using PFC to control water injection

#1

using PFC to control water injection

Here is an idea that just came to me and I'll just throw it out there, not that I am seriously considering it. What if you drilled the secondary runners on your UIM and installed a custom fuel rail with top feed injectors (size would have to be determined). You can use an FPR that is mounted to the rail (like on a factory rail) or an external. It would be sort of like a 2nd gen factory rail with integrated FPR, but the proper size. And of course it would have to be mounted securely.

Then you could have them controlled by the secondary injector drivers (with appropriate resistors per the PFC manual).

As far as the pump goes, could you use a Denso style pump or would you want to use a pump traditional used for A/I ? This is assuming you are injecting water only. Methanol would complicate things wouldn't it? The biggest drawback I see is a lack of adjustability beyond changing injector size or fuel pressure. But I would think it would atomize pretty well if injected right into the UIM.

What it then comes down to is whether it would be worth it to put that setup together when you can just buy a kit that has already gone through the proper engineering and testing (FJO for example).

Then you could have them controlled by the secondary injector drivers (with appropriate resistors per the PFC manual).

As far as the pump goes, could you use a Denso style pump or would you want to use a pump traditional used for A/I ? This is assuming you are injecting water only. Methanol would complicate things wouldn't it? The biggest drawback I see is a lack of adjustability beyond changing injector size or fuel pressure. But I would think it would atomize pretty well if injected right into the UIM.

What it then comes down to is whether it would be worth it to put that setup together when you can just buy a kit that has already gone through the proper engineering and testing (FJO for example).

#2

Rotor or no motor

iTrader: (24)

the idea does not sound too bad however this will cost you big bucks. I would suggest to go with a coolingmist kit 4-150psi pump with controlers etc for 350$

Here is an idea that just came to me and I'll just throw it out there, not that I am seriously considering it. What if you drilled the secondary runners on your UIM and installed a custom fuel rail with top feed injectors (size would have to be determined). You can use an FPR that is mounted to the rail (like on a factory rail) or an external. It would be sort of like a 2nd gen factory rail with integrated FPR, but the proper size. And of course it would have to be mounted securely.

Then you could have them controlled by the secondary injector drivers (with appropriate resistors per the PFC manual).

As far as the pump goes, could you use a Denso style pump or would you want to use a pump traditional used for A/I ? This is assuming you are injecting water only. Methanol would complicate things wouldn't it? The biggest drawback I see is a lack of adjustability beyond changing injector size or fuel pressure. But I would think it would atomize pretty well if injected right into the UIM.

What it then comes down to is whether it would be worth it to put that setup together when you can just buy a kit that has already gone through the proper engineering and testing (FJO for example).

Then you could have them controlled by the secondary injector drivers (with appropriate resistors per the PFC manual).

As far as the pump goes, could you use a Denso style pump or would you want to use a pump traditional used for A/I ? This is assuming you are injecting water only. Methanol would complicate things wouldn't it? The biggest drawback I see is a lack of adjustability beyond changing injector size or fuel pressure. But I would think it would atomize pretty well if injected right into the UIM.

What it then comes down to is whether it would be worth it to put that setup together when you can just buy a kit that has already gone through the proper engineering and testing (FJO for example).

#3

I'm not saying it would be cheap, but how do you figure it would cost big bucks? The whole point of it isn't to be 100% cheap. It's to have the duty cycle control of a fuel injection system without a lot of redundant stuff, but again that's only the idea. Our secondary injectors already switch themselves on only under high loads. Clearly I could just switch it on the old fashioned way if I wanted to go cheap. On to pricing:

instead of building a custom rail, use two additional injector kits ($130 or so total). http://www.atpturbo.com/Merchant2/me...egory_Code=FUL

Then let's say two flow tested civic LX injectors (210cc each, high impedence), that would be like $100 max, or some F-150 inline six injectors (Bosch size diameter which are I think 145cc or so). Or if you need a ton of flow, two 2nd gen 460CC injectors.

Then some AN hose and fittings, which would be a little more complicated because of the extra fittings. Then another external FPR ($100 used, maybe $150 new). Then a pump and tank, which I can't see being much more expensive than it would be on any other setup. Then you just have to buy some injector clips and wire them in, which would be pretty simple for me especially because I have a patch harness down by the ECU (2nd gen with PFC adapter kit). I figure you could do it for $500-600 if you can weld aluminum or get someone else to do it cheaply.

What am I missing here? Would regular old fuel injectors and fuel pumps work with water?

instead of building a custom rail, use two additional injector kits ($130 or so total). http://www.atpturbo.com/Merchant2/me...egory_Code=FUL

Then let's say two flow tested civic LX injectors (210cc each, high impedence), that would be like $100 max, or some F-150 inline six injectors (Bosch size diameter which are I think 145cc or so). Or if you need a ton of flow, two 2nd gen 460CC injectors.

Then some AN hose and fittings, which would be a little more complicated because of the extra fittings. Then another external FPR ($100 used, maybe $150 new). Then a pump and tank, which I can't see being much more expensive than it would be on any other setup. Then you just have to buy some injector clips and wire them in, which would be pretty simple for me especially because I have a patch harness down by the ECU (2nd gen with PFC adapter kit). I figure you could do it for $500-600 if you can weld aluminum or get someone else to do it cheaply.

What am I missing here? Would regular old fuel injectors and fuel pumps work with water?

#5

putting auxiliary injection in the primary slots in lieu of actual fuel injectors seems like a bad idea to me. Mazda put them there for a reason. Even the 84-85 GSL-SE 13B's, which only had two injectors, had them located in the middle iron in the normal primary spot. I've actually got a 2nd gen and s5 manifolds so I don't need to run an Xcessive LIM...

somebody come up with a technical reason why this will not work, assuming I can get potential fitment issues worked out and I can keep costs under control. I could use reman'd Denso or Bosch injectors (just auto parts store stuff) from an OEM application, and those are going for like $25-$30 each.

somebody come up with a technical reason why this will not work, assuming I can get potential fitment issues worked out and I can keep costs under control. I could use reman'd Denso or Bosch injectors (just auto parts store stuff) from an OEM application, and those are going for like $25-$30 each.

#6

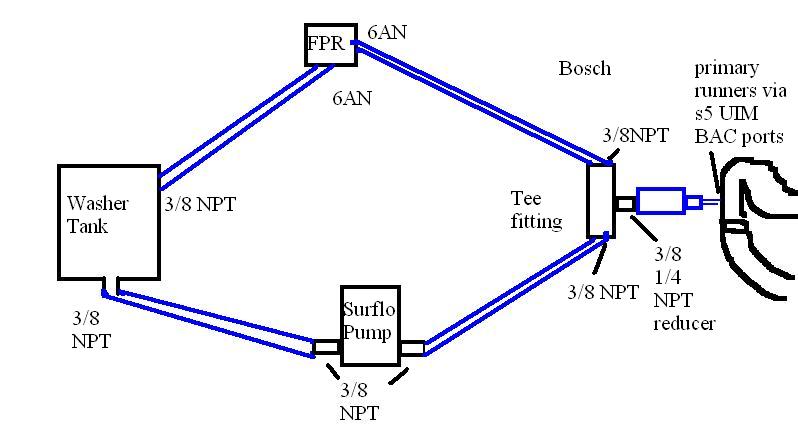

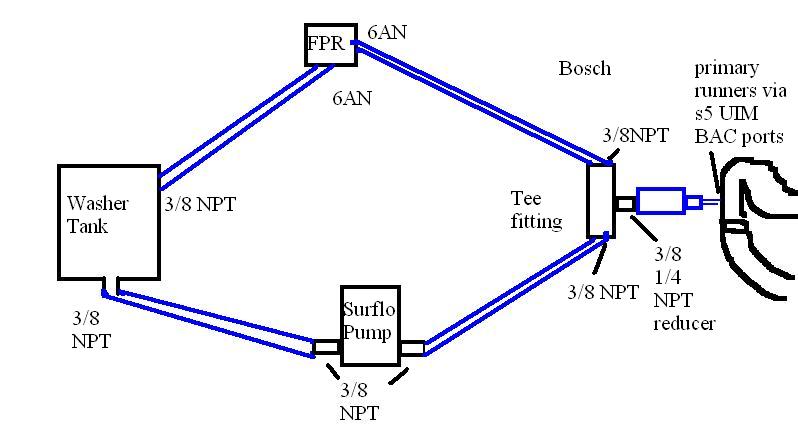

Alright, I have drawn out a tentative diagrams for the plumbing and the wiring and I'd like to get some input from the guru's.

I think it would be simpler and cheaper to run one larger injector, especially for a system that could easily not work. Instead of drilling and tapping the secondary runners, I could just weld the injector boss into the intercooler piping. Or here's another idea. On the side of the s5 UIM is the BAC valve, which is the equivalent of the FD's IAC. It injectors bypass air into two small holes in the primary runners. I could enlarge those holes, then drill my blockoff plate and weld the injector boss into that. I have a spare UIM that I can mess with to see if it's doable. If the system doesn't work out, I can just buy another BAC blockoff plate and I won't have to scrap the manifold.

For a pump would there be any problem running the Surflo pump? Even if I couldn't mount it below the factory washer bottle, all that affects is the speed at which the system primes, right? I know the Surflo pump can run dry without failing. Water pressure, and ultimately water injection flow, would be adjusted by the adjustable FPR. I could also sell the FPR and not lose too much money on that if this doesn't work.

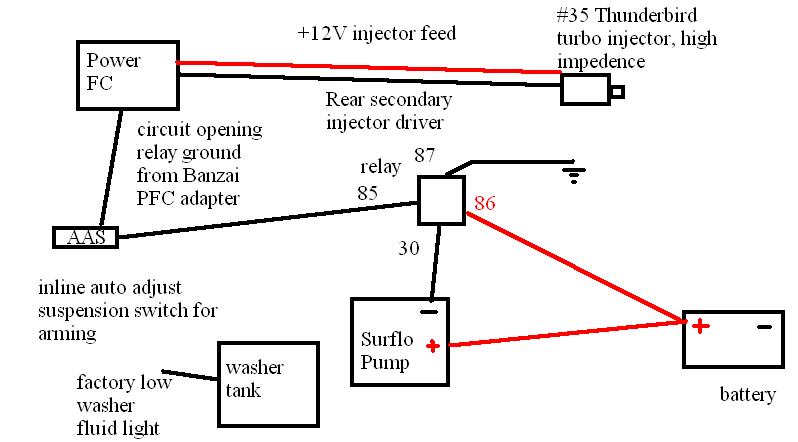

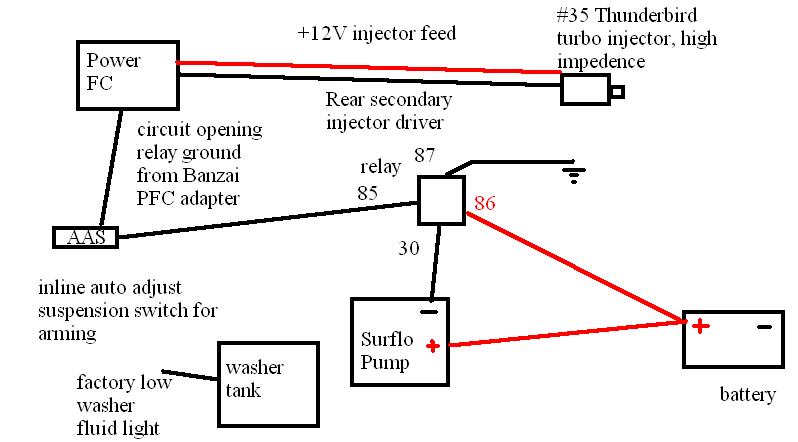

Wiring wise, the pump would run continuously as long as the system is armed, in the same way that an OEM fuel injection system runs the pump continuously when the engine is on. Arming would be accomplished by using an auto adjust suspension switch from a GXL model, wired in-line with the circuit opening relay trigger ground (unsure what PFC pin it is). In that way the Surflo pump would never run unless the engine is running and the system is armed.

Then the water injector, a 1988 35 lb SVO/Thunderbird Bosch style injector (high impedence I believe), would be triggered by the rear secondary injector driver. Based on the datalogit manual, the injector drivers can see a total of 3 AMPS. I am running 4 low impedence injectors (2 Denso 720, 2 bosch 1680) with the factory 6 ohm resistor pack. It should be ok with one more high impedence injector.

The low fluid warning would be the OEM low washer fluid idiot light.

In theory, the result would be water injection directly into the primary runners utilizing mostly factory or factory-replacement hardware. Now somebody needs to pick this plan apart or I may have to actually do this...

I think it would be simpler and cheaper to run one larger injector, especially for a system that could easily not work. Instead of drilling and tapping the secondary runners, I could just weld the injector boss into the intercooler piping. Or here's another idea. On the side of the s5 UIM is the BAC valve, which is the equivalent of the FD's IAC. It injectors bypass air into two small holes in the primary runners. I could enlarge those holes, then drill my blockoff plate and weld the injector boss into that. I have a spare UIM that I can mess with to see if it's doable. If the system doesn't work out, I can just buy another BAC blockoff plate and I won't have to scrap the manifold.

For a pump would there be any problem running the Surflo pump? Even if I couldn't mount it below the factory washer bottle, all that affects is the speed at which the system primes, right? I know the Surflo pump can run dry without failing. Water pressure, and ultimately water injection flow, would be adjusted by the adjustable FPR. I could also sell the FPR and not lose too much money on that if this doesn't work.

Wiring wise, the pump would run continuously as long as the system is armed, in the same way that an OEM fuel injection system runs the pump continuously when the engine is on. Arming would be accomplished by using an auto adjust suspension switch from a GXL model, wired in-line with the circuit opening relay trigger ground (unsure what PFC pin it is). In that way the Surflo pump would never run unless the engine is running and the system is armed.

Then the water injector, a 1988 35 lb SVO/Thunderbird Bosch style injector (high impedence I believe), would be triggered by the rear secondary injector driver. Based on the datalogit manual, the injector drivers can see a total of 3 AMPS. I am running 4 low impedence injectors (2 Denso 720, 2 bosch 1680) with the factory 6 ohm resistor pack. It should be ok with one more high impedence injector.

The low fluid warning would be the OEM low washer fluid idiot light.

In theory, the result would be water injection directly into the primary runners utilizing mostly factory or factory-replacement hardware. Now somebody needs to pick this plan apart or I may have to actually do this...

#7

parts list:

Surflo Pump (DevilsOwn) $110 + S&H

Relay and injector clip $20

Injector Boss (ATP) $65 + S&H

35# injector, Thunderbird turbo (Advance Auto) $30

Aeromotive FPR $150 or maybe $100 used

Misc Fittings, hose, and wires $100, depending if I go stainless or not

That puts me at anywhere from $400-$550

Surflo Pump (DevilsOwn) $110 + S&H

Relay and injector clip $20

Injector Boss (ATP) $65 + S&H

35# injector, Thunderbird turbo (Advance Auto) $30

Aeromotive FPR $150 or maybe $100 used

Misc Fittings, hose, and wires $100, depending if I go stainless or not

That puts me at anywhere from $400-$550

Trending Topics

#8

can fuel injectors handle water? i thought they would rust.

also you may not need a fpr as you can get internally bypassed pumps that keep a constant pressure, coolingmist now offers a 250psi internally bypassed pump for $140, or you can get the 150psi shurflo with internal bypass kit for a bit less.

also you may not need a fpr as you can get internally bypassed pumps that keep a constant pressure, coolingmist now offers a 250psi internally bypassed pump for $140, or you can get the 150psi shurflo with internal bypass kit for a bit less.

#9

I like the idea, but I believe that a standard fuel injector will basically self-destruct if only injecting water. It rusts shut.

I believe these gentlemen tried it quite some time ago, but perhaps things have changed since then.

http://www.rbracing-rsr.com/waterinjection.html

I believe these gentlemen tried it quite some time ago, but perhaps things have changed since then.

http://www.rbracing-rsr.com/waterinjection.html

#12

why not getting a regular water injection nozzle with a high speed pwm valve, build up your system, and add an aquamist rx-7 injector duty summer? I'm adding that to my coolingmist kit.

What it does is read both primary and secondary injector duties and outputs an overall idc in both a 0-5V signal and a high speed pwm valve driver.

What it does is read both primary and secondary injector duties and outputs an overall idc in both a 0-5V signal and a high speed pwm valve driver.

#13

Savanna Rx-7

How would this affect your PFC settings?

I think I know where you are coing from, but how would this affect your lag settings, and etc.? If you ran two low impedance and wired them in series, you would no longer need a reistor for the PFC, but how would you determine your lag settings? more important will you set up a boost kill or timing retard for when you run out of water? 2 reasons..obvious engine dmage, secondly injector damage if you run them dry for two long. even if you were not boosting enough to need the AI, it might damage the injectors from running dry and overheating the injector... any thoughts on this?

cheers

kenn

cheers

kenn

#14

Full Member

iTrader: (4)

Join Date: Dec 2007

Location: Houston

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Interesting thread. I had the same idea.

I'm planning to try using an FJO to drive the low impedance 1600's. That would mean there were two free channels not being used on the FJO. Since the input impedance is so high on the FJO per channel (it won't load the PFC drivers), I'm going to try running two FJO channels per secondary injector PFC signal.

That should give two identical peak+hold driven signals per rotor. Two for the front driving one fuel injector and one S-HSV, and two for the rear also driving one fuel injector and one S-HSV.

I plan to be able to change the proportion of fuel to water that's being injected by changing the water nozzle size and controlling the water manifold pressure with the variable manifold referenced pressure regulator.

It's all theory right now...although I can't see why it wouldn't work as long as I can mechanically get the correct proportions and keep the S-HSV's operating within the portion of their response curve where things are linear..