80% Pump----- 20% Methanol

#276

BDC Motorsports

I've got a hellacious grinding that's rhythmic to the speed of the engine. It's really loud and vibrates the drivetrain. The noise only exists when the clutch is not pressed. If I push it in, the noise goes away completely. The grinding exists in any gear or in neutral and with the car stationary or moving. The only way to get rid of it is clutch in. The funny thing about this -- I swapped in another known-good transmission and it's doing the exact same thing. So, my guess is it's something I'm not doing right or heck I don't know.

B

B

#278

BDC Motorsports

Yep, hot-air, no intercooler setup. I've already become resolved about not doing an FMIC (I don't like the choice of location) and the stock TMIC's plumbing is potentially too small for the setup I'm running. My turbo is a 2.5" out -- the outlet pipe is 2.25", then the intercooler piping is 1 7/8". There's also the goofy, stock throttle body inlet adaptor. I want it to all go bye-bye, do a GReddy or Higgi-type 2.5" straight in to the throttle body then some 2.5" piping going around from the turbo. I figure the stock TMIC isn't doin' much of nothing anyways in terms of cooling. Plus, I can move the alcohol nozzles up-stream and therefore get better readings out of the IAT.

B

B

#279

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

hi guys... Brian, it sounds like your inputshaft bearing.

i was just looking back on the posts and found one of mine from May stating i would be on the dyno in a matter of "days." sure. 60-90 days.

i am getting really close though. there's alot of new beta stuff on the car and it takes time to sort out. i was actually thinking i would dyno tomorrow but looking at the pressure logs from the alcohol pump it isn't going to happen. my pump loses pressure when the injectors open. FJO is looking into it tonight and i hope to have a fix tomorrow.

the good news is the whole system is as of yesterday WORKING!

since it logs i can see that my solenoids/injectors are providing the actual duty cycle at the set RPM and boost that i set in the X Y Grid. neat. the only problem is i am not getting the alcohol amount needed as the pump is not maintaining pressure.

the FJO AI system includes a 4 bar MAP sensor and replaces your boost controller. the FJO WB AFR hooks into the AI module so it can, if the AFR goes lean, open the wastegate etc.

so, when we get the pump pressure straightened out we will be dynoing at 20+ psi.

hc

i was just looking back on the posts and found one of mine from May stating i would be on the dyno in a matter of "days." sure. 60-90 days.

i am getting really close though. there's alot of new beta stuff on the car and it takes time to sort out. i was actually thinking i would dyno tomorrow but looking at the pressure logs from the alcohol pump it isn't going to happen. my pump loses pressure when the injectors open. FJO is looking into it tonight and i hope to have a fix tomorrow.

the good news is the whole system is as of yesterday WORKING!

since it logs i can see that my solenoids/injectors are providing the actual duty cycle at the set RPM and boost that i set in the X Y Grid. neat. the only problem is i am not getting the alcohol amount needed as the pump is not maintaining pressure.

the FJO AI system includes a 4 bar MAP sensor and replaces your boost controller. the FJO WB AFR hooks into the AI module so it can, if the AFR goes lean, open the wastegate etc.

so, when we get the pump pressure straightened out we will be dynoing at 20+ psi.

hc

#280

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Tuning Update/Dyno july 29 08

Forging Fearlessly into new Frontiers w Fjo

--------------------------------------------------------------------------------

i finally got on the Beyond Redline eddy current dyno tuesday w the new generation FJO system.

the executive summary is: the electronics worked exactly as hoped. the simple stuff was the problem.

as you may know FJO is in the late stages of bringing a new system to market. unlike 90+% of all AI systems out there the FJO system uses solenoids (think fuel injectors) to dispense the injectant. just like your current daily driver. just like the FD.

computer controlled fuel injection, using 40 psi rail pressure is why we have much more efficient (better mpg, more accurate AFRs, more hp) cars.

most AI systems don't work like our fuel systems.

they simply have a pump and a nozzle (think your kitchen faucet) and they juice the pump w varying volts and out it comes. with no regard for RPM. further if you get on and off the throttle in boost the pump has zero ability to deliver similarly.

real crude.

it works pretty well for drag racing where your foot is on the floor.

it also is o k if you are just spraying water to cool your motor as the delivery requirements are not needed to be too precise.

it does not work for 100% methanol road racing or for screwwing around on the street.

FJO designed an entirely different AI setup and is on the second iteration.

FJO's system is much like the regular fuel system in your FD.

to determine the precise (we are talking milliseconds of injector ontime) amount of gasoline your computer has a lookup table w lots of cells in it. the cells are located by RPM and load. various sensors (RPM and MAP) determine the proper cell and a precise amount of fuel is injected. PRECISE.

that is exactly how the FJO system works. they have a 16 X 16 grid (256 cells) w RPM and Load. set it as you like.

their screen shows all the metrics.... whether the pump is running, what the rail pressure is, what duty the solenoids are running, rpm, throttle position % etc and it also allows you to log, replay and analise the data.

and it all works.

well, not exactly.

fuel pressure must be constant for constant delivery volume at a particular % duty.

here's where we get into a problem.

the FJO system uses the ubiquitous Shurflow pump. FJP did put a really neat aluminum housing on it w alot of fins to shed heat...

the pump pumps the methanol forward thru a filter and a pressure sensor to the solenoids. the concept is the pump is to provide constant pressure. with methanol it doesn't happen and therefore i did get varying pressures on my dyno runs.

varying pressure = varying AFRs.

according to FJO the setup works fine w no pressure problems w water.

methanol has a number of properties that challenge the current setup.... much greater density and volatility are a couple of keys. since the system deadheads at the solenoids the pump when on goes into internal bypass and overheats the liquid turning it into gas and dropping the pressure etc. once gas is created the pressure declines thru delivery... probably some cavitation.

back to the drawing boards...

as i said, FJO has already done the difficult work, we just need to fix the simple stuff.

so:

i will be adding a Weldon A2040 Bypass regulator. adj 0-200 PSI. Meth-happy.

by adding the regulator i will be able to lock my pressure. (70 PSI plus boost).

secondly, i will be adding a return (bypass) line back to my 4 gallon meth tank. by doing so i will avoid any pump churning issues.

i will also be changing to a real pump. medium term i think i will go w a custom Weldon pump but nearer term i plan to go w a Bosch variant of the 044 inline. the 044 puts out more than the 23 GPH (max) i need. Bosch makes the 909 variant that puts out 39 (V the 044s 53) GPH. normal pressure is 5 bar, 70+ PSI. so i will turn up the pressure about 25 psi and won't have to bypass as much as w the 044. the 044 is meth "tolerant."

i need to find out if the 909 is also "tolerant." if anyone has a source for obtaining that info i'd appreciate it.

it is appearing for 100% meth/w solenoids you need to build a real copy of the typical fuel system. i really want to get this done and be back on the dyno. i have waited around long enough.

why go thru all this?

because when i get the pumping straightened out the combo of a turbo'd rotary on a precise methanol and 93 octane diet will be a killer.

hc

Forging Fearlessly into new Frontiers w Fjo

--------------------------------------------------------------------------------

i finally got on the Beyond Redline eddy current dyno tuesday w the new generation FJO system.

the executive summary is: the electronics worked exactly as hoped. the simple stuff was the problem.

as you may know FJO is in the late stages of bringing a new system to market. unlike 90+% of all AI systems out there the FJO system uses solenoids (think fuel injectors) to dispense the injectant. just like your current daily driver. just like the FD.

computer controlled fuel injection, using 40 psi rail pressure is why we have much more efficient (better mpg, more accurate AFRs, more hp) cars.

most AI systems don't work like our fuel systems.

they simply have a pump and a nozzle (think your kitchen faucet) and they juice the pump w varying volts and out it comes. with no regard for RPM. further if you get on and off the throttle in boost the pump has zero ability to deliver similarly.

real crude.

it works pretty well for drag racing where your foot is on the floor.

it also is o k if you are just spraying water to cool your motor as the delivery requirements are not needed to be too precise.

it does not work for 100% methanol road racing or for screwwing around on the street.

FJO designed an entirely different AI setup and is on the second iteration.

FJO's system is much like the regular fuel system in your FD.

to determine the precise (we are talking milliseconds of injector ontime) amount of gasoline your computer has a lookup table w lots of cells in it. the cells are located by RPM and load. various sensors (RPM and MAP) determine the proper cell and a precise amount of fuel is injected. PRECISE.

that is exactly how the FJO system works. they have a 16 X 16 grid (256 cells) w RPM and Load. set it as you like.

their screen shows all the metrics.... whether the pump is running, what the rail pressure is, what duty the solenoids are running, rpm, throttle position % etc and it also allows you to log, replay and analise the data.

and it all works.

well, not exactly.

fuel pressure must be constant for constant delivery volume at a particular % duty.

here's where we get into a problem.

the FJO system uses the ubiquitous Shurflow pump. FJP did put a really neat aluminum housing on it w alot of fins to shed heat...

the pump pumps the methanol forward thru a filter and a pressure sensor to the solenoids. the concept is the pump is to provide constant pressure. with methanol it doesn't happen and therefore i did get varying pressures on my dyno runs.

varying pressure = varying AFRs.

according to FJO the setup works fine w no pressure problems w water.

methanol has a number of properties that challenge the current setup.... much greater density and volatility are a couple of keys. since the system deadheads at the solenoids the pump when on goes into internal bypass and overheats the liquid turning it into gas and dropping the pressure etc. once gas is created the pressure declines thru delivery... probably some cavitation.

back to the drawing boards...

as i said, FJO has already done the difficult work, we just need to fix the simple stuff.

so:

i will be adding a Weldon A2040 Bypass regulator. adj 0-200 PSI. Meth-happy.

by adding the regulator i will be able to lock my pressure. (70 PSI plus boost).

secondly, i will be adding a return (bypass) line back to my 4 gallon meth tank. by doing so i will avoid any pump churning issues.

i will also be changing to a real pump. medium term i think i will go w a custom Weldon pump but nearer term i plan to go w a Bosch variant of the 044 inline. the 044 puts out more than the 23 GPH (max) i need. Bosch makes the 909 variant that puts out 39 (V the 044s 53) GPH. normal pressure is 5 bar, 70+ PSI. so i will turn up the pressure about 25 psi and won't have to bypass as much as w the 044. the 044 is meth "tolerant."

i need to find out if the 909 is also "tolerant." if anyone has a source for obtaining that info i'd appreciate it.

it is appearing for 100% meth/w solenoids you need to build a real copy of the typical fuel system. i really want to get this done and be back on the dyno. i have waited around long enough.

why go thru all this?

because when i get the pumping straightened out the combo of a turbo'd rotary on a precise methanol and 93 octane diet will be a killer.

hc

#281

Awesome plans Howard.

So your bypass regulator(MPR) will be located after the solenoid(s)? And a return line will go back to your cell?

Will you control when the pump turns on with the FJO module still? Have the pump turn on a few psi before meth injection for priming, or will the pump always run?

So your bypass regulator(MPR) will be located after the solenoid(s)? And a return line will go back to your cell?

Will you control when the pump turns on with the FJO module still? Have the pump turn on a few psi before meth injection for priming, or will the pump always run?

#283

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

update:

i expect to be back on the dyno this week.

i now run a different alcohol pump. the new pump is a Bosch 044 variant (PN 0 580 254 909). the 044 puts out 53 GPH while the "909" pumps 39 GPH. since i use two 700 CC/Min solenoids/injectors my max is 23 GPH. the 909 is an inline external pump and as such has a nipple on the inflow side. i used a barb fitting. since you will need a short length of rubber hose to connect the two you need to know:

the only rubber hose to use w alcohol is SAE 30R9 spec. this is readily obtainable at NAPA or just about any auto parts store. do NOT use normal rubber hose or very bad things will happen almost immediately.

pump only runs in boost of course.

i selected a Weldon Adj pressure regulator ( PN A 2040) meth happy adj to 200 PSI.

the other key is a return line back to the alcohol fuel cell.

i now have constant pressure to my alcohol injectors and it is back to the dyno.

top line is return from press reg. dash 6. bottom is feed. small top line is vent to outside.

left line is feed from cell. top line is return to cell. right line is to injectors. this all gets neatly covered my the black plastic OEM panel.

note filter and line pressure sensor/logger

i expect to be back on the dyno this week.

i now run a different alcohol pump. the new pump is a Bosch 044 variant (PN 0 580 254 909). the 044 puts out 53 GPH while the "909" pumps 39 GPH. since i use two 700 CC/Min solenoids/injectors my max is 23 GPH. the 909 is an inline external pump and as such has a nipple on the inflow side. i used a barb fitting. since you will need a short length of rubber hose to connect the two you need to know:

the only rubber hose to use w alcohol is SAE 30R9 spec. this is readily obtainable at NAPA or just about any auto parts store. do NOT use normal rubber hose or very bad things will happen almost immediately.

pump only runs in boost of course.

i selected a Weldon Adj pressure regulator ( PN A 2040) meth happy adj to 200 PSI.

the other key is a return line back to the alcohol fuel cell.

i now have constant pressure to my alcohol injectors and it is back to the dyno.

top line is return from press reg. dash 6. bottom is feed. small top line is vent to outside.

left line is feed from cell. top line is return to cell. right line is to injectors. this all gets neatly covered my the black plastic OEM panel.

note filter and line pressure sensor/logger

Last edited by Howard Coleman; 09-22-08 at 03:37 PM.

#284

John Dillinger

iTrader: (2)

Join Date: Sep 2006

Location: 702

Posts: 1,515

Likes: 0

Received 0 Likes

on

0 Posts

how about this product... is it better so u dont have to mix it by urself.

http://www.snowperformance.net/product.php?pk=3

http://www.snowperformance.net/product.php?pk=3

#288

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

2008 UPDATE:

things are looking up in 08 for my twin TO4 turbo project. last year was the first year on the dyno. we did 3 dyno sessions each averaging 4+ hours w ace tuner Luke Stubbs at BeyondRedline Green Bay Wisconsin.

challenges for 07 were tuning my Alkycontrol 100% methanol AI system and dealing w a declining torque curve after a decent ascent. due to a few problems real and illusory we were only able to tune to about 15.8 psi and made about 420/360. i did switch the rear turbines from stage 3 to stage 5 in the middle of the 07 process.

last thursday i was back on the (new) eddy current Beyond Redline dyno. we made 23 2000-8000 4th gear pulls.

the big new deal was a new generation alcohol system from FJO. unlike most systems which use nozzles the FJO system uses fuel injectors. nozzles are great for watering your lawn. fuel injectors are great for precisely tuning your motor. as in milliseconds of "ontime."

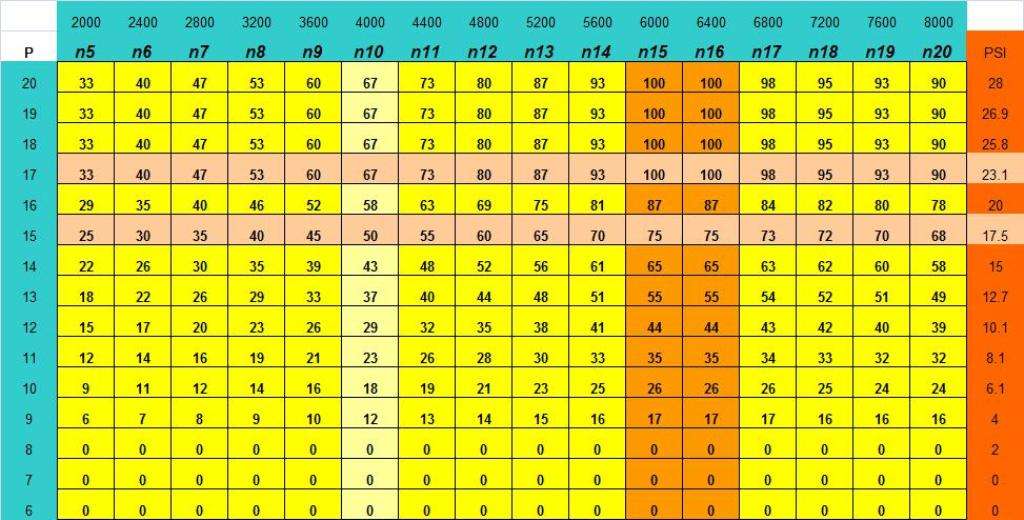

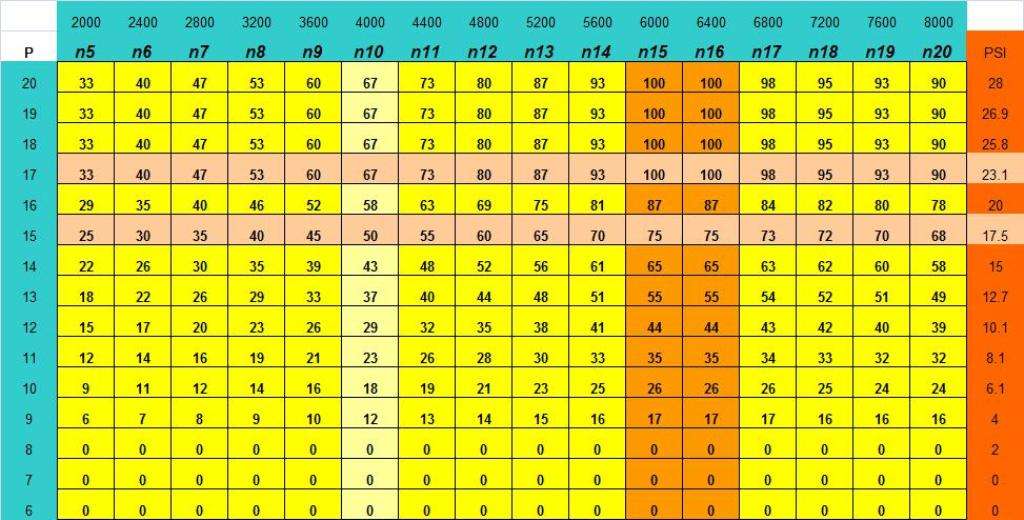

here's what the tuning table looks like. the values are % of max deliverability.

the older gen (spray and pray) systems work o k for drag racing where your right foot is always on the floor. since the only variability as to delivery is an electric pump they really can't parallel fuel needs on a road course where you are always on and off the gas.

(if you are just using the setup to spray water to cool your engine they are fine... if you are partially fueling your engine w magic methanol on the street or a road course.... no way)

anyway, i was on the dyno initially in july. we found that the alcohol pressure behind the injectors (2 700 CC/Min) was varying and with it our AFRs.

back to the drawing board.

remove Shurflow pump. insert a Bosch variant of the 044.... the 909. add a Weldon Adj alcohol compatible pressure regulator. add return to AI fuel cell line.

result: absolutely constant alcohol line pressure and back to tuning on the dyno.

so, we did 23 runs last thursday. after the first run we never even thought about the alcohol system. it was there. it was constant. and combined w pump 93 octane it was magic.

20 pounds of boost. PFC knock reading between 7000 and 8000 was between 10 and 20! on pump gas

my descending torque readings from last year have vanished. i spent too much time chasing that last year. it turned out to be boost related.

BTW, my exhaust backpressure at 20 psi boost is 21!!!!

my turbos are designed to put out 82-84 pounds per minute at 27 psi. unfortunately, my actuator springs are maxxed at 20 psi. i am using the stock FD actuators adapted to my ATP Ultimate Wastegates. they do 10 psi w the boost controller turned off.

i removed one of them yesterday with the idea of screwing the rod in to make it shorter and preload the actuator spring for more boost but found the travel to be only .31 inches. if i were to shorten the rod to stiffen the spring i would lose travel and probably WG flow so i will need to find stiffer (different) actuators.

since i want to get ontrack in the next few weeks 27 psi and 600 rw will have to wait.

i made 498 at 20 psi but do expect i can raise the output a bit as i am conservative on timing at 12 degrees w 11 split. further, my lead plug (NGK R6725 10.5 heat range) is black and oily. i am going to a hotter plug in the lead only.

finally, we have been tuning too cold on the egts. the target temps pre turbo have been 1420 F for spool and 1550 F at target boost. actually these are the temps for 100% meth (no gasoline at all)... so we will bump EGTs a bit since 70% of my fuel is 93 octane gasoline and we have seen zero knock.

it looks like my twins are proving out V my target. spool is either the same or slightly better than a recently posted GT42.

i really don't want 400 rw at 5000 anyway as it would be more difficult to drive on a road course.

the setup is great around town and should be exciting when it finally gets tuned out.

stay tuned more to come this year. OBTW, i have about 13,000 miles on my twins. and my motor has been in my car for 3 years now... 0ver 100 dyno pulls and it reads 17 inches of vacuum at idle.

pics of my FJO setup in the Auxiliary Injection section.

hc

things are looking up in 08 for my twin TO4 turbo project. last year was the first year on the dyno. we did 3 dyno sessions each averaging 4+ hours w ace tuner Luke Stubbs at BeyondRedline Green Bay Wisconsin.

challenges for 07 were tuning my Alkycontrol 100% methanol AI system and dealing w a declining torque curve after a decent ascent. due to a few problems real and illusory we were only able to tune to about 15.8 psi and made about 420/360. i did switch the rear turbines from stage 3 to stage 5 in the middle of the 07 process.

last thursday i was back on the (new) eddy current Beyond Redline dyno. we made 23 2000-8000 4th gear pulls.

the big new deal was a new generation alcohol system from FJO. unlike most systems which use nozzles the FJO system uses fuel injectors. nozzles are great for watering your lawn. fuel injectors are great for precisely tuning your motor. as in milliseconds of "ontime."

here's what the tuning table looks like. the values are % of max deliverability.

the older gen (spray and pray) systems work o k for drag racing where your right foot is always on the floor. since the only variability as to delivery is an electric pump they really can't parallel fuel needs on a road course where you are always on and off the gas.

(if you are just using the setup to spray water to cool your engine they are fine... if you are partially fueling your engine w magic methanol on the street or a road course.... no way)

anyway, i was on the dyno initially in july. we found that the alcohol pressure behind the injectors (2 700 CC/Min) was varying and with it our AFRs.

back to the drawing board.

remove Shurflow pump. insert a Bosch variant of the 044.... the 909. add a Weldon Adj alcohol compatible pressure regulator. add return to AI fuel cell line.

result: absolutely constant alcohol line pressure and back to tuning on the dyno.

so, we did 23 runs last thursday. after the first run we never even thought about the alcohol system. it was there. it was constant. and combined w pump 93 octane it was magic.

20 pounds of boost. PFC knock reading between 7000 and 8000 was between 10 and 20! on pump gas

my descending torque readings from last year have vanished. i spent too much time chasing that last year. it turned out to be boost related.

BTW, my exhaust backpressure at 20 psi boost is 21!!!!

my turbos are designed to put out 82-84 pounds per minute at 27 psi. unfortunately, my actuator springs are maxxed at 20 psi. i am using the stock FD actuators adapted to my ATP Ultimate Wastegates. they do 10 psi w the boost controller turned off.

i removed one of them yesterday with the idea of screwing the rod in to make it shorter and preload the actuator spring for more boost but found the travel to be only .31 inches. if i were to shorten the rod to stiffen the spring i would lose travel and probably WG flow so i will need to find stiffer (different) actuators.

since i want to get ontrack in the next few weeks 27 psi and 600 rw will have to wait.

i made 498 at 20 psi but do expect i can raise the output a bit as i am conservative on timing at 12 degrees w 11 split. further, my lead plug (NGK R6725 10.5 heat range) is black and oily. i am going to a hotter plug in the lead only.

finally, we have been tuning too cold on the egts. the target temps pre turbo have been 1420 F for spool and 1550 F at target boost. actually these are the temps for 100% meth (no gasoline at all)... so we will bump EGTs a bit since 70% of my fuel is 93 octane gasoline and we have seen zero knock.

it looks like my twins are proving out V my target. spool is either the same or slightly better than a recently posted GT42.

i really don't want 400 rw at 5000 anyway as it would be more difficult to drive on a road course.

the setup is great around town and should be exciting when it finally gets tuned out.

stay tuned more to come this year. OBTW, i have about 13,000 miles on my twins. and my motor has been in my car for 3 years now... 0ver 100 dyno pulls and it reads 17 inches of vacuum at idle.

pics of my FJO setup in the Auxiliary Injection section.

hc

#289

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

09 update...

back to Beyond Redline, Green Bay, Wi and ace tuner Luke Stubbs.

new for 09 is the engine and the AGP aluminum modular actuators. last year boost was limited to 20 as we ran out of wastegate spring pressure.

the AGP units disassemble w a C clip and various spring rates can be obtained. i have the 15 and 19 springs from AGP and ran the 15s for this session.

ultimately i am looking to do 27 psi and 630 rwhp. on pump gas and meth.

that's the plan.

i did 23 4th gear pulls from 2-3000 to 8300. best run was the last and netted 506 rwhp at 20.1 psi. knock averaged 20 on the lowest P line. AFR average was 11.4. IDC rose from 60 to 77% (850/1600). IGL moved from 13 to 16 along the P line w 11 split. preturbo EGTs 1600 tops.

it turned out that the new actuators w the 15 pound springs were done at 20 psi so i will be swapping in the 19 springs to run 27 next session.

the FJO HD AI ran flawlessly. we did change the map so as to not decrease alcohol from the 100% level after peak torque.

the new engine's advanced port design delivered exactly the same spool but added alot more ponies in the curve.

hc

back to Beyond Redline, Green Bay, Wi and ace tuner Luke Stubbs.

new for 09 is the engine and the AGP aluminum modular actuators. last year boost was limited to 20 as we ran out of wastegate spring pressure.

the AGP units disassemble w a C clip and various spring rates can be obtained. i have the 15 and 19 springs from AGP and ran the 15s for this session.

ultimately i am looking to do 27 psi and 630 rwhp. on pump gas and meth.

that's the plan.

i did 23 4th gear pulls from 2-3000 to 8300. best run was the last and netted 506 rwhp at 20.1 psi. knock averaged 20 on the lowest P line. AFR average was 11.4. IDC rose from 60 to 77% (850/1600). IGL moved from 13 to 16 along the P line w 11 split. preturbo EGTs 1600 tops.

it turned out that the new actuators w the 15 pound springs were done at 20 psi so i will be swapping in the 19 springs to run 27 next session.

the FJO HD AI ran flawlessly. we did change the map so as to not decrease alcohol from the 100% level after peak torque.

the new engine's advanced port design delivered exactly the same spool but added alot more ponies in the curve.

hc

Last edited by Howard Coleman; 07-11-09 at 08:05 AM.

#291

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

yes on the NRS. i run one piece 2 MM along w the required NRS ceramic tipped springs. since there's been no knock to date they haven't really had to work for a living.

i will be changing out my hotside housings as i need more spool earlier for my purposes. i am retaining the large efficient stage 5 turbine wheels.

hc

i will be changing out my hotside housings as i need more spool earlier for my purposes. i am retaining the large efficient stage 5 turbine wheels.

hc

#295

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

the right side column starts at zero psi and rises to 28 psi.

entries in the cells are % of max deliverability of the injectors

hope this clears it up.

hc

entries in the cells are % of max deliverability of the injectors

hope this clears it up.

hc

#296

YOUR TRIANGLE NIGHTMARE

iTrader: (6)

Join Date: Mar 2006

Location: automotive purgatory

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

not trying to thread jack but is it a good idea to start using a a different premix ( I use Idemitsu) and or use more premix when using a large amount of 100% methanol injection or doing what your doing with mixing 20% methanol to your tank? the reason i ask is because I know methanol is a solvent granted so is gasoline, but not quiet as potent as methanol as I understand it.

after hearing about how you went to the fjo and how it is using injectors instead of nozzles im kinda of regreting putting in my order with Julio today maybe i should sell it when it gets here and just by the fjo system. or could i just buy the fjo software and injectors and run it with the pump he sells?

after hearing about how you went to the fjo and how it is using injectors instead of nozzles im kinda of regreting putting in my order with Julio today maybe i should sell it when it gets here and just by the fjo system. or could i just buy the fjo software and injectors and run it with the pump he sells?

Thread

Thread Starter

Forum

Replies

Last Post

Shainiac

Single Turbo RX-7's

12

07-17-19 02:20 PM

Sammy Built

Haltech Forum

8

09-28-15 03:18 PM