CNC'd Keychain

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

CNC'd Keychain

Things have settled down a little in the shop so I decided to make myself a little something. I've been wanting a new keychain for my rx7 keys and I figured this would be a good excuse to use up some brass I had in the shop. From design to finished it took about 3 hours total, although I was very conservative with my feed rates as I don't work with brass often. Since I had the space on the material I also made some matching emblems to go on my fenders.

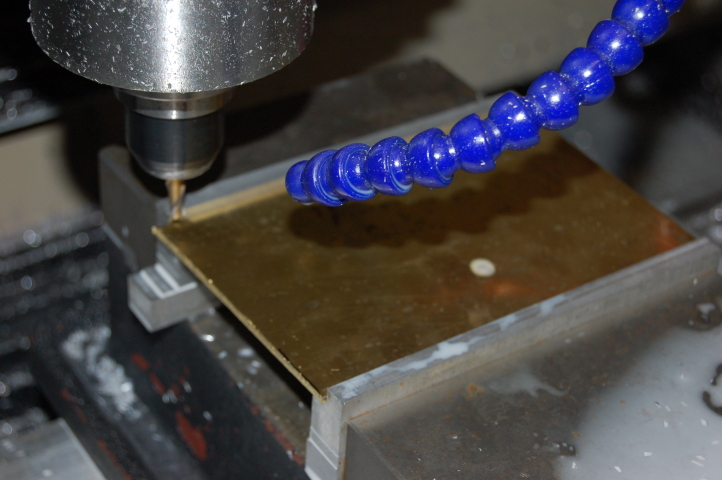

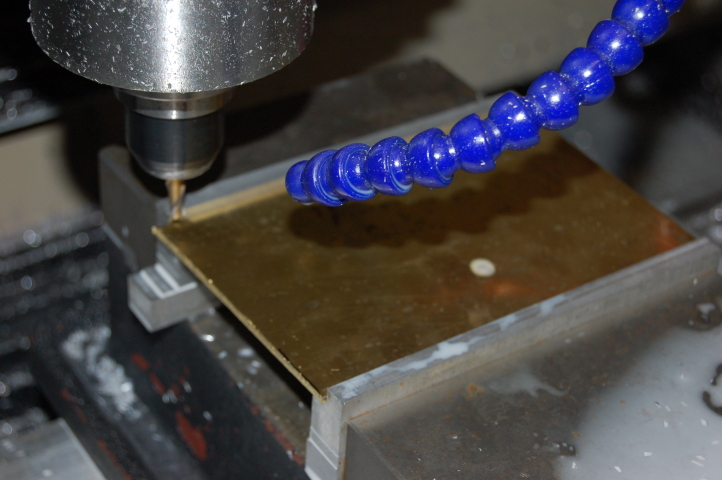

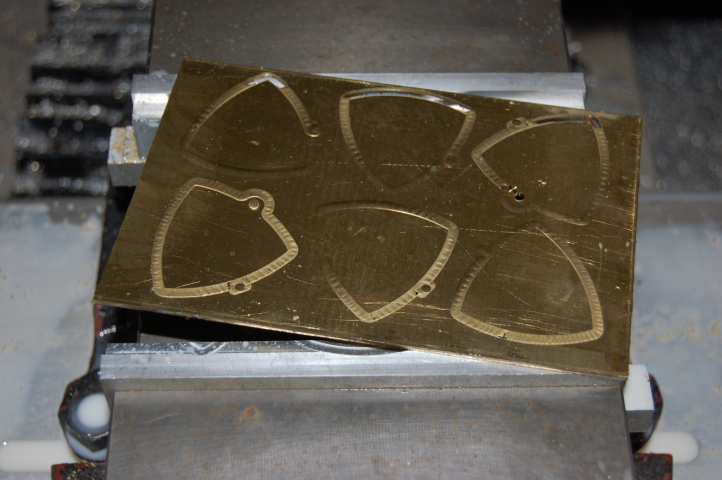

Setting up the material. This isn't ideal but for a quick job it works as long as you don't cut too aggressively.

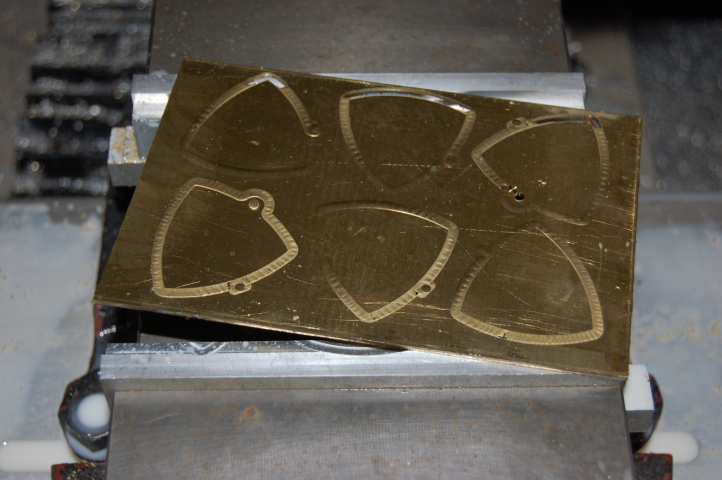

Part way through engraving the design.

Finish engraving.

Finished Cutting

Back side. You can see how the parts are only cut 99% of the way through.

After deburring and finishing.

Close up. You can see some faint lines where I need to adjust the cutting paths to overlap better.

Installed. It's not 100% perfect but I'm quite happy with it.

Because I had a spare set, I polished one of the sets of fender emblems to see the difference. I couldn't be happier with the result and just hope they look as good on the car as they do on my desk. Polished one is on the right.

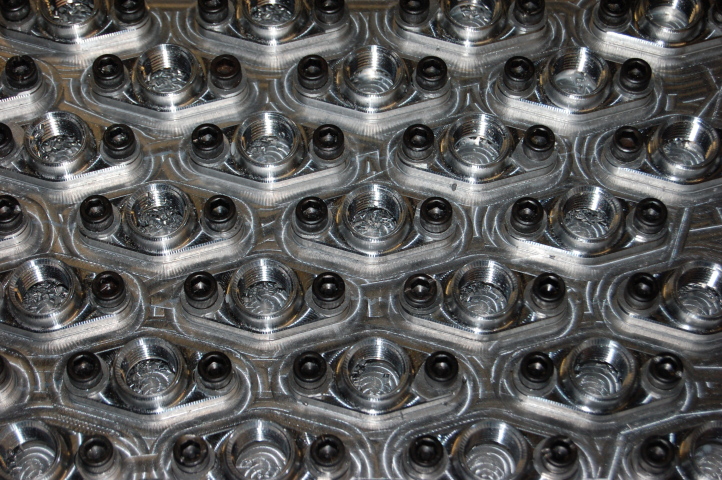

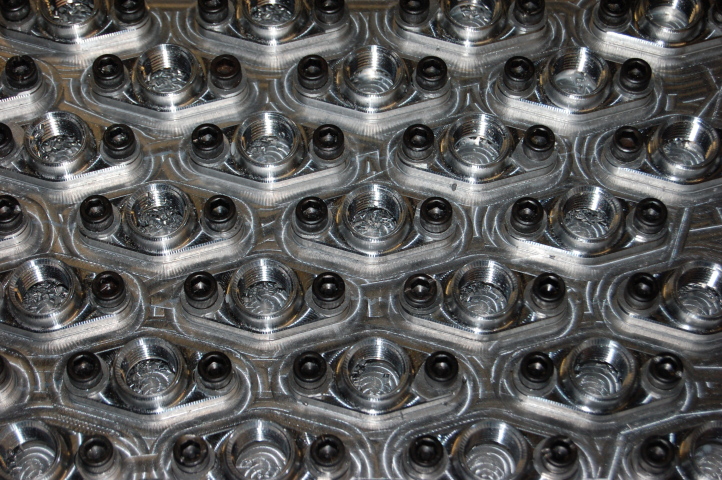

While I was waiting for the parts to cut I unloaded one of my subplates. I thought this looked pretty cool so I snapped a picture.

Setting up the material. This isn't ideal but for a quick job it works as long as you don't cut too aggressively.

Part way through engraving the design.

Finish engraving.

Finished Cutting

Back side. You can see how the parts are only cut 99% of the way through.

After deburring and finishing.

Close up. You can see some faint lines where I need to adjust the cutting paths to overlap better.

Installed. It's not 100% perfect but I'm quite happy with it.

Because I had a spare set, I polished one of the sets of fender emblems to see the difference. I couldn't be happier with the result and just hope they look as good on the car as they do on my desk. Polished one is on the right.

While I was waiting for the parts to cut I unloaded one of my subplates. I thought this looked pretty cool so I snapped a picture.

#2

Whipping thru traffic.

iTrader: (12)

Join Date: Nov 2008

Location: In a box.

Posts: 777

Likes: 0

Received 0 Likes

on

0 Posts

Holy crap dude, those are awesome.

If you're ever willing to donate one of the extra fender ones, let me know. I keep my 7 key by itself cause it's to good for the other keys.

I keep my 7 key by itself cause it's to good for the other keys.

If you're ever willing to donate one of the extra fender ones, let me know.

I keep my 7 key by itself cause it's to good for the other keys.

I keep my 7 key by itself cause it's to good for the other keys.

#3

What did you design that in? Any chance I could have a copy of the

file? Im building my own cnc and would love to use that as one of my first tests when its done.

link to my CNC build

www.stevetotheo.weebly.com/cnc-space.html

Thanks!

file? Im building my own cnc and would love to use that as one of my first tests when its done.

link to my CNC build

www.stevetotheo.weebly.com/cnc-space.html

Thanks!

#5

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

What did you design that in? Any chance I could have a copy of the

file? Im building my own cnc and would love to use that as one of my first tests when its done.

link to my CNC build

www.stevetotheo.weebly.com/cnc-space.html

Thanks!

file? Im building my own cnc and would love to use that as one of my first tests when its done.

link to my CNC build

www.stevetotheo.weebly.com/cnc-space.html

Thanks!

What are you planning to use for the cad/cam side of things?

There is a really good chance I'm going to make some more. I've been wanting to add more rotary specific products to my catalog.

#7

rx7 almost a religon

iTrader: (1)

Join Date: May 2010

Location: aurora colorado

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

you should make something similar but instead of the "M" use a "rx7" or just "7" that would be so sick to have that keychain are you planning on selling some or just for yourself?

Trending Topics

#9

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

I'm not a vendor so I can't offer them for sale or speculate publicly on selling them. But I can say that I manufacture automotive parts for a living and this is the sort of thing I would make and sell even though it was originally designed for my own personal use.

#10

All my design work is done in solidworks. I think I've actually read your blog before. One of my back burner projects is a automated polisher powered by an arduino. I wasn't planning to have it interpret gcode though, I was just going to hardcode the paths into the sketch. Right now I'm still designing the linear motion portions though.

What are you planning to use for the cad/cam side of things?

What are you planning to use for the cad/cam side of things?

#11

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

https://www.rx7club.com/2nd-generation-non-technical-pictures-198/my-new-emblems-installed-910355/#post10077687

Installed the fender emblems.

Installed the fender emblems.

#13

Full Member

Join Date: Mar 2010

Location: portbyron il.

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

like the key chain --im putting the the big block chevy radiator in mine right now -lots of fab to strengthen it back up building a lower crossmember for the bottom of the radiator .the hood at the front is only aprox 2 inches wider than the radiator .this means the scoop has to run all the way to the front of the hood .im glad i choose to go the route and put this radiator in the car .measured up the big block and its 32 inches from the back to the dowl on the water pump a very tall order to get it in and the radiator .i have only found one other big block chevy fc and he has a small radiator (its a drag car) mine will be driven on the street and it has to run cool ---make it yourself if ya can is my motto +dare to be different!

#14

Learned alot | Alot to go

iTrader: (2)

Join Date: Apr 2002

Location: Rotaryland, New Hampshire

Posts: 4,232

Likes: 0

Received 0 Likes

on

0 Posts

Wow nice looking pieces. I dont do brass ever and wouldnt have thought it would polish out so nice.

What do you do for work if you dont mind me asking?

Nice looking cnc Nice to know someone else is building one

Nice to know someone else is building one

A friend and myself are almost done (whatever that means) with a our cnc wood router we use for work. Started as a JGRO however im redesigning it for leaner ways, uses rack and pinon and its longer, has a 15x96x6 cutting area

Were getting 780inch's per min feed rates, would go faster but i run out of X travel. Right now its mostly MDF however the gantry is being rebuilt out of aluminium. Aiming for 1000ipm cutting in the Y

Heres an old pic of our pile

-Jacob

What do you do for work if you dont mind me asking?

What did you design that in? Any chance I could have a copy of the

file? Im building my own cnc and would love to use that as one of my first tests when its done.

link to my CNC build

www.stevetotheo.weebly.com/cnc-space.html

Thanks!

file? Im building my own cnc and would love to use that as one of my first tests when its done.

link to my CNC build

www.stevetotheo.weebly.com/cnc-space.html

Thanks!

Nice looking cnc

Nice to know someone else is building one

Nice to know someone else is building oneA friend and myself are almost done (whatever that means) with a our cnc wood router we use for work. Started as a JGRO however im redesigning it for leaner ways, uses rack and pinon and its longer, has a 15x96x6 cutting area

Were getting 780inch's per min feed rates, would go faster but i run out of X travel. Right now its mostly MDF however the gantry is being rebuilt out of aluminium. Aiming for 1000ipm cutting in the Y

Heres an old pic of our pile

-Jacob

#15

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

Wow nice looking pieces. I dont do brass ever and wouldnt have thought it would polish out so nice.

What do you do for work if you dont mind me asking?

Nice looking cnc Nice to know someone else is building one

Nice to know someone else is building one

A friend and myself are almost done (whatever that means) with a our cnc wood router we use for work. Started as a JGRO however im redesigning it for leaner ways, uses rack and pinon and its longer, has a 15x96x6 cutting area

Were getting 780inch's per min feed rates, would go faster but i run out of X travel. Right now its mostly MDF however the gantry is being rebuilt out of aluminium. Aiming for 1000ipm cutting in the Y

-Jacob

What do you do for work if you dont mind me asking?

Nice looking cnc

Nice to know someone else is building one

Nice to know someone else is building oneA friend and myself are almost done (whatever that means) with a our cnc wood router we use for work. Started as a JGRO however im redesigning it for leaner ways, uses rack and pinon and its longer, has a 15x96x6 cutting area

Were getting 780inch's per min feed rates, would go faster but i run out of X travel. Right now its mostly MDF however the gantry is being rebuilt out of aluminium. Aiming for 1000ipm cutting in the Y

-Jacob

Thats a unique cutting area. How's the repeatability at those speeds?

#16

Learned alot | Alot to go

iTrader: (2)

Join Date: Apr 2002

Location: Rotaryland, New Hampshire

Posts: 4,232

Likes: 0

Received 0 Likes

on

0 Posts

Well we have only run it at the 780imp for maby 10min substained and that was without a dial indicator, however we were running it from as close to the limit switch to limit switchs we could and it never tripped one. takes about 6" to ramp upto speed and the same to slow down. We were limited to that short timeframe because the mosfet's on the driver board got hot enough to melt there on solder  They now have a massive heatsink and temps peak around 120F

They now have a massive heatsink and temps peak around 120F

We did however loose some accuracy being we went with such a high available feed rate, about 0.0083s accuracy in X and once Y's done the same there, which granted isnt great, however its roughing out snowboard and ski cores profiles and shapes which are hand sanded after, so its plenty accurate for what we are doing with it. the z axis has 0.00025 accuracy however (not accounting for backlash). If we build another we will go with a microstepping board and servo's so we can get back into tenth's accuracy and still have atleast 700ipm cutting speeds

and some random gloating, heres board #1, no cnc router all hand profiled and shaped

-Jacob

They now have a massive heatsink and temps peak around 120F

They now have a massive heatsink and temps peak around 120F We did however loose some accuracy being we went with such a high available feed rate, about 0.0083s accuracy in X and once Y's done the same there, which granted isnt great, however its roughing out snowboard and ski cores profiles and shapes which are hand sanded after, so its plenty accurate for what we are doing with it. the z axis has 0.00025 accuracy however (not accounting for backlash). If we build another we will go with a microstepping board and servo's so we can get back into tenth's accuracy and still have atleast 700ipm cutting speeds

and some random gloating, heres board #1, no cnc router all hand profiled and shaped

-Jacob

Last edited by CrackHeadMel; 07-12-10 at 05:30 AM.

#19

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

Nice board. The router will make the cores alot easier to produce. A router is on my list of machines to get, but I'm looking for something beefy enough to cut 0.5" 6061 at full DOC.

#20

Learned alot | Alot to go

iTrader: (2)

Join Date: Apr 2002

Location: Rotaryland, New Hampshire

Posts: 4,232

Likes: 0

Received 0 Likes

on

0 Posts

I dont think our motors would allow 1/16th deep cuts with a half inch mill in alu, built for speed not tq.

You looking to build a machine to cut alu or you buying one? Not sure how BC's doing manufacturing wise, however in NH there are piles of deals on pretty new milling and turning machines.

-Jacob

You looking to build a machine to cut alu or you buying one? Not sure how BC's doing manufacturing wise, however in NH there are piles of deals on pretty new milling and turning machines.

-Jacob

#22

Week-ends driver!

iTrader: (1)

Join Date: Jun 2010

Location: Canada

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

Sorry, I guess this is what I should have read before replying in the badge thread.

Very nice work....

If you ever have time to "waste", let me know... maybe we could work on some "RX-7" logos for FD owners!!!!

Very nice work....

If you ever have time to "waste", let me know... maybe we could work on some "RX-7" logos for FD owners!!!!

#23

rx7 almost a religon

iTrader: (1)

Join Date: May 2010

Location: aurora colorado

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

this is all i could find for keychains and they sale this for 15 bucks

i would rather have one like yours... if you make another one and get bored of the one you made first just send it to me lol

keep up the good work can't wait to see more of your work must be nice to make pretty much any accessory for your car like infini symbols

i would rather have one like yours... if you make another one and get bored of the one you made first just send it to me lol

keep up the good work can't wait to see more of your work must be nice to make pretty much any accessory for your car like infini symbols

#24

Senior Member

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: Vancouver, BC

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

this is all i could find for keychains and they sale this for 15 bucks

i would rather have one like yours... if you make another one and get bored of the one you made first just send it to me lol

keep up the good work can't wait to see more of your work must be nice to make pretty much any accessory for your car like infini symbols

i would rather have one like yours... if you make another one and get bored of the one you made first just send it to me lol

keep up the good work can't wait to see more of your work must be nice to make pretty much any accessory for your car like infini symbols