Dual Radiators: When amateurs take on big projects

#1

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Dual Radiators: When amateurs take on big projects

Try not to cringe at some of these pics. My goal was to do something similar to rallimike's dual rad setup. I'm pretty far along and any tips or advice would be keen.

The basic idea is to put a radiator in the R1 oil cooler locations, then run basically a V-mount with an oil cooler on the bottom. Rallimike used very nice custom griffin rads that were about $400 each. I'm using rads off a Yamaha R6 that I got for ~$150 each. Combined they have more surface area than a koyo and volume somewhere between stock and a koyo. Major potention problem: 1in outlets.

They have a very cool curved core design:

And plenty of brackets for mounting and fans:

With a few words of advice from rynberg and others I special ordered earl's massive 60 row oil cooler. About 18x7x2in. I was running 1 stock cooler that was beat to crap like so many are.

The rads were a bitch to fit. Rallimike uses an aftermarket bumper but I want to fit it with the stock bumper AND undertrays. Here's what I've ended up with:

That piece of aluminum on the right is about what one bracket will look like. I'll bolt that in where I think the tow hook used to be, and dampen it with rubber washers. Another bracket will mount on whats left of that "shelf" in the top/middle.

The shiny hose on top is Summit's flexible stainless steel hose. Rallimike has run it for 2 years with no problem and it's very easy to work with. 1.5in ID with plenty of couplers and inserts for mounting. That runs to the water pump. I had to use a 1in 90deg bend out of the rad to fit with the stock undertray and not rub the tire, then coupled it to a 1.5in to 1in reducer as you can see here:

Another pic of the coupler:

The outlet on the right is also a 1in 90deg reducer to a 1in pipe then to a 1in to1.5in 90 deg reducer (a pain to find!). From there i'll run a 1.5in pipe and do the same on the driver side which I haven't started yet.

I haven't decided exactly what I'm going to do with the IC, for now I'm trying it moved and leaned forward just a bit. Custom pipes and what not can come after I confirm this contraption works

This cardboard is a bit bigger than the OC all around but this is about how I'll mount it. Probably with the same method as rallimike; aluminum angle cradle.

It will have to be more vertical but I also plan to use a Kinetik_FD3S style splitter.

This pic shows the route of the flexiSS. The pipe to the right of it was just to mockup how the angle will mount for the OC cradle, and also to mount ducting to.

If someone wants to pitch in with a quick lesson on fluid dynamics and what a horrible thing it is to be necking up and down between 1in and 1.5 in please do. Figure the rad internals are the biggest restriction in the system, then the t-stat in the stock setup. The only thing i've learned from the net is that by adding hose you reduce the pressure in the system. Ioughno. Would running evans in a 0 pressure system work better with this?

Also, i've searched the forum for the best ways to plug up coolant outlets, like all those crazy small ones on the rads here. JB weld and a cap? Or tap and cap?

Thanks to rallimike for pics and answers, same to dave@KD, rynberg for OC answers, kinetik for his awesome writeup on the custom v-mount, and the thread dubulup started for the DIY dual oil coolers. That answered every question I had on the OC part of this project.

If you think it will just explode...well you'll find out. I've invested enough where i'm going through with it and will vid the first startup, hopefully next month.

The basic idea is to put a radiator in the R1 oil cooler locations, then run basically a V-mount with an oil cooler on the bottom. Rallimike used very nice custom griffin rads that were about $400 each. I'm using rads off a Yamaha R6 that I got for ~$150 each. Combined they have more surface area than a koyo and volume somewhere between stock and a koyo. Major potention problem: 1in outlets.

They have a very cool curved core design:

And plenty of brackets for mounting and fans:

With a few words of advice from rynberg and others I special ordered earl's massive 60 row oil cooler. About 18x7x2in. I was running 1 stock cooler that was beat to crap like so many are.

The rads were a bitch to fit. Rallimike uses an aftermarket bumper but I want to fit it with the stock bumper AND undertrays. Here's what I've ended up with:

That piece of aluminum on the right is about what one bracket will look like. I'll bolt that in where I think the tow hook used to be, and dampen it with rubber washers. Another bracket will mount on whats left of that "shelf" in the top/middle.

The shiny hose on top is Summit's flexible stainless steel hose. Rallimike has run it for 2 years with no problem and it's very easy to work with. 1.5in ID with plenty of couplers and inserts for mounting. That runs to the water pump. I had to use a 1in 90deg bend out of the rad to fit with the stock undertray and not rub the tire, then coupled it to a 1.5in to 1in reducer as you can see here:

Another pic of the coupler:

The outlet on the right is also a 1in 90deg reducer to a 1in pipe then to a 1in to1.5in 90 deg reducer (a pain to find!). From there i'll run a 1.5in pipe and do the same on the driver side which I haven't started yet.

I haven't decided exactly what I'm going to do with the IC, for now I'm trying it moved and leaned forward just a bit. Custom pipes and what not can come after I confirm this contraption works

This cardboard is a bit bigger than the OC all around but this is about how I'll mount it. Probably with the same method as rallimike; aluminum angle cradle.

It will have to be more vertical but I also plan to use a Kinetik_FD3S style splitter.

This pic shows the route of the flexiSS. The pipe to the right of it was just to mockup how the angle will mount for the OC cradle, and also to mount ducting to.

If someone wants to pitch in with a quick lesson on fluid dynamics and what a horrible thing it is to be necking up and down between 1in and 1.5 in please do. Figure the rad internals are the biggest restriction in the system, then the t-stat in the stock setup. The only thing i've learned from the net is that by adding hose you reduce the pressure in the system. Ioughno. Would running evans in a 0 pressure system work better with this?

Also, i've searched the forum for the best ways to plug up coolant outlets, like all those crazy small ones on the rads here. JB weld and a cap? Or tap and cap?

Thanks to rallimike for pics and answers, same to dave@KD, rynberg for OC answers, kinetik for his awesome writeup on the custom v-mount, and the thread dubulup started for the DIY dual oil coolers. That answered every question I had on the OC part of this project.

If you think it will just explode...well you'll find out. I've invested enough where i'm going through with it and will vid the first startup, hopefully next month.

#2

Originally Posted by airborne

Also, i've searched the forum for the best ways to plug up coolant outlets, like all those crazy small ones on the rads here. JB weld and a cap? Or tap and cap?

I toyed with the idea of doing the Porsche radiator setup before but never got up enough ***** to make it happen.

I would recommend to tap the coolant outlets. Then use a bolt with some teflon tape or thread sealant on the threads.

#3

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Mahjik. This is a way bigger project than anything I've taken on so I'll be pretty proud if it works. Next biggest thing was maybe a new master cylinder or rebuilding calipers.

For the outlets, even tap those small ones? Left side in the first pic.

For the outlets, even tap those small ones? Left side in the first pic.

#5

Originally Posted by airborne

Thanks Mahjik. This is a way bigger project than anything I've taken on so I'll be pretty proud if it works. Next biggest thing was maybe a new master cylinder or rebuilding calipers.

Originally Posted by airborne

For the outlets, even tap those small ones? Left side in the first pic.

#6

development

Nice! I was wondering when I get to see a thread about this project...

for the small radiator nipples...can you take them to a radiator shop and have them cut and weld over it? Should be simple for an aluminum welder. IMO that'd be the best perm fix.

I'd also like to know about the dynamics of the reducing...like you said, it basically gets "reduced" in the rows of the radiator as well. this will be a more gradual reducing system...Ioughno <-LOL

BTW...I didn't start the dual oil cooler thread, I just added (A LOT) to it.

for the small radiator nipples...can you take them to a radiator shop and have them cut and weld over it? Should be simple for an aluminum welder. IMO that'd be the best perm fix.

I'd also like to know about the dynamics of the reducing...like you said, it basically gets "reduced" in the rows of the radiator as well. this will be a more gradual reducing system...Ioughno <-LOL

BTW...I didn't start the dual oil cooler thread, I just added (A LOT) to it.

Trending Topics

#8

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Just getting that website (racerpartswholesale) was helpful. And that socketless stuff is hilariously easy.

Also, what about the small coolant line that usually goes to the small outlet in the rad from the filler neck? Could I plug that?

dubulup you seem to be attacking the problem the same way i am. with a lot of common sense but little science.

The thing that's holding me up is getting the 1 to 1.5 in 90 deg bends. Samco only has 2 us distributors that carry random hoses and not just kits. They had 1 in stock. I need 2. 4-6 week wait while they're made and shipped from the UK. Other manufacturers don't do silicone in that small of an ID.

This weekend hopefully I'll drain the oil and pull out the stock lines and cooler. Take some measurements and order up my fittings and hose. Like you did dubulup I'll use the aeroquip socketless. A mocal t-stat. The respeed pedestal to install oil temp and pressure gauges. Before this i was running M1 20-50 and when my pressure sender was working the oil press. was fine.

looking at the space i'm working with for the OC i can't wait to start on that part. The rads have like ZERO clearance. I'll be heat taping the lights, wires and where ever the rad might touch the bumper.

I'll also need to adapt the stock fan wiring to the R6 fans.

Also, what about the small coolant line that usually goes to the small outlet in the rad from the filler neck? Could I plug that?

dubulup you seem to be attacking the problem the same way i am. with a lot of common sense but little science.

The thing that's holding me up is getting the 1 to 1.5 in 90 deg bends. Samco only has 2 us distributors that carry random hoses and not just kits. They had 1 in stock. I need 2. 4-6 week wait while they're made and shipped from the UK. Other manufacturers don't do silicone in that small of an ID.

This weekend hopefully I'll drain the oil and pull out the stock lines and cooler. Take some measurements and order up my fittings and hose. Like you did dubulup I'll use the aeroquip socketless. A mocal t-stat. The respeed pedestal to install oil temp and pressure gauges. Before this i was running M1 20-50 and when my pressure sender was working the oil press. was fine.

looking at the space i'm working with for the OC i can't wait to start on that part. The rads have like ZERO clearance. I'll be heat taping the lights, wires and where ever the rad might touch the bumper.

I'll also need to adapt the stock fan wiring to the R6 fans.

#9

fart on a friends head!!!

you probably dont wanna tap those.  what are they made of? brass? aluminum? i would think about cutting them off, and either welding them shut or brazing (sp?) them shut.

what are they made of? brass? aluminum? i would think about cutting them off, and either welding them shut or brazing (sp?) them shut.

pretty cool stuff you got going there, btw!!!

what are they made of? brass? aluminum? i would think about cutting them off, and either welding them shut or brazing (sp?) them shut.

what are they made of? brass? aluminum? i would think about cutting them off, and either welding them shut or brazing (sp?) them shut. pretty cool stuff you got going there, btw!!!

#10

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

RE7: I haven't decided on angles yet, but that will definitely be more vertical. Even so a lot of the v-mounts running around have pretty extreme angles on both the IC and rad. I was hoping that OC would be good enough where the mounting didn't have to be ideal. And there will be a splitter. And i'll be running the stock under tray which I hope will keep air flowing towards the rear.

Any advice on an exact angle RE7?

Any advice on an exact angle RE7?

#11

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

I definitely liked the welding idea from dubulup rotorbrain. Already fired off a message to a buddy who should know a welder in the area. Those really small outlets don't have a lot of metal. oh, and aluminum.

#12

Originally Posted by Rotary Experiment Seven

I like the radiator idea, but I don't think the oil cooler is going to get much air mounted flat like that.

Dave

#13

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Speaking of flow...The AC and powersteering will basically be laid flatter but in their stock location. Unless I think of something better. I'm not worried much about the AC but how bad is it to practically eliminate airflow to the PS lines?

i'd rather not get a seperate cooler but i would if necessary.

i'd rather not get a seperate cooler but i would if necessary.

#14

development

Originally Posted by airborne

Also, what about the small coolant line that usually goes to the small outlet in the rad from the filler neck? Could I plug that?

Originally Posted by airborne

I'll also need to adapt the stock fan wiring to the R6 fans.

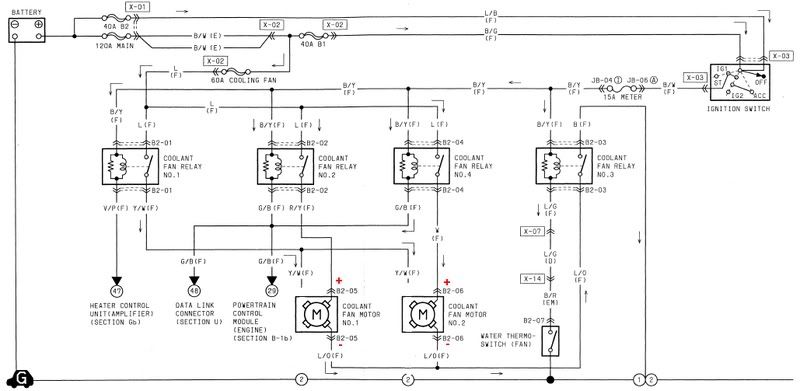

Now this is just a simple one speed set-up (if the fans have two speeds let me know; I've been running one speed set-up with my haltech for over 2 years with no issues on the track/autoX/mountain roads/Louisiana heat)...note that relay no.1 is for when you turn on the A/C...which won't be an issue since your condensor isn't infront of your radiator anymore.

Relay no.2 and no.4 will apply power to the fans when the ECU feels necessary...and relay no.3 turns them on (by GND) when the thermo switch is triggered.

Basically all you will need to do is run the Blue/Orange wire to both (-) terminals on the fans (from relay no.3) and Red/Yellow to fan no. 1 (+) terminal (from relay no.2) and White to fan no. 2 (+) terminal (from relay no.4)

hope this helps.

#15

Derwin

iTrader: (2)

Join Date: Apr 2005

Location: MTL, QC

Posts: 2,888

Likes: 0

Received 0 Likes

on

0 Posts

Nice project and it is great to see how fast members chime in and the knowledge.

I am wondering is the reason for your project that you wanted radiators to get maximum exposure to the incomming air all while having the largest volume IC? It is a sweet project, these custom mental to material things are my favorite threads.

I am wondering is the reason for your project that you wanted radiators to get maximum exposure to the incomming air all while having the largest volume IC? It is a sweet project, these custom mental to material things are my favorite threads.

#16

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

The part in english was very helpful dubulup:

"Basically all you will need to do is run the Blue/Orange wire to both (-) terminals on the fans (from relay no.3) and Red/Yellow to fan no. 1 (+) terminal (from relay no.2) and White to fan no. 2 (+) terminal (from relay no.4)"

Everything else was greek. I hate electrical stuff. No I can't explain why i relocated the fuse boxes.

The point is pretty much the same as every cooling project seems to be: get heat out of the engine bay and more cold air to the IC ...and intake if any is left. Having this massive IC is great but the duct opening is what? 2in x 6in? And I could never get it fitted right.

and what dradon said. thanks for all the knowhow.

"Basically all you will need to do is run the Blue/Orange wire to both (-) terminals on the fans (from relay no.3) and Red/Yellow to fan no. 1 (+) terminal (from relay no.2) and White to fan no. 2 (+) terminal (from relay no.4)"

Everything else was greek. I hate electrical stuff. No I can't explain why i relocated the fuse boxes.

The point is pretty much the same as every cooling project seems to be: get heat out of the engine bay and more cold air to the IC ...and intake if any is left. Having this massive IC is great but the duct opening is what? 2in x 6in? And I could never get it fitted right.

and what dradon said. thanks for all the knowhow.

#17

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Oh, here's the budget on this mess:

60 row earl's OC (-10 fittings) = $350 from anplumbing.com (awesome service)

(2) 03-04 Yamaha R6 Rads = $350 from whoever my buddy's source is...the ray of yamaha

(8) Samco couplers = ~$160 (boostcontroller.com -awesome service)

(2) 4ft Summit FlexiSS = $160

(1)Big roll of heat tape = $15

(1) 6ft 1.5in ID alum pipe = $30 (onlinemetals.com awesome service)

Assorted angle and aluminum from HDR. cheap.

probably be in the $1500 area after the oil t-stat, fittings, lines, gauges etc.

anyone know where i can get bigger pieces of aluminum cheap? online metals has 3ft x 4ft pieces for $50+shipping. HDR has some 1x3 but i may need bigger.

60 row earl's OC (-10 fittings) = $350 from anplumbing.com (awesome service)

(2) 03-04 Yamaha R6 Rads = $350 from whoever my buddy's source is...the ray of yamaha

(8) Samco couplers = ~$160 (boostcontroller.com -awesome service)

(2) 4ft Summit FlexiSS = $160

(1)Big roll of heat tape = $15

(1) 6ft 1.5in ID alum pipe = $30 (onlinemetals.com awesome service)

Assorted angle and aluminum from HDR. cheap.

probably be in the $1500 area after the oil t-stat, fittings, lines, gauges etc.

anyone know where i can get bigger pieces of aluminum cheap? online metals has 3ft x 4ft pieces for $50+shipping. HDR has some 1x3 but i may need bigger.

#18

I'll be doing a setup very similiar to this probably next year and the guy who does some of the work on my car has essentially this setup and he runs by far the best cooling temps I have ever seen, you'll def be happy when its done.

#19

Originally Posted by airborne

anyone know where i can get bigger pieces of aluminum cheap? online metals has 3ft x 4ft pieces for $50+shipping. HDR has some 1x3 but i may need bigger.

Dave

#20

Since the radiator is not going to be behind the center hole in the bumper, why not just do a front mount intercooler and mount the massive oil cooler behind it?

Will the volume of air you can get through the stock oil cooler ducts in the front bumper support the cooling of the fluid in both of those R6 radiators? What is the surface area of the center hole in the bumper compared to the surface area of the two oil cooler holes?

I think coolant is more efficient at cooling the engine than oil, and that is why the biggest area in the bumper and most air flow is given to the radiator. I will be anxious to see how this turns out.

I bet you could probably work out mathematically what would be the best way to setup a cooling system on an RX7. There has to be a physical limitations to cooler size for each bumper opening. I think the biggest key would be to get more air in...that would mean bigger holes!

Will the volume of air you can get through the stock oil cooler ducts in the front bumper support the cooling of the fluid in both of those R6 radiators? What is the surface area of the center hole in the bumper compared to the surface area of the two oil cooler holes?

I think coolant is more efficient at cooling the engine than oil, and that is why the biggest area in the bumper and most air flow is given to the radiator. I will be anxious to see how this turns out.

I bet you could probably work out mathematically what would be the best way to setup a cooling system on an RX7. There has to be a physical limitations to cooler size for each bumper opening. I think the biggest key would be to get more air in...that would mean bigger holes!

#21

2/4 wheel cornering fiend

The two biggest obstacles I see in this project are the ducting behind the radiators, and the usage of the stock Yamaha R6 cooling fans to create airflow when the car isn't moving.

If the ducting behind the radiators creates enough of a low pressure zone, then the "size of the hole (bumper opening)" won't matter as much as people think. The problem is creating enough of a low pressure zone to help "pull" airflow into the OC openings. Simply dumping the airflow into the wheel wells won't be enough, IMO. However, I'm not sure what a reasonable solution would be. You will probably have to build some sort of lip around the OC openings to help create positive pressure in front of the radiators and stave off airflow "spillover" (basically the same priniciple that the R1 bumper lip helps serve).

The other problem is that the stock R6 radiator fans aren't the most efficient designs around. While they can keep the relatively small heat output of a 599cc piston engine from boiling the coolant while sitting in traffic, doing the same for a turbocharged rotary (even with two of them) is another story entirely. The stock R6 fans don't have the benefit of a shroud to help fan efficiency (like the stock Mazda fans), because the Yamaha engineers were interested in making the radiators as efficient as possible while the bike is at speed, as well as keeping weight to an absolute bare minimum. Again, I'm not sure what a good solution would be at this point, but I seriously doubt that the stock R6 fans will be up to the job.

The oil cooler will definitely need a sufficient amount of airflow, and mounting it behind a FMIC would be a mistake.

If the ducting behind the radiators creates enough of a low pressure zone, then the "size of the hole (bumper opening)" won't matter as much as people think. The problem is creating enough of a low pressure zone to help "pull" airflow into the OC openings. Simply dumping the airflow into the wheel wells won't be enough, IMO. However, I'm not sure what a reasonable solution would be. You will probably have to build some sort of lip around the OC openings to help create positive pressure in front of the radiators and stave off airflow "spillover" (basically the same priniciple that the R1 bumper lip helps serve).

The other problem is that the stock R6 radiator fans aren't the most efficient designs around. While they can keep the relatively small heat output of a 599cc piston engine from boiling the coolant while sitting in traffic, doing the same for a turbocharged rotary (even with two of them) is another story entirely. The stock R6 fans don't have the benefit of a shroud to help fan efficiency (like the stock Mazda fans), because the Yamaha engineers were interested in making the radiators as efficient as possible while the bike is at speed, as well as keeping weight to an absolute bare minimum. Again, I'm not sure what a good solution would be at this point, but I seriously doubt that the stock R6 fans will be up to the job.

The oil cooler will definitely need a sufficient amount of airflow, and mounting it behind a FMIC would be a mistake.

#22

development

with the huge oil cooler...a lot of internal heat will be dumped from the engine (oil can account for 40+% of rotary engine cooling), leaving less heat to get "into" the coolant...as a plus these radiators are plumbed in series. Also not having the radiator exhaust dumped back into the engine bay should help a bit too.

Agreed (as I waited for Kento to chime in). Maybe better/custom ducts need to be made in the fenders exiting the ducts behind the front wheels??? That uses what Mazda has "thought" of...just making it better/more effective.

Did I miss where he said he was using the stock R6 fans?? I think some SPAL shrouded fans would work great if they can be fitted.

Originally Posted by Kento

If the ducting behind the radiators creates enough of a low pressure zone, then the "size of the hole (bumper opening)" won't matter as much as people think.

Did I miss where he said he was using the stock R6 fans?? I think some SPAL shrouded fans would work great if they can be fitted.

#23

I applaud the ambition here, but I question the net benefit. You've still got X amount of air opening in the front of the car, that will provide X amount of incoming air... how you slice and dice that between the three really doesn't matter..

But, oil lines are typically smaller and easier to route all over hill and dale, whereas the water inlets and air inlets are central in the engine bay, and the computer-controlled fans are right there es well.

But, oil lines are typically smaller and easier to route all over hill and dale, whereas the water inlets and air inlets are central in the engine bay, and the computer-controlled fans are right there es well.

#24

2/4 wheel cornering fiend

Originally Posted by dubulup

with the huge oil cooler...a lot of internal heat will be dumped from the engine (oil can account for 40+% of rotary engine cooling), leaving less heat to get "into" the coolant...as a plus these radiators are plumbed in series. Also not having the radiator exhaust dumped back into the engine bay should help a bit too.

Originally Posted by dubulup

Maybe better/custom ducts need to be made in the fenders exiting the ducts behind the front wheels??? That uses what Mazda has "thought" of...just making it better/more effective.

Originally Posted by dubulup

Did I miss where he said he was using the stock R6 fans?? I think some SPAL shrouded fans would work great if they can be fitted.

#25

King of the Duct Tape

Thread Starter

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Dubulup, if i wanted both fans to come on at once could I just tap the two wires off the first relay for both fans? And I did mention using the R6 fans. Having made to fit mounting points is too tempting to pass up.

If the 2 biggest problems are a fan and flow behind the rad that's great! I'm really surprised that air flow has come up and the consequences of going between 1in and 1.5in hose hasn't.

It would be difficult to match what the stock fan setup does at low speed, but with any movement this should flow much better. The stock rad is mounted at a decent angle, has the AC condenser and PS lines in front of it. These rads are curved to encourage air to go thru and not around. And they're mounted nearly perpendicular to air flow with no restriction in front. If you've seen the R6 fan setup you can see it only covers 1/2 of the surface area so there's less restriction at speed.

If low speed cooling isn't enough I could add a second fan. But with the rads out of the engine bay the ambient air around the rad is certain to be cooler, whatever the flow is.

And, though turbulent, the area around the wheel is a low pressure area.

Plus I'm adding 6ft of SS hose to the setup, that will dissipate heat. And 4ft of thin walled aluminum pipe, that will cool some too. Maybe I could clamp or weld fins on to the pipe, like an inline cooler:

Obviously the oil cooler will be significantly better but I'm not counting on that as a crutch for the radiators. I've based this off an already very well functioning setup. If I recall right rallimike started by calling up Griffin and speaking to an engineer there about what he was doing, what space he had and would it work. The answer was yes and one reason was that you don't just add the cooling capacity of the radiators, they're actually 115% efficient working in series or so.

The best part, there will be an answer to all these questions. Just need another month or so.

If the 2 biggest problems are a fan and flow behind the rad that's great! I'm really surprised that air flow has come up and the consequences of going between 1in and 1.5in hose hasn't.

It would be difficult to match what the stock fan setup does at low speed, but with any movement this should flow much better. The stock rad is mounted at a decent angle, has the AC condenser and PS lines in front of it. These rads are curved to encourage air to go thru and not around. And they're mounted nearly perpendicular to air flow with no restriction in front. If you've seen the R6 fan setup you can see it only covers 1/2 of the surface area so there's less restriction at speed.

If low speed cooling isn't enough I could add a second fan. But with the rads out of the engine bay the ambient air around the rad is certain to be cooler, whatever the flow is.

And, though turbulent, the area around the wheel is a low pressure area.

Plus I'm adding 6ft of SS hose to the setup, that will dissipate heat. And 4ft of thin walled aluminum pipe, that will cool some too. Maybe I could clamp or weld fins on to the pipe, like an inline cooler:

Obviously the oil cooler will be significantly better but I'm not counting on that as a crutch for the radiators. I've based this off an already very well functioning setup. If I recall right rallimike started by calling up Griffin and speaking to an engineer there about what he was doing, what space he had and would it work. The answer was yes and one reason was that you don't just add the cooling capacity of the radiators, they're actually 115% efficient working in series or so.

The best part, there will be an answer to all these questions. Just need another month or so.

Last edited by airborne; 02-25-07 at 06:54 AM.