water pump pulley solution

#1

water pump pulley solution

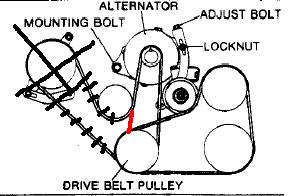

Hey guys this is my solution to the stock water pump pulley problem.

What do you think?

I have about 90* of contact with the pulley, so I think that should about do it for contact area without over tightening it to compensate for the lack of friction/area in contact.

Plus I donít have to underdrive it with one of those pulley kits, and can keep the stock pumping capacity and flow characteristics.

Benefits should include being able to use a standard 5 rib serpentine belt, no squeaking, stock pump drive ratio, and not over tightening the belt to compensate for insufficient pulley surface area.

I have yet to finish up cutting my mount and making it look at home in the engine bay, but I have all the dimensions down for a standard sized belt and plan on ordering it up tonight.

And I wanted to say thanks to jdhuegel1 ďJustinĒ for hooking me up with a Alt pulley to experiment with for a very good price!

Thanks brother!

What do you think?

I have about 90* of contact with the pulley, so I think that should about do it for contact area without over tightening it to compensate for the lack of friction/area in contact.

Plus I donít have to underdrive it with one of those pulley kits, and can keep the stock pumping capacity and flow characteristics.

Benefits should include being able to use a standard 5 rib serpentine belt, no squeaking, stock pump drive ratio, and not over tightening the belt to compensate for insufficient pulley surface area.

I have yet to finish up cutting my mount and making it look at home in the engine bay, but I have all the dimensions down for a standard sized belt and plan on ordering it up tonight.

And I wanted to say thanks to jdhuegel1 ďJustinĒ for hooking me up with a Alt pulley to experiment with for a very good price!

Thanks brother!

#4

Rotary Freak

Garfinkles idler bolts up where the stock air pump was and has a larger wheel . It is adjustable as the air pump was .Your turbo is in that area . You will need a high speed bearing for sure, good job , good thinking .Garfinkle has over 42k miles on his idler .

#5

yep, high speed, high load, stainless bearings.

Should be good providing the stainless bolt I used will hold the deflection.

Might have to upgrade to grade 8 or 10 if I see excess bending at stock tension, doubt that will happen though.

I used two flanged 17mm OD, 9mm ID bearings and a center piece to compress the inner bearing rases, and set it up to accept a easy to find standard 34.5 inch 5 rib belt. And with what little play there is in the alternator I should be able to use either a 34 or a 35 inch belt if it was a necessity, both of which are also readily available sizes.

Should be good providing the stainless bolt I used will hold the deflection.

Might have to upgrade to grade 8 or 10 if I see excess bending at stock tension, doubt that will happen though.

I used two flanged 17mm OD, 9mm ID bearings and a center piece to compress the inner bearing rases, and set it up to accept a easy to find standard 34.5 inch 5 rib belt. And with what little play there is in the alternator I should be able to use either a 34 or a 35 inch belt if it was a necessity, both of which are also readily available sizes.

Trending Topics

#8

What do you mean?? The FD WP is a centrifugal WP and I donít think that it can be run in reverse effectively.

The reason for the extra idler it to create more surface area to the WP pulley, if you look at the pic of how the belts are routed you will notice that there is little to no deflection in the alt drive belt when the AP is deleted. You will also notice that it wraps around the pulley in the same direction in my picture.

Or are you are talking about the aftermarket WP and alt pulleys such as unorthidox, but they still roll around the WP pulley the same way as stock to I believe. They still donít provide the same amount of surface area as using an idler though. And they underdrive the pump.

The reason for the extra idler it to create more surface area to the WP pulley, if you look at the pic of how the belts are routed you will notice that there is little to no deflection in the alt drive belt when the AP is deleted. You will also notice that it wraps around the pulley in the same direction in my picture.

Or are you are talking about the aftermarket WP and alt pulleys such as unorthidox, but they still roll around the WP pulley the same way as stock to I believe. They still donít provide the same amount of surface area as using an idler though. And they underdrive the pump.

Last edited by rotarypower101; 02-14-04 at 12:37 AM.

#10

I understand all this, it is elementary.

You guys keep telling me that the wp pulley can only operate in one direction, but DAMN IT, I'm no newb thats making this **** up!!!!!

I have seen about 9 RX7's with the belt running the on the outside of the wp pulley.

ON TOPIC:

The Nitrous Express 800 flywheel hp FD has the belt wrapped on the other side of the wp.

This is the 3rd time I have asked this question with only "shut up newb" type answers, so it must be a very little known procedure, but someone must know.

Raj

You guys keep telling me that the wp pulley can only operate in one direction, but DAMN IT, I'm no newb thats making this **** up!!!!!

I have seen about 9 RX7's with the belt running the on the outside of the wp pulley.

ON TOPIC:

The Nitrous Express 800 flywheel hp FD has the belt wrapped on the other side of the wp.

This is the 3rd time I have asked this question with only "shut up newb" type answers, so it must be a very little known procedure, but someone must know.

Raj

#11

PV = nRT

Join Date: Jan 2003

Location: New Zealand (was California)

Posts: 2,250

Likes: 0

Received 0 Likes

on

0 Posts

It's quite possible reversing the pump rotation results in the coolant flow direction through the block and radiator also being reversed. This would seem to be very inefficient, however.

rp101,

Don't forget that the under-driven affect of aftermarket pullies is part of the design to reduce pump cavitation at high rpms.

rp101,

Don't forget that the under-driven affect of aftermarket pullies is part of the design to reduce pump cavitation at high rpms.

#12

The Man

installing the belt on the outside of the pulley WILL result in very poor water circulation, and will overheat since the water will not circulate adequately since the water pump vanes are centrifugal they move the water outward and thus cause it to produce pressure on the outlet side of the pump body. this allows proper circulation to the recirc bypass at startup and ample pressure developed to push the water through the low slung radiator emplaced in our setups. If you reverse the flow the water pump will move some water but the pressure at which it moves isn't sufficient to get the water to flow back up into the lower radiator hose and up into the water pump pickup. This is especially true in hot lap conditions and will overheat rapidly when boost is excessive for sustained periods. Trust me

1st engine 1(reversed wp belt) - Art 0

Art

1st engine 1(reversed wp belt) - Art 0

Art

#13

Originally posted by rajeevx7

I have seen about 9 RX7's with the belt running the on the outside of the wp pulley.

The Nitrous Express 800 flywheel hp FD has the belt wrapped on the other side of the wp.

Raj

I have seen about 9 RX7's with the belt running the on the outside of the wp pulley.

The Nitrous Express 800 flywheel hp FD has the belt wrapped on the other side of the wp.

Raj

I would be interested to see if it is true, I suspect if it was they would have had to severely modify the pump by using a blade that ran in the opposite direction as the FDs WP.

The way the internals of the WP are built definitely would not help it flow very well though, as it is directional.

I suppose it is possible to make the pump flow in reverse if this is done, just not very practical effective or logical as it runs as rts3gen has described

Lets see some of those pics.

#14

Originally posted by clayne

Don't forget that the under-driven affect of aftermarket pullies is part of the design to reduce pump cavitation at high rpms.

Don't forget that the under-driven affect of aftermarket pullies is part of the design to reduce pump cavitation at high rpms.

I am not one of those people that thinks that mazda did everything right on this car, but I cant understand why people think the pump is cavitating at higher RPMs.

Donít you think that is a pretty simple thing to catch in the R&D phase when this car was being built? I would think it would be almost impossible when testing the pump not to catch a problem with its capabilities and solve it immediately.

Has there been any data to confirm these allegations of breakup of the flow pattern at high RPMs? Any links or threads I missed that has real test data and unbiased results

#15

The Man

Originally posted by rotarypower101

Do you have a picture of any of these cars??

I would be interested to see if it is true, I suspect if it was they would have had to severely modify the pump by using a blade that ran in the opposite direction as the FDs WP.

The way the internals of the WP are built definitely would not help it flow very well though, as it is directional.

I suppose it is possible to make the pump flow in reverse if this is done, just not very practical effective or logical as it runs as rts3gen has described

Lets see some of those pics.

Do you have a picture of any of these cars??

I would be interested to see if it is true, I suspect if it was they would have had to severely modify the pump by using a blade that ran in the opposite direction as the FDs WP.

The way the internals of the WP are built definitely would not help it flow very well though, as it is directional.

I suppose it is possible to make the pump flow in reverse if this is done, just not very practical effective or logical as it runs as rts3gen has described

Lets see some of those pics.

Rotary,

It's not really a problem for short bursts, but when the engine is revved and revved(as in road racing) the water gets hot fast, and with a radiator that is lower than the engine level a lot of air gets caught in the system. When this happens and the engine is maintained at high rpm's, it's almost impossible to bleed off the air in the system. This is when the cavitation really starts to occur. When the air in the system gets too high, the wp blades act like a big blender and start to whip the water into a froth and thus no real circulation. You're absolutely right though on your point. Mazda did do a lot of Rand D to make many of the systems on this car efficient for most conditions. But since they were in a rush to get the car on the lots to sell, they didn't really do any "racing" tests, and that's where the problems really start to be realized. So, if you're car is an occasional drag car, the stock sized pulley is fine. Street car, stock sized is fine. But if you do all including road racing, a good underdrive pulley is a help. This is one of those cases that really depends on the conditions in which the car is driven and used that determines the right answer to the question.

Art

#17

Sounded like I was yelling when I re-read my post, sorry.

Well, that explanation of it working but not as well makes great scense.

The most recent application I have seen is in this months

SuperStreet, with the red Nitrous Express FD on the cover. Several engine shots make the looped belts postition evident. Do I smell a scense of doubt coming at the RajMan?

Sorry, I'm just a newb.

Well, that explanation of it working but not as well makes great scense.

The most recent application I have seen is in this months

SuperStreet, with the red Nitrous Express FD on the cover. Several engine shots make the looped belts postition evident. Do I smell a scense of doubt coming at the RajMan?

Sorry, I'm just a newb.

#18

Originally posted by RTS3GEN

Rotary,

It's not really a problem for short bursts, but when the engine is revved and revved(as in road racing) the water gets hot fast, and with a radiator that is lower than the engine level a lot of air gets caught in the system. When this happens and the engine is maintained at high rpm's, it's almost impossible to bleed off the air in the system. This is when the cavitation really starts to occur. When the air in the system gets too high, the wp blades act like a big blender and start to whip the water into a froth and thus no real circulation. You're absolutely right though on your point. Mazda did do a lot of Rand D to make many of the systems on this car efficient for most conditions. But since they were in a rush to get the car on the lots to sell, they didn't really do any "racing" tests, and that's where the problems really start to be realized. So, if you're car is an occasional drag car, the stock sized pulley is fine. Street car, stock sized is fine. But if you do all including road racing, a good underdrive pulley is a help. This is one of those cases that really depends on the conditions in which the car is driven and used that determines the right answer to the question.

Art

Rotary,

It's not really a problem for short bursts, but when the engine is revved and revved(as in road racing) the water gets hot fast, and with a radiator that is lower than the engine level a lot of air gets caught in the system. When this happens and the engine is maintained at high rpm's, it's almost impossible to bleed off the air in the system. This is when the cavitation really starts to occur. When the air in the system gets too high, the wp blades act like a big blender and start to whip the water into a froth and thus no real circulation. You're absolutely right though on your point. Mazda did do a lot of Rand D to make many of the systems on this car efficient for most conditions. But since they were in a rush to get the car on the lots to sell, they didn't really do any "racing" tests, and that's where the problems really start to be realized. So, if you're car is an occasional drag car, the stock sized pulley is fine. Street car, stock sized is fine. But if you do all including road racing, a good underdrive pulley is a help. This is one of those cases that really depends on the conditions in which the car is driven and used that determines the right answer to the question.

Art

However if it is done by the autox people I am sure there is a good reason for doing so.

I just hate to see people touting the benefits of something that really doesnít do anything for the car under normal circumstances, and people reading it thinking that they NEED these parts, when in reality it is only a special case scenario that could benefit from these parts.

For me its not an issue, as I have an extra nipple on the top of my aluminum radiator that directs any air in the system to the top of the filler neck and bypasses the pump.

#19

PV = nRT

Join Date: Jan 2003

Location: New Zealand (was California)

Posts: 2,250

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by rotarypower101

Clayne what is everybodys hangup on underdriving the WP?

I am not one of those people that thinks that mazda did everything right on this car, but I cant understand why people think the pump is cavitating at higher RPMs.

Donít you think that is a pretty simple thing to catch in the R&D phase when this car was being built? I would think it would be almost impossible when testing the pump not to catch a problem with its capabilities and solve it immediately.

Has there been any data to confirm these allegations of breakup of the flow pattern at high RPMs? Any links or threads I missed that has real test data and unbiased results

Clayne what is everybodys hangup on underdriving the WP?

I am not one of those people that thinks that mazda did everything right on this car, but I cant understand why people think the pump is cavitating at higher RPMs.

Donít you think that is a pretty simple thing to catch in the R&D phase when this car was being built? I would think it would be almost impossible when testing the pump not to catch a problem with its capabilities and solve it immediately.

Has there been any data to confirm these allegations of breakup of the flow pattern at high RPMs? Any links or threads I missed that has real test data and unbiased results

http://www.mazdamotorsports.com/weba...ubject=cooling

"Pulleys

Changing to competition drive and water pump pulleys will significantly reduce, if not eliminate, water pump cavitation. Water pump cavitation on a rotary engine (with stock pulleys) is unavoidable at rpms above 6500-7000 and is a significant contributor to engine overheating. Cavitation is defined as a disruption of the water/coolant flow through the water pump. It is created when the water pump impeller spins at such a high speed that it is actually churning instead of pushing the coolant through the pump. Changing to a larger water pump pulley and a smaller drive pulley, allows the water pump to spin at lower rpms, effectively transporting the fluid through the pump.

NOTE: An alternate size alternator pulley is available that reduces the speed at which your alternator spins, providing longer alternator life. "

#20

The Man

Originally posted by rotarypower101

I still would like to see some flow charts on the pump at elevated rpms, just to see if it is breaking up at all. I donít think you would see any data to support that claim.

However if it is done by the autox people I am sure there is a good reason for doing so.

I just hate to see people touting the benefits of something that really doesnít do anything for the car under normal circumstances, and people reading it thinking that they NEED these parts, when in reality it is only a special case scenario that could benefit from these parts.

For me its not an issue, as I have an extra nipple on the top of my aluminum radiator that directs any air in the system to the top of the filler neck and bypasses the pump.

I still would like to see some flow charts on the pump at elevated rpms, just to see if it is breaking up at all. I donít think you would see any data to support that claim.

However if it is done by the autox people I am sure there is a good reason for doing so.

I just hate to see people touting the benefits of something that really doesnít do anything for the car under normal circumstances, and people reading it thinking that they NEED these parts, when in reality it is only a special case scenario that could benefit from these parts.

For me its not an issue, as I have an extra nipple on the top of my aluminum radiator that directs any air in the system to the top of the filler neck and bypasses the pump.

Art

#21

Lives on the Forum

The impeller on the water pump cannot be perfectly efficient along the entire rpm range from idle to 7,000 rpm. Mazda shaded towards the everyday side in designing the water pump. I too don't see problems until extended use at high rpm (several laps on a road course) but my findings seem to reinforce Mazda's advice: for constant high rpm (high as in 6,000+ rpm) underdriving the water pump will in fact aid cooling. I plan to underdrive my water pump at track days only this year; leaving the stock pulley on for everyday use.

High rpm does not create air in the coolant; the system is sealed. Pump cavitation is caused by the coolant frothing from the impellor whipping it up so quickly. Run your blender at home from low speed to high and you'll see the same effect.

High rpm does not create air in the coolant; the system is sealed. Pump cavitation is caused by the coolant frothing from the impellor whipping it up so quickly. Run your blender at home from low speed to high and you'll see the same effect.

Thread

Thread Starter

Forum

Replies

Last Post

[For Sale] Scratch & Dent, Used, and Open-Box Sale!

SakeBomb Garage

Vendor Classifieds

5

08-09-18 05:54 PM