Pre-Turbo or Post Turbo????????

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Pre-Turbo or Post Turbo????????

with the addition of an AI Section back in 06 lively debate ensued re water or alcohol, safeguards, tuning, various systems etc. while the section may not be as active as other sections i do believe the information has been of significant help for the turbo'd rotary and it's fans.

many of the subjects above have been covered in stickied threads because they are of primary importance.

as we move forward i believe another area has emerged and deserves it's own freestanding space in the section:

injectant location in relation to the turbo.

as with most subjects there is a divided opinion. there is also more opinion than fact. the good news is the realities are out there, they just need to be discovered and that is what this new thread is about.

of course we are not examining something that has yet to be done. RiceRacing has pioneered the pre-turbo location for a number of years and probably was following earlier engineering data. numerous members of our club have either tried an A B comparison or simply run pre-turbo.

as always on this board we welcome and solicit all contributions on the subject from any perspective.

as many are aware, the concept behind the pre-turbo location is pretty simple. a compressor, any compressor, is governed by physical laws. there is a point where additional pressure creates heat/expansion to the point that no more oxygen molecules can be packed into the space.

power is all about oxygen. more oxygen, more power. period.

at that (rightward) point on a compressor map the RPM line ceases to rise and the line goes static. no more RPM gain.

ballgame.

all because of the heat of compression.

brick wall.

the pre-turbo concept is to introduce cooling BTUs (latent heat) and thus allow for additional oxygen to be able to enter the compressor volume.

more oxygen molecules, more power.

that's the concept.

there are pre-turbo FDs out there doing amazing things...

RiceRacing is running around 33 psi boost w his setup and maintains a healthy engine.

thewird is running in the mid 20s boostwise.

Rice runs WM and thewird runs water.

tom94RX-7 did an A B comparative test on the dyno... maybe it was track...

1revin7 also did a comparison

as you might expect, results vary.

the concept is intriguing and potentially quite significant.

i have run AI since 04. my Alkycontrol system worked flawlessly. i chose to run an M10 and M15 nozzle and had many happy experiences with it as did my engine. when a more accurate delivery system emerged (FJO) i made the switch to a solenoid/injector setup using an X Y grid. it also worked perfectly. my third setup was to deliver the methanol thru two fuel injectors running in parallel w my secondary injectors.

the system worked well but i may have reached a point where methanol being too large a part of my fuel became unstable. a backfire into my UIM took out a diffuser and my engine.

i believe the system was fine, just too much methanol.

all my locations were in the greddy elbow.

my new setup changes things around.

i have a new ECU (ViPEC V88) that can control 8 peak and hold injectors separately. the V88 will run my two AI fuel injectors.

one injector is in the elbow and one is pre-turbo. we will tune out using the elbow AI location (only) and then shut it off and tune out w the pre-turbo location.

i have switched to water meth 50/50 based on volume.

here's a picture of my injector fixture in a semi-finished for to give you an idea of my setup:

an in process pic showing the airfilter and lines.

i run an Alkycontrol pump, a Weldon pressure regulator (boost referenced), a return line from the regulator to my tank and a large Aeromotive filter.

i monitor and log the AI pressure (which i run at 110 psi static), air temperature between the turbo and intercooler and also at the stock UIM location. i use a K thermocouple so my readings are instantaneous and accurate.

pics are a month or two old as the setup is up and running and at Beyond Redline for evaluation.

there are of course a million questions that beg for answers re AI location...

some use AI for engine longevity and de-carbonisation

given this objective are there any benefits to justify re-location?

what really is necessary to maintain the compressor wheel integrity?

and of course the big question: does the pre-turbo location deliver more oxygen molecules/power?

this post hasn't scratched the surface so let's get a conversation started.

howard

many of the subjects above have been covered in stickied threads because they are of primary importance.

as we move forward i believe another area has emerged and deserves it's own freestanding space in the section:

injectant location in relation to the turbo.

as with most subjects there is a divided opinion. there is also more opinion than fact. the good news is the realities are out there, they just need to be discovered and that is what this new thread is about.

of course we are not examining something that has yet to be done. RiceRacing has pioneered the pre-turbo location for a number of years and probably was following earlier engineering data. numerous members of our club have either tried an A B comparison or simply run pre-turbo.

as always on this board we welcome and solicit all contributions on the subject from any perspective.

as many are aware, the concept behind the pre-turbo location is pretty simple. a compressor, any compressor, is governed by physical laws. there is a point where additional pressure creates heat/expansion to the point that no more oxygen molecules can be packed into the space.

power is all about oxygen. more oxygen, more power. period.

at that (rightward) point on a compressor map the RPM line ceases to rise and the line goes static. no more RPM gain.

ballgame.

all because of the heat of compression.

brick wall.

the pre-turbo concept is to introduce cooling BTUs (latent heat) and thus allow for additional oxygen to be able to enter the compressor volume.

more oxygen molecules, more power.

that's the concept.

there are pre-turbo FDs out there doing amazing things...

RiceRacing is running around 33 psi boost w his setup and maintains a healthy engine.

thewird is running in the mid 20s boostwise.

Rice runs WM and thewird runs water.

tom94RX-7 did an A B comparative test on the dyno... maybe it was track...

1revin7 also did a comparison

as you might expect, results vary.

the concept is intriguing and potentially quite significant.

i have run AI since 04. my Alkycontrol system worked flawlessly. i chose to run an M10 and M15 nozzle and had many happy experiences with it as did my engine. when a more accurate delivery system emerged (FJO) i made the switch to a solenoid/injector setup using an X Y grid. it also worked perfectly. my third setup was to deliver the methanol thru two fuel injectors running in parallel w my secondary injectors.

the system worked well but i may have reached a point where methanol being too large a part of my fuel became unstable. a backfire into my UIM took out a diffuser and my engine.

i believe the system was fine, just too much methanol.

all my locations were in the greddy elbow.

my new setup changes things around.

i have a new ECU (ViPEC V88) that can control 8 peak and hold injectors separately. the V88 will run my two AI fuel injectors.

one injector is in the elbow and one is pre-turbo. we will tune out using the elbow AI location (only) and then shut it off and tune out w the pre-turbo location.

i have switched to water meth 50/50 based on volume.

here's a picture of my injector fixture in a semi-finished for to give you an idea of my setup:

an in process pic showing the airfilter and lines.

i run an Alkycontrol pump, a Weldon pressure regulator (boost referenced), a return line from the regulator to my tank and a large Aeromotive filter.

i monitor and log the AI pressure (which i run at 110 psi static), air temperature between the turbo and intercooler and also at the stock UIM location. i use a K thermocouple so my readings are instantaneous and accurate.

pics are a month or two old as the setup is up and running and at Beyond Redline for evaluation.

there are of course a million questions that beg for answers re AI location...

some use AI for engine longevity and de-carbonisation

given this objective are there any benefits to justify re-location?

what really is necessary to maintain the compressor wheel integrity?

and of course the big question: does the pre-turbo location deliver more oxygen molecules/power?

this post hasn't scratched the surface so let's get a conversation started.

howard

#2

Daily Used and Abused

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

subscribed for sure. im almost positive that methanols tendency of pre-ignition(as read from other threads especially with platinum plugs) could play a part in a split plate(knock). since then i also decided to run 50/50. already have the nozzle just need the time to relocate and tune(pre-turbo and after).

what size nozzle/injector will you be running. im also wondering how total timing will change.

what size nozzle/injector will you be running. im also wondering how total timing will change.

#3

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

my AI injectors are Bosch EV14 1000 CC/Min. the EV14 can run at 8 BAR (116 psi).

116 minus boost, lets use 25 PSI, is 91 net

91/43.5 = 2.09

square root of 2.09 is 1.45

1.45 X 1000 is 1455 CC/Min less 13% lag so net max delivery is 1266CC/Min per injector.

we will have to wait til we are on the dyno to determine the max delivery.

of course it won't be that simple since we have 440 cells available and we will carefully tune each cell.

supposedly timing doesn't change w water however water allows you to run more boost and more boost of course leads into areas of the map previously un-tuned... so we will see. the amount of meth is modest and won't effect timing all that much.

just to review nozzles....

the M1 nozzle delivers 63 CC/Min at 100 net PSI

the M10 is 10X the M1

HC

116 minus boost, lets use 25 PSI, is 91 net

91/43.5 = 2.09

square root of 2.09 is 1.45

1.45 X 1000 is 1455 CC/Min less 13% lag so net max delivery is 1266CC/Min per injector.

we will have to wait til we are on the dyno to determine the max delivery.

of course it won't be that simple since we have 440 cells available and we will carefully tune each cell.

supposedly timing doesn't change w water however water allows you to run more boost and more boost of course leads into areas of the map previously un-tuned... so we will see. the amount of meth is modest and won't effect timing all that much.

just to review nozzles....

the M1 nozzle delivers 63 CC/Min at 100 net PSI

the M10 is 10X the M1

HC

#5

Daily Used and Abused

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

finally got my setup up and running 50/50 one M10 nozzle and a smaller 175 ml/min pre-turbo. progressive controller pump running at 200psi. Egts registered at 1420F at 20psi, i lowered the timing to 10deg, before with 100% methanol injection was running 16deg sadly i didnt have an Egt gauge then to spot a difference. Hope this is helpful, ill post a video of the run for your enjoyment

#6

Howard,

I will be interested to see how your results come out. I'm planning on building my own system this year, but I am unsure of placement, and using a fast acting value or fuel injector.

Do you have any concerns running 50% water through the fuel injectors? I haven't located much data on the Bosch EV14 regarding water effects.

I will be interested to see how your results come out. I'm planning on building my own system this year, but I am unsure of placement, and using a fast acting value or fuel injector.

Do you have any concerns running 50% water through the fuel injectors? I haven't located much data on the Bosch EV14 regarding water effects.

#7

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

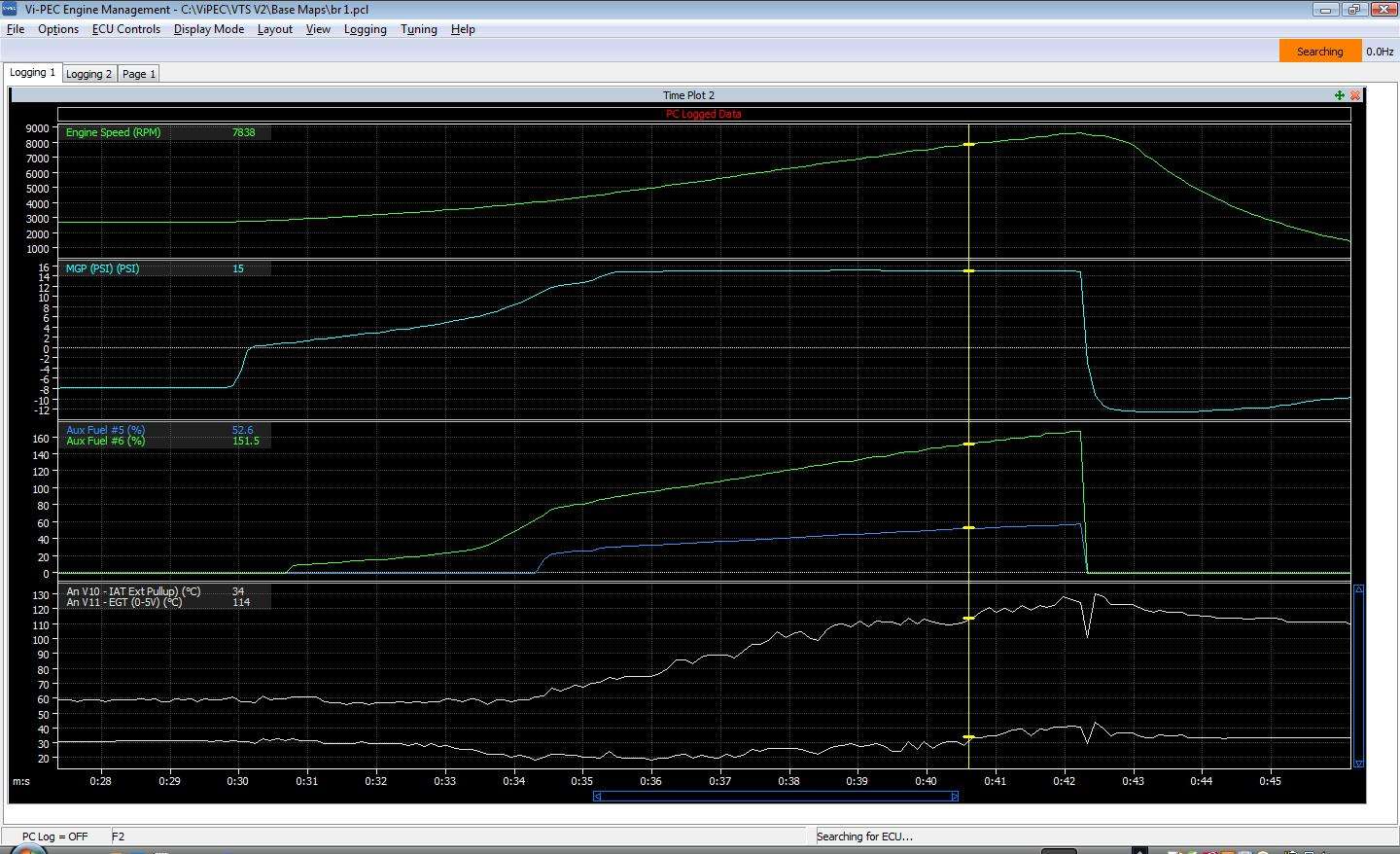

here's a run from last friday off the spring at 15 PSI...

i now have the setup that is capable of giving me the data i want and then working the tune. it is going to answer lot of questions.

top plot is RPM.

second plot is boost off the spring

third plot is the duty cycle of the AI injectors. one is pre turbo, one is in the elbow

fourth plot is IAT measured between the turbo and intercooler and in the OE location

ECU is the Vi-PEC V88. it can run 8 fuel injectors. of course it is running 4 for the base fuel and two which are AI. the AI injectors fire once every crank revolution.

the cursor is at 7838 RPM which is the point where the IAT finally exceeds ambient. i am running a 50/50 water meth combo.

the IAT coming directly from the turbo is 237 F

the IAT at the stock location is 93 F

prior to the run at - 7 psi 2716 RPM

IAT after turbo pre-IC was 138

IAT at OE location was 88

max temps at 8534 RPM

262 F out of turbo

106 OE location

IAT are measured w an EGT thermocouple and, as such, are literally instantaneous and accurate to a degree or two.

the motor duplicated my Jan 2012 power output of 394 at 15 psi. this amazes me because we were hugely richer at average AFR of 10.9 and had 5 degrees less timing in the motor.

the big difference was last year was 100% methanol.... no water.

well, maybe that wasn't the biggest factor. it seems we were a bit off on setting AI delivery.

if you can see the details you will note that the pre turbo injector was at 52.6% injector duty and the OE location was at 151.5%!

of course anything higher than 100% is just a nominal calculation. the injector was set at 11 mS, fires once a revolution which takes 7.65 mS. 11/7.65 gets you to approx 1.5.

we were at 100% duty w the OE AI injector from 5100 RPM and up...

the pre turbo location had been dialed back V the OE located injector.

(we were primarily just testing to see that they worked)

total AI at 5219 RPM was 2143 CC/Min... yikes

total AI at 8644 RPM was 2509 CC/Min

i find it humorous that one of the primary reasons for my setup was to accurately control the delivery of AI at all points on the map and our first outing was probably further off the mark than i have ever experienced.

we were focusing on other things and overall the engine ran well. i have a Vi-PEC Knock Amplifier Kit on the way (headphones to determine knock) and will be back on the dyno as soon as it arrives.... probably March 4/5.

we will then be able to focus on trimming the AI table properly and assessing pre-turbo V post turbo AI.

this info hopefully will be of help to all.

howard

Trending Topics

#10

Set up is a 93 with a streetported engine doing single turbo just haven't decided which turbo would be best yet ( BW S366, T04z or T61) adaptronic 440 select,FMIC AEM smart coils injector dynamics Id720 and id2000 injectors no power steering or ac looking to drive the car on the street sometimes and take it to the track and do some road courses want about 425-500 for hp thank you

#15

Pre turbo is great, just make sure everything is working properly and failsafes, I made more power during my dyno tests. Now injecting water/meth pre turbo and pre throttle body, more volume is needed compared to just using water, to keep knock low. I haven't been back to the dyno though.

#17

Arrogant Wankeler

Surely given the fine atomisation of the air/water rigs most are running in pre-turbo setups, the vapour pressure of methanol even at ambient and the incredibly lean AFR the preturbo injection represents there would be no liquid condensation reaching the seal area, even if you were expecting boost blowbye into the core from the compressor side the heat in the turbo/sump system and very lean meth mix would make it almost impossible to create oil contamination as it would stay in gaseous form and be sucked back through the motor or pushed to atmosphere through the vent system?

#18

Full Member

iTrader: (1)

so... pre or post? was thinking about running the AEM kit mostly as a safety feature on my FC (pfc, fmic, stock turbo) and maybe for some not so extreme power gains later.

how would turbo size affect you guys' choice of pre or post turbo injection if at all? what other factors affect ones decision?

thanks,

carrington

how would turbo size affect you guys' choice of pre or post turbo injection if at all? what other factors affect ones decision?

thanks,

carrington

#21

2SoonJr

iTrader: (8)

Join Date: Mar 2008

Location: OrangeCounty-Santa Ana

Posts: 525

Likes: 0

Received 5 Likes

on

4 Posts

Given that E85 in a Rotary seems to be a lil controversial with regards to the pitting effect on the irons and the effect to the OEM oil seals; not sure what it does to the OEM water seals.

AI seems to be the way to go especially with 91 here in CA. I think post intercooler by the elbow location would seem ideal. But i am wondering about how much of a distance from the throttle body it would need to have proper atomization.

AI seems to be the way to go especially with 91 here in CA. I think post intercooler by the elbow location would seem ideal. But i am wondering about how much of a distance from the throttle body it would need to have proper atomization.

#23

And I suspect "proper atomization" is largely a function of nozzle quality, size and pump psi as much as anything else.

Last edited by Sgtblue; 02-05-17 at 02:56 PM.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM