'80 with 6-port engine

#76

ancient wizard...

Yes,time... assumed you were doing more than you were writing,your English is more than good enough to understand what you're talking about. I am aware of standalone tunable ECUs that can control pretty much all aspects of engine management,ignition mapping included,but don't know of any strictly for ignition mapping. Not certain what FiTech unit you have,the basic unit(up to 400hp)or 600hp model,the 600hp unit has a programmable timing advance module built in but believe it oriented to piston engine with single ignition system. Like stated previously,considering a FiTech unit to add fuel injection to a truck am restoring and would be interested in your opinion of the quality/performance of it after dialed in and some miles on it.

#77

Full Member

Thread Starter

while I'm on weekend vacation, waiting to work again on the car, I'm searching in the forum for information about ignition-only ECUs for my project, and all the alternatives are way too expensive, so I was wondering if I install an fc3s ECU (n380) would it work without all the sensors for my ignition only setup? maybe I should start another thread in the 2nd gen section...

Last edited by the thing; 03-19-17 at 10:15 AM.

#78

ancient wizard...

As best i can remember from when i worked on them when they were new,their ECM requires several sensor inputs to calculate dwell and map ignition timing/advance. I know incoming info from air flow meter is key along with coolant temperature,rpm signal would come from CAS and i think there's a map/baro sensor input of some kind it needs. Been a long time,would have to do some research,i could be incorrect for some of that info.

#79

Full Member

Thread Starter

While I'm keeping an eye on the FC ignition conversion (I doubt that would be possible without spending a lot of money, from what I've read) I'm continuing to run after the gremlins in my engine..

Usually the car started well and after a dozen minutes of driving around the block it began to flood. It's very difficult to track down the problem, because at times is very lean, and others very rich, and probably has to do with the fact that the Fitech EFI is made for much bigger engines and has a very low air-speed through, and also the stock ignition (remember, i'm still not using DLDFIS at the moment) is probably not burning all the fuel. I can't watch what happens on the throttle body while I'm driving, but it seems that a lot of fuel accumulates on the butterflies and when I open the throttle the engine floods. Even with very negative values on the accel pump I still get 10:1 AFR when I put my foot down. If I put it very slowly there are no issues and I can get to the redline without stumbling and explosions.

Anyway I'm doing SOME progress, since today I'm able to not completely flood the engine and actually park the car in working condition for the next day.

Now in normal driving conditions is drivable, it keeps a 900rpm idle at 13:1 and does not stumble when creeping or starting at the traffic light. I had to tweak the ecu A LOT to get to this point.

Usually the car started well and after a dozen minutes of driving around the block it began to flood. It's very difficult to track down the problem, because at times is very lean, and others very rich, and probably has to do with the fact that the Fitech EFI is made for much bigger engines and has a very low air-speed through, and also the stock ignition (remember, i'm still not using DLDFIS at the moment) is probably not burning all the fuel. I can't watch what happens on the throttle body while I'm driving, but it seems that a lot of fuel accumulates on the butterflies and when I open the throttle the engine floods. Even with very negative values on the accel pump I still get 10:1 AFR when I put my foot down. If I put it very slowly there are no issues and I can get to the redline without stumbling and explosions.

Anyway I'm doing SOME progress, since today I'm able to not completely flood the engine and actually park the car in working condition for the next day.

Now in normal driving conditions is drivable, it keeps a 900rpm idle at 13:1 and does not stumble when creeping or starting at the traffic light. I had to tweak the ecu A LOT to get to this point.

#80

ancient wizard...

When is it running lean and when is it running rich,is it inconsistent in steady state cruise,what is AFR when cruising. Not familiar with setup on this system,is engine displacement a value that can be entered into ecm for calibration?

#82

Full Member

Thread Starter

While it's going rich, the first half second of WOT makes a lot of power and then it floods.

Tomorrow I'll try to save some data and see what it looks like on a graph.

I can choose the displacement, right now is at 160, which is the bare minimum.

About the lean idle, yes it's leaner than most people runs their modified 13b, but I'm trying to get as lean as possible right now, and when it's done, I'll come back, depending on the temperatures.

Last edited by the thing; 03-22-17 at 07:06 AM.

#83

Full Member

Thread Starter

Nope. I'm totally stuck. The EFI doesn't want to work properly. I wrote to Fitech, and I will stop working on the car until they answer to my questions.

If you wanted to buy the EFI, I suggest you to wait too. From what I've tried is very, very difficult to make it work with a 13B, if not impossible.

I've tried everything... everything... When the engine idles, the injectors are squirting buckets of fuel. no matter what I do or set. It idles correctly, using the IAC, at the AFR I want, but as soon as the throttle opens, all that fuel goes into the engine. If I set the idle screw to open the throttle more so to not accumulate fuel above the throttle, it's impossible to go below 2000rpm.

I don't have vacuum leaks, and the ignition is not the best, but it sparks as it should.

I even modified the controller to put different smaller values for displacement, but below 160 it goes even worse.

I just hope the guys at Fitech will be able to help me.

If you wanted to buy the EFI, I suggest you to wait too. From what I've tried is very, very difficult to make it work with a 13B, if not impossible.

I've tried everything... everything... When the engine idles, the injectors are squirting buckets of fuel. no matter what I do or set. It idles correctly, using the IAC, at the AFR I want, but as soon as the throttle opens, all that fuel goes into the engine. If I set the idle screw to open the throttle more so to not accumulate fuel above the throttle, it's impossible to go below 2000rpm.

I don't have vacuum leaks, and the ignition is not the best, but it sparks as it should.

I even modified the controller to put different smaller values for displacement, but below 160 it goes even worse.

I just hope the guys at Fitech will be able to help me.

#84

Full Member

Thread Starter

Fitech doesn't answer as usual. They have better things to do I guess..

However, since the FC parts arrived in the mail, I continued to work on the ignition:

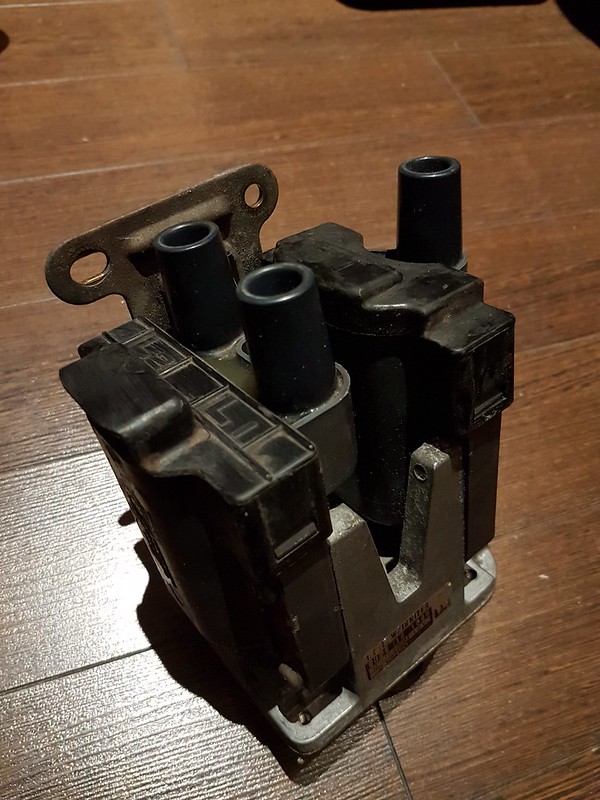

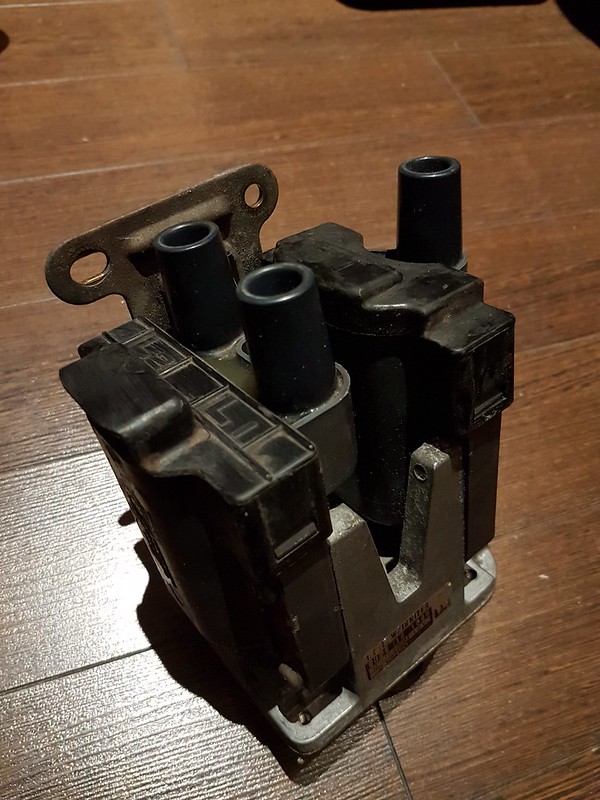

These are the parts: leading coil, trailing coils, and CAS.

For the moment the ECU ignition project will be put aside because I'm wasting enough money, but I will still use the coils in a DLDFIS configuration:

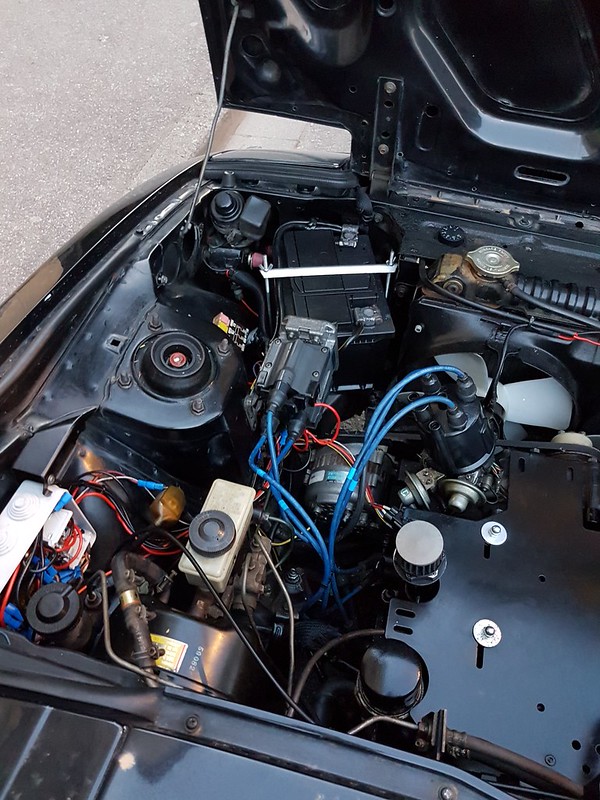

This is the combined coil assembly: the FC igniter of course is not connected and I'm driving the coils directly with my own two igniters, as you can see, since the bolt pattern is the same, I'm able to mount one trailing and the double leading onto the original igniter chassis.

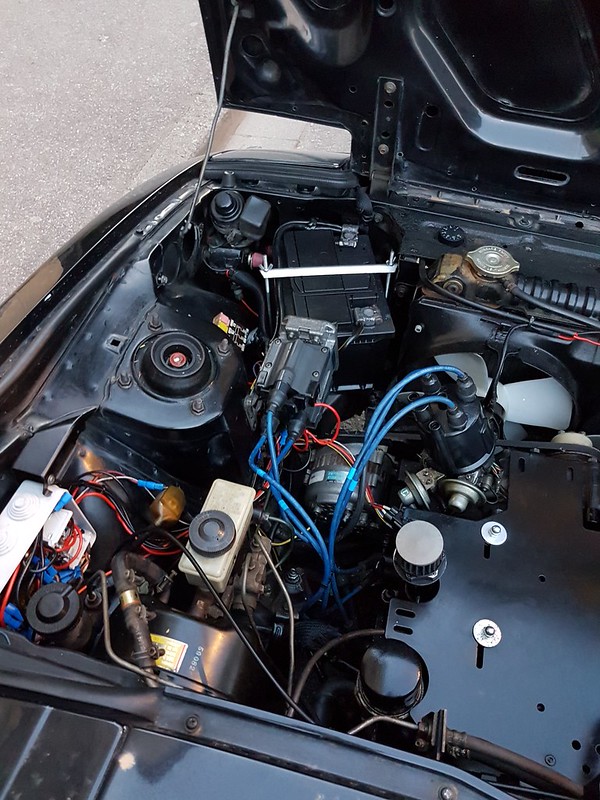

For the moment I'm mounting it in the only place where I have a free hole on the chassis, but it's not that bad, so it will probably remain there more or less.

Now, if you have read some of my latest posts you'll know that I'm trying to get around some big issues, like flooding non stop, loud pops from the exhaust and generally not drivable. I could get power at full throttle but only under certain conditions, and idle and low load were a huge mess.

So, since I can't do anything to the EFI until they answer, I started to check everything else: first of all, the TDC. I used the method of watching through the second rotor plug-holes, and marking on the pulley when the apex seal is visible, and then marking the exact middle of those two marks. I didn't have the time that day so no pictures, but you can find this method explained in many other forum threads, the result was that my pulley is FAR OFF the real TDC, I don't know how many but the timing marks on the pulley are like 30° AFTER tdc. I have to take the pulley off and measure it, but I don't know how can it be possible.. If the polarity of the pickups was inverted I would get 90° and I also tried it, it gets even more far off..

So I simply roughly set the timing to 20° before the new TDC mark and everything started to magically run much better.

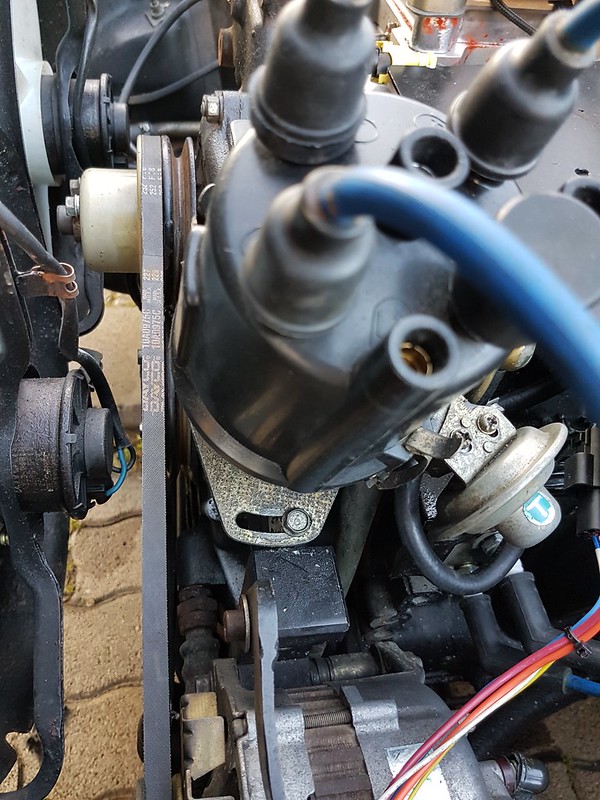

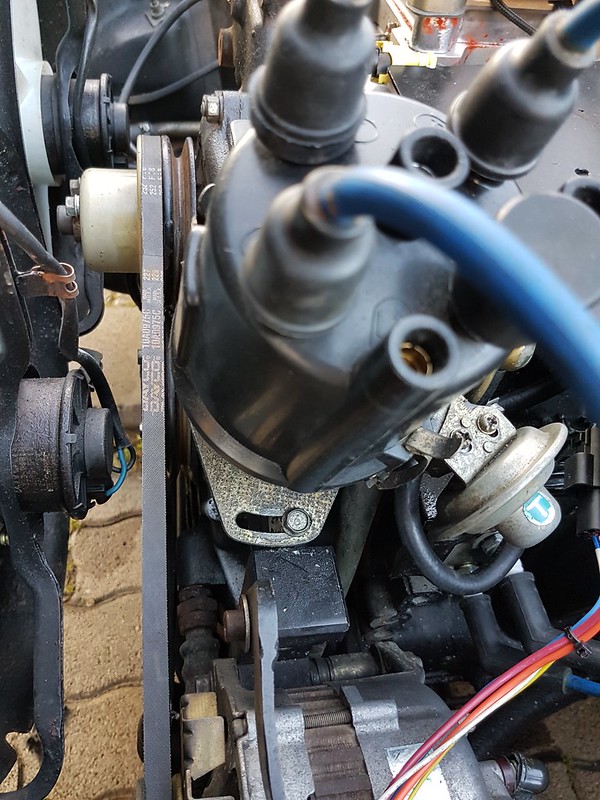

This is where I have to set the distributor to get near a correct timing: many would say the distributor is simply a tooth off, but that doesn't explain the difference from the shaft to the pulley.

After all this now I can actually drive the car: the EFI is miles off from where it should be in terms of AFR at any given time, but at least now it doesn't flood or annoy the neighbours with explosions like it's new year's eve.

The main issue now is basically the same as before (very lean just after throttle, and then very rich, like 10:1 for few seconds after) minus the constant flooding and pops. Also now with this timing I can't get the engine below 1100rpm, with throttle completely closed and idle valve at zero. Before you say I have vacuum leaks, I checked everywhere and with every method possible. I don't have leaks.

My hybrid setup of DLDFIS with FC coils seems to work fine and it's more good looking than all those can-style coils. Does anyone knows why the strobe doesn't see any spark on L1? the actual plug sparks normally, but the strobe doesn't detect it.

Next time I'll sort out this TDC issue, move the distributor, make precise marks on the pulley, etc.

However, since the FC parts arrived in the mail, I continued to work on the ignition:

These are the parts: leading coil, trailing coils, and CAS.

For the moment the ECU ignition project will be put aside because I'm wasting enough money, but I will still use the coils in a DLDFIS configuration:

This is the combined coil assembly: the FC igniter of course is not connected and I'm driving the coils directly with my own two igniters, as you can see, since the bolt pattern is the same, I'm able to mount one trailing and the double leading onto the original igniter chassis.

For the moment I'm mounting it in the only place where I have a free hole on the chassis, but it's not that bad, so it will probably remain there more or less.

Now, if you have read some of my latest posts you'll know that I'm trying to get around some big issues, like flooding non stop, loud pops from the exhaust and generally not drivable. I could get power at full throttle but only under certain conditions, and idle and low load were a huge mess.

So, since I can't do anything to the EFI until they answer, I started to check everything else: first of all, the TDC. I used the method of watching through the second rotor plug-holes, and marking on the pulley when the apex seal is visible, and then marking the exact middle of those two marks. I didn't have the time that day so no pictures, but you can find this method explained in many other forum threads, the result was that my pulley is FAR OFF the real TDC, I don't know how many but the timing marks on the pulley are like 30° AFTER tdc. I have to take the pulley off and measure it, but I don't know how can it be possible.. If the polarity of the pickups was inverted I would get 90° and I also tried it, it gets even more far off..

So I simply roughly set the timing to 20° before the new TDC mark and everything started to magically run much better.

This is where I have to set the distributor to get near a correct timing: many would say the distributor is simply a tooth off, but that doesn't explain the difference from the shaft to the pulley.

After all this now I can actually drive the car: the EFI is miles off from where it should be in terms of AFR at any given time, but at least now it doesn't flood or annoy the neighbours with explosions like it's new year's eve.

The main issue now is basically the same as before (very lean just after throttle, and then very rich, like 10:1 for few seconds after) minus the constant flooding and pops. Also now with this timing I can't get the engine below 1100rpm, with throttle completely closed and idle valve at zero. Before you say I have vacuum leaks, I checked everywhere and with every method possible. I don't have leaks.

My hybrid setup of DLDFIS with FC coils seems to work fine and it's more good looking than all those can-style coils. Does anyone knows why the strobe doesn't see any spark on L1? the actual plug sparks normally, but the strobe doesn't detect it.

Next time I'll sort out this TDC issue, move the distributor, make precise marks on the pulley, etc.

Last edited by the thing; 03-28-17 at 03:41 PM.

#85

ancient wizard...

Dario,the eccentric shaft drive belt pulley can be installed four different ways,only one is correct of course. Recommend you find tdc by your method again,take alt belt off,remove four nuts that retain pulleys to eccentric shaft snout and pull the pulleys off and see if one of the other possibilities will correct the timing mark/pin situation. Noticed you have your trailing ignition wires in their original configuration on dist. cap. Move them to the leading positions on the cap and benefit from better spark to trailing plugs by eliminating one gap to jump in dist. Does your timing/strobe light flash on trailing ignition? . Inability to lower idle speed is possibly overadvanced timing. Does your centrifugal advance work properly and return to base timing consistently on deceleration. Do your leading and trailing vacuum canisters hold vacuum,since you don't have oe FI or carb what is vacuum source for dist. vacuum advance, ported or manifold? Have a suggestion or two on your ignition system that may help it run better.

#86

ancient wizard...

You are now essentially running same ignition setup that i am. No idea why timing light doesn't flash on L1 works fine on mine,try moving it to L2 and see if that works. Recall you having some weird intermittent ignition gremlins,have couple suggestions: twist the wires coming from dist. pickups to ig.modules,helps prevent signal degradation from outside sources or cross triggering. Check airgap of both pickups,spec is .020-.035. The closer the airgap,the stronger/cleaner signal is. .022 is about perfect. The GM HEI module is somewhat more finicky about the signal than the J109 and an airgap close to .035 end of spec can cause an intermittent misfire that's kind of hard to trace down.

Last edited by GSLSEforme; 03-28-17 at 08:42 PM.

#87

If the engine is from a second generation car, the pulley can only be installed one way.

With the pulley at the leading timing mark the front rotor should be in this position or very close:

I built my last engine with the pulley 180 degrees off and it was able to start, but ran very, very rough.

With the pulley at the leading timing mark the front rotor should be in this position or very close:

I built my last engine with the pulley 180 degrees off and it was able to start, but ran very, very rough.

#88

ancient wizard...

If the engine is from a second generation car, the pulley can only be installed one way.

With the pulley at the leading timing mark the front rotor should be in this position or very close:

I built my last engine with the pulley 180 degrees off and it was able to start, but ran very, very rough.

With the pulley at the leading timing mark the front rotor should be in this position or very close:

I built my last engine with the pulley 180 degrees off and it was able to start, but ran very, very rough.

#89

Full Member

Thread Starter

Thank you guys as always for your suggestions

I dunno what's up with the pulley, I didn't have time to take it off, but now I stabbed the distributor according to the correct TDC. so I can do fine adjustments.

I think I figured out what the main problem is about the Fitech EFI: it's simply too big for this kind of engine and the 4 barrels are always active. Maybe you can pull it off with a really long intake manifold, but with the rotary engine unless you build a really complicated manifold, it's not worth the hassle.

The air speed and turbulence are too low and it's very difficult to maintain a correct AFR. With the Holley carb I had the vacuum secondaries, so the idle and cruising part were easy to deal with, now it's a fine line between running ok and flooding the engine.

I can't do data logging, well really I'm not sure I can't, but the guys from Fitech don't answer, and their comment-system on their website is rigged so only "good" questions are published.. so without data logging I can't drive and watch the screen all the time, and I don't know what vacuum values I'm getting while driving, but one thing I can say: if I connect the vacuum advance to the manifold, the thing moves like crazy, but at the ported vacuum, I don't even know if it's working or not for how little it moves! (I'm using ported vacuum now,after trying both)

Now with the ignition sorted out and with the car not flooding every 2 seconds I started to drive it:

The pump they give you in the kit is very loud and annoying, and even with a full tank I can hear it blowing air a bit too much for my taste.. I set it to 40% power when at low RPM and TPS so it's not too loud all the time; I need to find the time to make a better mounting bracket with rubber feet for the pump, to isolate the sound.

I'm trying all my best to follow their instructions and not to touch anything on the menus until the EFI self learning is done, and that takes a lot of miles (now it still goes all over the place with the AFR, from 10 to 18 while accelerating). I tried also a couple of times to go full throttle to the red line, and I feel it lacks power over 4500RPM. I'll give it time. Let's see next week.

Last thing: now that I have a real temperature gauge (not precise but I know how much it overshoots) I saw that I often run too hot, so The only thing I can do for the moment is removing the thermostat.

(Picture from when I was bleeding air from the system)

I know it's not a good thing to do, but I still have the original radiator and an engine with a lot more heat to dissipate, so this is the best counter measure I can think for the moment. Now it runs at the correct temperature all the time, so I'm not worried about that.

I dunno what's up with the pulley, I didn't have time to take it off, but now I stabbed the distributor according to the correct TDC. so I can do fine adjustments.

I think I figured out what the main problem is about the Fitech EFI: it's simply too big for this kind of engine and the 4 barrels are always active. Maybe you can pull it off with a really long intake manifold, but with the rotary engine unless you build a really complicated manifold, it's not worth the hassle.

The air speed and turbulence are too low and it's very difficult to maintain a correct AFR. With the Holley carb I had the vacuum secondaries, so the idle and cruising part were easy to deal with, now it's a fine line between running ok and flooding the engine.

I can't do data logging, well really I'm not sure I can't, but the guys from Fitech don't answer, and their comment-system on their website is rigged so only "good" questions are published.. so without data logging I can't drive and watch the screen all the time, and I don't know what vacuum values I'm getting while driving, but one thing I can say: if I connect the vacuum advance to the manifold, the thing moves like crazy, but at the ported vacuum, I don't even know if it's working or not for how little it moves! (I'm using ported vacuum now,after trying both)

Now with the ignition sorted out and with the car not flooding every 2 seconds I started to drive it:

The pump they give you in the kit is very loud and annoying, and even with a full tank I can hear it blowing air a bit too much for my taste.. I set it to 40% power when at low RPM and TPS so it's not too loud all the time; I need to find the time to make a better mounting bracket with rubber feet for the pump, to isolate the sound.

I'm trying all my best to follow their instructions and not to touch anything on the menus until the EFI self learning is done, and that takes a lot of miles (now it still goes all over the place with the AFR, from 10 to 18 while accelerating). I tried also a couple of times to go full throttle to the red line, and I feel it lacks power over 4500RPM. I'll give it time. Let's see next week.

Last thing: now that I have a real temperature gauge (not precise but I know how much it overshoots) I saw that I often run too hot, so The only thing I can do for the moment is removing the thermostat.

(Picture from when I was bleeding air from the system)

I know it's not a good thing to do, but I still have the original radiator and an engine with a lot more heat to dissipate, so this is the best counter measure I can think for the moment. Now it runs at the correct temperature all the time, so I'm not worried about that.

#91

Senior Member

#92

Full Member

Thread Starter

YES, as I said, this is not the right thing to do: removing the thermostat is never the right solution, but I had to test the thermostat and to do that I have to remove it, and to remove it I have to bring the car in the garage. I don't have space in the garage to keep the car right now so I had to park the car outside. So I had the idea to see if the car without thermostat ran cooler, and it did. maybe it's a false reading because the coolant is bypassed from the hose, but was 5°C cooler. The infrared thermometer confirmed that on all the cooling system and engine. Tomorrow I will test the thermostat in hot water to see if maybe it's not opening enough or at all.

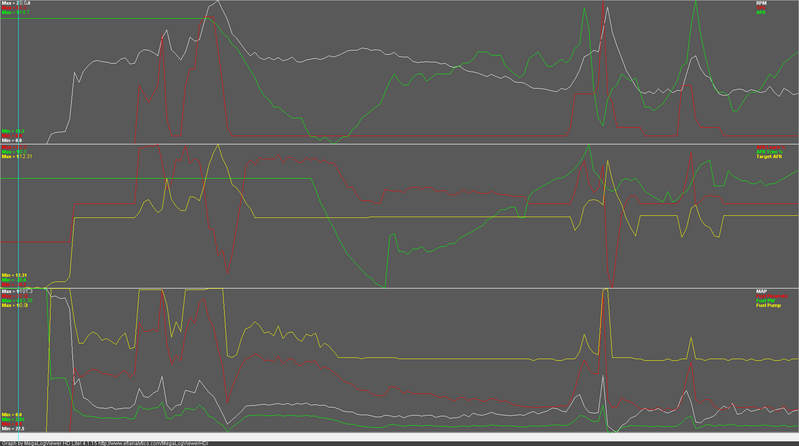

Anyway I'm doing some further progress on the EFI: I made a little software modification to enable data logging, and now I am able to record all the values and see what's happening.

Also I'm able to see many hidden values from the fuel learning, very useful to learn myself what the ECU is doing in real-time and if it's going where it shouldn't. for example I saw huge positive corrections in some areas that matched the issue I'm having. So now when I see corrections like that I try other initial set-ups and see what works with the smallest learning corrections.

I'm trying various chart-plotting software like megalogviewer and others, and it works with no problems.

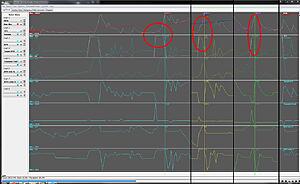

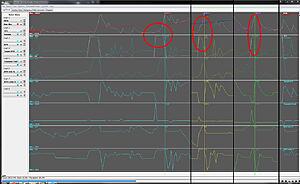

( full size image this log is only few seconds long, and the learn data had been reset, but you can already start to see the enrichment I was talking about. It will show better next time)

The next software mod would be enabling some of the "pro" features, normally not available with the "street" version, but I don't think I'm able to do it.

Anyway I'm doing some further progress on the EFI: I made a little software modification to enable data logging, and now I am able to record all the values and see what's happening.

Also I'm able to see many hidden values from the fuel learning, very useful to learn myself what the ECU is doing in real-time and if it's going where it shouldn't. for example I saw huge positive corrections in some areas that matched the issue I'm having. So now when I see corrections like that I try other initial set-ups and see what works with the smallest learning corrections.

I'm trying various chart-plotting software like megalogviewer and others, and it works with no problems.

( full size image this log is only few seconds long, and the learn data had been reset, but you can already start to see the enrichment I was talking about. It will show better next time)

The next software mod would be enabling some of the "pro" features, normally not available with the "street" version, but I don't think I'm able to do it.

Last edited by the thing; 04-03-17 at 03:19 PM.

#96

Full Member

Thread Starter

Thank you guys! reverse engineering is my specialty, but not in this field. I'm not an expert in electronics or software but these things are usually easy for me to understand.

I enabled the "pro" features I was talking about, but in the string there is an address that is probably referring to a data channel, and since I don't have a map of the channels, I'm not sure if they are really enabled or not, so for the moment I will continue to have them disabled to avoid even more confusion than already is.

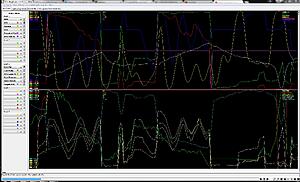

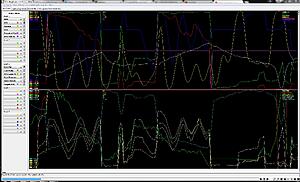

I tried different data log viewers, but nothing pleases me. The best I've found is Megalogviewer HD but it's very difficult to visualize the data as I want in the graph format, so I have to screenshot the different tests and compare them afterwards in Photoshop.

Here it's a composite image with three different maps, and as you can see the first stock one is terrible. several seconds between the opening of the throttle and the actual revving of the engine. the next runs (in different colors) are overlaid on top to find the differences, and as you can see test 2 and 3 are progressively more responsive.

I think I'm on the right path: I don't have a laptop at the moment so the process is very slow, but I think I'll be able to set this thing right using this method.

I still didn't have time to test the thermostat yet, but It's not a priority right now.

I enabled the "pro" features I was talking about, but in the string there is an address that is probably referring to a data channel, and since I don't have a map of the channels, I'm not sure if they are really enabled or not, so for the moment I will continue to have them disabled to avoid even more confusion than already is.

I tried different data log viewers, but nothing pleases me. The best I've found is Megalogviewer HD but it's very difficult to visualize the data as I want in the graph format, so I have to screenshot the different tests and compare them afterwards in Photoshop.

Here it's a composite image with three different maps, and as you can see the first stock one is terrible. several seconds between the opening of the throttle and the actual revving of the engine. the next runs (in different colors) are overlaid on top to find the differences, and as you can see test 2 and 3 are progressively more responsive.

I think I'm on the right path: I don't have a laptop at the moment so the process is very slow, but I think I'll be able to set this thing right using this method.

I still didn't have time to test the thermostat yet, but It's not a priority right now.

Last edited by the thing; 04-04-17 at 03:04 PM.

#97

Great progress so far! Have you tried dataloglab? Yes it is old, but sometimes old things are easier to work with and do enough to help... plus it is free. I've been using it on my Link ECU turbo miata with varied success. Basic, but very helpful.

https://www.flyinmiata.com/FMcontent/dataloglab/

It starts in 30 day trial mode, main program and serial key generator are available in the downloads section.

https://www.flyinmiata.com/FMcontent/dataloglab/

It starts in 30 day trial mode, main program and serial key generator are available in the downloads section.

Last edited by swbtm; 04-05-17 at 11:26 AM.

#98

Full Member

Thread Starter

Hi, dataloglabs seems to not like the fitech's CSV files. I only get errors from it.

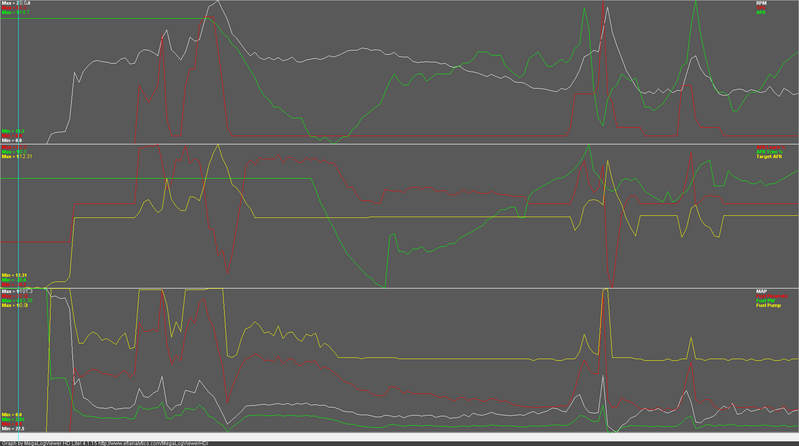

Anyway: last weekend I managed to drive the car for few hundred of kilometers on a trip to the beach, where I drove it on the highway, on hills, in traffic.. and most of the usual stuff. I'm dialing closer and closer to something to be proud of but it still bogs every time I open the throttle more than usual.

If you have the software and you like to play with data, I'll attach the csv file.

As you can see, while the target and learn are fairly linear, I get huge waves of AFR and injectors' duty cycle. Also it's clear that the whole throttle body is too big and even at half the throttle I get atmospheric pressure.. maybe it's all because of that?

Here also some cute pictures from the trip:

(more pictures on my flickr page)

Anyway: last weekend I managed to drive the car for few hundred of kilometers on a trip to the beach, where I drove it on the highway, on hills, in traffic.. and most of the usual stuff. I'm dialing closer and closer to something to be proud of but it still bogs every time I open the throttle more than usual.

If you have the software and you like to play with data, I'll attach the csv file.

As you can see, while the target and learn are fairly linear, I get huge waves of AFR and injectors' duty cycle. Also it's clear that the whole throttle body is too big and even at half the throttle I get atmospheric pressure.. maybe it's all because of that?

Here also some cute pictures from the trip:

(more pictures on my flickr page)

#100

Rotary Enthusiast

I'm enjoying this thread. I'm intrigued by the FITech thing but mostly I'm impressed with your persistence and creativity!

I looked at your csv file...I think the dataloglab sproblem is that the format isn't delimited by commas but with <TAB> characters. Maybe dataloglabs stuff can import tab separated files if you set a preference? Anyway, it seems like you are happy with your current graphing package.

I pulled it into Excel because I was curious. The AFR target vs. actual seems tough for it to control. Every time the target moves a little bit, the measured AFR spikes wildly high or low. I've never reviewed this kind of data before, so maybe this kind of volatility is common? It would be nice to see some data from an engine where the FITech thing performs excellently.

I multiplied the TPS value by 10 to make it fit better on the chart. And I put RPM onto the 2nd Y-Axis.