting this right by manually swapping pills.

And increasing primary boost via the wastegate will also increase secondary boost - so you can't just keep increasing it because your secondary boost may get too high.

I had trouble getting this right via in-cabin control of the dual MBCs and did somewhere between 50-100 adjustments (and may still have not got it quite right).

Good luck getting this right by manually swapping pills.

Trending Topics

#8

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

The brass adjustable valve will work perfectly to adust pre-control transistion as it is nothing more than a variable "PILL", and Mazda used a pill. Thus this is one step smarter than Mazda as it allows tuning do to modification.

The reason a Hallman boost controller doesn't work is due to the sping loaded ball. Pressure has to build up to the spring pressure before it starts to bleed through. It helps build boost faster because boost is not being bleed off until the last moment. Which is not what you want for the precontrol.

Before PFCs, Hallmans, and the better boost controllers, there were Pettit and XS ecus. Many of you were still playing with Hot Wheels while us older owners were pushing the envelope of rotory power. That is why there is less blown engines today then back then.

I had the XS reprogrammed ECU and used two of the brass valves. One controlled

the pre-control actuator and the other controlled boost. With proper adjustment,

you could get a nice flat boost curve.

It still can be used with the PFC to fine tune the setup. With a DATALOGIT, you can even adjust the rpms and TPS load to affect the transistion point. Some say lowering the 2nd rpm point makes transistion even smoother. But I can't play with that as I left seq mode back in 1998 and went single in 2004.

James is on the right track!

The reason a Hallman boost controller doesn't work is due to the sping loaded ball. Pressure has to build up to the spring pressure before it starts to bleed through. It helps build boost faster because boost is not being bleed off until the last moment. Which is not what you want for the precontrol.

Before PFCs, Hallmans, and the better boost controllers, there were Pettit and XS ecus. Many of you were still playing with Hot Wheels while us older owners were pushing the envelope of rotory power. That is why there is less blown engines today then back then.

I had the XS reprogrammed ECU and used two of the brass valves. One controlled

the pre-control actuator and the other controlled boost. With proper adjustment,

you could get a nice flat boost curve.

It still can be used with the PFC to fine tune the setup. With a DATALOGIT, you can even adjust the rpms and TPS load to affect the transistion point. Some say lowering the 2nd rpm point makes transistion even smoother. But I can't play with that as I left seq mode back in 1998 and went single in 2004.

James is on the right track!

Last edited by cewrx7r1; 03-29-07 at 06:40 PM.

#9

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

DAAAAAAMMMMMMMMMMMMMMNNNNNNNNNNNNNNNN!!!!!!!!!!!!! !

This site is really starting to suck big-time with it's snail pace performance.

Time for the owners to get off the NA wagon and turbo charge it.

I can write long hand faster than this site is getting.

This site is really starting to suck big-time with it's snail pace performance.

Time for the owners to get off the NA wagon and turbo charge it.

I can write long hand faster than this site is getting.

#10

R2Excited,

I believe that the problem with a needle valve on the pre spool line, is the long length of hose that has to be used. I believe that this long hose causes a delay in the proper pressure getting to where it is supposed to be. Cewrx7r1 mentioned that it should work perfectly. If the valve were placed in the original (short length) hose, it would likely work correctly. Of course, it would be very inconvenient to adjust.

I believe that the problem with a needle valve on the pre spool line, is the long length of hose that has to be used. I believe that this long hose causes a delay in the proper pressure getting to where it is supposed to be. Cewrx7r1 mentioned that it should work perfectly. If the valve were placed in the original (short length) hose, it would likely work correctly. Of course, it would be very inconvenient to adjust.

#11

Magnet Boy

Thread Starter

Could be. But here is an electrical circuit analogy (got a little engineering under my belt):

restrictor = resistor

hose = capacitor

We are doing a one for one swap of the resistor. The difference is I now have a variable resistor, my valve. It is true I am changing the capacitor since my hose is longer. However, I think the pressure "capacitance" of the hose is probably negligible compared to the other "capacitances" in the system. I am referring to the volumes of air in the primary turbo output housing and in the actuator diaphragm. These volumes have a much larger capacity to absorb and store pressure than the hose itself, even a longer one. The small capacity of the hose, even a longer one, should have little effect.

I guess the proof will be in the pudding. I'll let you know how it goes!

restrictor = resistor

hose = capacitor

We are doing a one for one swap of the resistor. The difference is I now have a variable resistor, my valve. It is true I am changing the capacitor since my hose is longer. However, I think the pressure "capacitance" of the hose is probably negligible compared to the other "capacitances" in the system. I am referring to the volumes of air in the primary turbo output housing and in the actuator diaphragm. These volumes have a much larger capacity to absorb and store pressure than the hose itself, even a longer one. The small capacity of the hose, even a longer one, should have little effect.

I guess the proof will be in the pudding. I'll let you know how it goes!

Originally Posted by adam c

R2Excited,

I believe that the problem with a needle valve on the pre spool line, is the long length of hose that has to be used. I believe that this long hose causes a delay in the proper pressure getting to where it is supposed to be. Cewrx7r1 mentioned that it should work perfectly. If the valve were placed in the original (short length) hose, it would likely work correctly. Of course, it would be very inconvenient to adjust.

I believe that the problem with a needle valve on the pre spool line, is the long length of hose that has to be used. I believe that this long hose causes a delay in the proper pressure getting to where it is supposed to be. Cewrx7r1 mentioned that it should work perfectly. If the valve were placed in the original (short length) hose, it would likely work correctly. Of course, it would be very inconvenient to adjust.

#12

Originally Posted by cewrx7r1

The brass adjustable valve will work perfectly to adust pre-control transistion as it is nothing more than a variable "PILL", and Mazda used a pill.

The reason a Hallman boost controller doesn't work is due to the sping loaded ball. Pressure has to build up to the spring pressure before it starts to bleed through. It helps build boost faster because boost is not being bleed off until the last moment. Which is not what you want for the precontrol.

I actually have a very nice transition now (11-9.5-11.5) and it is extremely quick (< 0.3s). However, I want to go to something like 13.5-11.5-13.5 but am having creep problems due to the addition of an SMB metallic cat.

#13

Magnet Boy

Thread Starter

I keep wavering on whether I understand how the pre-control works. There is the complication that there are two input nipples to the pre-control diaphragm. One of them is controlled by the ECU and the other is the one that is tied to the output of the primary turbo with the intervening restrictor pill.

If the ECU controlled nipple were left blocked all the time, then boost building in the primary turbo would cause the pre-control to actuate at some pre-determined mechanical rate. This rate would be dependent on the rate at which pressure is building in the primary turbo and the restrictor/hose properites. But you don't want the pre-spool to start until you get close to transition.

So the second nipple is controlled by the ECU. My understanding is that it is left open when pre-control is not desired. Pressure building in the primary turbo comes through the pre-control hose with the restrictor, and just leaks out instead of actuating the pre-control actuator. When the ECU decides transition is about to happen, it closes this nipple so that the pre-control happens at the mechanical rate determined by the level of primary boost and the hose/restrictor configuration.

Once transition has occurred, I am not clear on whether the ECU leaves this nipple blocked so the pre-spool flapper stays open, or if it opens it so the pre-spool flapper is closed. I have been told the later is what happens, but if you are running WOT, why wouldn't you want exhaust entering the secondary turbo through the main port and the pre-control port?

If the ECU controlled nipple were left blocked all the time, then boost building in the primary turbo would cause the pre-control to actuate at some pre-determined mechanical rate. This rate would be dependent on the rate at which pressure is building in the primary turbo and the restrictor/hose properites. But you don't want the pre-spool to start until you get close to transition.

So the second nipple is controlled by the ECU. My understanding is that it is left open when pre-control is not desired. Pressure building in the primary turbo comes through the pre-control hose with the restrictor, and just leaks out instead of actuating the pre-control actuator. When the ECU decides transition is about to happen, it closes this nipple so that the pre-control happens at the mechanical rate determined by the level of primary boost and the hose/restrictor configuration.

Once transition has occurred, I am not clear on whether the ECU leaves this nipple blocked so the pre-spool flapper stays open, or if it opens it so the pre-spool flapper is closed. I have been told the later is what happens, but if you are running WOT, why wouldn't you want exhaust entering the secondary turbo through the main port and the pre-control port?

#14

Originally Posted by moconnor

That is not at all obvious and really depends on how the precontrol really works. For example, assume the precontrol is set to open at 7psi with a ball and spring controller, then at 7psi the precontrol gate will open fully. With a ball and spring controller, the wastegate will gradually start opening at, say, 6psi and will be fully open at, say 8psi.

#15

Originally Posted by rxcited2

Once transition has occurred, I am not clear on whether the ECU leaves this nipple blocked so the pre-spool flapper stays open, or if it opens it so the pre-spool flapper is closed. I have been told the later is what happens, but if you are running WOT, why wouldn't you want exhaust entering the secondary turbo through the main port and the pre-control port?

#16

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

The #1 turbo supplies the source of air under pressure to operate the PC and WG

actuators. The ECU through the PC and WG solenoids controls the bleed off of the pressure from the actuators. The pills fine tune them both by affecting how quickly that pressure can build up in the actuators while the solenoids bleed them off.

If the pills are extremely small, bleed off can be greater than pressure build up and nothing happens. The opposite is also true.

If the two valves are placed up where the fan relays are, the extra length of hose has

negligible affect.

Some of you over theorize and do not accomplish anything worthwhile.

A cheap and simple test will give real results.

actuators. The ECU through the PC and WG solenoids controls the bleed off of the pressure from the actuators. The pills fine tune them both by affecting how quickly that pressure can build up in the actuators while the solenoids bleed them off.

If the pills are extremely small, bleed off can be greater than pressure build up and nothing happens. The opposite is also true.

If the two valves are placed up where the fan relays are, the extra length of hose has

negligible affect.

Some of you over theorize and do not accomplish anything worthwhile.

A cheap and simple test will give real results.

#17

Originally Posted by cewrx7r1

........If the two valves are placed up where the fan relays are, the extra length of hose has negligible affect.

Some of you over theorize and do not accomplish anything worthwhile.

A cheap and simple test will give real results.

Some of you over theorize and do not accomplish anything worthwhile.

A cheap and simple test will give real results.

#18

Originally Posted by adam c

I'm all about cheap and simple. That's why I installed needle valve controllers. I theorize that the prespool controller didn't work with the extra length of hose, because I can't conceive of any other reason for it to not work. I tried for 6 weeks to get the two needle valves to work together. The FACT was, they didn't work, and the prespool controller had to be removed.

I have had better success with dual Halmann MBCs, and with some adjustments over the weekend now have a decent 0.82-0.66-0.84 kg/cm2 (11.7-9.4-12 psi) pattern with a 0.4 second transition. However, some have reported getting a much higher, shorter transition so I did some experimentation. I attached my boost gauge to the secondary turbo chamber on the y-pipe and found that pre-transition boost climbs only 0.4 kg/cm2 - it should be closer to 0.8 kg/cm2 here. My guess is that the prespool is not opening fully. Next step is to adjust the length of the prespool actuator rod.

Under theorizing is fine if you have not actually had to debug transition on an FD in almost a decade.

#19

Rotary Enthusiast

Originally Posted by adam c

I'm all about cheap and simple. That's why I installed needle valve controllers. I theorize that the prespool controller didn't work with the extra length of hose, because I can't conceive of any other reason for it to not work. I tried for 6 weeks to get the two needle valves to work together. The FACT was, they didn't work, and the prespool controller had to be removed.

--------------------

As this plot shows, PC starts at 100% dc for max vent and minimum opening, then at 3k goes to a controlled duty clcle to get the secondary spinning, then after transition goes to zip duty cycle so the PC wg stays open.

https://www.rx7club.com/forum/showpo...2&postcount=22

Thread

Thread Starter

Forum

Replies

Last Post

boost, difference, mazda, needle, orifice, pc, pill, pills, precontrol, restrictor, rx7, rx7club, turbo, valve