Mannykillers/ AAPARKAH Street/time Attack/Drift Build (heavy Pics) #Thisisthewolf

#2101

heeeeelll yeah

I have been in this car and seen it perform. Aaron has been doing a lot of homework and testing on everything he has done. Some people will never understand this concept of building a car.

Build the car up to your standards for you to enjoy it .....not for others.

Alex

I have been in this car and seen it perform. Aaron has been doing a lot of homework and testing on everything he has done. Some people will never understand this concept of building a car.

Build the car up to your standards for you to enjoy it .....not for others.

Alex

Car runs better and feels even better than mazfest....which I don't think you even got to feel!!

I'll talk to you soon buddy.

#2102

Update:

Well the past week I've been going through little things once again that I thought I might've overlooked.

Every once in a while its an excellent idea to jack the car up and just get under the car. Yo'd be amazed at the things you "Forgot" or maybe didn't forget but put on the "not important/i'll get to it later" list. What did I find?

I found that one of my fuel lines was running a little closer than I would like to my 4" exhaust. I'd say theres about 4" in between the two... And obviously it was fine at the maz fest track day and the line still feels nice soft and pliable.. But just to be safe. I went ahead and wrapped it with some insulation and held the insulation around it with some left over DEI reflective gold adhesive tape. HOle heap of it on my car now.

Anyways.. I'm not using my AEM water/Methanol kit at all.... so rather than selling it off.... I really think I can put it to good use.

So I'm going to make a speed racer defense mechanism. There have been times when people follow me too close. So I'm going to angle my Water Meth nozzle down at the pavement on my rear bumper. And when people get all up in my business because they hate imports. I'm going to give them some traction problems and squirt oil all over the road. I've always wanted to do this. It'll be hooked up to a push button my my steering wheel. Just like speed racers Mach 5!! Cool ayyy?!!

Haha....jkjk But seriously. What I'm going to do with it is make a "Hot start/Cool down mist system." My plan is to take the Nozzle and angle it either at my Radiator or my oil coolers. I'm leaning towards my radiator because there is just a larger volume going through it and I think it does a better job regulating over-all temp than oil. So if you keep water temp down...I'm hoping oil temp will stay down as well. So like I said.... The plan is to set up the nozzle so that it is on a push button on/off switch. in the pits I'll be able to spray water onto my Radiator or oil coolers (if I change my mind/maybe even both) to be able to help with Hot start's or cool downs after a hard session.

Anyways...picked up a set of base seats for cheap all the way up in Santa Barbera

Saw my dream car on the freeway..

what a beautiful drive

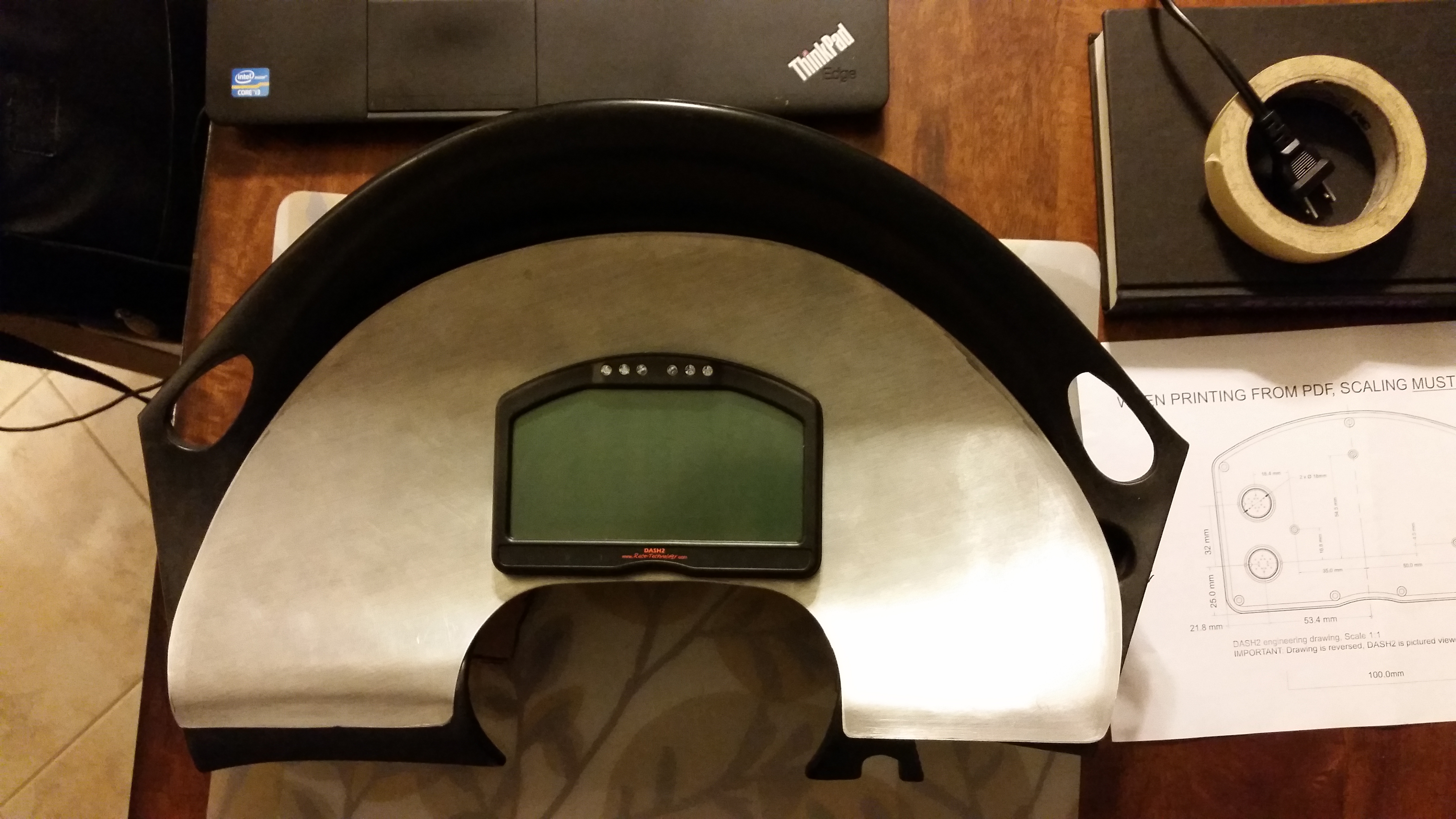

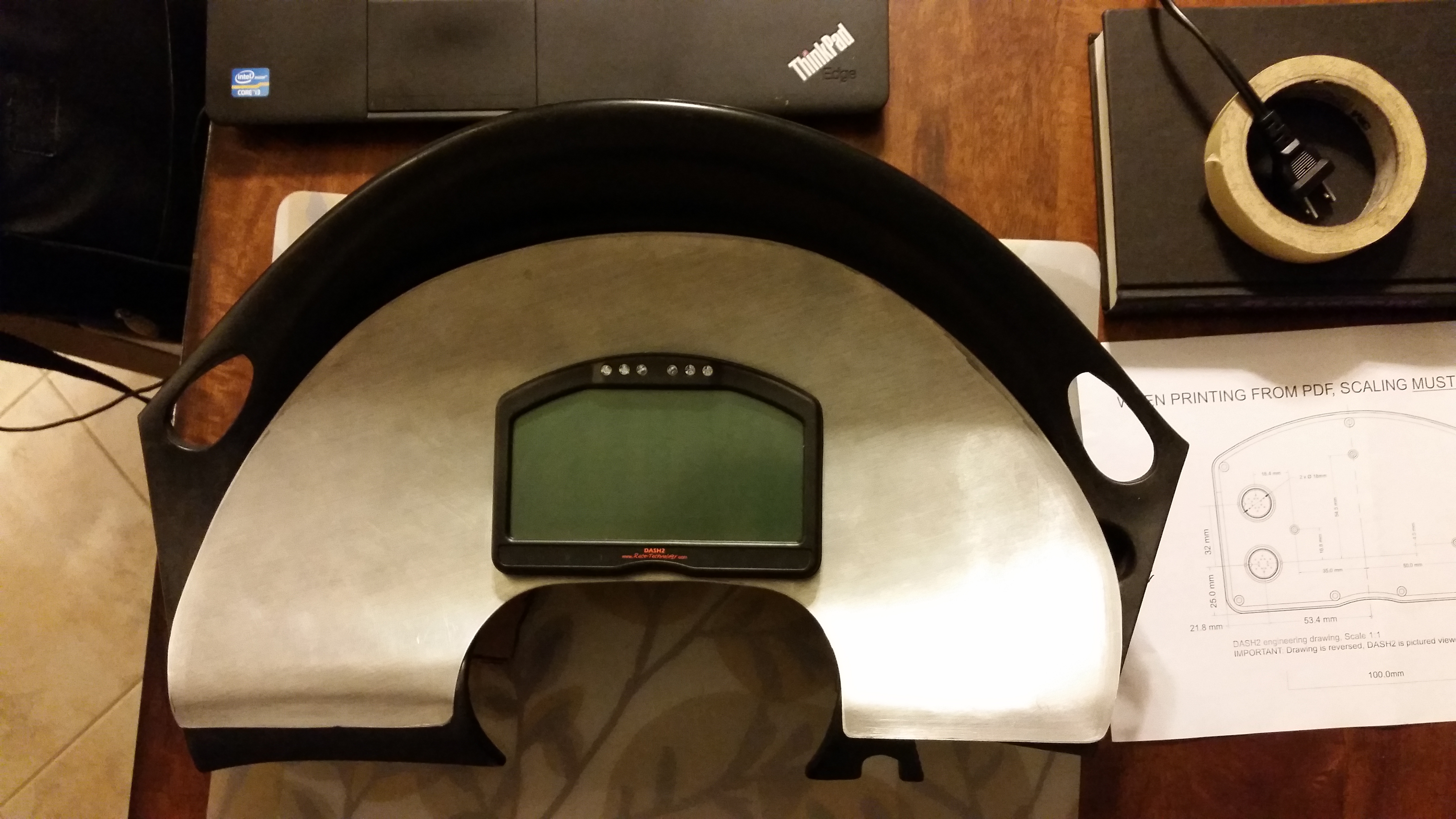

Got home and messed with my race technologies Mount made from sheet metal

Mounted my seat and seatbelt

more cutting fitting/bending/planning

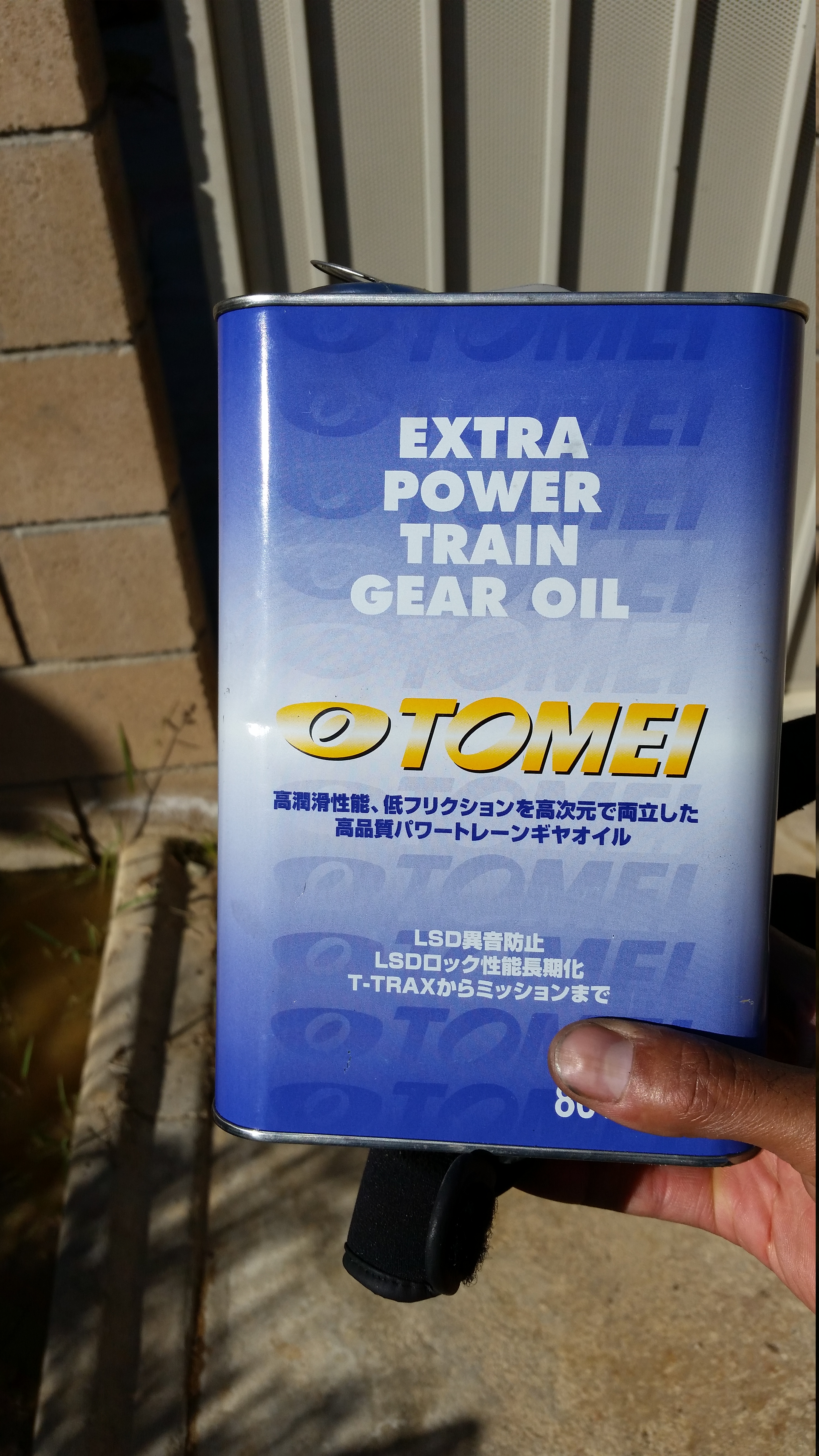

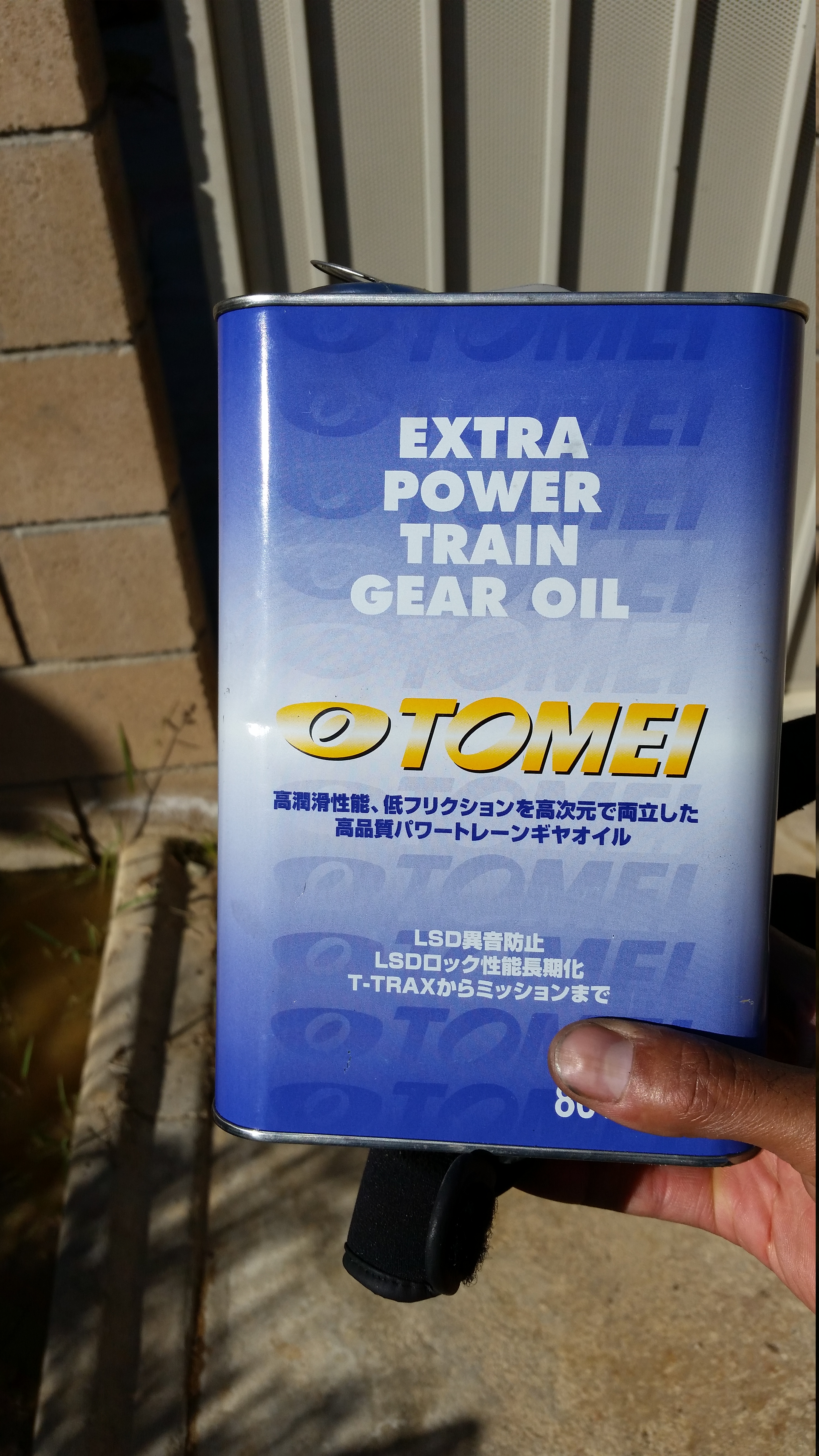

took a break and changed my diff fluid

More dinoc 3m

Wiring up the buttons and making them fit nice and snug/organizing the routing

All finished up

99%done

More Updates soon!!

Stay tuned!!

Well the past week I've been going through little things once again that I thought I might've overlooked.

Every once in a while its an excellent idea to jack the car up and just get under the car. Yo'd be amazed at the things you "Forgot" or maybe didn't forget but put on the "not important/i'll get to it later" list. What did I find?

I found that one of my fuel lines was running a little closer than I would like to my 4" exhaust. I'd say theres about 4" in between the two... And obviously it was fine at the maz fest track day and the line still feels nice soft and pliable.. But just to be safe. I went ahead and wrapped it with some insulation and held the insulation around it with some left over DEI reflective gold adhesive tape. HOle heap of it on my car now.

Anyways.. I'm not using my AEM water/Methanol kit at all.... so rather than selling it off.... I really think I can put it to good use.

So I'm going to make a speed racer defense mechanism. There have been times when people follow me too close. So I'm going to angle my Water Meth nozzle down at the pavement on my rear bumper. And when people get all up in my business because they hate imports. I'm going to give them some traction problems and squirt oil all over the road. I've always wanted to do this. It'll be hooked up to a push button my my steering wheel. Just like speed racers Mach 5!! Cool ayyy?!!

Haha....jkjk But seriously. What I'm going to do with it is make a "Hot start/Cool down mist system." My plan is to take the Nozzle and angle it either at my Radiator or my oil coolers. I'm leaning towards my radiator because there is just a larger volume going through it and I think it does a better job regulating over-all temp than oil. So if you keep water temp down...I'm hoping oil temp will stay down as well. So like I said.... The plan is to set up the nozzle so that it is on a push button on/off switch. in the pits I'll be able to spray water onto my Radiator or oil coolers (if I change my mind/maybe even both) to be able to help with Hot start's or cool downs after a hard session.

Anyways...picked up a set of base seats for cheap all the way up in Santa Barbera

Saw my dream car on the freeway..

what a beautiful drive

Got home and messed with my race technologies Mount made from sheet metal

Mounted my seat and seatbelt

more cutting fitting/bending/planning

took a break and changed my diff fluid

More dinoc 3m

Wiring up the buttons and making them fit nice and snug/organizing the routing

All finished up

99%done

More Updates soon!!

Stay tuned!!

#2103

Update:

So I was able to get the dash fully mounted with power and everything. But I needed to use a fuse and holder for the dash just for some extra protection....even though I'm using the OEM circuit which was already protected. So I purchased these little guys from radio shack

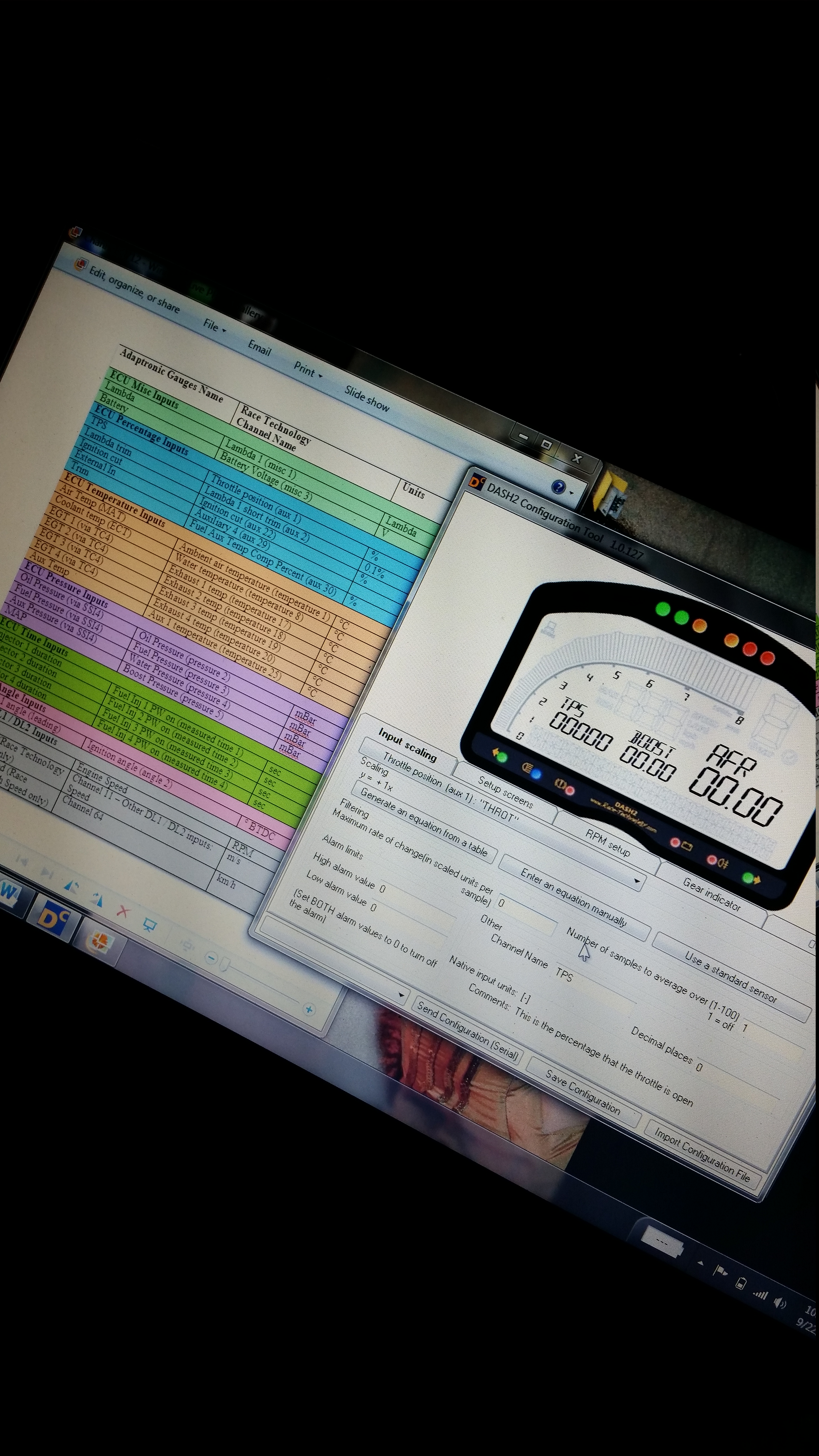

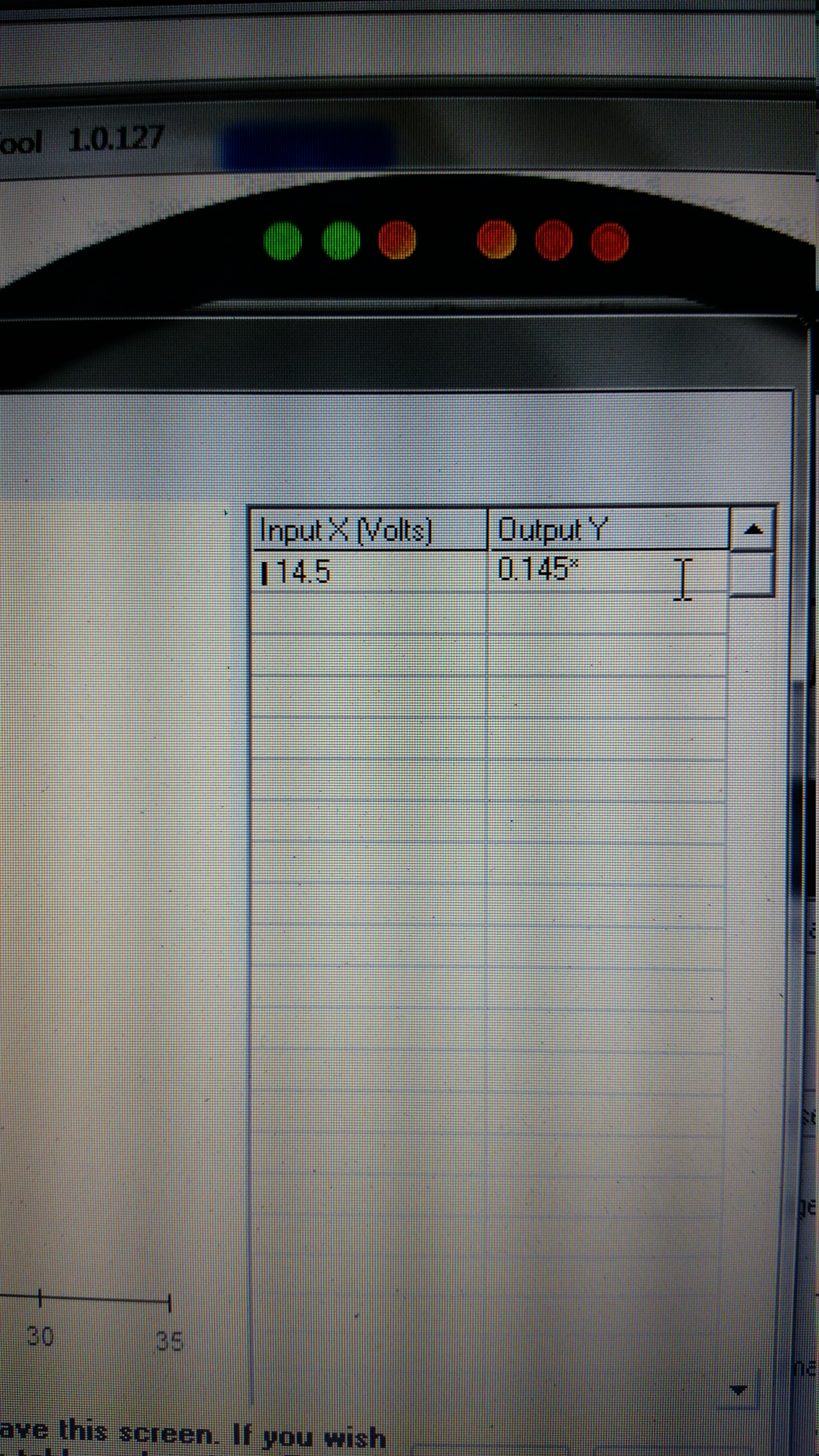

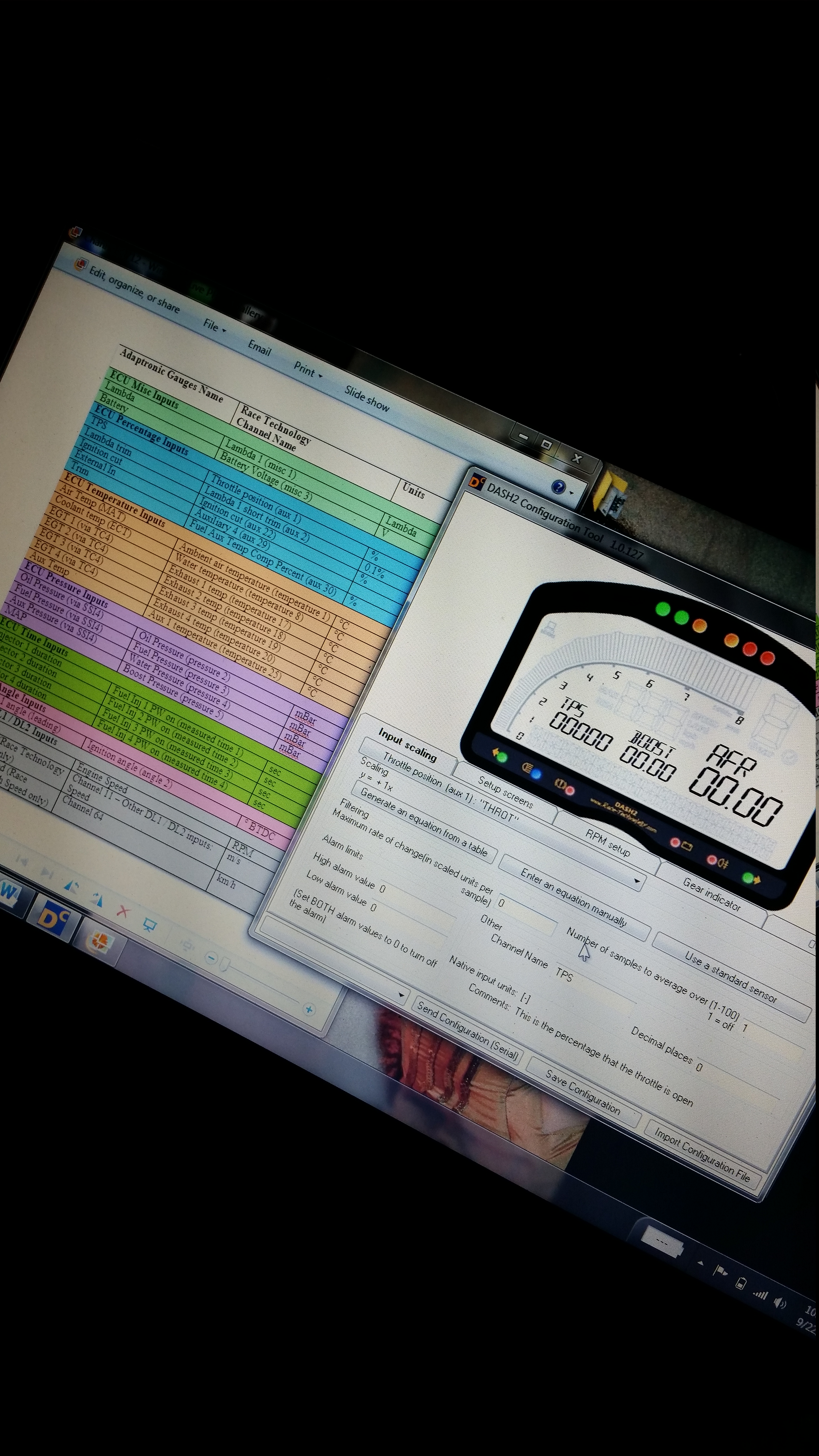

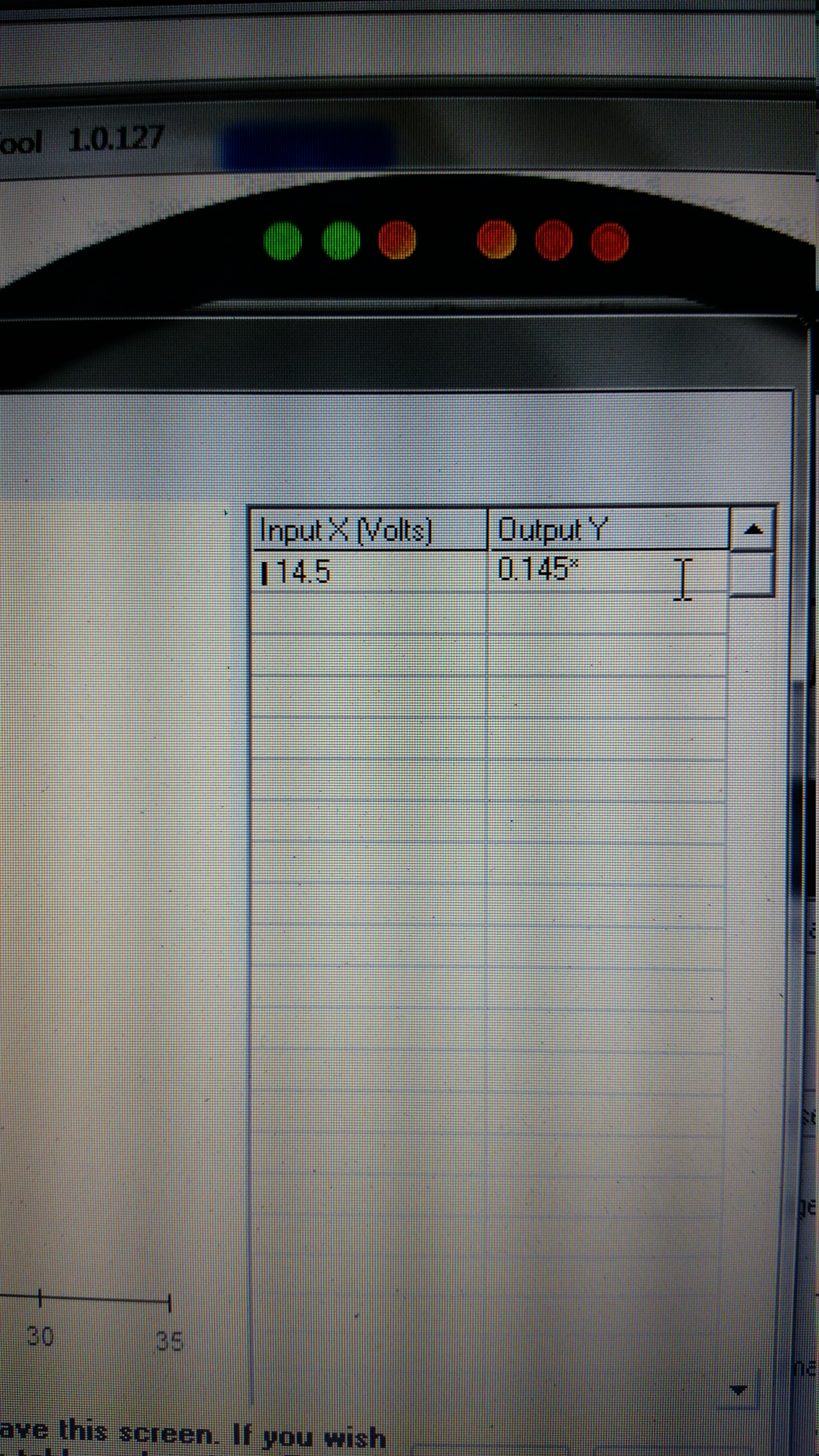

Opened up the software to get my screens set, and set up warning lights etc

And wanted to change some units..from lambda to AFR so I had to do a little bit of research.

Got it all figured so that screen 1 displays:

Water Temp.........Oil Temp.........Oil Pressure

Screen 2

TPS.............Boost................AFR

Screen 3

EGT Front.......EGT Rear.......Air Intake Temp

Screen 4

Battery V........TPS..........Boost/Vac/Map

Screen 5

Unsure of what to put so I just left the default.

I Can always go back and change things but As of right now...that's really all I need.

Set up my Warning's for all important things, and even the Sweet *** shift lights.

And Finally Finished

Came out Pretty damn good. There are a couple small bubbles that **** me off....but you couldn't pay me to make that damn thing again. Well I guess you could...But It would have to be under my own terms haha. I'll be putting a couple things here and there on the display surround. But The main thing is it's perfectly visible through my Steering wheel gap while I'm in the drivers seat, And by that I mean I could see everything. The buttons were easily accessible...which they are thanks to my long monkey arms. And the thing was sturdy enough not to worry about. Which it is VERY sturdy. Feels just as strong as OEM...maybe more because my Push Button start plate actually sandwhiches the surround between the mount points. And lastly...that if there were a problem with the dash... I wouldn't have to cut a bunch of wires and re-route everything to get it in/out. And I accomplished that. The supplied Mil-spec connectors were really useful here and they really compliment the dash well/ease of install. I did mess up though. I forgot to connect the Alt Charge Light to the top Connector 1 #10 pin... so I took the car out for a drive and It ran Amazing....then would hardly idle super crappy because the ALT wasn't charging the batt. I was @ 7 Volts...surprised the damn car even idled on its own. Freaked me out for a second till I saw the log..which Is now just part of my own protocol after I install something lol.

All In all, I couldn't be happier with how the car is running currently.

The New OIl

Diff Fluid

NGK R7420's

Race Tech Dash 2 Display unit

Full Tank of Ethanol and Benol premix

and full 18Lbs of boost ....SERIOUSLY has never felt better.

I couldn't believe how strong the car pulls. And I'll have to take note to make sure I am logging Miles/Events on Diff Fluid. This is the third change and the Diff was getting kind of loud. It's always going to clunk. But the New Fluid Helps a ton.

Sat I'll be At Balcony just to give the car a shakedown after the Shakedown for the Just Drift Pre ASB Event. Going to burn up a couple sets of tires and call it an early day. Then save some Cash cheddah flow for tires for ASB. I really wish I could afford to have the car painted before ASB....but it's just not in the budget. I'll see you guys out there and don't be afraid to say whats up!

So I was able to get the dash fully mounted with power and everything. But I needed to use a fuse and holder for the dash just for some extra protection....even though I'm using the OEM circuit which was already protected. So I purchased these little guys from radio shack

Opened up the software to get my screens set, and set up warning lights etc

And wanted to change some units..from lambda to AFR so I had to do a little bit of research.

Got it all figured so that screen 1 displays:

Water Temp.........Oil Temp.........Oil Pressure

Screen 2

TPS.............Boost................AFR

Screen 3

EGT Front.......EGT Rear.......Air Intake Temp

Screen 4

Battery V........TPS..........Boost/Vac/Map

Screen 5

Unsure of what to put so I just left the default.

I Can always go back and change things but As of right now...that's really all I need.

Set up my Warning's for all important things, and even the Sweet *** shift lights.

And Finally Finished

Came out Pretty damn good. There are a couple small bubbles that **** me off....but you couldn't pay me to make that damn thing again. Well I guess you could...But It would have to be under my own terms haha. I'll be putting a couple things here and there on the display surround. But The main thing is it's perfectly visible through my Steering wheel gap while I'm in the drivers seat, And by that I mean I could see everything. The buttons were easily accessible...which they are thanks to my long monkey arms. And the thing was sturdy enough not to worry about. Which it is VERY sturdy. Feels just as strong as OEM...maybe more because my Push Button start plate actually sandwhiches the surround between the mount points. And lastly...that if there were a problem with the dash... I wouldn't have to cut a bunch of wires and re-route everything to get it in/out. And I accomplished that. The supplied Mil-spec connectors were really useful here and they really compliment the dash well/ease of install. I did mess up though. I forgot to connect the Alt Charge Light to the top Connector 1 #10 pin... so I took the car out for a drive and It ran Amazing....then would hardly idle super crappy because the ALT wasn't charging the batt. I was @ 7 Volts...surprised the damn car even idled on its own. Freaked me out for a second till I saw the log..which Is now just part of my own protocol after I install something lol.

All In all, I couldn't be happier with how the car is running currently.

The New OIl

Diff Fluid

NGK R7420's

Race Tech Dash 2 Display unit

Full Tank of Ethanol and Benol premix

and full 18Lbs of boost ....SERIOUSLY has never felt better.

I couldn't believe how strong the car pulls. And I'll have to take note to make sure I am logging Miles/Events on Diff Fluid. This is the third change and the Diff was getting kind of loud. It's always going to clunk. But the New Fluid Helps a ton.

Sat I'll be At Balcony just to give the car a shakedown after the Shakedown for the Just Drift Pre ASB Event. Going to burn up a couple sets of tires and call it an early day. Then save some Cash cheddah flow for tires for ASB. I really wish I could afford to have the car painted before ASB....but it's just not in the budget. I'll see you guys out there and don't be afraid to say whats up!

#2105

Update:

Just Drift- Pre ASB Test and Tune event @ Willow Springs

Well the whole week leading up to the event went damn smooth. I double checked and triple checked everything, oil was changed, diff fluid, plugs. Car had never felt better. The day before the event on Fri, I was notified that my trailer might not be available. So I went to a local business and rented one for 60 bucks. Not too bad. But it was a pain because the width. ......I literally had about 2" total before I destroyed my wheels on the sides of the trailer. Because of this it took me 45 min on my own to load the car up. Parking in the driveway like this is really helpful angle wise..and makes getting on and off a breeze.

I ended up working Friday, so I did all of this in the morning before going to my second job down in LA. Loaded up the car and had it waiting for me so the next morning I could simply hook up the trailer and be on my way. Got home at 3AM, and was feeling really tired, but I couldn't wait till morning to get out on the track!

You know....there's a major sense of satisfaction when your towing your car. Can't remember when I've felt so proud. Moments like this when you just thank life for giving you the means to produce everything you have. It was a beautiful morning.

Got to the track behind a few friends and we all decided we'd share a pit spot.

Drivers meeting, designated groups and everyone was ready to rip.

Even though I was in the A group, I decided to wait and warm my car up before I went out on track. About 5 min Later... I lined up, waited for the next car to finish their run and Got the go flag. Dropped the clutch and spun through first.... then Second.. then Back fire..Back fire...and Limp Mode.. Looked up and saw a bit of smoke from my hood and made a U-turn to stage and cut the car off. Opened the Hood and saw Oil....Literally EVERYWHERE.

Got a tow back to the pits.... and saw that my Oil Feed line to my turbo was Loose at the source. The front Iron. Backed it out to have a look and was heart-broken to find it had Cracked

This sucked pretty bad as you could imagine. And the first thing I thought of was months and months ago when I was installing the feed line. The Fitting I used......I really had to crank it in there in order to get it to seal properly...and even then I sed Honda-bond High Temp on the threads to be sure it didn't leak as it has always in the past. Now I remember telling myself I should just make sure it was the correct thread size....but it's been the same fitting since I rebuilt the engine originally and I kept thinking "well it's been on there since the beginning, should be fine." But Obviously....it wasn't. The fitting I used was an NPT fitting that actually tapers out towards the base of the fitting. This is a big No No. I'm pretty positive the problem was just too many cycles,...Moderate power..and the fact that this was the coldest morning I had actually ever driven the car in. When I originally put the fitting in there...It was tight from the first turn.....Stupid of me. But all I can do at this point is live and learn.

Damned fitting

I stayed at the track for about 30 min to watch a bit.....but It was really kind of killing me. A few friends offered to let me drive their cars....but I kind decided I'd just sit it out. Thanks Eddie and everyone else who helped me push the car back onto the trailer. I went home, unloaded the car, dropped the trailer back off at the local renter and went home to look at the wolf. I got home and realized I had the day off from work....then I started doing Math. ANd realized that I could still make All Star Bash.

So I pulled the Motor, made a few Phone calls, and Mr. Howard Coleman is sending me a new ported Front Iron, and it should be shipped out by tomorrow. Can't thank him enough for putting in the rush Job.

I'll take the motor down and Me and Abel are going to do the swap. I havn't gotten this far only to miss ASB Yet again for the 3rd year.

A Nice Good Look at my Parts. Kind of cool to see them all off like this...but then again..Not at all.

So The question has been brought up about Detonation and the possibility of Mis-firing causing this damage. And yes it is a possibility, but I highly doubt it. And the reason why is the car really isn't making all that much power. I'm running Ethanol, and timing is Moderately conservative especially for E85 (17 Degrees). On top of that, Although I didn't log when the failure happened.... I did take a log before I put the car on the trailer. 18.34Lbs of boost at 8100RPM @ 11.7 AFR and EGT's 673/678 Celsius which equates to 1240's F. It was about 63 Degrees F outside so it wassss the coolest I've driven the car on this new build....but it wasn't cold by any means.. the car was warmed up to 73 Degrees Celsius....and maybe that was a contributing factor... Who knows. All I know is that to make sure this doesn't happen again... We may end up pulling even more of the timing, and I won't be using this location again. I'll simply use the extra port on my oil filter pedestal. I'm hustling to make ASB. THis does cut into my tire fund.. but At this point.. If I make it and am able to drive. I'll be Amped. More Updates to come.

Just Drift- Pre ASB Test and Tune event @ Willow Springs

Well the whole week leading up to the event went damn smooth. I double checked and triple checked everything, oil was changed, diff fluid, plugs. Car had never felt better. The day before the event on Fri, I was notified that my trailer might not be available. So I went to a local business and rented one for 60 bucks. Not too bad. But it was a pain because the width. ......I literally had about 2" total before I destroyed my wheels on the sides of the trailer. Because of this it took me 45 min on my own to load the car up. Parking in the driveway like this is really helpful angle wise..and makes getting on and off a breeze.

I ended up working Friday, so I did all of this in the morning before going to my second job down in LA. Loaded up the car and had it waiting for me so the next morning I could simply hook up the trailer and be on my way. Got home at 3AM, and was feeling really tired, but I couldn't wait till morning to get out on the track!

You know....there's a major sense of satisfaction when your towing your car. Can't remember when I've felt so proud. Moments like this when you just thank life for giving you the means to produce everything you have. It was a beautiful morning.

Got to the track behind a few friends and we all decided we'd share a pit spot.

Drivers meeting, designated groups and everyone was ready to rip.

Even though I was in the A group, I decided to wait and warm my car up before I went out on track. About 5 min Later... I lined up, waited for the next car to finish their run and Got the go flag. Dropped the clutch and spun through first.... then Second.. then Back fire..Back fire...and Limp Mode.. Looked up and saw a bit of smoke from my hood and made a U-turn to stage and cut the car off. Opened the Hood and saw Oil....Literally EVERYWHERE.

Got a tow back to the pits.... and saw that my Oil Feed line to my turbo was Loose at the source. The front Iron. Backed it out to have a look and was heart-broken to find it had Cracked

This sucked pretty bad as you could imagine. And the first thing I thought of was months and months ago when I was installing the feed line. The Fitting I used......I really had to crank it in there in order to get it to seal properly...and even then I sed Honda-bond High Temp on the threads to be sure it didn't leak as it has always in the past. Now I remember telling myself I should just make sure it was the correct thread size....but it's been the same fitting since I rebuilt the engine originally and I kept thinking "well it's been on there since the beginning, should be fine." But Obviously....it wasn't. The fitting I used was an NPT fitting that actually tapers out towards the base of the fitting. This is a big No No. I'm pretty positive the problem was just too many cycles,...Moderate power..and the fact that this was the coldest morning I had actually ever driven the car in. When I originally put the fitting in there...It was tight from the first turn.....Stupid of me. But all I can do at this point is live and learn.

Damned fitting

I stayed at the track for about 30 min to watch a bit.....but It was really kind of killing me. A few friends offered to let me drive their cars....but I kind decided I'd just sit it out. Thanks Eddie and everyone else who helped me push the car back onto the trailer. I went home, unloaded the car, dropped the trailer back off at the local renter and went home to look at the wolf. I got home and realized I had the day off from work....then I started doing Math. ANd realized that I could still make All Star Bash.

So I pulled the Motor, made a few Phone calls, and Mr. Howard Coleman is sending me a new ported Front Iron, and it should be shipped out by tomorrow. Can't thank him enough for putting in the rush Job.

I'll take the motor down and Me and Abel are going to do the swap. I havn't gotten this far only to miss ASB Yet again for the 3rd year.

A Nice Good Look at my Parts. Kind of cool to see them all off like this...but then again..Not at all.

So The question has been brought up about Detonation and the possibility of Mis-firing causing this damage. And yes it is a possibility, but I highly doubt it. And the reason why is the car really isn't making all that much power. I'm running Ethanol, and timing is Moderately conservative especially for E85 (17 Degrees). On top of that, Although I didn't log when the failure happened.... I did take a log before I put the car on the trailer. 18.34Lbs of boost at 8100RPM @ 11.7 AFR and EGT's 673/678 Celsius which equates to 1240's F. It was about 63 Degrees F outside so it wassss the coolest I've driven the car on this new build....but it wasn't cold by any means.. the car was warmed up to 73 Degrees Celsius....and maybe that was a contributing factor... Who knows. All I know is that to make sure this doesn't happen again... We may end up pulling even more of the timing, and I won't be using this location again. I'll simply use the extra port on my oil filter pedestal. I'm hustling to make ASB. THis does cut into my tire fund.. but At this point.. If I make it and am able to drive. I'll be Amped. More Updates to come.

#2106

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

Just use the correct fitting and be done, no need to plug that one and then use ANOTHER port. Just another spot for failure. Timing had nothing to do with it. I would bet heat cycling is what caused the eventual failure of the cast iron obviously combined with the completely wrong fitting. Aluminum expands more than cast iron so when the oil got hot your problem was exacerbated.

Last edited by RENESISFD; 09-30-14 at 05:12 PM.

#2107

Just use the correct fitting and be done, no need to plug that one and then use ANOTHER port. Just another spot for failure. Timing had nothing to do with it. I would bet heat cycling is what caused the eventual failure of the cast iron obviously combined with the completely wrong fitting. Aluminum expands more than cast iron so when the oil got hot your problem was exacerbated.

I agree with that...but the other port is on the oil filter pedestal, which is all alum anyways. I guess I could just get the correct fitting. I've just seen more than few of these break here... not on mine but others builds in the past. I'm not one of those really superstitious people who think it'll happen for no reason. I just don't want it to have the chance to happen again...if that makes sense.

Anyone know the correct thread pattern/fitting I could use here? with a -4 outlet

#2108

Just use the correct fitting and be done, no need to plug that one and then use ANOTHER port. Just another spot for failure. Timing had nothing to do with it. I would bet heat cycling is what caused the eventual failure of the cast iron obviously combined with the completely wrong fitting. Aluminum expands more than cast iron so when the oil got hot your problem was exacerbated.

i have never actually tried this, but i would be willing to bet that even that tapered aluminum fitting in the metric hole could be cranked down to the point of ripping the threads off of the fitting or shearing off under the hex section before it could crack iron like that, even with heat cycles.

i haven't seen that happen in 10+ years of being on this forum, although 99% of people are going to use a metric fitting in that hole (i'm not hating, aaron, as i've easily made several mistakes like this).

i'm curious to see the front dowel area when you tear the engine down.

i would guess that it was not detonation, but possibly spark blowout/misfire. it could also be a combination of misfire and the extra stress on the metric hole.

just my two cents. i'm sorry to hear about your troubles. i know you were enjoying the car.

#2109

I thought about that......but then I remembered I'm using 4X AEM smart coils, direct fire config, R7420 Race plugs and the plugs were practically Brand new. I'm not saying misfire couldn't cause this because it could. But I am saying it's highly un-likely given the "robust-ness" of my ignition set up. I'll let you guys know as soon as the motor is open.

#2110

i think the threads for the port in question are M14x1.5 (someone please confirm that)

edit: yes, it is.

here's the earl's part # from when i bought my oil feed stuff last

m14x1.5 -4an fitting for oil feed (EAR-9919BFHERL)

and IIRC people also use dowty seals to help it seal and not seep oil from the fitting like they can sometimes do with a conventional crush washer:

edit: yes, it is.

here's the earl's part # from when i bought my oil feed stuff last

m14x1.5 -4an fitting for oil feed (EAR-9919BFHERL)

and IIRC people also use dowty seals to help it seal and not seep oil from the fitting like they can sometimes do with a conventional crush washer:

#2112

yeah that's very interesting. i could be totally wrong.

sleeper7 has been making power for a long time too.

i also know how easy it is to crack irons. i cracked a rear iron in my TII in 2005 and i had no idea it was even cracked. obviously that's the REAR and not the front, but i had no hint of misfires or anything, and it just cracked one day after some ripping on the car. the crack also wasn't as large as yours.

it seems unlikely that the OP in that thread broke both those irons the exact same way in the same spot with seemingly incorrect threads (based on his pics) and it be misfiring, but stranger things have happened.

regardless, you know which fitting/seal to get for next time

sleeper7 has been making power for a long time too.

i also know how easy it is to crack irons. i cracked a rear iron in my TII in 2005 and i had no idea it was even cracked. obviously that's the REAR and not the front, but i had no hint of misfires or anything, and it just cracked one day after some ripping on the car. the crack also wasn't as large as yours.

it seems unlikely that the OP in that thread broke both those irons the exact same way in the same spot with seemingly incorrect threads (based on his pics) and it be misfiring, but stranger things have happened.

regardless, you know which fitting/seal to get for next time

#2114

I was going to mention you need to plug that hole with something so those threads need to be correct as well or it will be an issue again.

There is a local earls store by my house and an old timer there helped me with some advice on that exact fitting. He recommended a copper crush washer on that adapter and anytime aluminum is threading to iron. He said it's old school but proven. I need to get some large crush washers for my oil cooler lines to the block in the near future.

I hope everything works out Aaron. Good luck!

There is a local earls store by my house and an old timer there helped me with some advice on that exact fitting. He recommended a copper crush washer on that adapter and anytime aluminum is threading to iron. He said it's old school but proven. I need to get some large crush washers for my oil cooler lines to the block in the near future.

I hope everything works out Aaron. Good luck!

#2115

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

^ This might be one of those situations where buying the higher quality fitting that has tighter thread tollerances is worth it.

FWIW, I am using a Earls or XRP fiting on my front iron turbo oil feed with a copper crush washer and have no leaks. IMO the copper washers seal better than the rubberized aluminum/steel ones. Copper is what is used on your brakes at much higher pressures and those pretty much never leak over time.

FWIW, I am using a Earls or XRP fiting on my front iron turbo oil feed with a copper crush washer and have no leaks. IMO the copper washers seal better than the rubberized aluminum/steel ones. Copper is what is used on your brakes at much higher pressures and those pretty much never leak over time.

#2117

I was going to mention you need to plug that hole with something so those threads need to be correct as well or it will be an issue again.

There is a local earls store by my house and an old timer there helped me with some advice on that exact fitting. He recommended a copper crush washer on that adapter and anytime aluminum is threading to iron. He said it's old school but proven. I need to get some large crush washers for my oil cooler lines to the block in the near future.

I hope everything works out Aaron. Good luck!

There is a local earls store by my house and an old timer there helped me with some advice on that exact fitting. He recommended a copper crush washer on that adapter and anytime aluminum is threading to iron. He said it's old school but proven. I need to get some large crush washers for my oil cooler lines to the block in the near future.

I hope everything works out Aaron. Good luck!

Thanks for the support and help! Always appreciated from long time buddies

Thanks guys. New Iron is shipped tomorrow. Luckily Howard had one laying around. Makes me want to purchase a spare shorty and keep it for times in need.

More Updates soon!

stay tuned!!

#2118

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

That fitting is a straight thread metric fitting. Its design does not seal on the threads it seals on the flange. You have to use a washer in order for it to not leak. That's the way it is designed to work. It will leak if you do not use a sealing washer. Do not use thread sealant on that fitting either.

#2119

Racing Rotary Since 1983

iTrader: (6)

i am wondering about the use of an aluminum fitting given it expands lots more than steel. i use a steel fitting. i realise there are many alu fittings in use but perhaps a combo of plate movement and the fitting...

also, i suggest that ALL sharp edges of any kind near the port be chamfered.

howard

also, i suggest that ALL sharp edges of any kind near the port be chamfered.

howard

#2120

Racing Rotary Since 1983

iTrader: (6)

cracked front irons at the dowel pin is an important subject.

while your fitting was incorrect i doubt if it was the primary cause and if my suspicion is correct you may be looking at another cracked iron down the road. i have pasted a lengthy and slightly wandering collage on the subject that should be read very carefully.

most of the heavy lifting is courtesy of my friend Lynn Hanover who posts his thoughts on another board...

Thanks Lynn for all your rotary contributions.

hc

"So here's the thing. I've been tuning the car myself, and it has been going well. I was running 15 pounds wastegate spring pressure for boost, with meth coming on strong and early at 5 psi. The car is blazing fast, and has a ton of fuel. Afr's are super safe, deep in the 10s at high rpm full boost, running conservative timing, 12 degrees (at full boost), and stock split timing.

I have not done many full gear pulls in 3rd and 4th, I was tuning very slowly and getting used to it. Suddenly one night I did a short second gear pull and I cracked the front iron right where the oil feed comes put of the block. The piece came right off. There was no bucking at all, and no funny noises. Just broke. NO hint of detonation. Just smooth and hard acceleration then look in the rear view mirror and there's a mega cloud of smoke.

Three weeks later which was this last weekend, I rebuilt the engine again with a new front iron, and after over a dozen short blips to make sure everything was Ok, I broke the front iron AGAIN in a small 2nd gear pull. Same spot, no signs of detonation again. This time I was on 94 octane too.

So what's causing this?? I read just today about breaking front irons, and it said it can be from severe detonation or from cross fire. Apparently if your spark plug wires all touch each other is can cause crossfire? It will cause an ignition even to happen 180* when it's not supposed to. I have mine zip tied together to keep them tidy, so could that be it?

Just to reiterate, i'm still getting familiar with tuning, but I know more than enough to know I was in a good safe zone. Correct me if i'm wrong on my specs though. if there was detonation present I really believe I would be breaking the weaker atkins apex seals I'm running. Really want to figure this out before it goes together again shortly.

I know the S4 rear plates are weak but this just amazes me."

here's another, this time an FC so crack is in rear...

"Let me give you a little detail on the motor and the situation. Car is a 88 10th AE. 1000 miles on the motor. Good sized street port and exhaust port. Turbo is a 60-1 w/ 84. A/R. Full 3inch 304 stainless exhaust. Front mount intercooler. No a/c, p/s, OMP blocked running premix. Engine management is a Haltech E8. Coils are LS1 coils set up direct fire. Injectors are 550 and 1680.

Anyhow we had our Fall BBQ and Track day I ran the car about 12 times around the track. Wish it was more, but since I was organizing it I couldn't run as much. Always shifted by 6200 rpms since the motor is still new. Max water temps wer 209F. Max intake temps at the elbow before the throttle plates was 122F. No issues until the last trip around.

Car had cooled down. I started it up let it reach 190F. Coming out of the first turn, in 2nd gear, I laid into it shifting again around 6000 rpms give or take 100 rpms. Boost was at 16 psi, A/F was 10.9-11.1, leading timing at 13* trailing split at 12*.

I had 1/2 a tank of gas w/ 1/2 101 and 1/2 91. Air intake temps were 105F and water temp was 192F. Turn was a right hand tight turn so no fuel starvation of the pump. Just before shifting into 3rd I saw the oil pressure drop and smoke everywhere. Got it off the track as fast as possible. Car still idled perfectly and the low oil light came. Shut it down as soon as possible while getting of the track. After inspection I had cracked the rear dowell area below the oil filter...

Anyone have any ideas???? I am going to try and upgrade to a later s5 iron. I have a S4 rear plate in the garage and may use it until I brake it. I would like to keep this from happening again. Any help is much appreciated. Pictures are on my other computer and will be uploaded tomorrow."

Lynn Hanover....

"Let me speculate (because I have no experience tuning a turbo engine).

Racing Beat recommends 12 degrees both leading and trailing for turbo engines with timing checked at 6,000 RPM. I would regard this as a hint, and probably the maximum advance used.

They also recommend that torque for case bolts of boosted engines be 32 pounds. Apparently in an effort to develop more clamping power to resist the dowel shearing and iron breaking problem. ..

One of the rotary advantages over the piston engine is extended Dwell time. Dwell time is the period of time when the combustion chamber is at or close to TDC. You can burn more of the charge with less ignition advance, if you have a longer period with the chamber not moving. This is important because if you light the fire well before TDC, then the pressure generated, Brake Mean Effective Pressure (BMEP) must be subtracted from the BMEP from TDC on to exhaust port open point. So it is to reduce the power lost because of ignition advance BTDC.

Simple.

Another advantage is that the length of time the burning charge is heating the combustion chamber is reduced. So, lower charge temperatures, and then you can run higher compression before detonation starts.

The rotary has a very long Dwell time, and therefore requires very little ignition advance.

And that is true of NA rotaries. Boosted rotaries require even less advance than NA rotaries.

Two factors to think about.

When boost is high, effective compression is high. The bits that burn heat each other at a rate inverse to distance. So, in the NA engine the burn rate (Flame front velocity) is low, and a long smooth combustion takes place, and nobody breaks anything. In the boosted engine, the bits that burn are very close together, (the effective compression ratio is higher) and the flame front velocity is very high. So the combustion is quick and peak pressure at the ideal 50 degrees ATDC requires that ignition be retarded compared to the NA engine.

Now review the Detonation definition, and note that the trailing plug igniting starts to look like a detonation event if the time after the leading plug firing is too long. Note Racing Beat says no split timing.

One of the airplane guys shuts off his trailing ignition during nitrous injection to eliminate detonation. Mmmmm.......Think about that.

A detonation event in a NA rotary might go unnoticed due to the limited amount of mixture left to burn late in the combustion event. In the boosted engine, a detonation event would include more mixture in the same area, it is likely to be at higher temperature than in the NA engine. It will not go unnoticed as it may result in damage the very first time it happens. The rattle in the muffler is the apex seals.

The detonation events are likely to happen right beside the apex seals...........

Early rotaries used the front case as the engine mounting point. So you end up torque loading the whole stack during hard use. The engine is being twisted in opposition to and in the exact same amount as the torque output.(Newton) So in later years the engines were mounted by the center iron, cutting the load to only half of the stack. Some folks picked up on this fact and mount the engine with only a plate between the rear iron and the bell housing. I figured this out far too late. So all of the torque loads on the stack are just those produced by the torque of the engine. No torque loads from downshifts, upshifts or misfires must use the stack to travel into the chassis. Duh............

So the higher case bolt torque makes more sense. Also the object of the extra dowels and the oversized case bolts is to carry the torsion loads from the housings into the rear iron where it is accepted by the bell housing.

So, 500 HP at 6,000 RPM requires 437.8 foot pounds of torque. That torque is twisting the stack and is prevented from twisting by the dowels and the friction caused by the case bolts squeezing the stack against the rear iron. Like a deck of cards held between your palms, when you twist the stack the pieces end up at slight angles to each other. In the rotary the pieces put the dowels into single shear, and that microscopic angle change puts the same section of dowel in a bending load.

So if the dowel does not shear off, it cracks the hole out of the iron.

When you see a drag racing rotary come off the line with the whole body torqued over in one direction what part of the engine is twisting the whole car that much? Would you mount that engine with the front cover, the center iron, or the rear iron?

So I suggest backing off the ignition advance a bit, shorten the split, spraying water into the intake, spraying water onto the radiator and intercooler, and oil cooler. Run the fans manually.

use all high Octane, use a bit extra ash free synthetic premix (to keep the apex seals cooler).

Use a monster ignition system at least on the leading plugs. Use inductive secondary plug wires.

Keep the wires well away from low voltage wires, and away from each other. No full throttle until the revs are up........

Just a guess though....

Lynn E. Hanover"

Originally Posted by rotaryinspired

Thanks for the informative post Lynn. I appreciate you taking the time to share your knowledge and experiences. After taking the time to review everything I believe I had a misfire due to leading and trailing plug wires touching and not being shielded from each other appropriately. I was also running the car too hard too early without making sure everything was completely ready. I can be impatient, which explains the plug wires. We all spend too much time and money on these cars to let little mistakes side line us. Lesson learned.

"i was gonna suggest that. firing the trailing 180 degrees early will break things

Quite true. If your failure involves the top dowel hole breaking out of the front iron, there has been a cross fire.

Induced by secondary wires from the front housing being too close to rear housing wires, or, early igniters talking to each other. For other than stock operations, most folks discard the igniters (points eliminating SCRs) and use an aftermarket system triggered by the stock pickup coils. Wires from a crank trigger system can also cross talk, as output at speed can exceed 100 volts.

At high boost it takes a huge amount of voltage to get an arc across the plug gap.

Triggering wires need to be run through Dash 4 braided stainless fuel hose. The braid needs to be grounded at both ends.

Lynn E. Hanover"

executive summary from Howard:

stock FD makes 184 pound feet Tq

many of us are making 400

our engines are a layered sandwich held together w modest quality thru bolts and 4 tool steel quality dowel pins... anchored in weak cast iron. the rear FD plate is supported by the bellhousing and the dowel pin area is stronger than the front dowel pin anchor well.

twist from detonation, elec crossfire or poorly torqued thru bolts will break the front iron at the upper dowel pin hole.

since our motors are small in displacement but are able to make huge power we need very strong ignition systems. given our split setup it is extremely important to maintain electrical integrity as crossfire can be a front plate breaker.

i suggest a very careful review of all ignition components to eliminate any possibility of crossfire.

howard

while your fitting was incorrect i doubt if it was the primary cause and if my suspicion is correct you may be looking at another cracked iron down the road. i have pasted a lengthy and slightly wandering collage on the subject that should be read very carefully.

most of the heavy lifting is courtesy of my friend Lynn Hanover who posts his thoughts on another board...

Thanks Lynn for all your rotary contributions.

hc

"So here's the thing. I've been tuning the car myself, and it has been going well. I was running 15 pounds wastegate spring pressure for boost, with meth coming on strong and early at 5 psi. The car is blazing fast, and has a ton of fuel. Afr's are super safe, deep in the 10s at high rpm full boost, running conservative timing, 12 degrees (at full boost), and stock split timing.

I have not done many full gear pulls in 3rd and 4th, I was tuning very slowly and getting used to it. Suddenly one night I did a short second gear pull and I cracked the front iron right where the oil feed comes put of the block. The piece came right off. There was no bucking at all, and no funny noises. Just broke. NO hint of detonation. Just smooth and hard acceleration then look in the rear view mirror and there's a mega cloud of smoke.

Three weeks later which was this last weekend, I rebuilt the engine again with a new front iron, and after over a dozen short blips to make sure everything was Ok, I broke the front iron AGAIN in a small 2nd gear pull. Same spot, no signs of detonation again. This time I was on 94 octane too.

So what's causing this?? I read just today about breaking front irons, and it said it can be from severe detonation or from cross fire. Apparently if your spark plug wires all touch each other is can cause crossfire? It will cause an ignition even to happen 180* when it's not supposed to. I have mine zip tied together to keep them tidy, so could that be it?

Just to reiterate, i'm still getting familiar with tuning, but I know more than enough to know I was in a good safe zone. Correct me if i'm wrong on my specs though. if there was detonation present I really believe I would be breaking the weaker atkins apex seals I'm running. Really want to figure this out before it goes together again shortly.

I know the S4 rear plates are weak but this just amazes me."

here's another, this time an FC so crack is in rear...

"Let me give you a little detail on the motor and the situation. Car is a 88 10th AE. 1000 miles on the motor. Good sized street port and exhaust port. Turbo is a 60-1 w/ 84. A/R. Full 3inch 304 stainless exhaust. Front mount intercooler. No a/c, p/s, OMP blocked running premix. Engine management is a Haltech E8. Coils are LS1 coils set up direct fire. Injectors are 550 and 1680.

Anyhow we had our Fall BBQ and Track day I ran the car about 12 times around the track. Wish it was more, but since I was organizing it I couldn't run as much. Always shifted by 6200 rpms since the motor is still new. Max water temps wer 209F. Max intake temps at the elbow before the throttle plates was 122F. No issues until the last trip around.

Car had cooled down. I started it up let it reach 190F. Coming out of the first turn, in 2nd gear, I laid into it shifting again around 6000 rpms give or take 100 rpms. Boost was at 16 psi, A/F was 10.9-11.1, leading timing at 13* trailing split at 12*.

I had 1/2 a tank of gas w/ 1/2 101 and 1/2 91. Air intake temps were 105F and water temp was 192F. Turn was a right hand tight turn so no fuel starvation of the pump. Just before shifting into 3rd I saw the oil pressure drop and smoke everywhere. Got it off the track as fast as possible. Car still idled perfectly and the low oil light came. Shut it down as soon as possible while getting of the track. After inspection I had cracked the rear dowell area below the oil filter...

Anyone have any ideas???? I am going to try and upgrade to a later s5 iron. I have a S4 rear plate in the garage and may use it until I brake it. I would like to keep this from happening again. Any help is much appreciated. Pictures are on my other computer and will be uploaded tomorrow."

Lynn Hanover....

"Let me speculate (because I have no experience tuning a turbo engine).

Racing Beat recommends 12 degrees both leading and trailing for turbo engines with timing checked at 6,000 RPM. I would regard this as a hint, and probably the maximum advance used.

They also recommend that torque for case bolts of boosted engines be 32 pounds. Apparently in an effort to develop more clamping power to resist the dowel shearing and iron breaking problem. ..

One of the rotary advantages over the piston engine is extended Dwell time. Dwell time is the period of time when the combustion chamber is at or close to TDC. You can burn more of the charge with less ignition advance, if you have a longer period with the chamber not moving. This is important because if you light the fire well before TDC, then the pressure generated, Brake Mean Effective Pressure (BMEP) must be subtracted from the BMEP from TDC on to exhaust port open point. So it is to reduce the power lost because of ignition advance BTDC.

Simple.

Another advantage is that the length of time the burning charge is heating the combustion chamber is reduced. So, lower charge temperatures, and then you can run higher compression before detonation starts.

The rotary has a very long Dwell time, and therefore requires very little ignition advance.

And that is true of NA rotaries. Boosted rotaries require even less advance than NA rotaries.

Two factors to think about.

When boost is high, effective compression is high. The bits that burn heat each other at a rate inverse to distance. So, in the NA engine the burn rate (Flame front velocity) is low, and a long smooth combustion takes place, and nobody breaks anything. In the boosted engine, the bits that burn are very close together, (the effective compression ratio is higher) and the flame front velocity is very high. So the combustion is quick and peak pressure at the ideal 50 degrees ATDC requires that ignition be retarded compared to the NA engine.

Now review the Detonation definition, and note that the trailing plug igniting starts to look like a detonation event if the time after the leading plug firing is too long. Note Racing Beat says no split timing.

One of the airplane guys shuts off his trailing ignition during nitrous injection to eliminate detonation. Mmmmm.......Think about that.

A detonation event in a NA rotary might go unnoticed due to the limited amount of mixture left to burn late in the combustion event. In the boosted engine, a detonation event would include more mixture in the same area, it is likely to be at higher temperature than in the NA engine. It will not go unnoticed as it may result in damage the very first time it happens. The rattle in the muffler is the apex seals.

The detonation events are likely to happen right beside the apex seals...........

Early rotaries used the front case as the engine mounting point. So you end up torque loading the whole stack during hard use. The engine is being twisted in opposition to and in the exact same amount as the torque output.(Newton) So in later years the engines were mounted by the center iron, cutting the load to only half of the stack. Some folks picked up on this fact and mount the engine with only a plate between the rear iron and the bell housing. I figured this out far too late. So all of the torque loads on the stack are just those produced by the torque of the engine. No torque loads from downshifts, upshifts or misfires must use the stack to travel into the chassis. Duh............

So the higher case bolt torque makes more sense. Also the object of the extra dowels and the oversized case bolts is to carry the torsion loads from the housings into the rear iron where it is accepted by the bell housing.

So, 500 HP at 6,000 RPM requires 437.8 foot pounds of torque. That torque is twisting the stack and is prevented from twisting by the dowels and the friction caused by the case bolts squeezing the stack against the rear iron. Like a deck of cards held between your palms, when you twist the stack the pieces end up at slight angles to each other. In the rotary the pieces put the dowels into single shear, and that microscopic angle change puts the same section of dowel in a bending load.

So if the dowel does not shear off, it cracks the hole out of the iron.

When you see a drag racing rotary come off the line with the whole body torqued over in one direction what part of the engine is twisting the whole car that much? Would you mount that engine with the front cover, the center iron, or the rear iron?

So I suggest backing off the ignition advance a bit, shorten the split, spraying water into the intake, spraying water onto the radiator and intercooler, and oil cooler. Run the fans manually.

use all high Octane, use a bit extra ash free synthetic premix (to keep the apex seals cooler).

Use a monster ignition system at least on the leading plugs. Use inductive secondary plug wires.

Keep the wires well away from low voltage wires, and away from each other. No full throttle until the revs are up........

Just a guess though....

Lynn E. Hanover"

Originally Posted by rotaryinspired

Thanks for the informative post Lynn. I appreciate you taking the time to share your knowledge and experiences. After taking the time to review everything I believe I had a misfire due to leading and trailing plug wires touching and not being shielded from each other appropriately. I was also running the car too hard too early without making sure everything was completely ready. I can be impatient, which explains the plug wires. We all spend too much time and money on these cars to let little mistakes side line us. Lesson learned.

"i was gonna suggest that. firing the trailing 180 degrees early will break things

Quite true. If your failure involves the top dowel hole breaking out of the front iron, there has been a cross fire.

Induced by secondary wires from the front housing being too close to rear housing wires, or, early igniters talking to each other. For other than stock operations, most folks discard the igniters (points eliminating SCRs) and use an aftermarket system triggered by the stock pickup coils. Wires from a crank trigger system can also cross talk, as output at speed can exceed 100 volts.

At high boost it takes a huge amount of voltage to get an arc across the plug gap.

Triggering wires need to be run through Dash 4 braided stainless fuel hose. The braid needs to be grounded at both ends.

Lynn E. Hanover"

executive summary from Howard:

stock FD makes 184 pound feet Tq

many of us are making 400

our engines are a layered sandwich held together w modest quality thru bolts and 4 tool steel quality dowel pins... anchored in weak cast iron. the rear FD plate is supported by the bellhousing and the dowel pin area is stronger than the front dowel pin anchor well.

twist from detonation, elec crossfire or poorly torqued thru bolts will break the front iron at the upper dowel pin hole.

since our motors are small in displacement but are able to make huge power we need very strong ignition systems. given our split setup it is extremely important to maintain electrical integrity as crossfire can be a front plate breaker.

i suggest a very careful review of all ignition components to eliminate any possibility of crossfire.

howard

#2121

I am a bit at odds about this^ But after reading the above post several times over...examining my set up and doing some other online research the only thing I know is faulty in my set up is the fact that I used zip ties to keep my spark plug wires together up by the coils. they are separate closer to the plugs but they very well could have been touching. I'm unable to check because I pulled the engine directly prior to the mishap.

My ignition system consists of the following.

Sake Bomb Garage Aftermarket Custom Plug wires

AEM/Merc Marine Smart coils

Direct Fire set up

NGK R7420 10/10.5 Race plugs

But the Wires Were in fact touching. I just don't gey why the cross fire would happen all of the sudden when I've been beating on the car for 2/3 months straight.

I did swap from Rx8 Plat OEM 9's (Spark Plugs) to the NGK race plugs. which was instantly a giant improvement in Start up, idle and burn. Even noticed my AFR's leaned out .1/.2 all the way through compared to other logs.

In my opinion...that is the only culprit really... Other than that..how and why would there all of the sudden be detonation or crossfiring?

It really doesn't make sense to me that this would happen out of nowhere...which really makes me feel more confident that maybe I had already hairline cracked the front plate from running the fitting in there in the past...reinstalling it and really cranking down on it. + the heat cycle and the cooler morning in which I drove the car for the first time.

My ignition system consists of the following.

Sake Bomb Garage Aftermarket Custom Plug wires

AEM/Merc Marine Smart coils

Direct Fire set up

NGK R7420 10/10.5 Race plugs

But the Wires Were in fact touching. I just don't gey why the cross fire would happen all of the sudden when I've been beating on the car for 2/3 months straight.

I did swap from Rx8 Plat OEM 9's (Spark Plugs) to the NGK race plugs. which was instantly a giant improvement in Start up, idle and burn. Even noticed my AFR's leaned out .1/.2 all the way through compared to other logs.

In my opinion...that is the only culprit really... Other than that..how and why would there all of the sudden be detonation or crossfiring?

It really doesn't make sense to me that this would happen out of nowhere...which really makes me feel more confident that maybe I had already hairline cracked the front plate from running the fitting in there in the past...reinstalling it and really cranking down on it. + the heat cycle and the cooler morning in which I drove the car for the first time.

#2122

Update:

"Summon the Hustle"

In the Midst of the unfortunate failure.... there are a few things I've come to realize. The first is...I work best by staying "in it." .....Which means that I don't like to take breaks. When an issue comes to.... I'd much rather figure it, handle it, improve/fix it, and just all around handle it rather than sit around and mope around about how devastating it is. This isn't the first time someone's run into a problem with a rotary...let alone track car. And the second thing is....this isn't the last time i'll be pulling the motor out. This winter I want to do more upgrades.. It'll most likely require pulling the engine out again. This isn't a big deal to me and I'm okay with doing it. You know when people ask me now "what happened?!" I don't really want to respond in anyother way than just saying..."it's a track car." It's almost like...what do you mean what happened? I'm pushing the limits of myself and the car. There are a million things that can go wrong,...and if things aren't handled the way they should be, or set up the way they should be, or even fluke mis-haps...will in fact be exposed if your pushing the car. I've heard older more experienced people say theres a huge difference between a street car and a track car. And that rings very true. But it's again.. an even larger difference between owning a 400 WHP street car and a 400WHP track car. It's a dumb comparison...but I've seen 500+WHP fd's on the street last for a while. But chances are......if you take that same car to the track... it'd be done halfway through the session let alone event. And there is nothing wrong with owning a 400 WHP+ Street car at all. But the fact is.....it doesn't see the same abuse.

Things will happen at the track that you'd most likely never even notice on the street. With that said.. I've also gotten quite a bit of criticism from people and or groups and call it whatever... but I don't like the feeling. It bothers me when I sit and think about it but it's pointless banter otherwise. But it does reinforce the reason I've built this car in my garage on my own. I don't hang out with any which shop and I'm perfectly fine with that. I have had help, and I appreciate the people who have lent out the hand. But there is a huge difference between these real friends, and others who really just want to get a word in to be right. And that...is very annoying. It's like, you don't own a running car, and if you do it doesn't see the track, and if it see's the track it goes once every 3 years, the car has a completely different set up... yet they have the nerve to say something negative just to make it seem like they're right. And if they were right.....guess what? It's still my car, i'll still fix it, i'll still drive it the way I want and that'll be that. So to the same group of dudes that know how to build everyone else's car and don't have the hustle to "Over-build" their own car.... High Fives all around and I hope one day You get it.

For me.... I keep pushing until I'm satisfied.

And so on with the update.

To help prevent this mishap in the future...

I've taken a couple steps to reinforce things.

I have a Turblown Stud kit sitting with the engine currently (Just in case)

and I'll be taking the Zip ties off my spark plug wires to make sure they won't get the chance to touch (to help prevent the possibility of a cross-fire).

Again..I don't know how all of the sudden this could just happen out of no where...but I'm not going to play ignorant and leave the issue labeled as a freak accident.

Me and Abel are tearing the engine down Saturday Night, and assembling it back again sunday morning with the New ported iron. Updates to follow.

Stud kit and Iron

"Summon the Hustle"

In the Midst of the unfortunate failure.... there are a few things I've come to realize. The first is...I work best by staying "in it." .....Which means that I don't like to take breaks. When an issue comes to.... I'd much rather figure it, handle it, improve/fix it, and just all around handle it rather than sit around and mope around about how devastating it is. This isn't the first time someone's run into a problem with a rotary...let alone track car. And the second thing is....this isn't the last time i'll be pulling the motor out. This winter I want to do more upgrades.. It'll most likely require pulling the engine out again. This isn't a big deal to me and I'm okay with doing it. You know when people ask me now "what happened?!" I don't really want to respond in anyother way than just saying..."it's a track car." It's almost like...what do you mean what happened? I'm pushing the limits of myself and the car. There are a million things that can go wrong,...and if things aren't handled the way they should be, or set up the way they should be, or even fluke mis-haps...will in fact be exposed if your pushing the car. I've heard older more experienced people say theres a huge difference between a street car and a track car. And that rings very true. But it's again.. an even larger difference between owning a 400 WHP street car and a 400WHP track car. It's a dumb comparison...but I've seen 500+WHP fd's on the street last for a while. But chances are......if you take that same car to the track... it'd be done halfway through the session let alone event. And there is nothing wrong with owning a 400 WHP+ Street car at all. But the fact is.....it doesn't see the same abuse.

Things will happen at the track that you'd most likely never even notice on the street. With that said.. I've also gotten quite a bit of criticism from people and or groups and call it whatever... but I don't like the feeling. It bothers me when I sit and think about it but it's pointless banter otherwise. But it does reinforce the reason I've built this car in my garage on my own. I don't hang out with any which shop and I'm perfectly fine with that. I have had help, and I appreciate the people who have lent out the hand. But there is a huge difference between these real friends, and others who really just want to get a word in to be right. And that...is very annoying. It's like, you don't own a running car, and if you do it doesn't see the track, and if it see's the track it goes once every 3 years, the car has a completely different set up... yet they have the nerve to say something negative just to make it seem like they're right. And if they were right.....guess what? It's still my car, i'll still fix it, i'll still drive it the way I want and that'll be that. So to the same group of dudes that know how to build everyone else's car and don't have the hustle to "Over-build" their own car.... High Fives all around and I hope one day You get it.

For me.... I keep pushing until I'm satisfied.

And so on with the update.

To help prevent this mishap in the future...

I've taken a couple steps to reinforce things.

I have a Turblown Stud kit sitting with the engine currently (Just in case)

and I'll be taking the Zip ties off my spark plug wires to make sure they won't get the chance to touch (to help prevent the possibility of a cross-fire).

Again..I don't know how all of the sudden this could just happen out of no where...but I'm not going to play ignorant and leave the issue labeled as a freak accident.

Me and Abel are tearing the engine down Saturday Night, and assembling it back again sunday morning with the New ported iron. Updates to follow.

Stud kit and Iron

#2124

Good luck with the rebuild.

I spent most of my life in some of the best race shops in the world so I have no desire building a track car due to the cost of over engineering the car.

Just keep doing what you are doing and take your time, no need to worry about us street guys building cars to go WOT for a few seconds. The amount of load you put on your motor not to mention the heat generated from every part of your car in a hot climate is far more demanding.

I spent most of my life in some of the best race shops in the world so I have no desire building a track car due to the cost of over engineering the car.

Just keep doing what you are doing and take your time, no need to worry about us street guys building cars to go WOT for a few seconds. The amount of load you put on your motor not to mention the heat generated from every part of your car in a hot climate is far more demanding.

#2125

Good luck with the rebuild.

I spent most of my life in some of the best race shops in the world so I have no desire building a track car due to the cost of over engineering the car.

Just keep doing what you are doing and take your time, no need to worry about us street guys building cars to go WOT for a few seconds. The amount of load you put on your motor not to mention the heat generated from every part of your car in a hot climate is far more demanding.

I spent most of my life in some of the best race shops in the world so I have no desire building a track car due to the cost of over engineering the car.

Just keep doing what you are doing and take your time, no need to worry about us street guys building cars to go WOT for a few seconds. The amount of load you put on your motor not to mention the heat generated from every part of your car in a hot climate is far more demanding.

Thanks for the kind words.... This is a very expensive hobby...that's for damn sure. And I'm not so much worried about street guys and street builds. It's just people who have zero experience, think they know everything about everything and think it's super simple to keep a higher performing car on the track in 100% working order all the time. It's like the misconception of how people say their car is stage 4. When they say that......I always think to myself... WTF is stage 4? Stage's aren't universal for cars haha. Or they think because they have a few shells and a JZ swap they know exactly what your doing wrong with your build that actually runs. gnahhhh what I'm saying mang? haha